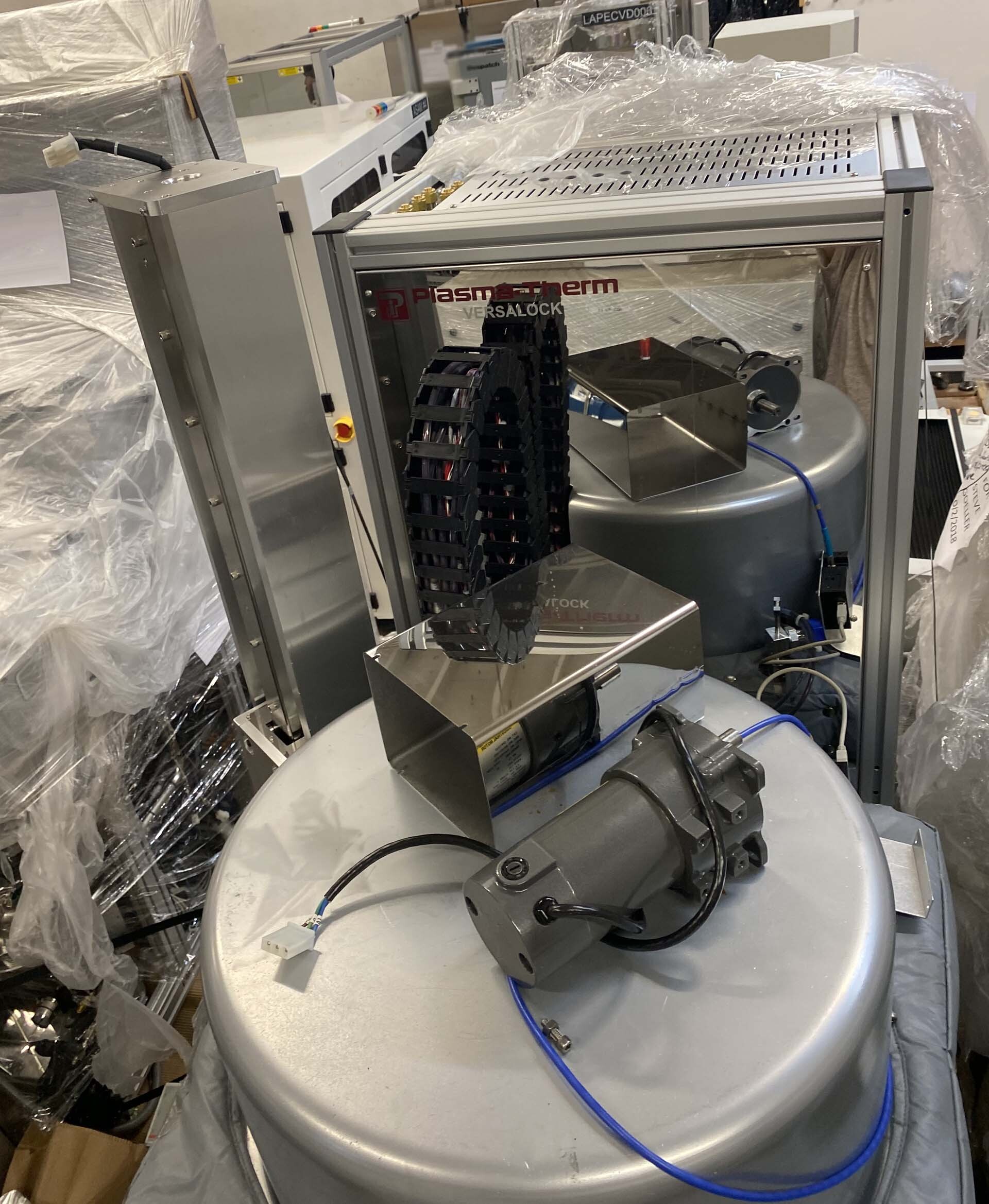

Used PLASMATHERM LAPECVD PM3 #9382240 for sale

URL successfully copied!

Tap to zoom

ID: 9382240

Vintage: 2009

PECVD System

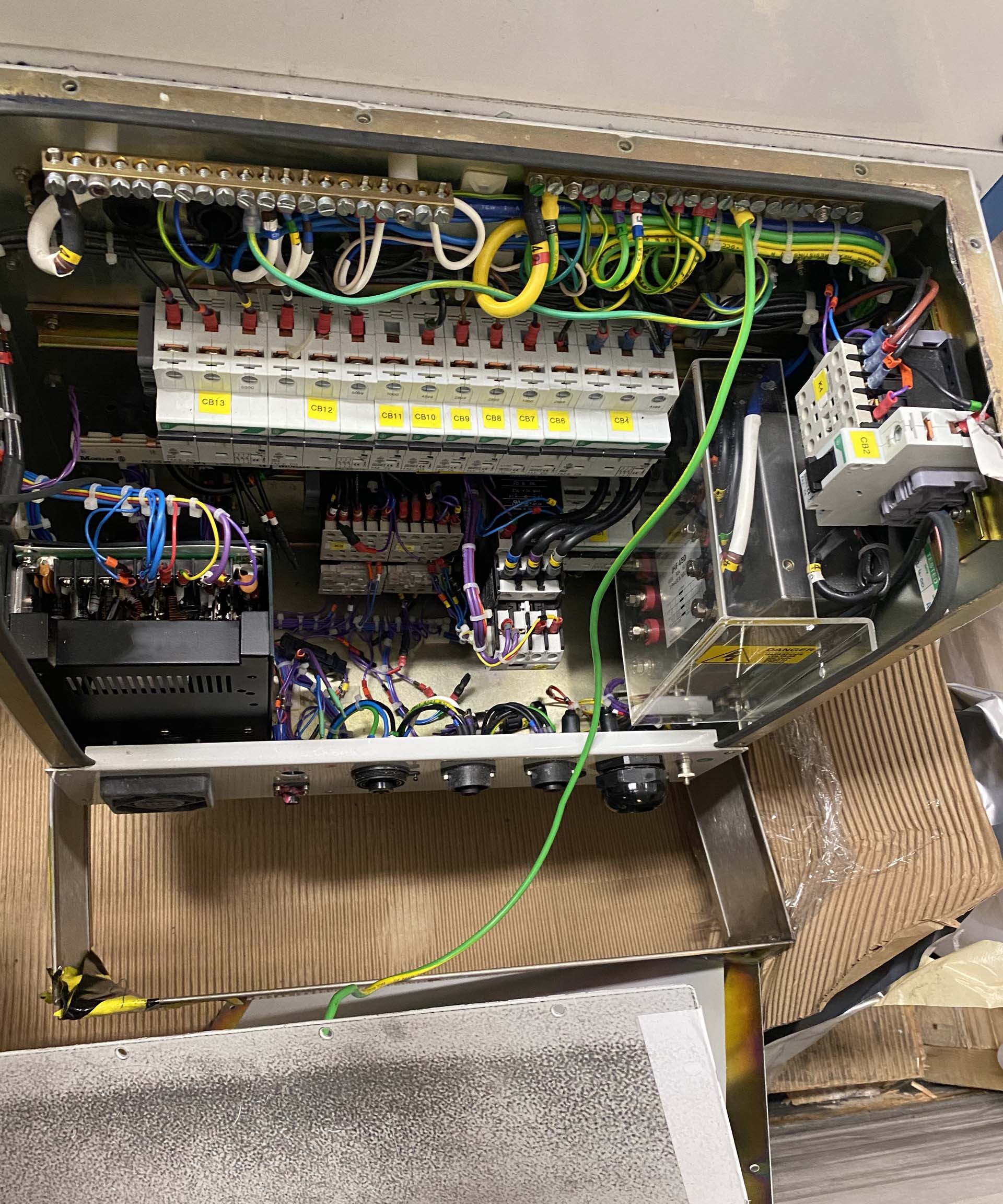

Power supply: 208 V, 63 Amps, 3 Phase, 50/60 Hz

2009 vintage.

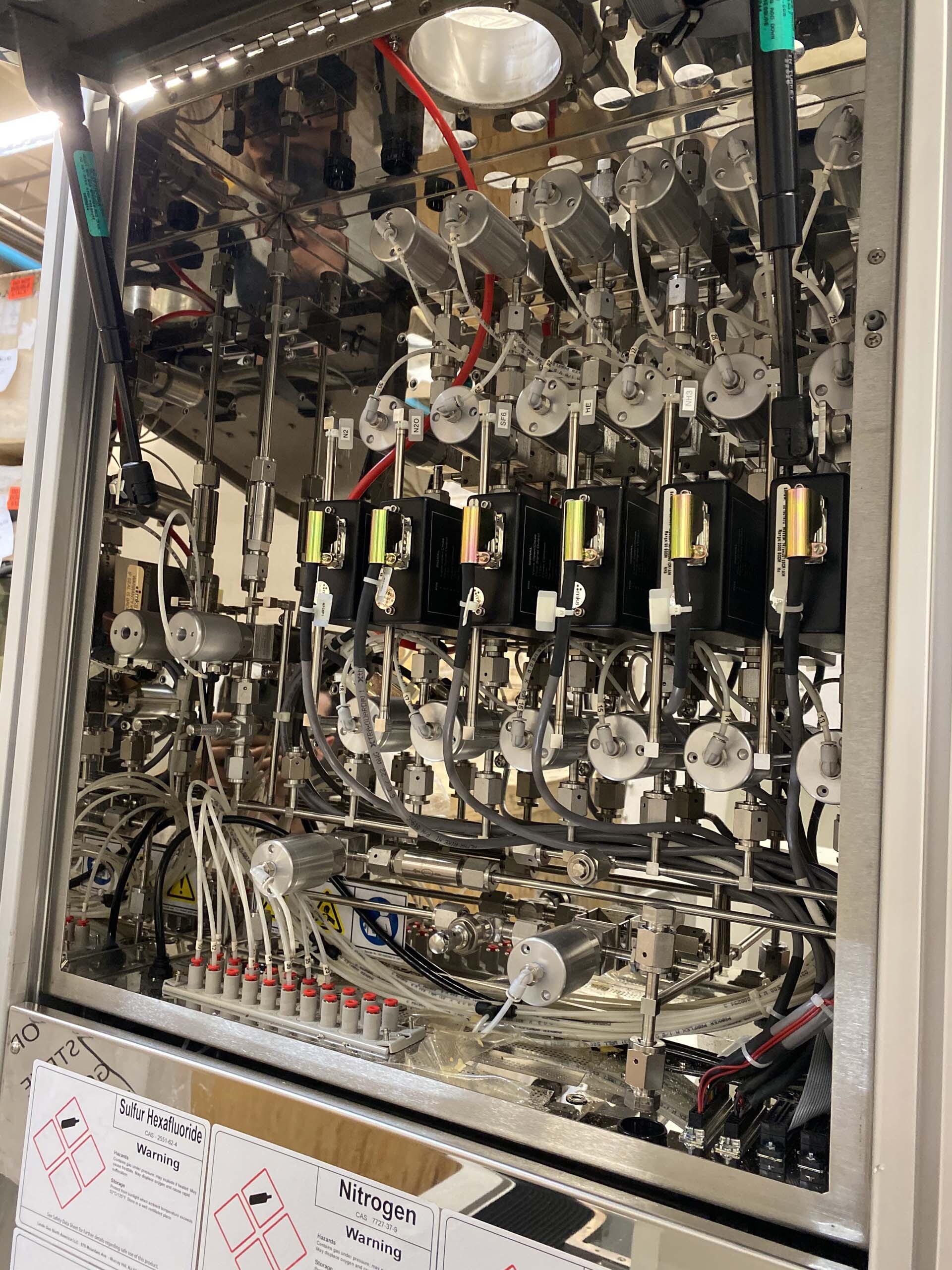

PLASMATHERM LAPECVD PM3 is a plasma enhanced chemical vapor deposition reactor intended for the deposition of thin films for semiconductor device manufacturing. The reactor is designed for atmospheric pressure operation, using radio-frequency (RF) inductive plasma for enhanced surface reactions, and for the deposition of multiple materials, including metals, alloys, oxides and nitrides. The reactor chamber is made up of a quartz tube with an inner diameter of 32 cm and is evacuated via the mechanical vacuum pump. A RF power generator supplies RF energy to the inductive coil which produces a high-frequency, low-pressure plasma. The electric field generated by the induction coil creates a uniform density plasma. An RF plasma shield is used to reduce surface charging effect and to provide additional gas homogeneity in the reactor chamber. The substrate holder is made from a graphite block to prevent material buildup, while allowing heat to be evenly distributed throughout the holder. The substrate holder is then suspended on an adjustable and rotatable mount. This allows the substrate to be heated, while allowing the substrate to rotate and be exposed to the plasma. This yields uniform deposition of materials on the substrate. The process gases are delivered to the process chamber through individual, segregated gas inlets for precise control of process conditions. Mass flow controllers precisely control the flow of process gases into the process chamber. The pressure in the process chamber is controlled through a throttle valve and can be adjusted from atmospheric pressure to 6 torr. An electrostatic chuck is used to hold a wafer in place during the deposition process. The electrostatic chuck applies a high voltage to the wafer, creating positive and negative electrostatic forces that hold the wafer in place during the deposition process. The reactor system is equipped with an optical pyrometer to measure substrate temperatures. The temperature of the substrate is measured by a pyrometer and is then automatically adjusted by the PLC to keep the substrate temperature within user-specified limits. LAPECVD PM3 provides a safe and efficient way to deposit thin protective layers on wafers. The reactor is designed for long-term stability with consistent results, enabling manufacturers to achieve enhanced yields of high-quality semiconductor devices.

There are no reviews yet