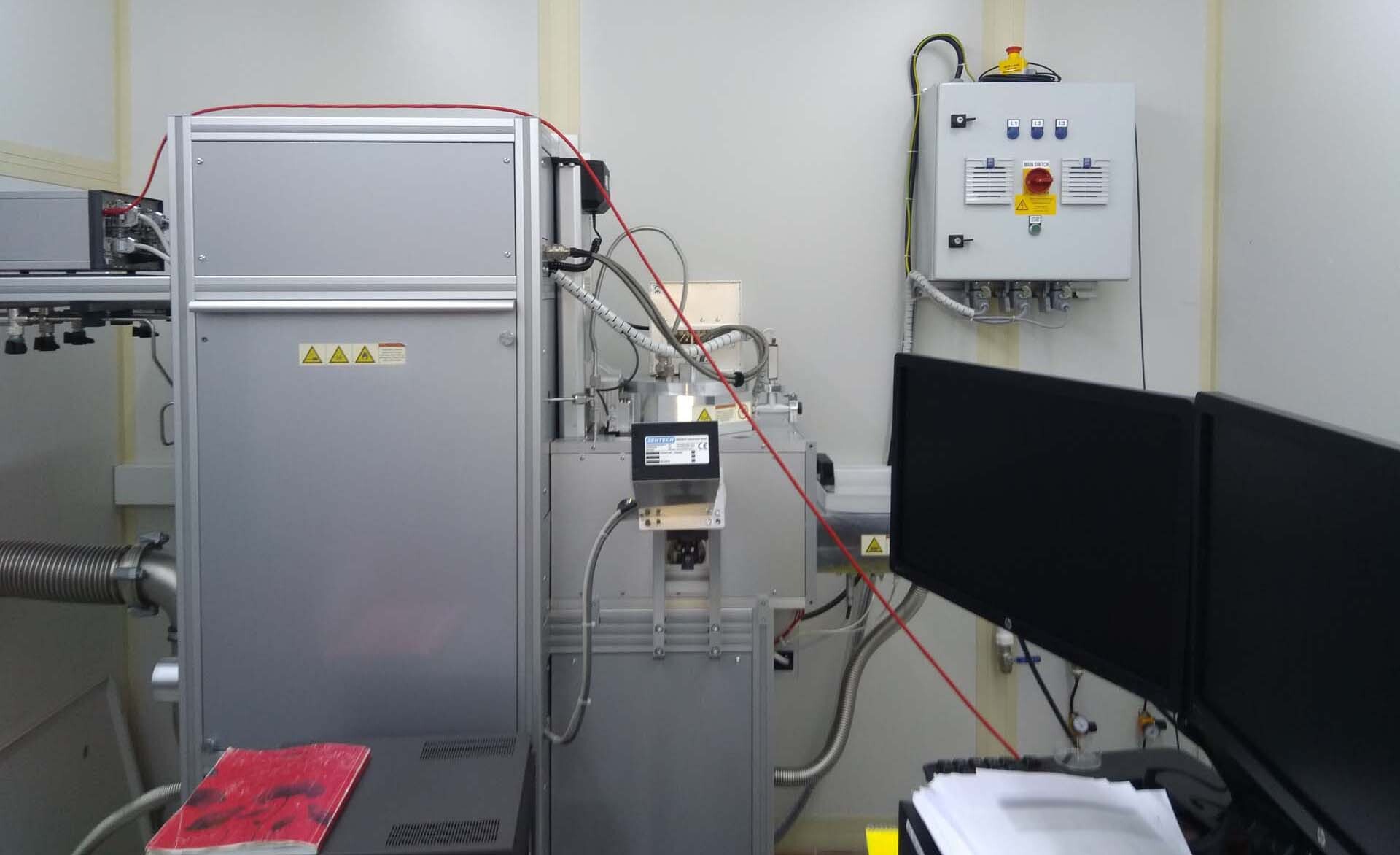

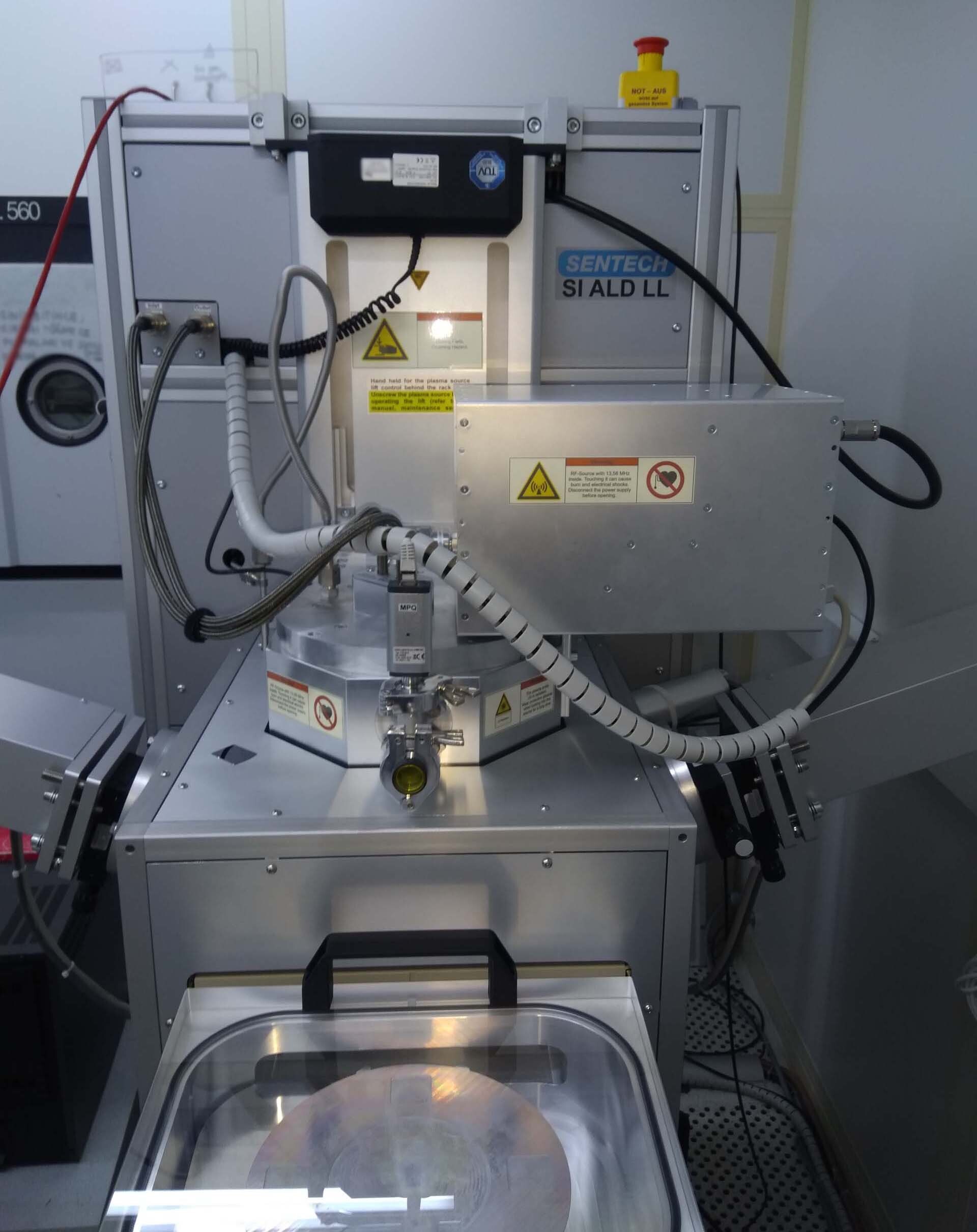

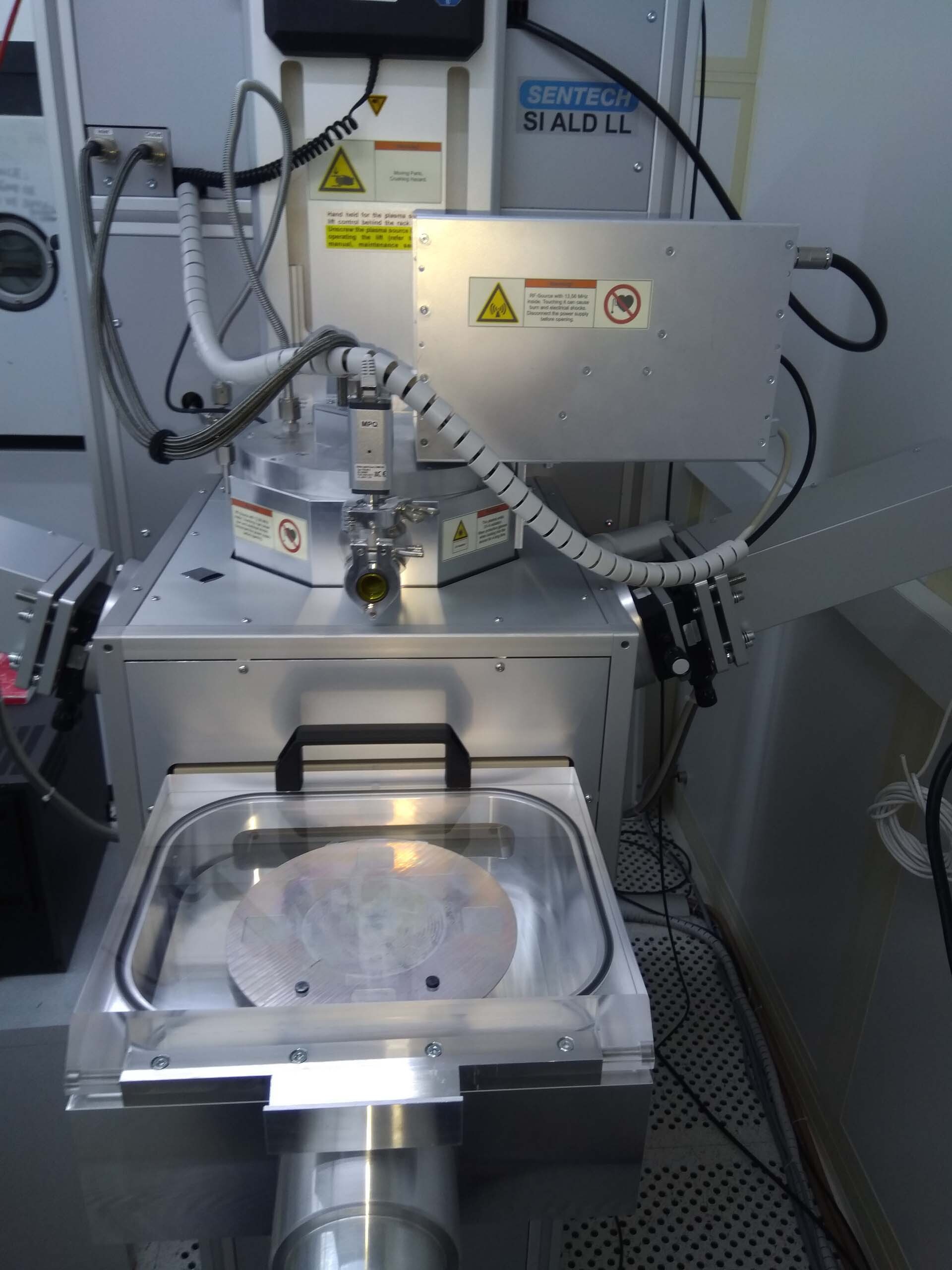

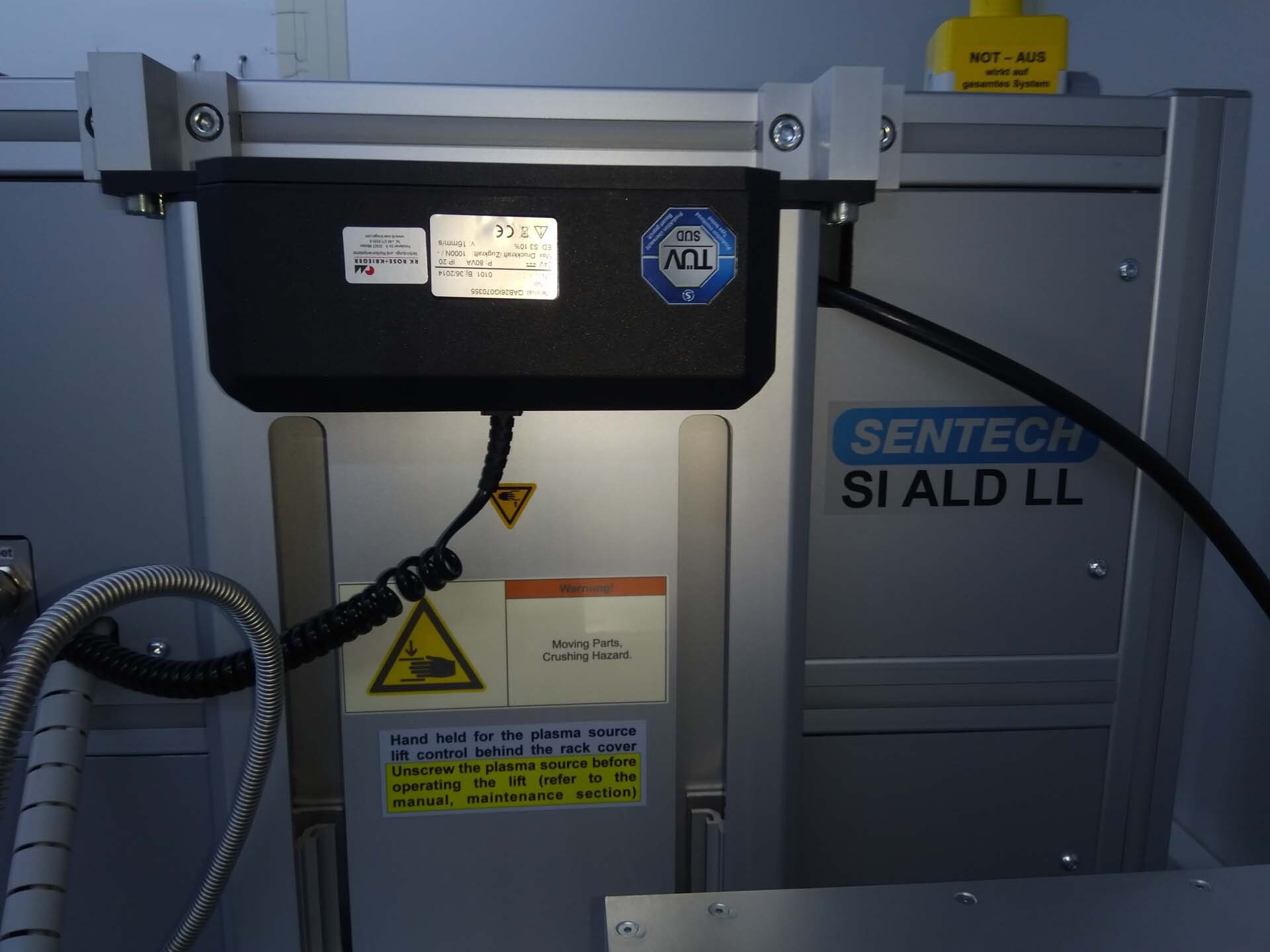

Used SENTECH SI ALD LL #293651896 for sale

URL successfully copied!

Tap to zoom

ID: 293651896

Vintage: 2015

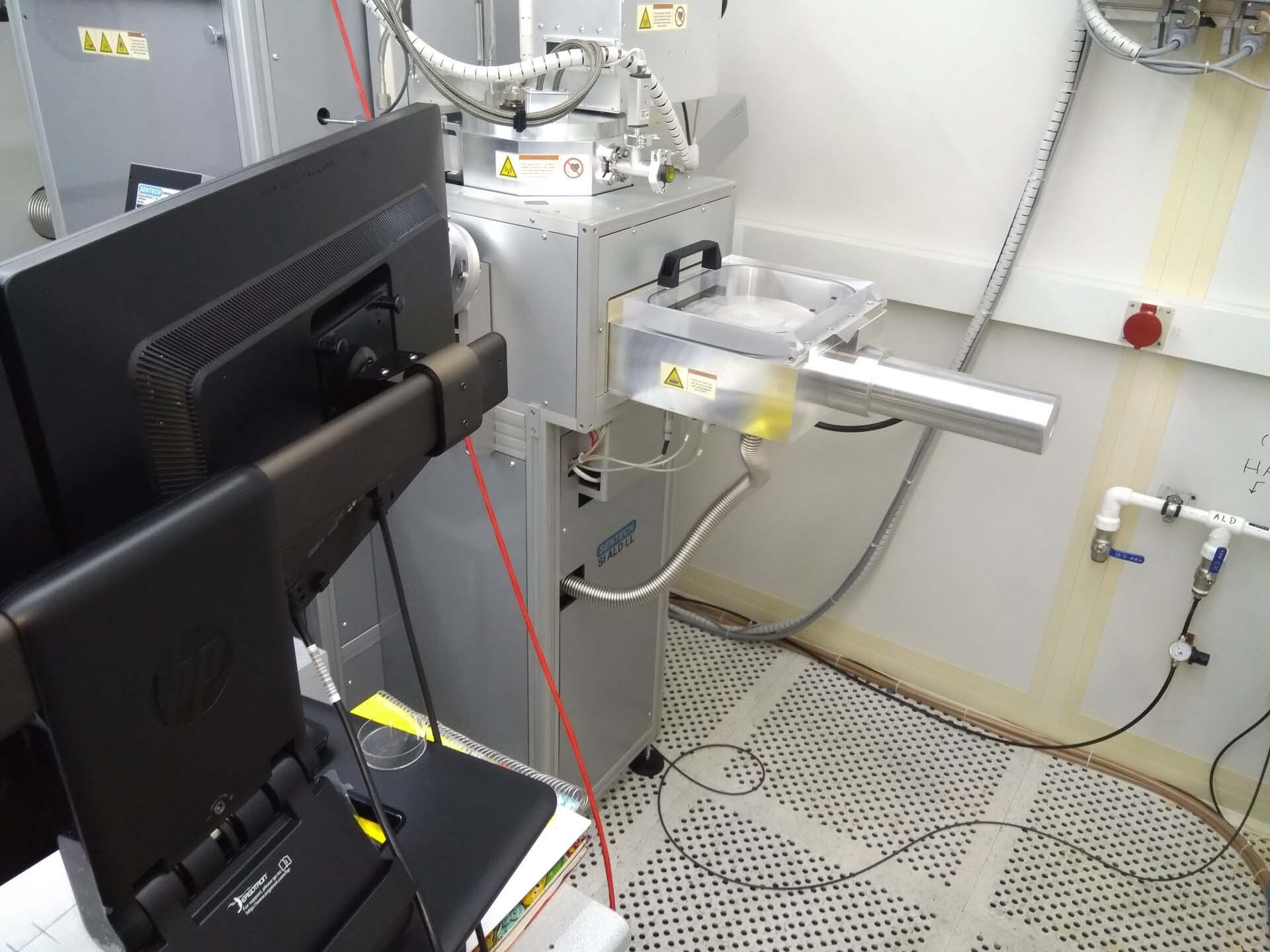

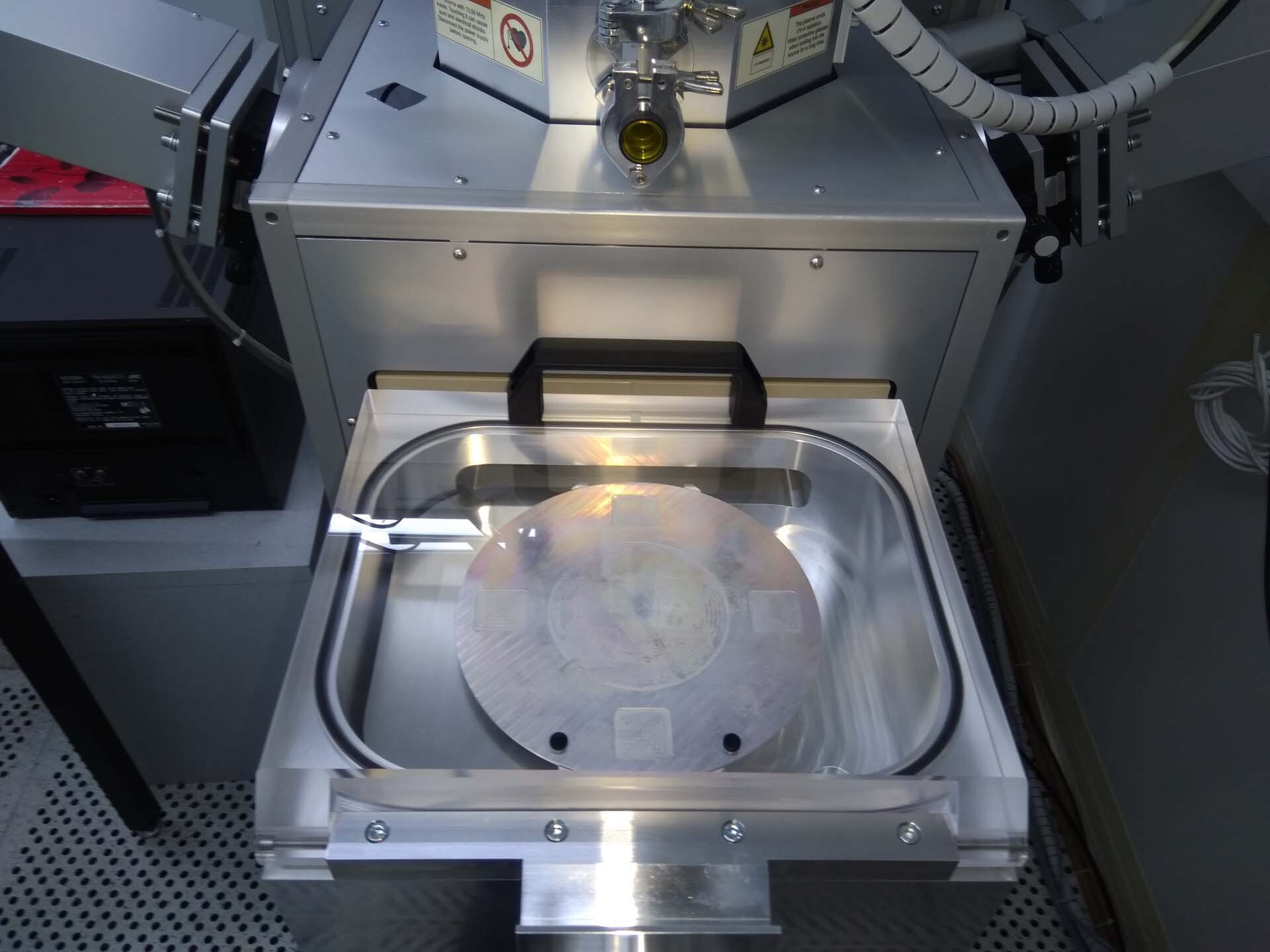

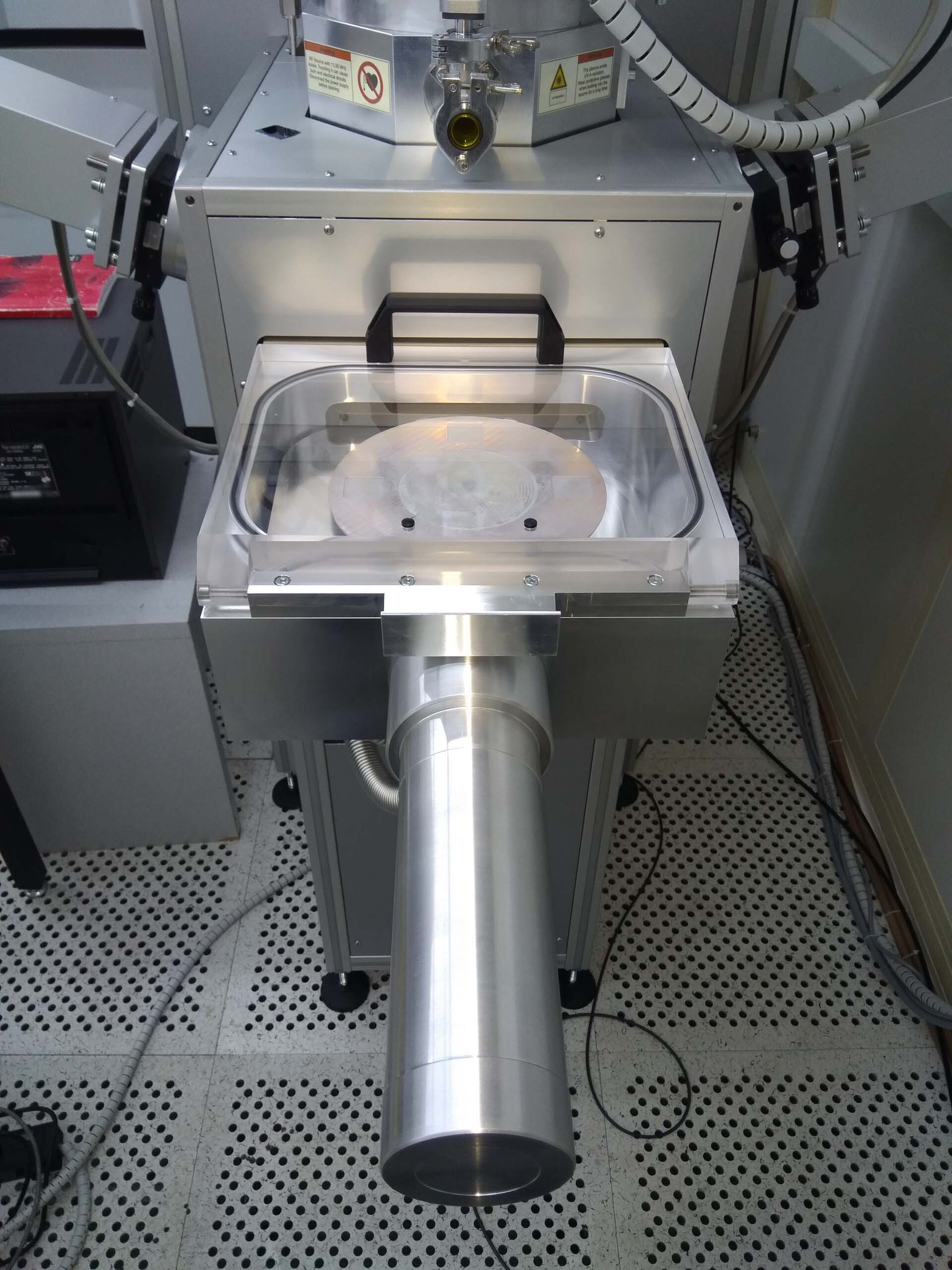

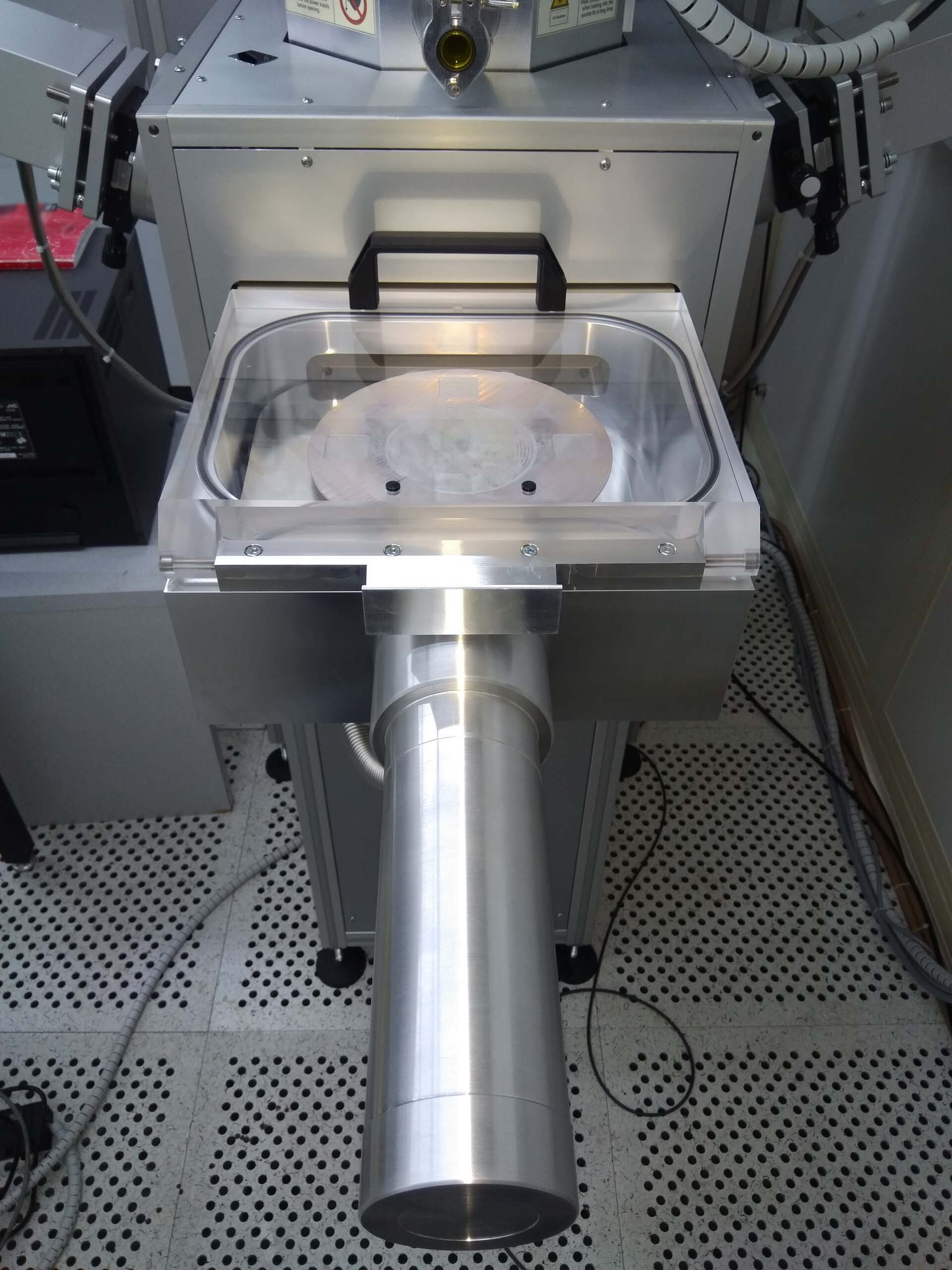

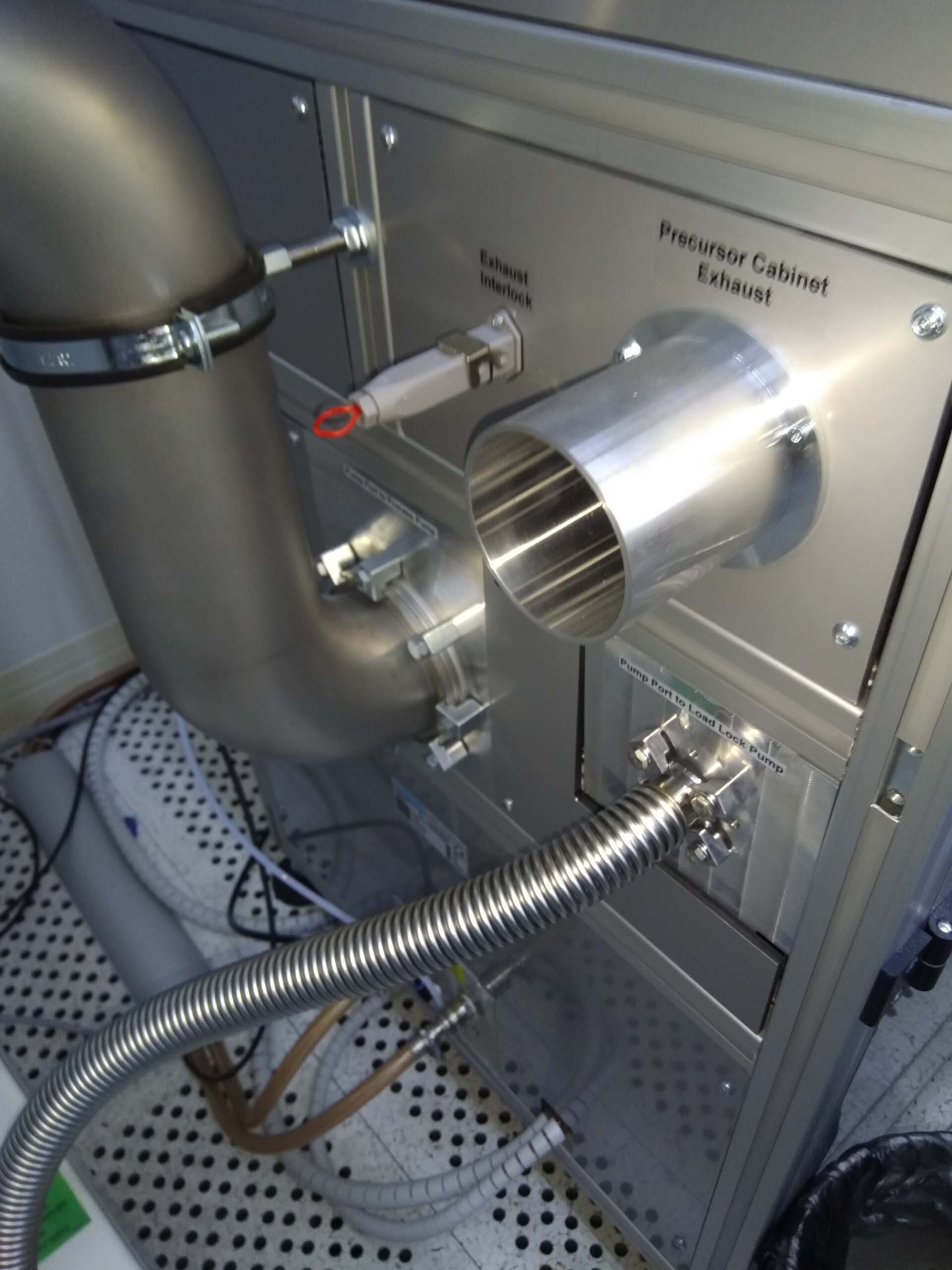

Atomic Layer Deposition (ALD) system

Loadlock

2015 vintage.

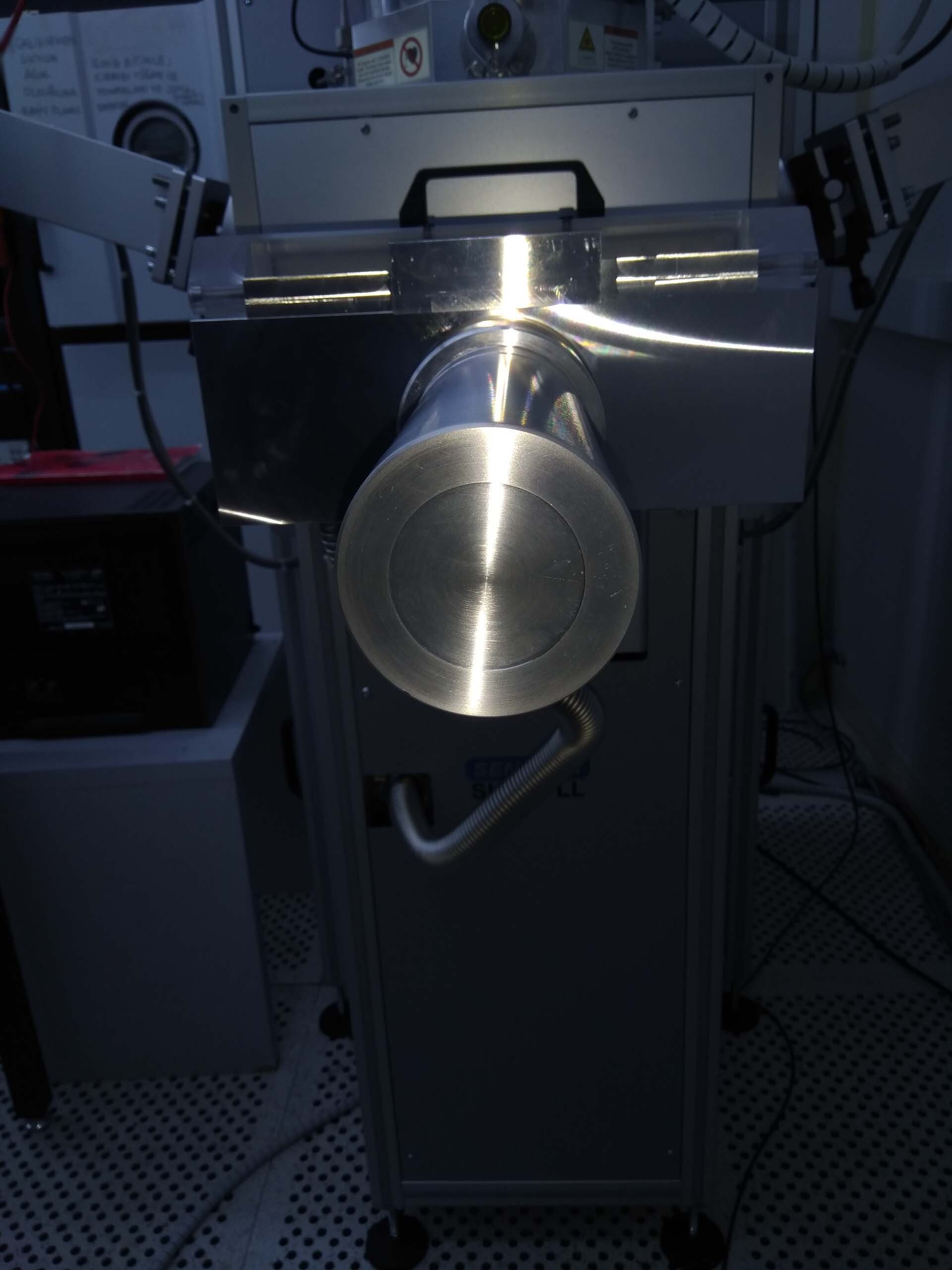

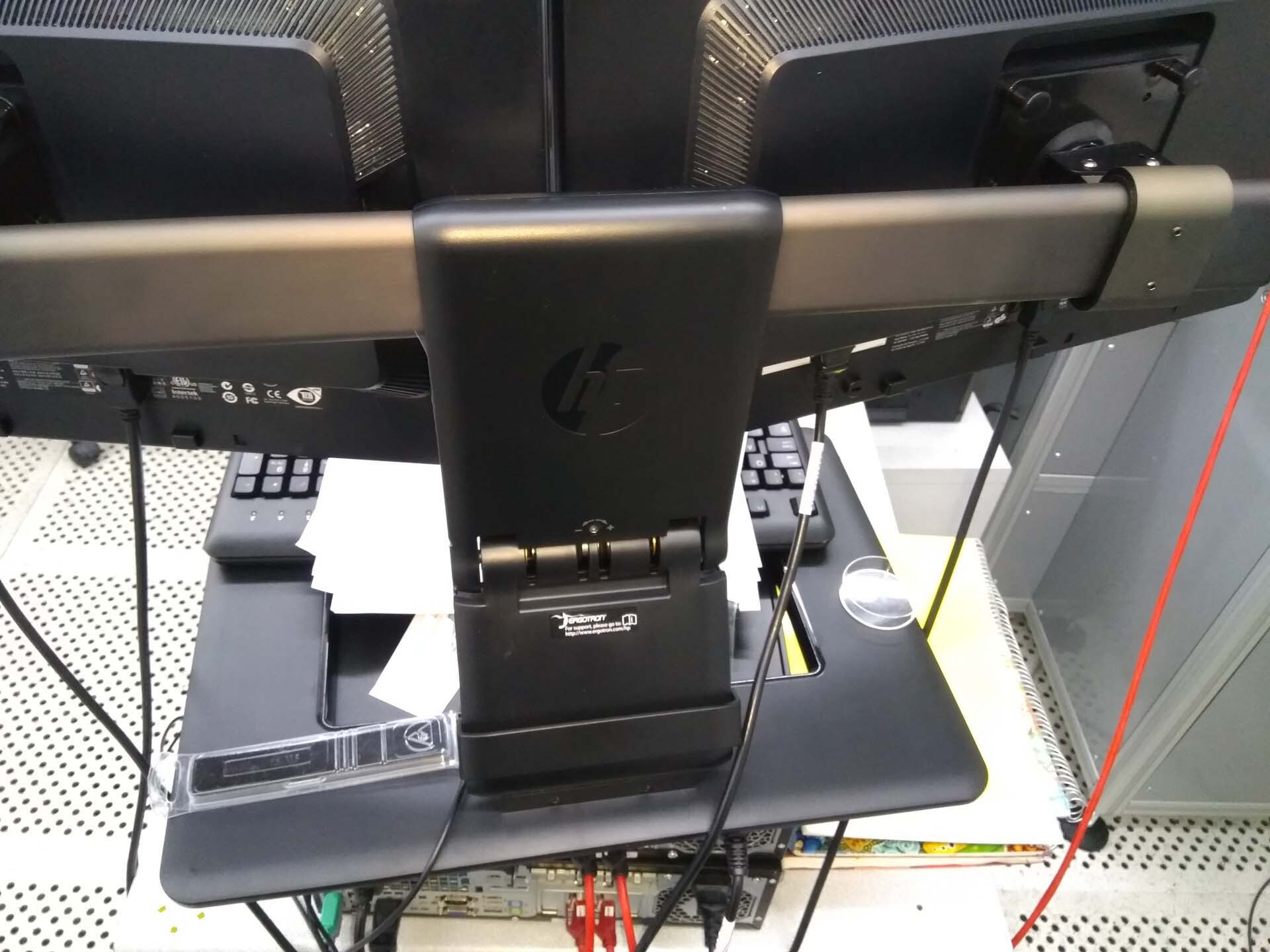

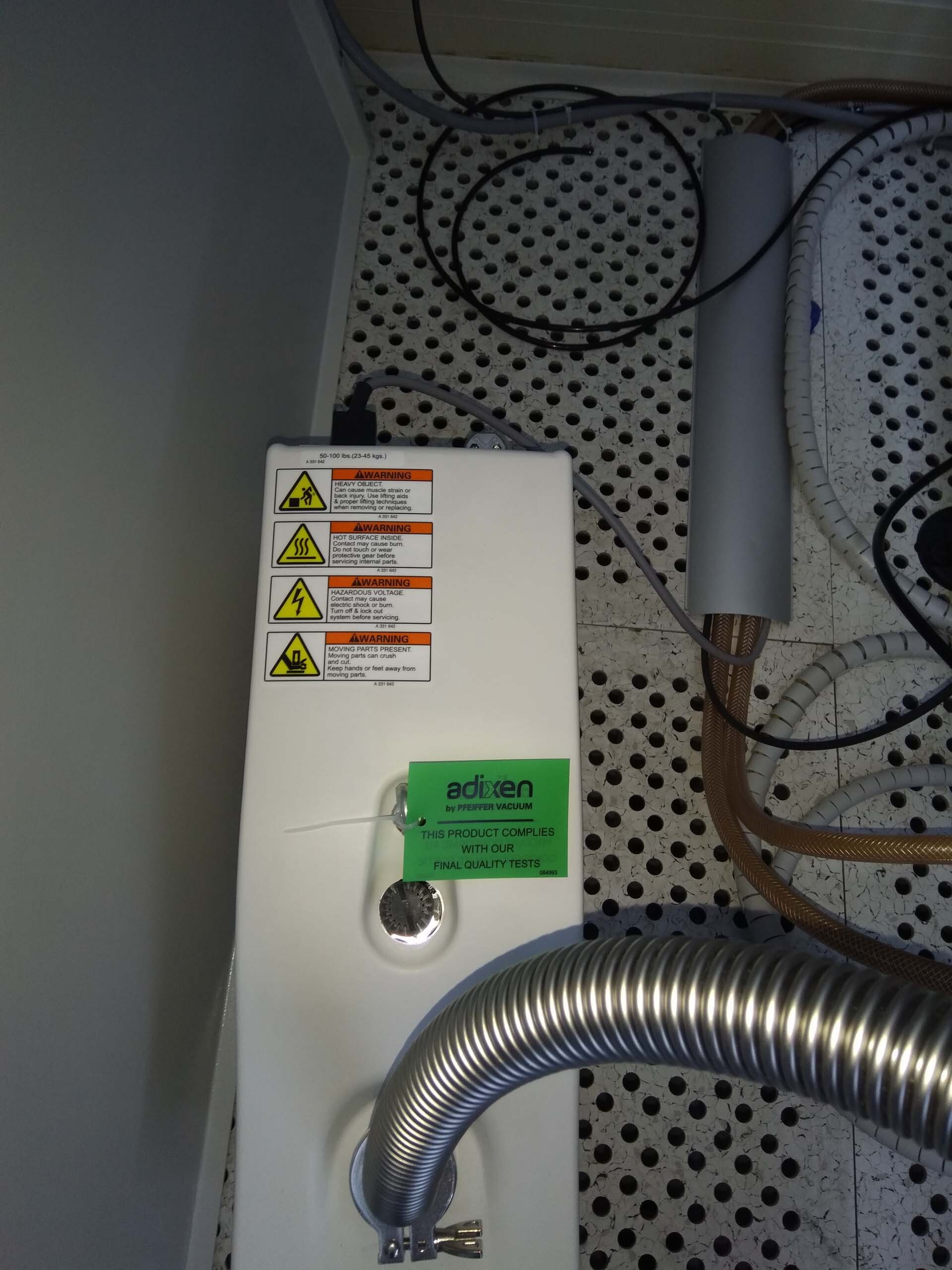

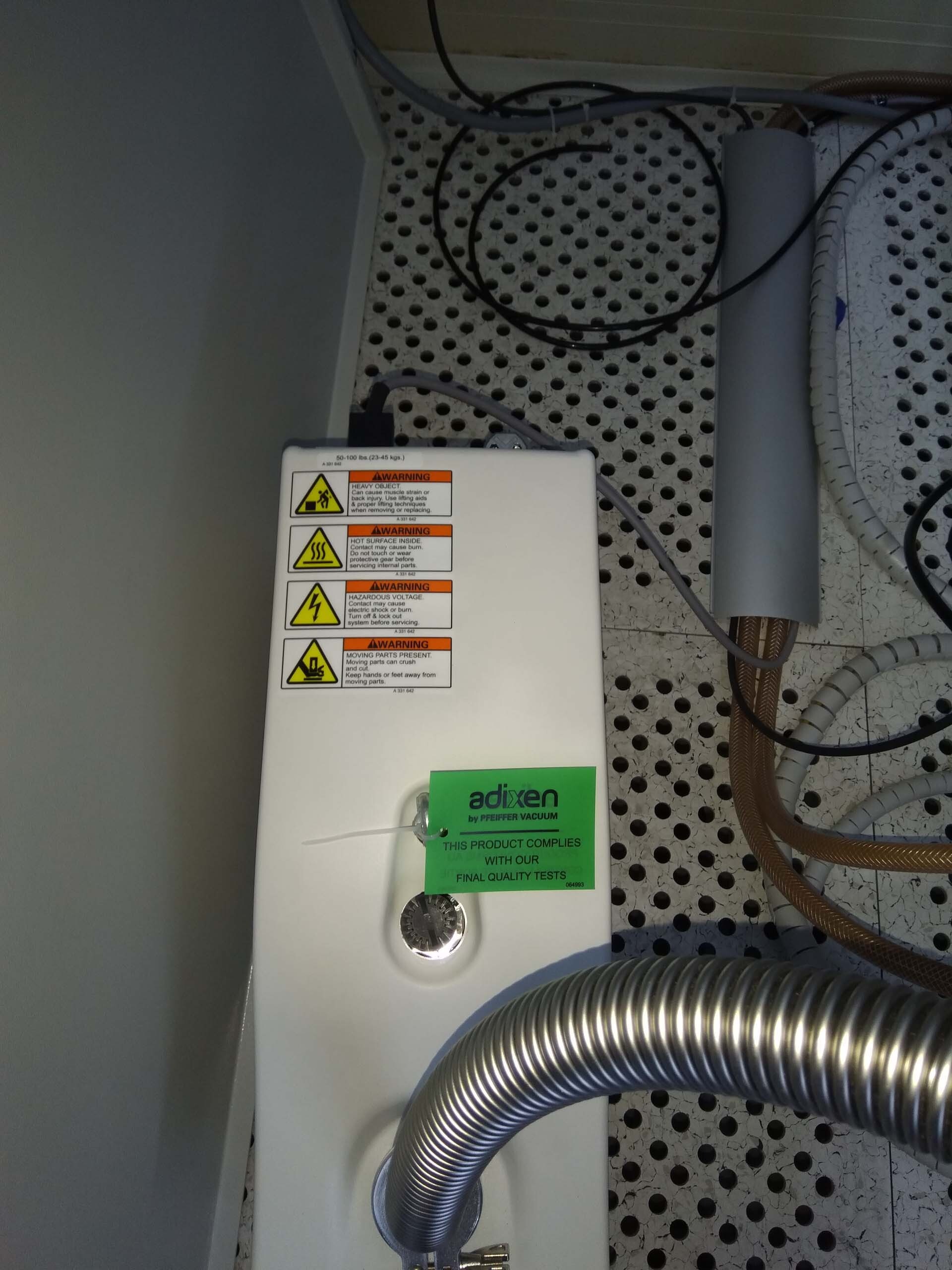

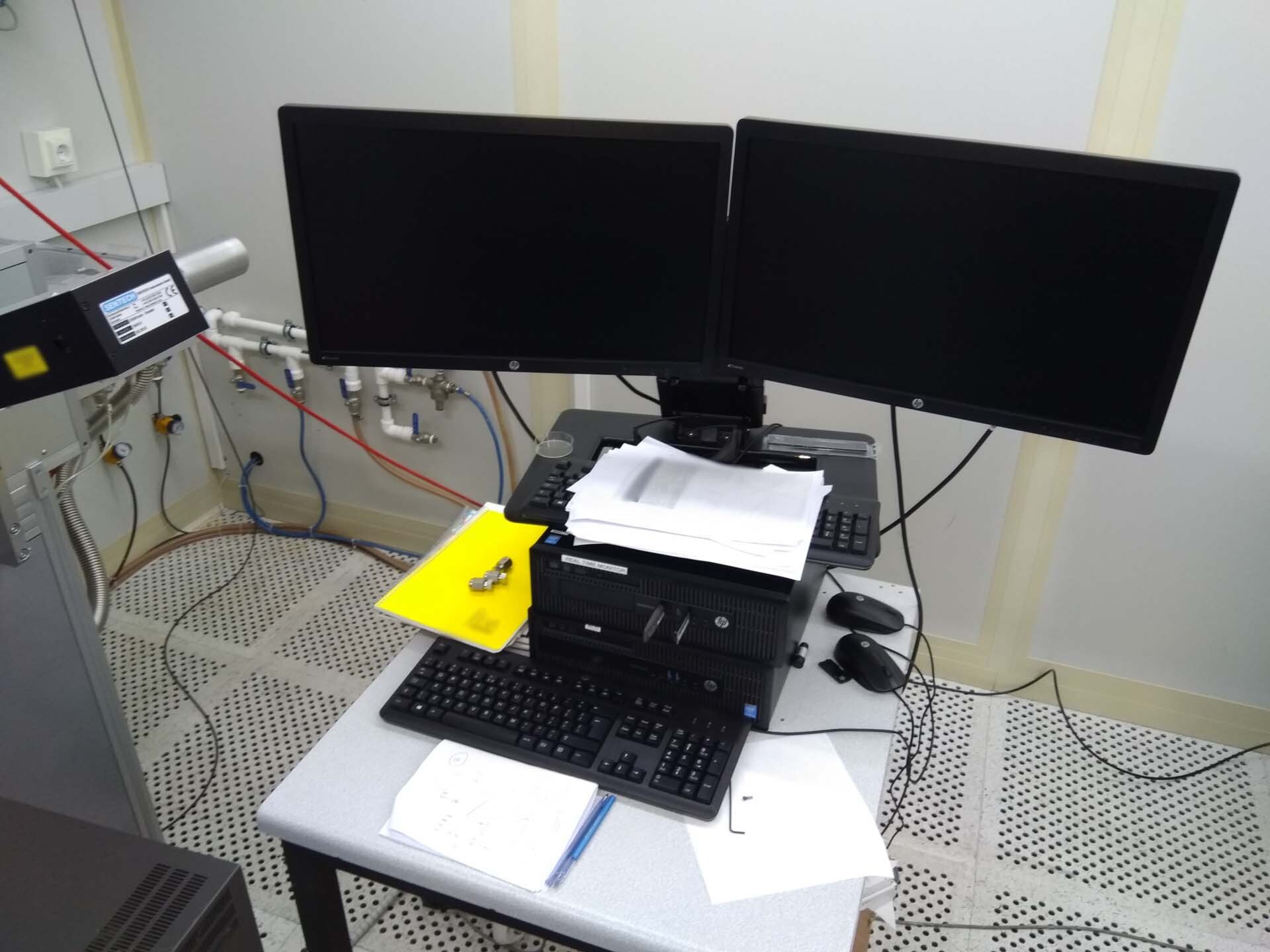

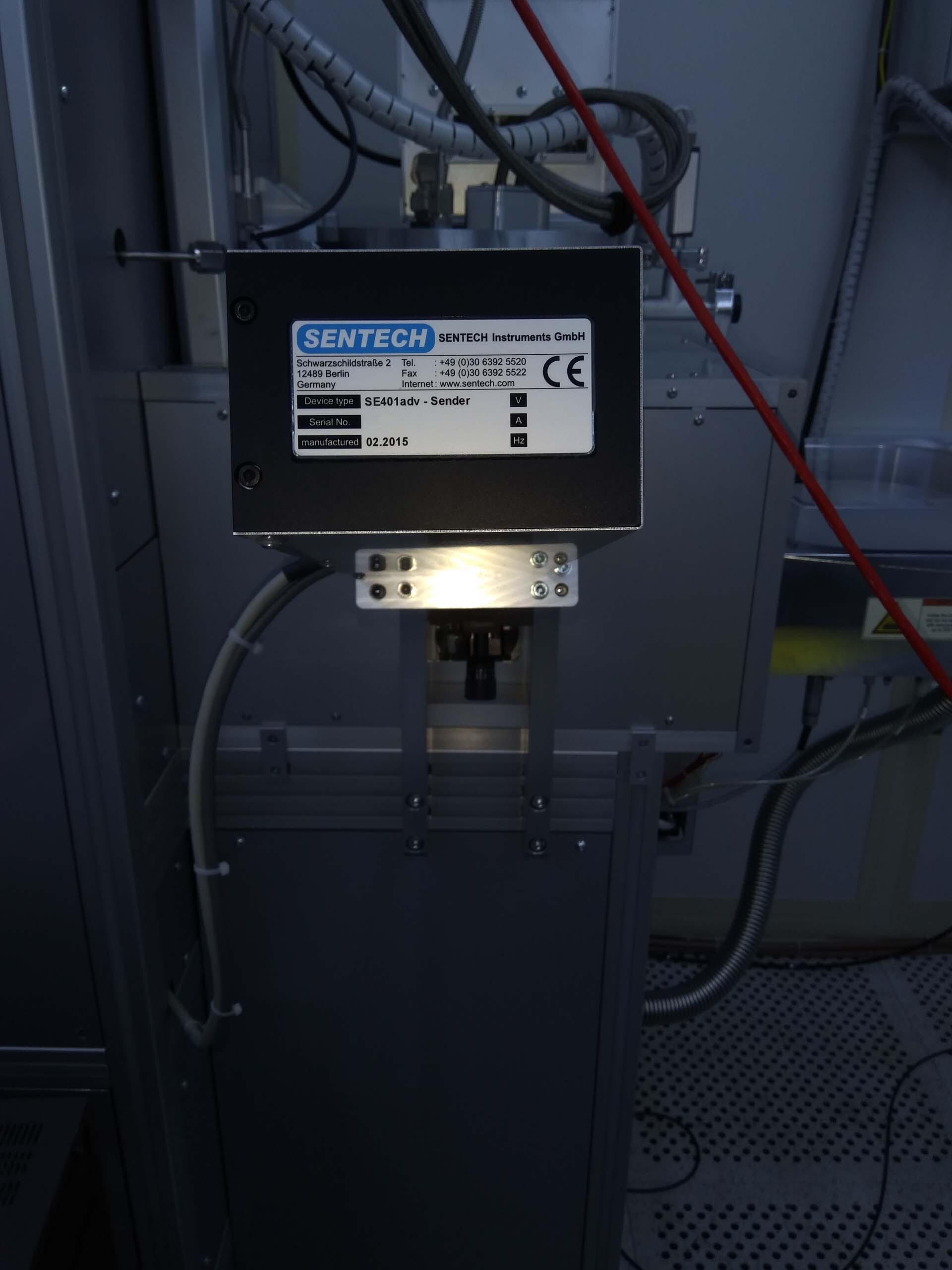

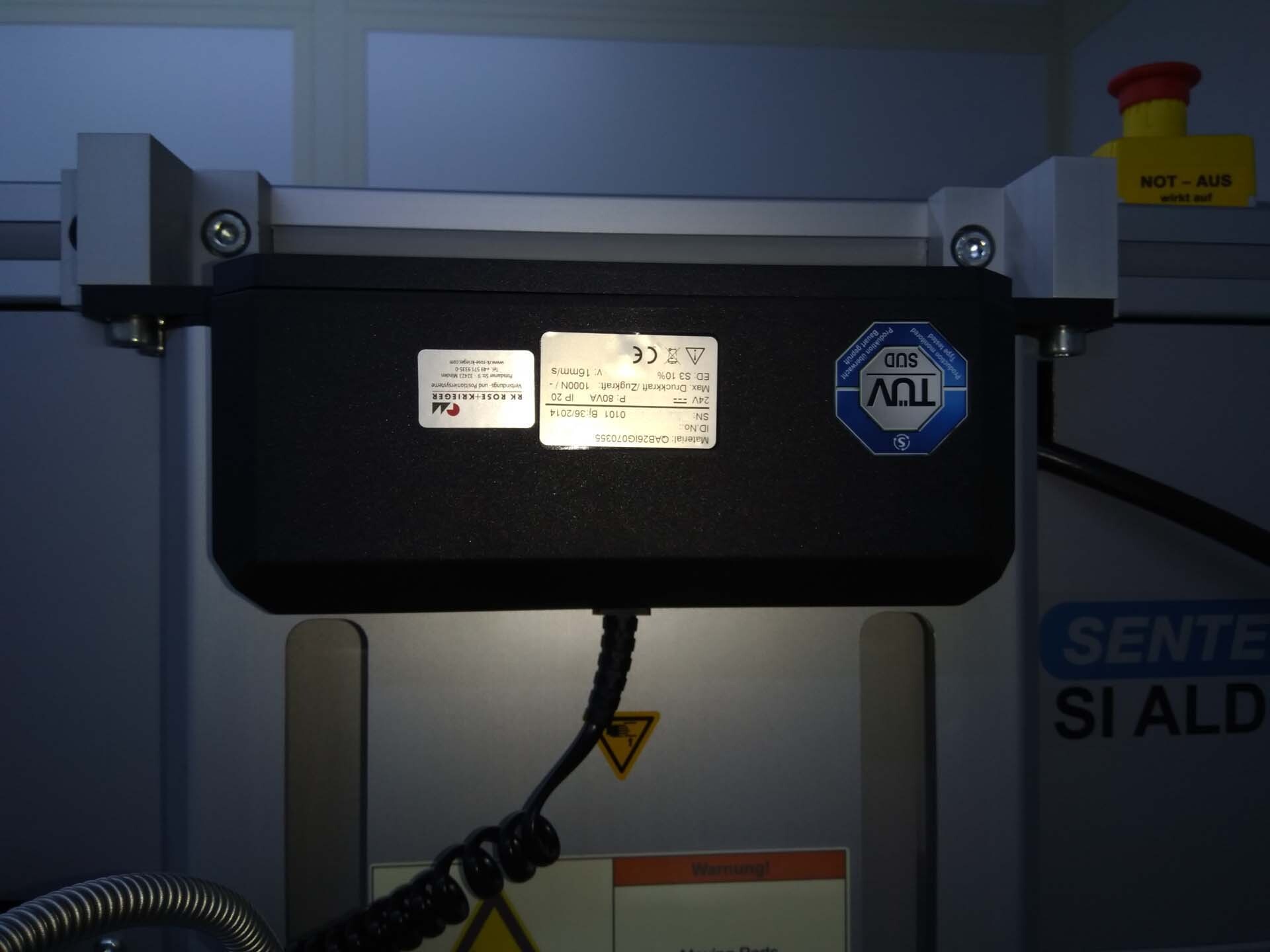

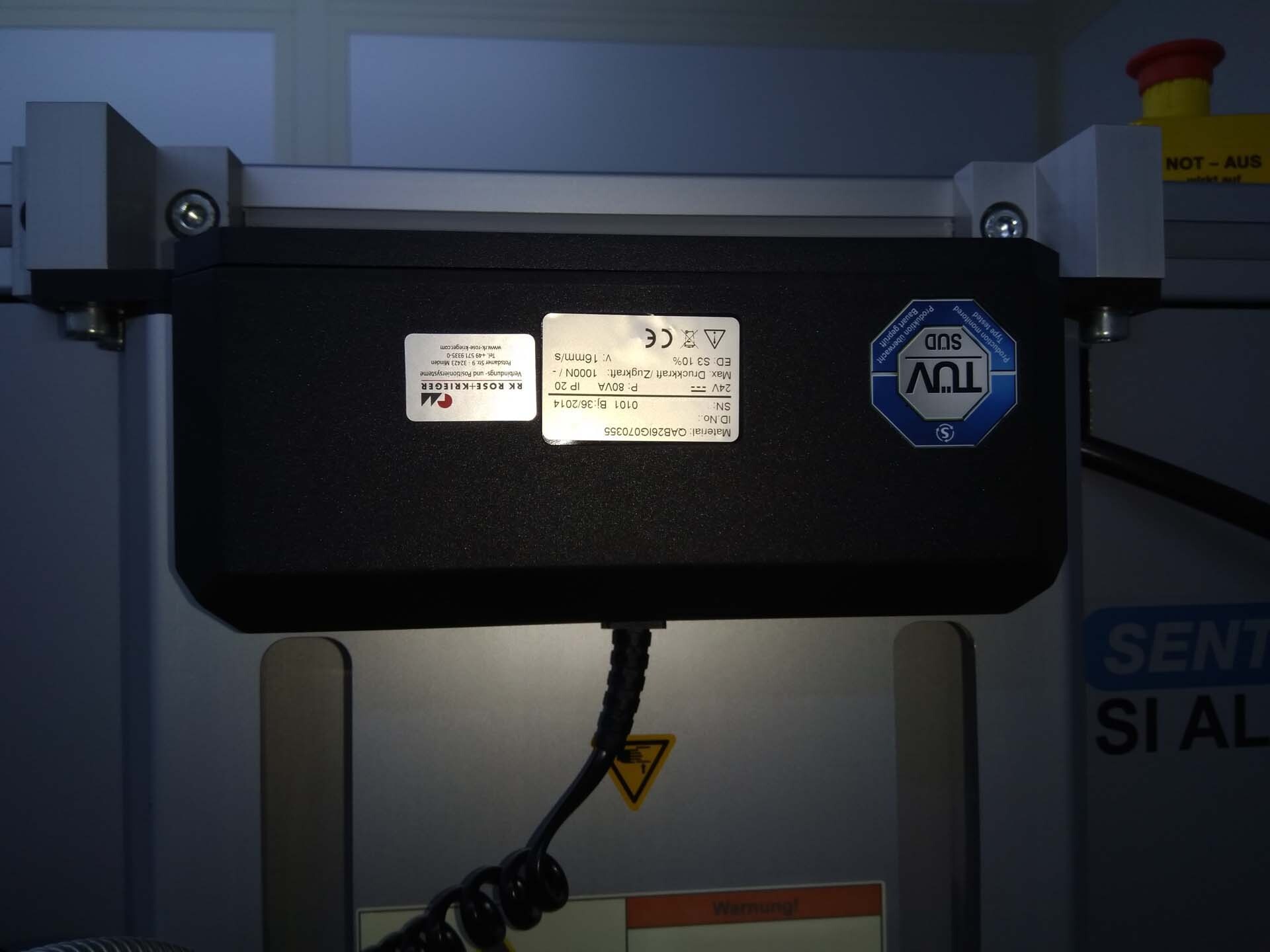

SENTECH SI ALD LL reactor is a state-of-the-art equipment designed to perform atomic layer deposition (ALD) of nanoscale thin films in a low-pressure environment with excellent uniformity and improved control over deposition parameters. The system is composed of three main components: the reactor chamber, the unit computer, and the control unit. The reactor chamber consists of a stainless steel vacuum chamber which houses the substrate, the source material, and the reaction gas. An integrated resource disposal unit and a differential pumping machine are also included. The interior is equipped with an Alkanicon™ electron energy analyzer (EEM) for monitoring substrate deposition and process control. In addition, the chamber is equipped with several heating elements and a turbo pump to maintain the desired atmosphere and pressure. The tool computer is a compact box that includes an color Touch Screen Display for operation of all machine functions. This unit is equipped with a powerful processor capable of automatically calibrating and controlling the ALD process. Its software allows users to program the process by defining deposition conditions and parameters, as well as allowing manual adjustments. The asset also has pre-programmed control systems to ensure optimal and reproducible processes. Finally, the control unit, or nucleus, is completely enclosed and contains all the electrical components of SENTECH model. It includes several analog ports, a digital signal processor (DSP) equipment, a servo control unit and a high-precision fiber-optic temperature control system. This unit fits externally on the chamber and has a modular design to make installation and maintenance easy. SI ALD LL reactor is a modern and feature-rich unit designed to deliver accurate deposition of nanoscale thin films in a safe and efficient manner. With its advanced technological components, the machine is capable of handling a variety of deposition processes and is suitable to industries such as bio-informatics, semiconductor, and aerospace.

There are no reviews yet