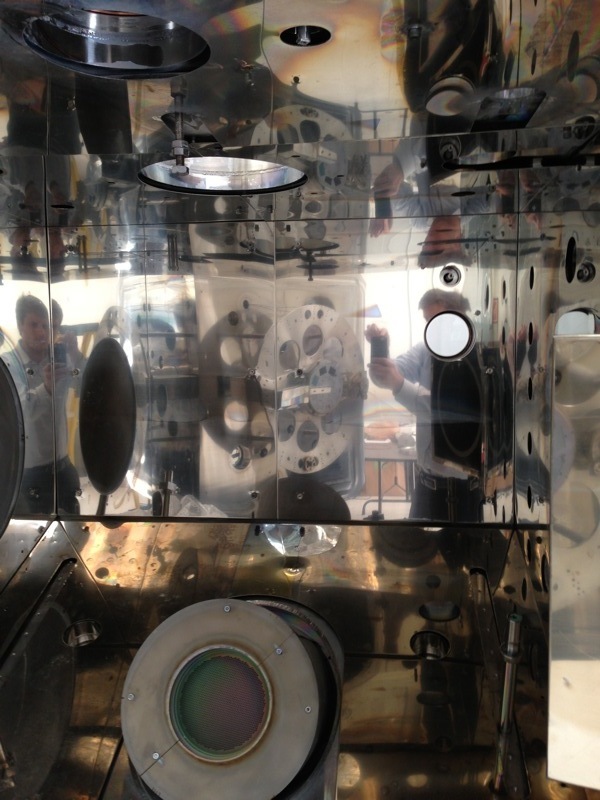

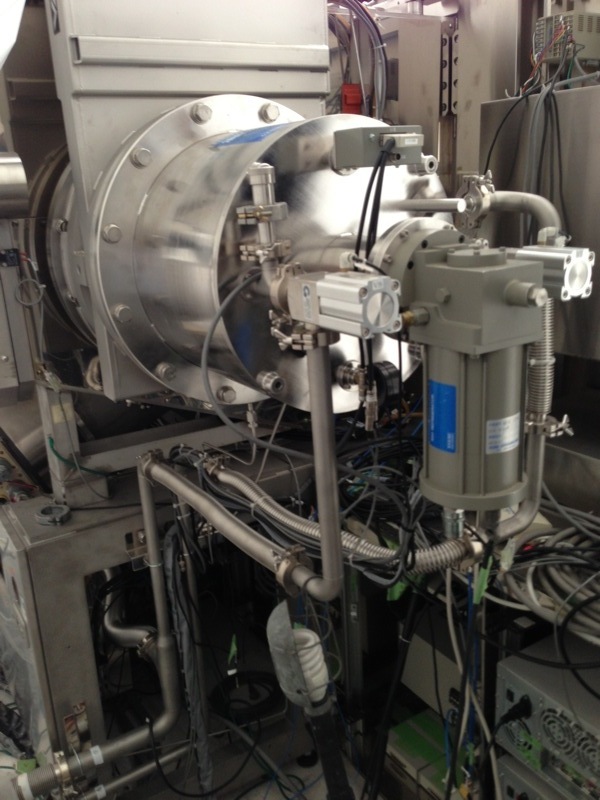

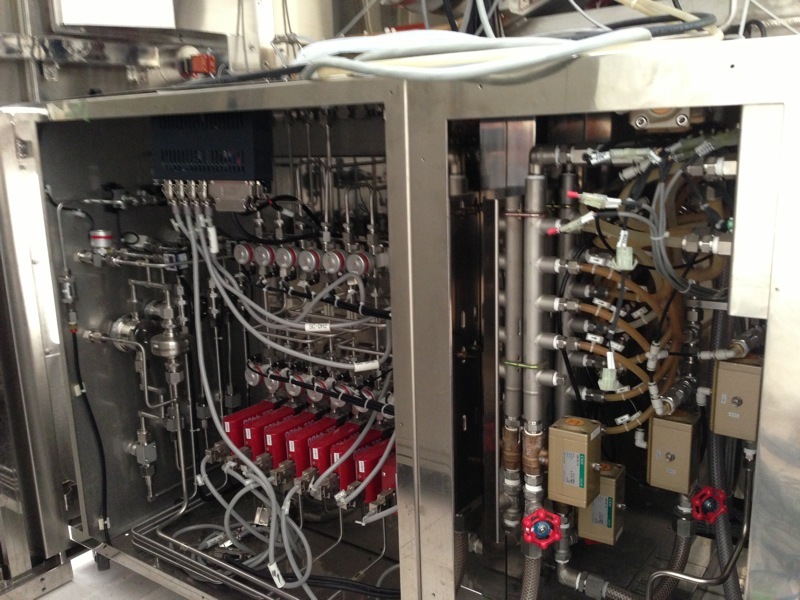

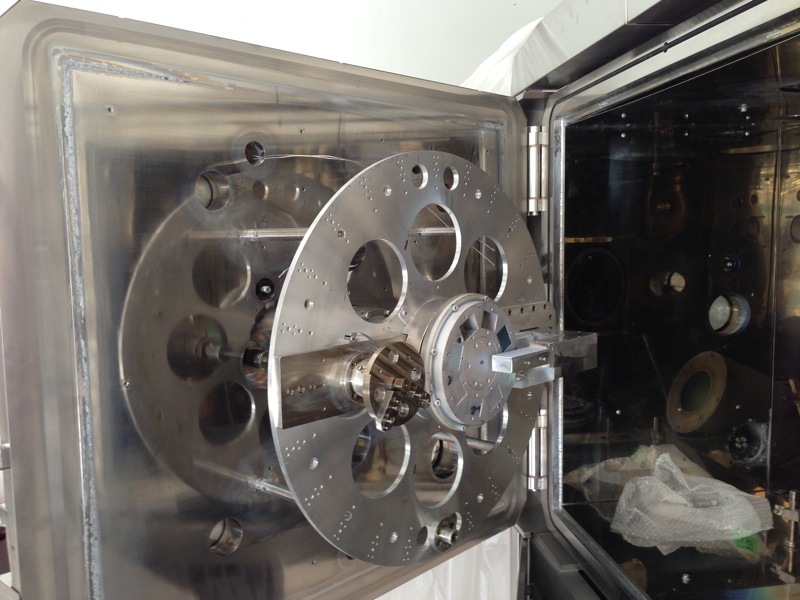

Used ULVAC System #9006539 for sale

URL successfully copied!

Tap to zoom

A ULVAC Equipment is a type of reactor designed to perform a variety of different processes. System consists of a body containing the components of a vacuum chamber, heat sources for heating the working gas, and a set of valves and piping to regulate and direct the movement of the material. The primary objective of any ULVAC Unit is to manipulate the environment within the working chamber to achieve desired results within the specified parameters.Machine is intrinsic to producing high-quality, clean, reproducible samples. It uses a small amount of energy to create large vacuum pressures, allowing for manipulation of the working space at an atomic level. This accuracy makes ULVAC systems highly desirable for a variety of scientific, industrial and laboratory applications. ULVAC systems are capable of applying a number of advanced processes to create and manipulate samples. These range from deposition processes, such as sputtering, to CVD techniques and etching processes such as RF plasma. ULVAC Tool also has the capability to accommodate a variety of reactors, including several different equipment types for various applications. ULVAC systems are designed to provide a complete and controlled environment for process-directed research and development. ULVAC systems typically employ very high vacuum pressures, which can range up to 10-10 Torr. This allows for ultra-high purity and high-performance systems free from contaminants that could lead to potential contamination or degradation. It also permits the use of higher-purity materials to create samples with minimal impurities. The vacuum Asset also employs a number of different components to ensure optimal performance, including an ion pump, backing pump, throttle valve, ion gauges, vacuum chamber quality monitors, and pressure controllers. ULVAC Model is also designed with the most testing and maintenance requirements to ensure Equipment reliability and repeatability. ULVAC systems are extremely versatile and capable of producing a wide range of samples. From basic sputter deposition to complex etching and fabrication processes, ULVAC System has the capability to accommodate a variety of materials and tailor the process to meet specific needs. This allows for custom-made samples to suit specific requirements. ULVAC systems are extremely versatile and reliable, making them an ideal solution for a variety of scientific, industrial and laboratory applications. These systems provide a controlled environment for process-directed research and development, allowing for greater consistency and accuracy. They are also extremely reliable and require minimal amounts of energy for operation. All these factors combine to make ULVAC systems the ideal choice for a variety of different processes.

There are no reviews yet