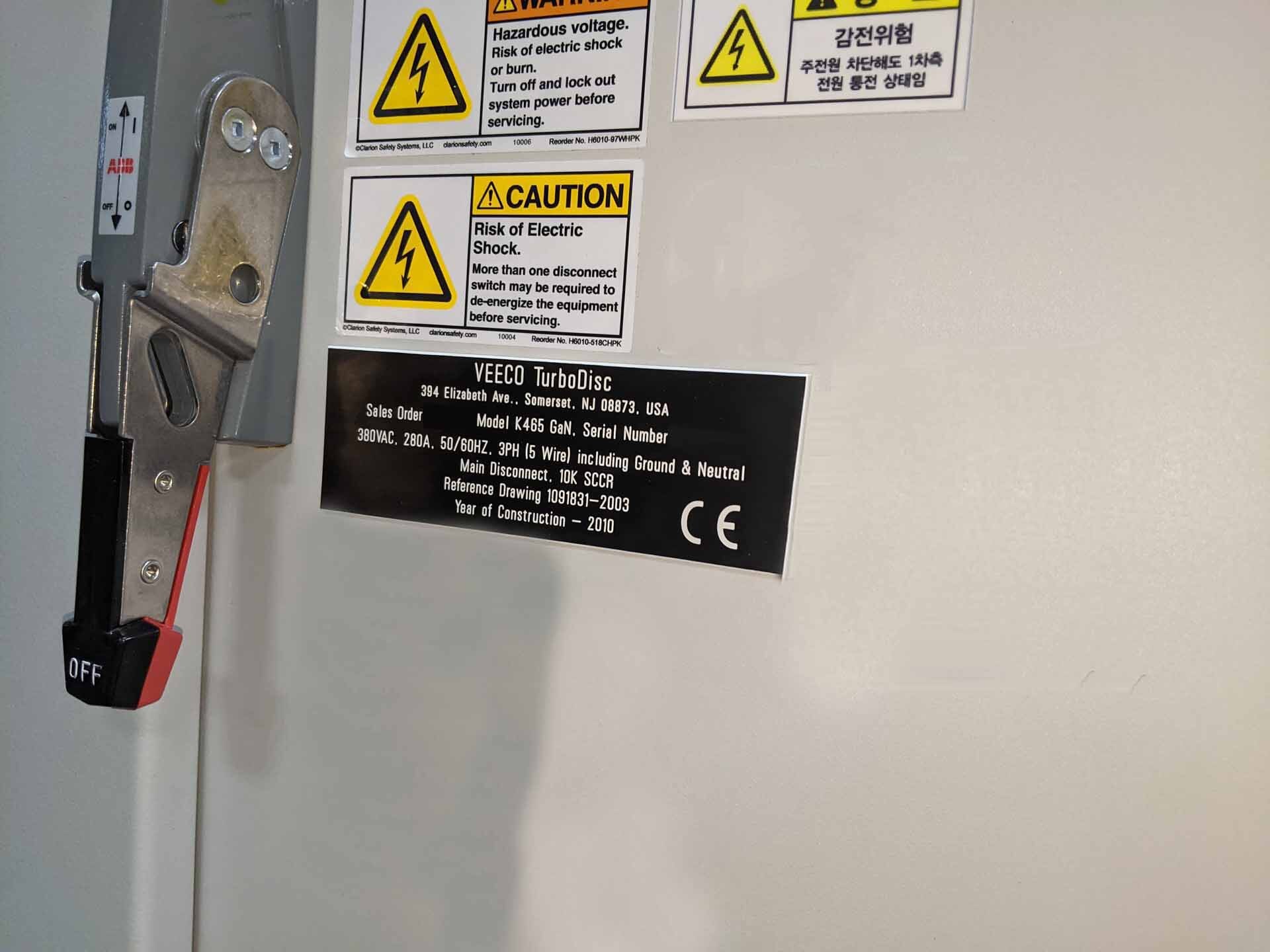

Used VEECO / DEKTAK K 465 I #9410042 for sale

URL successfully copied!

Tap to zoom

ID: 9410042

Vintage: 2010

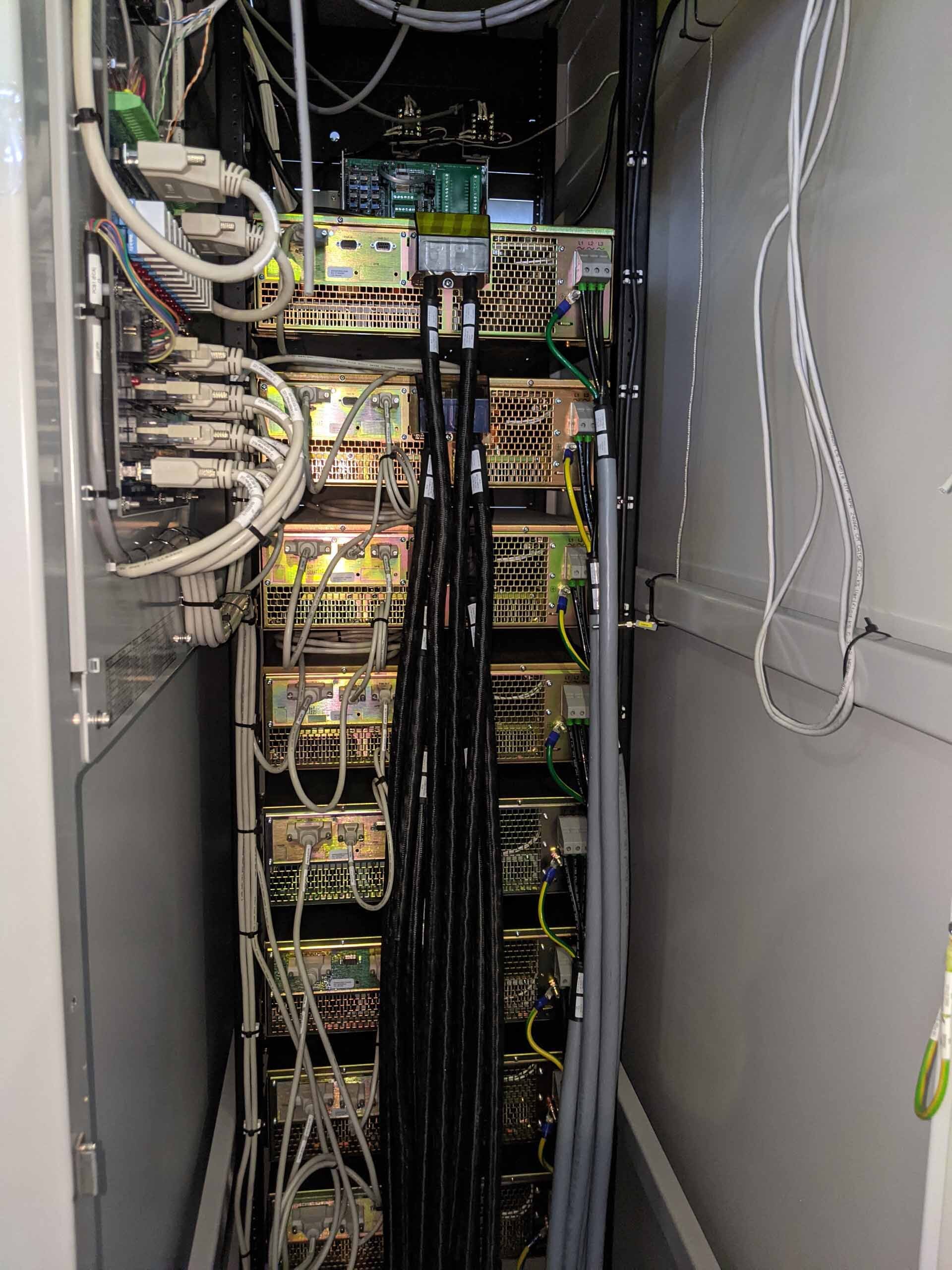

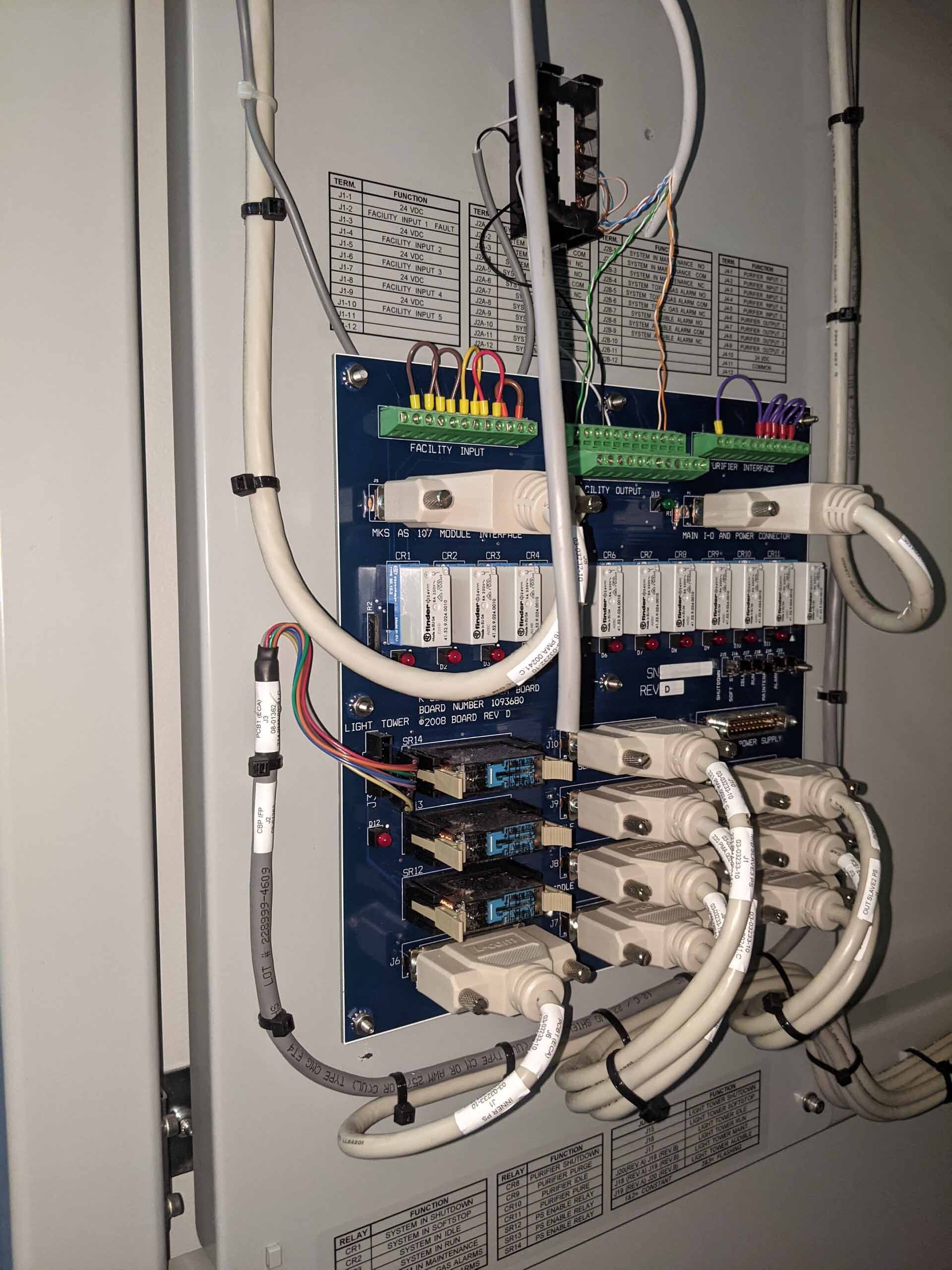

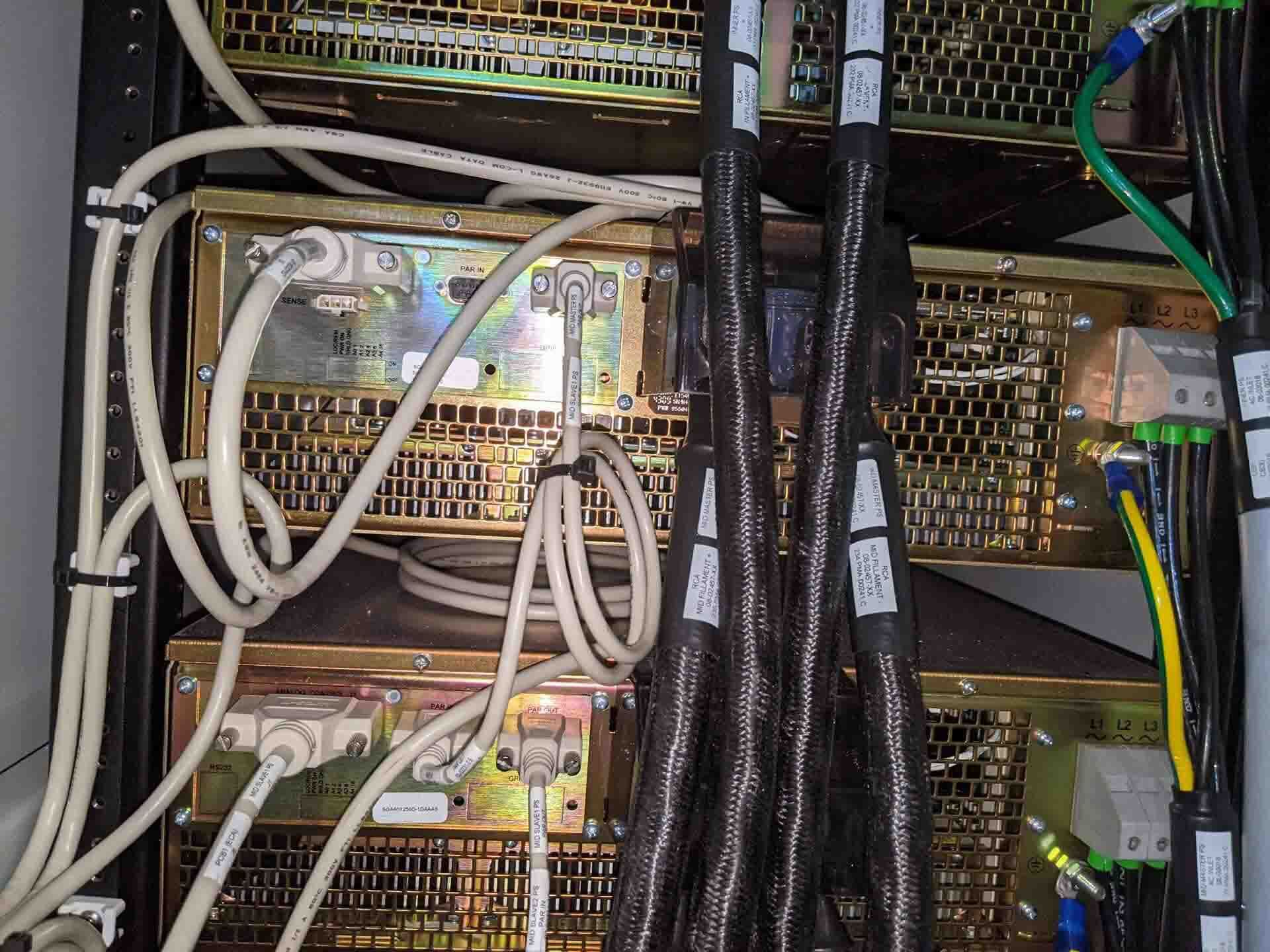

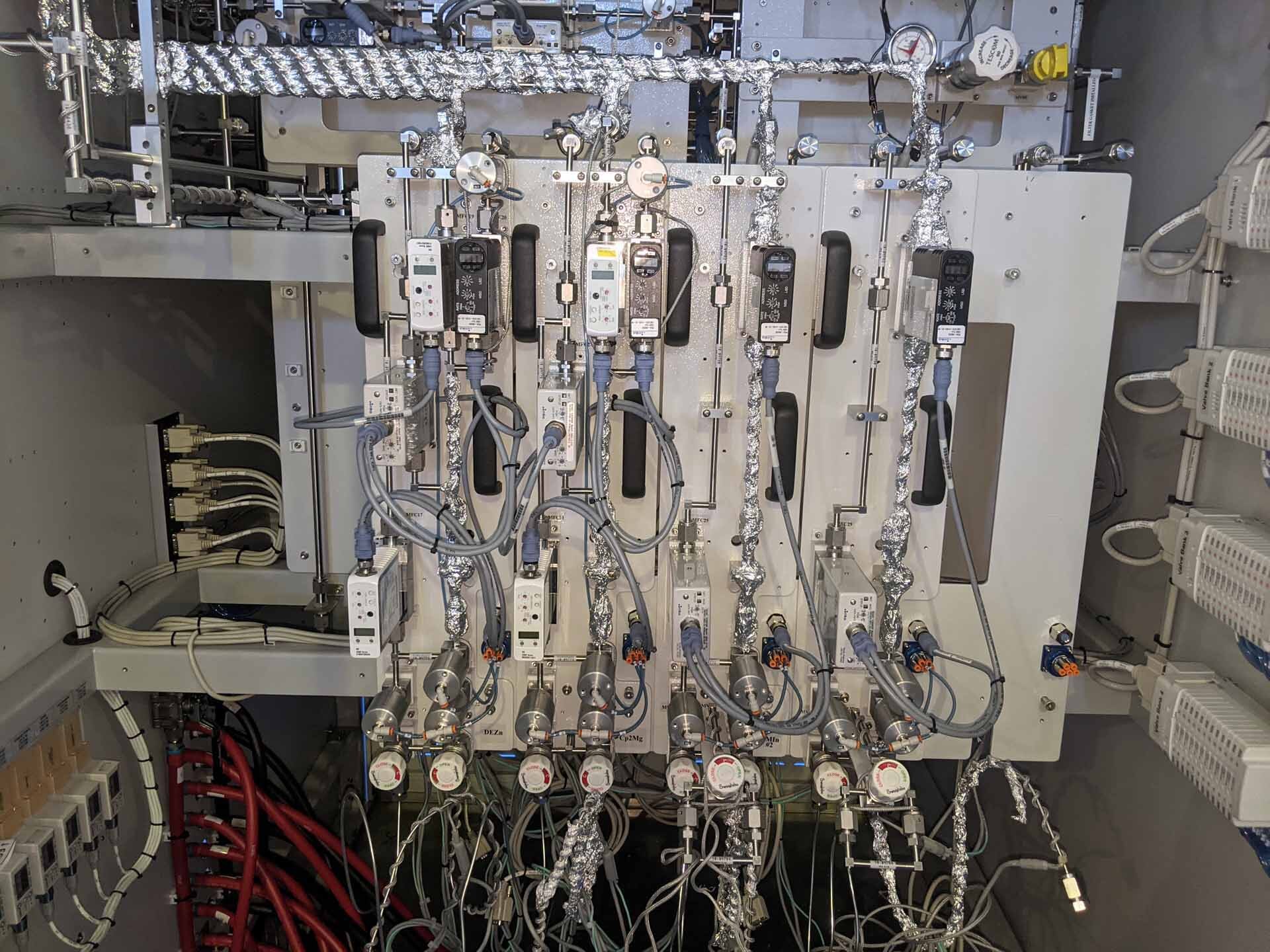

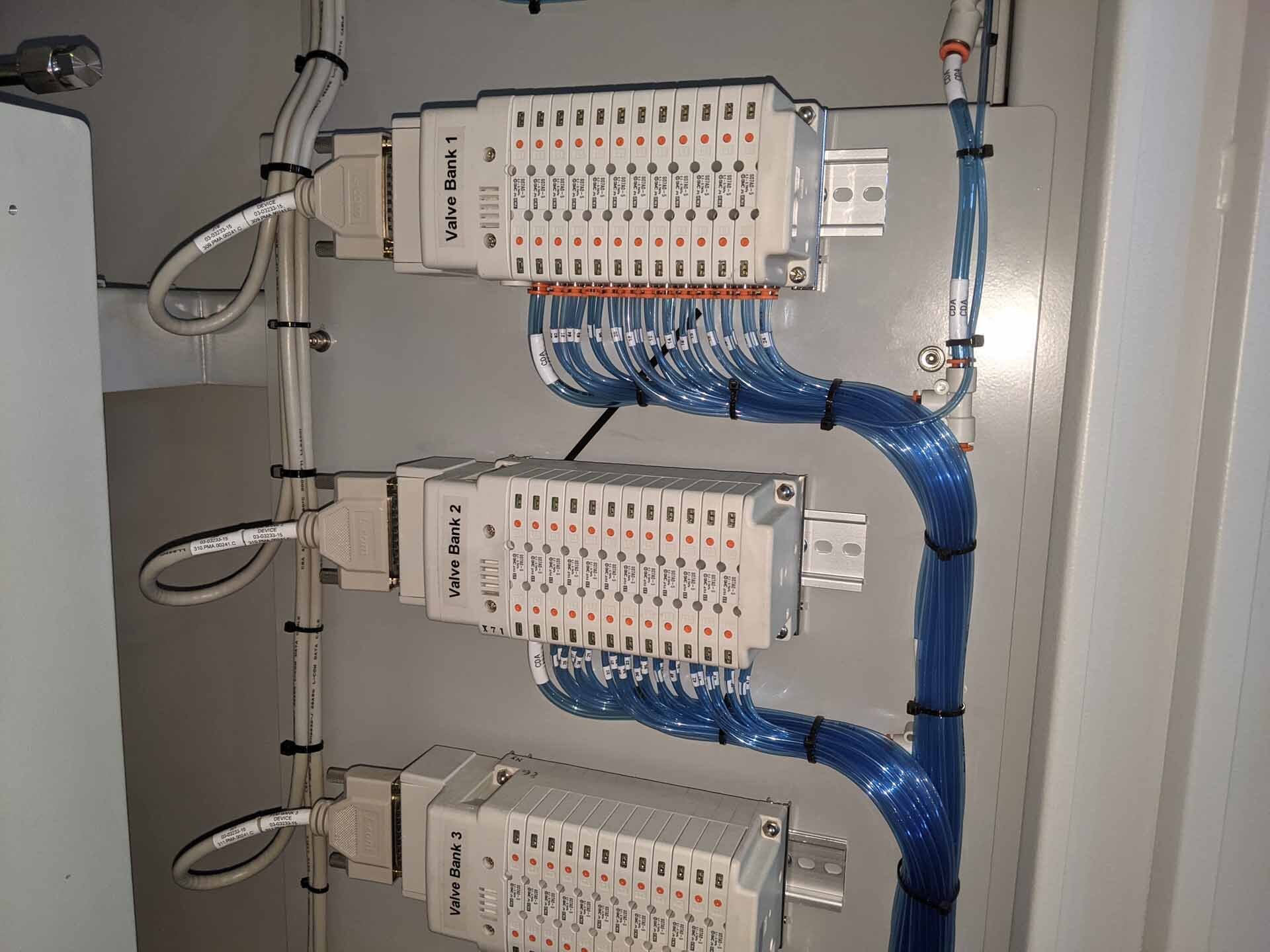

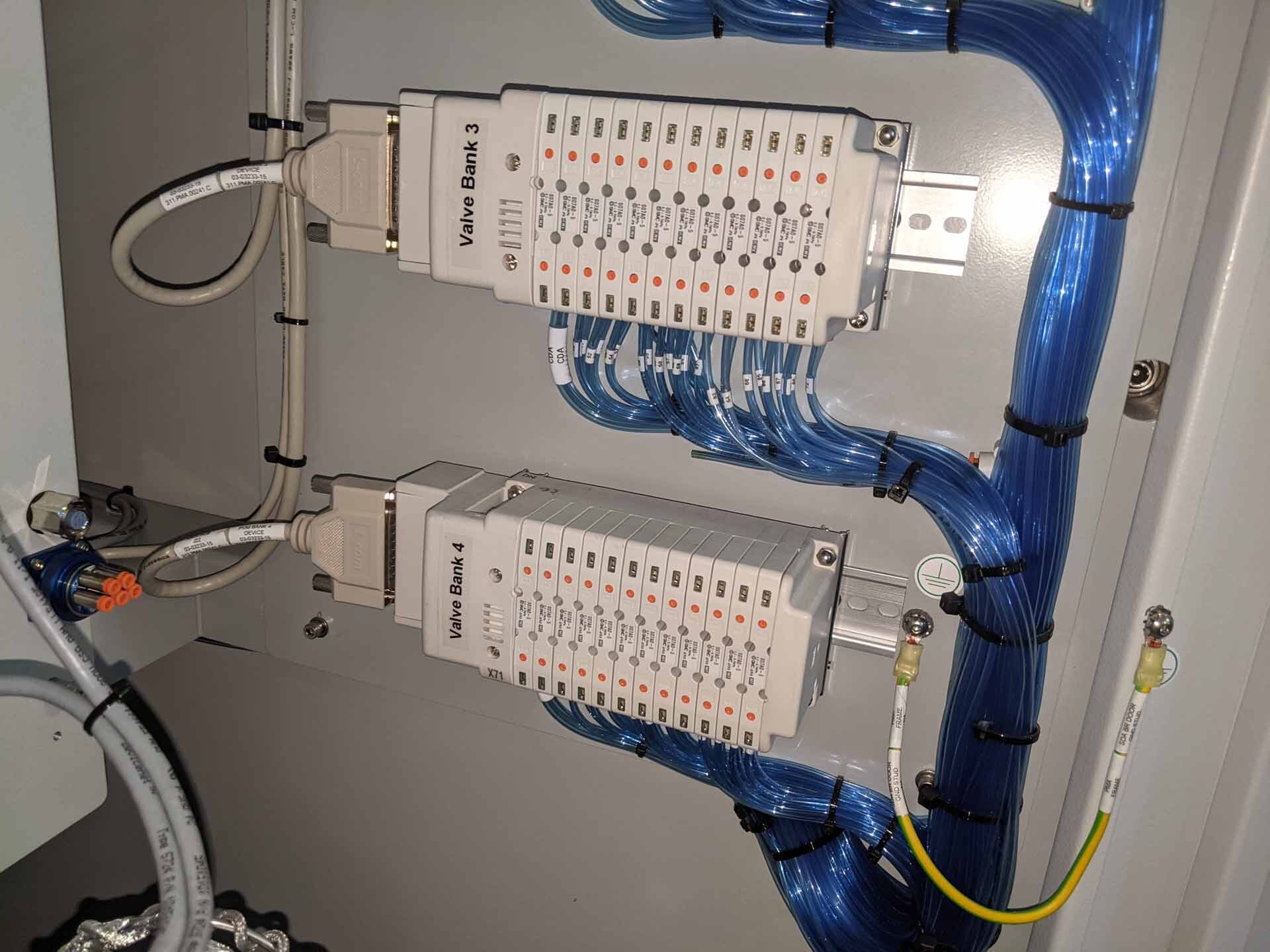

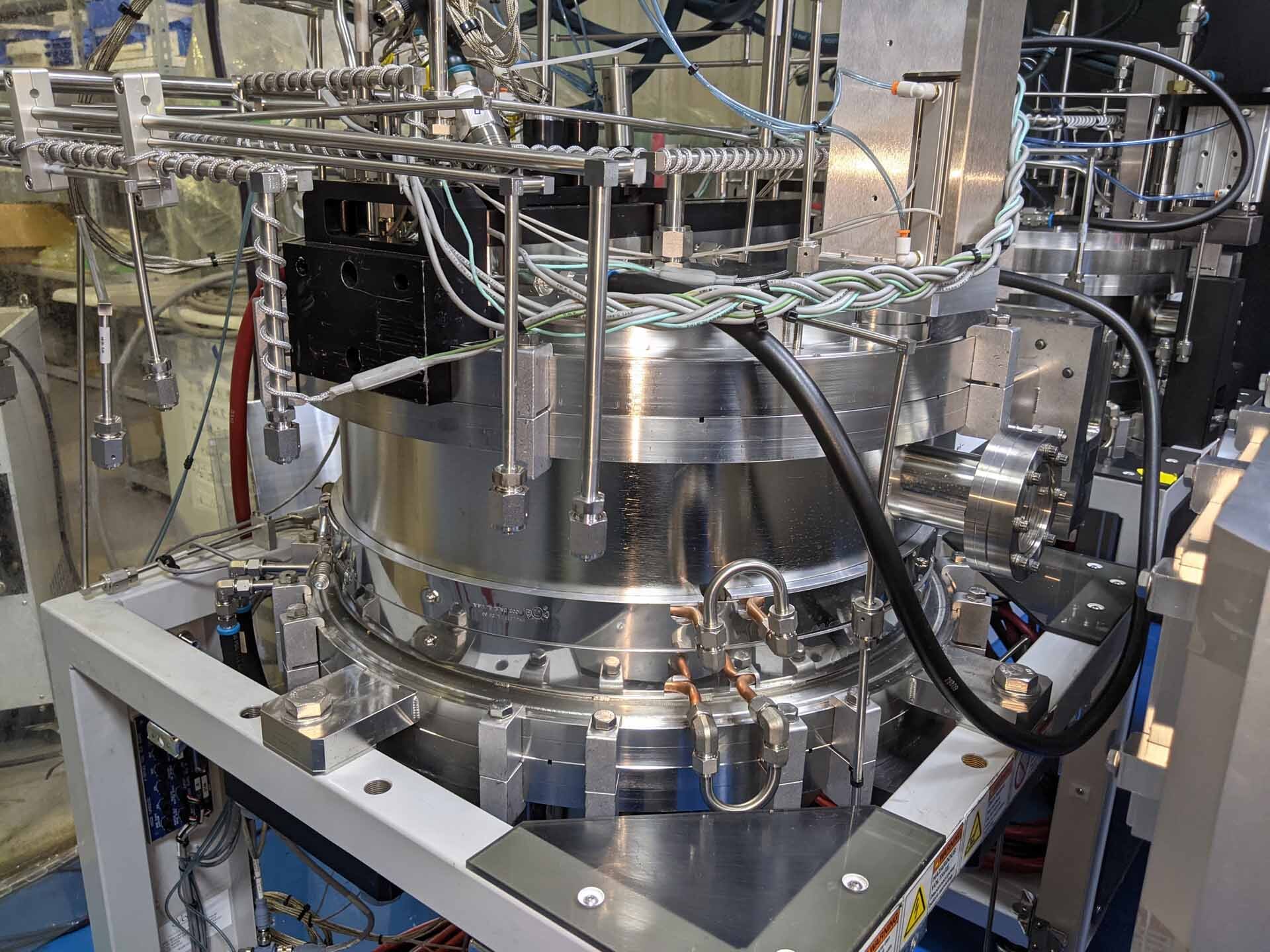

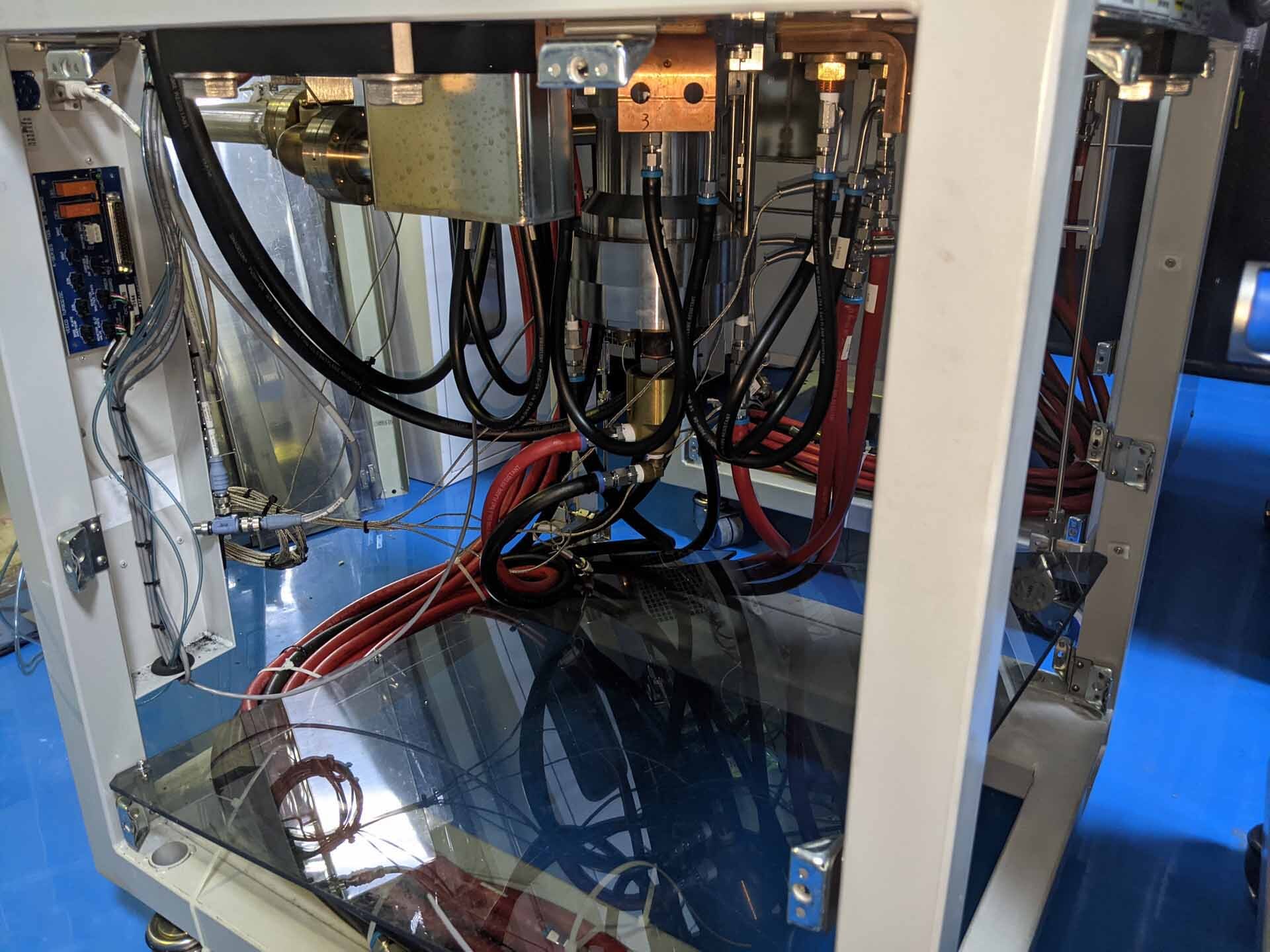

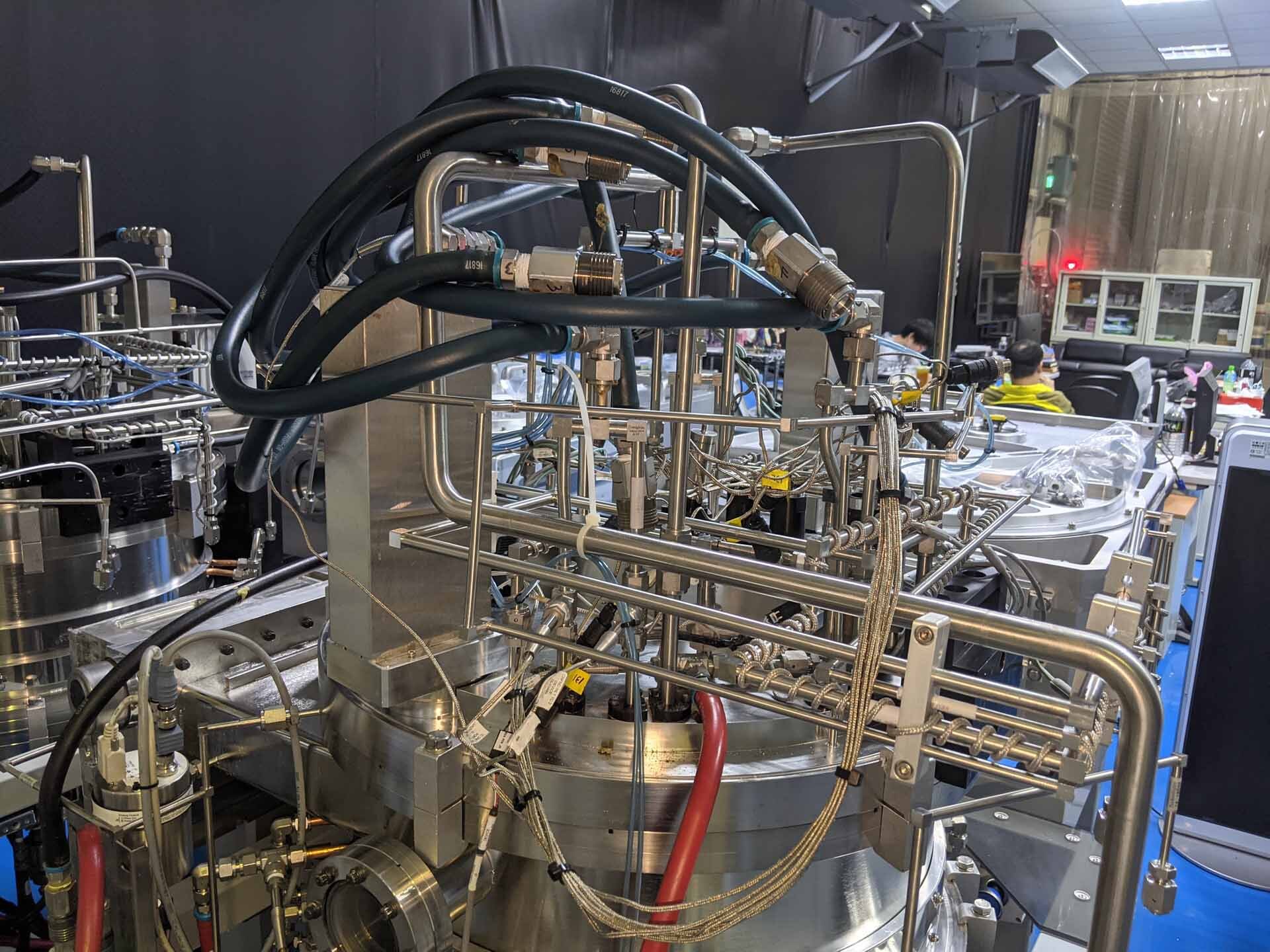

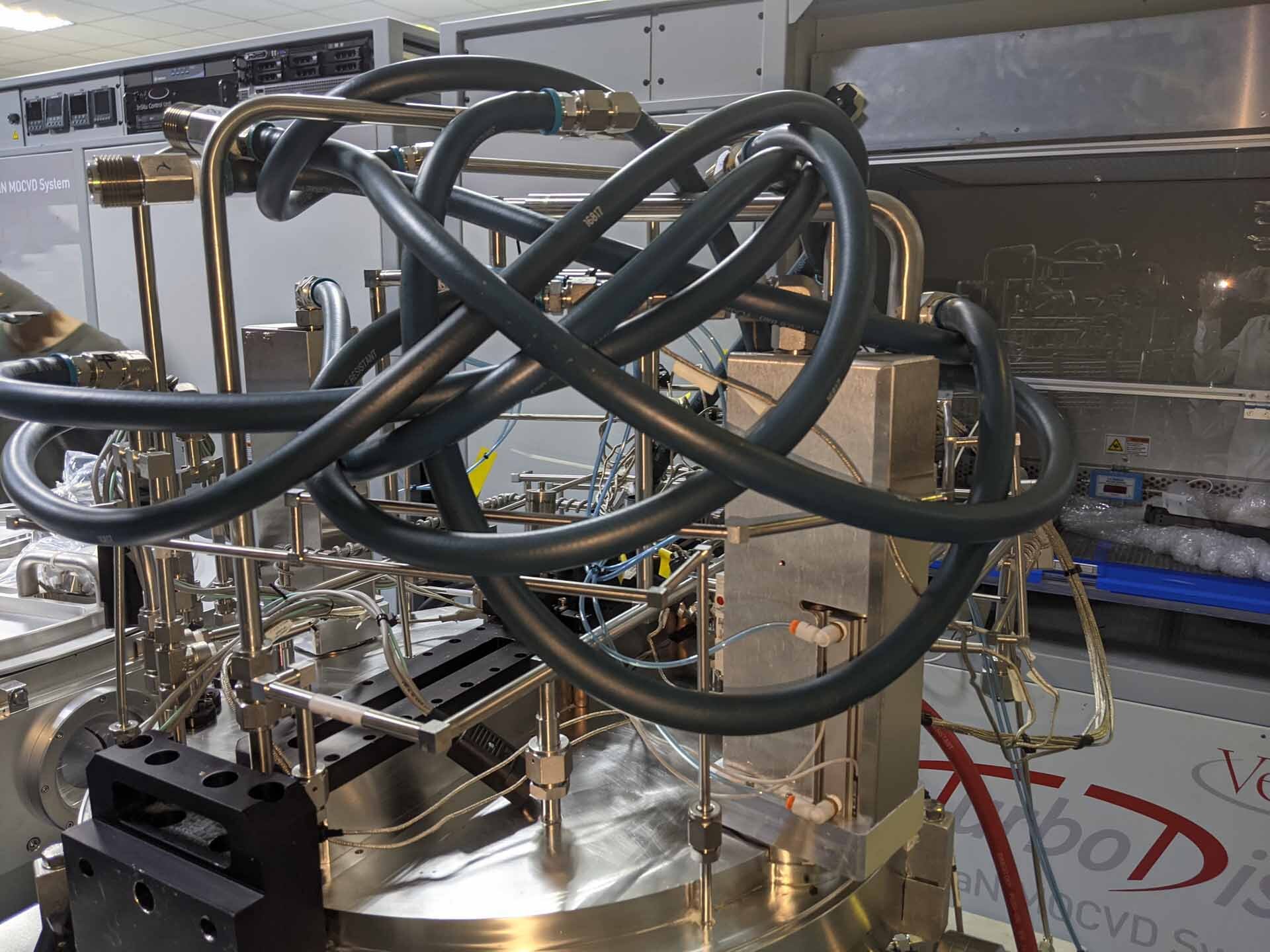

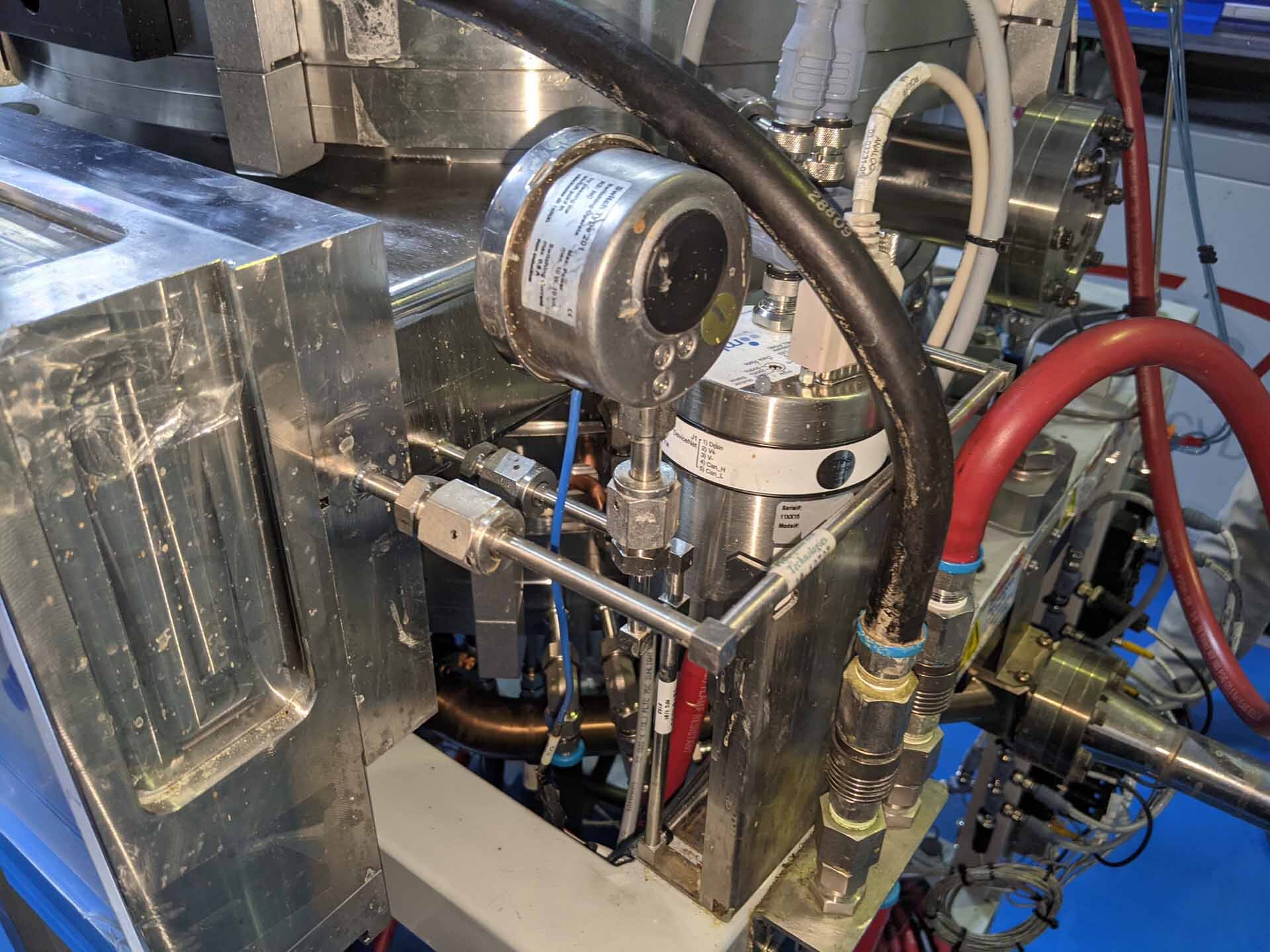

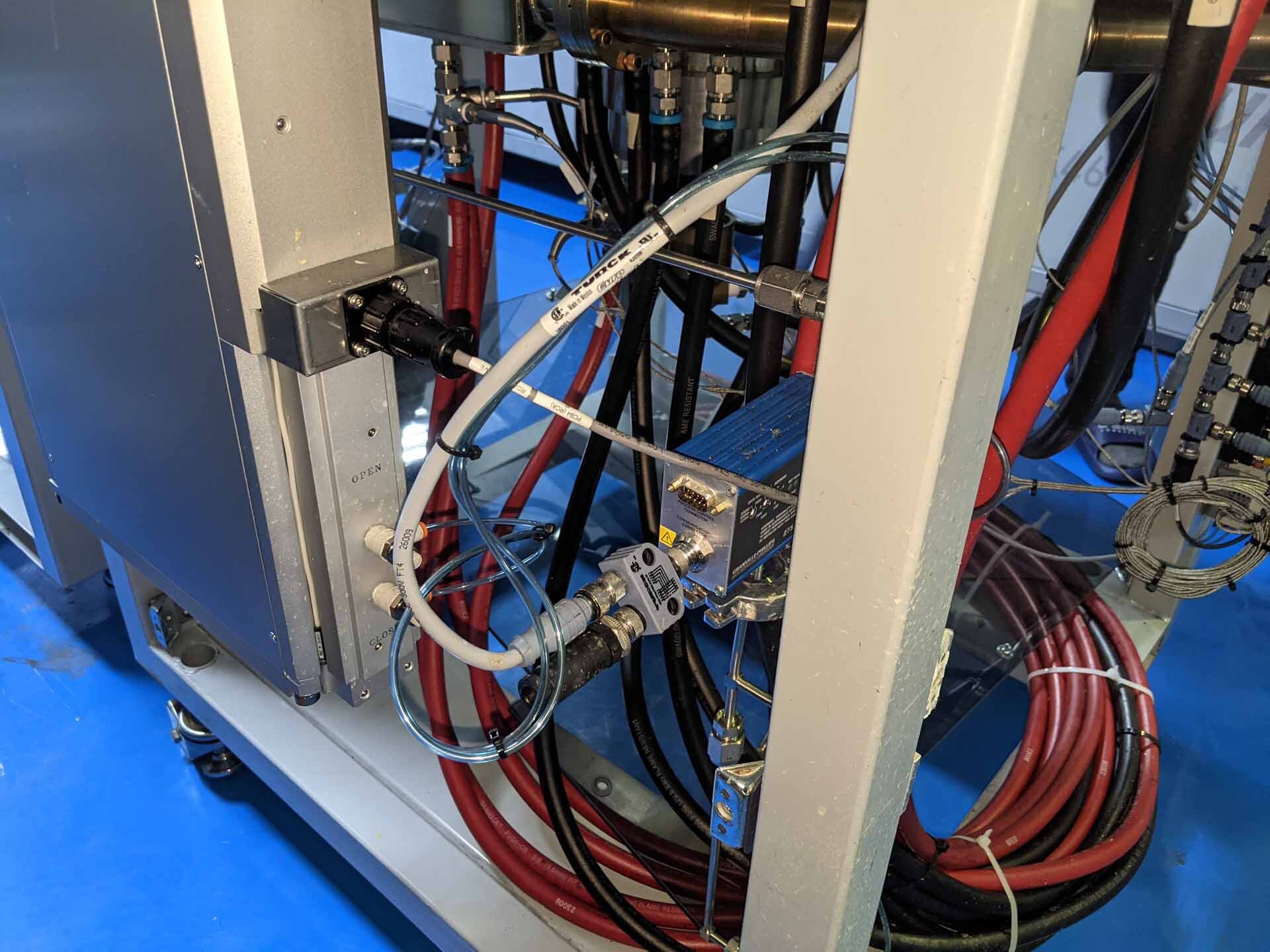

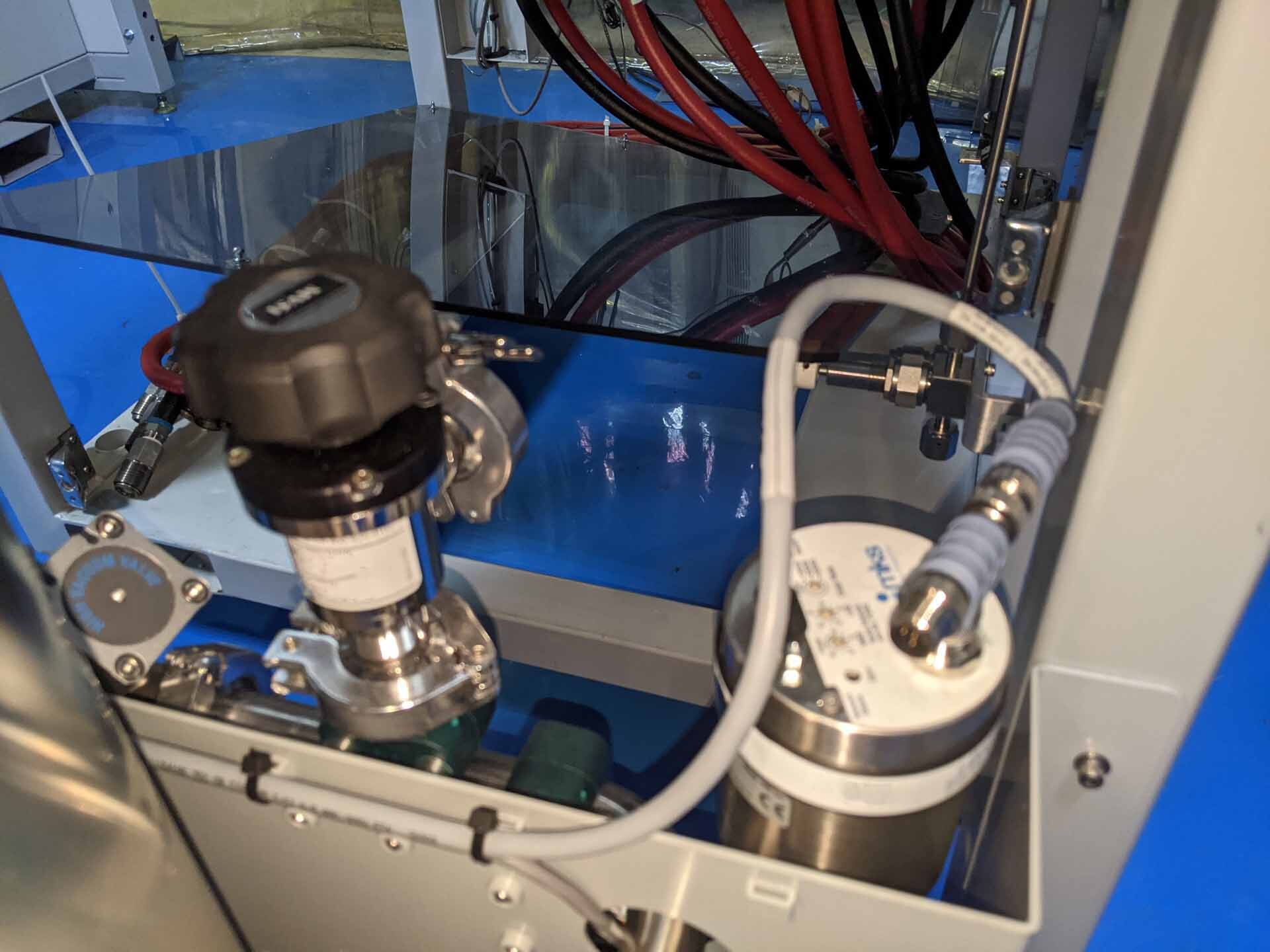

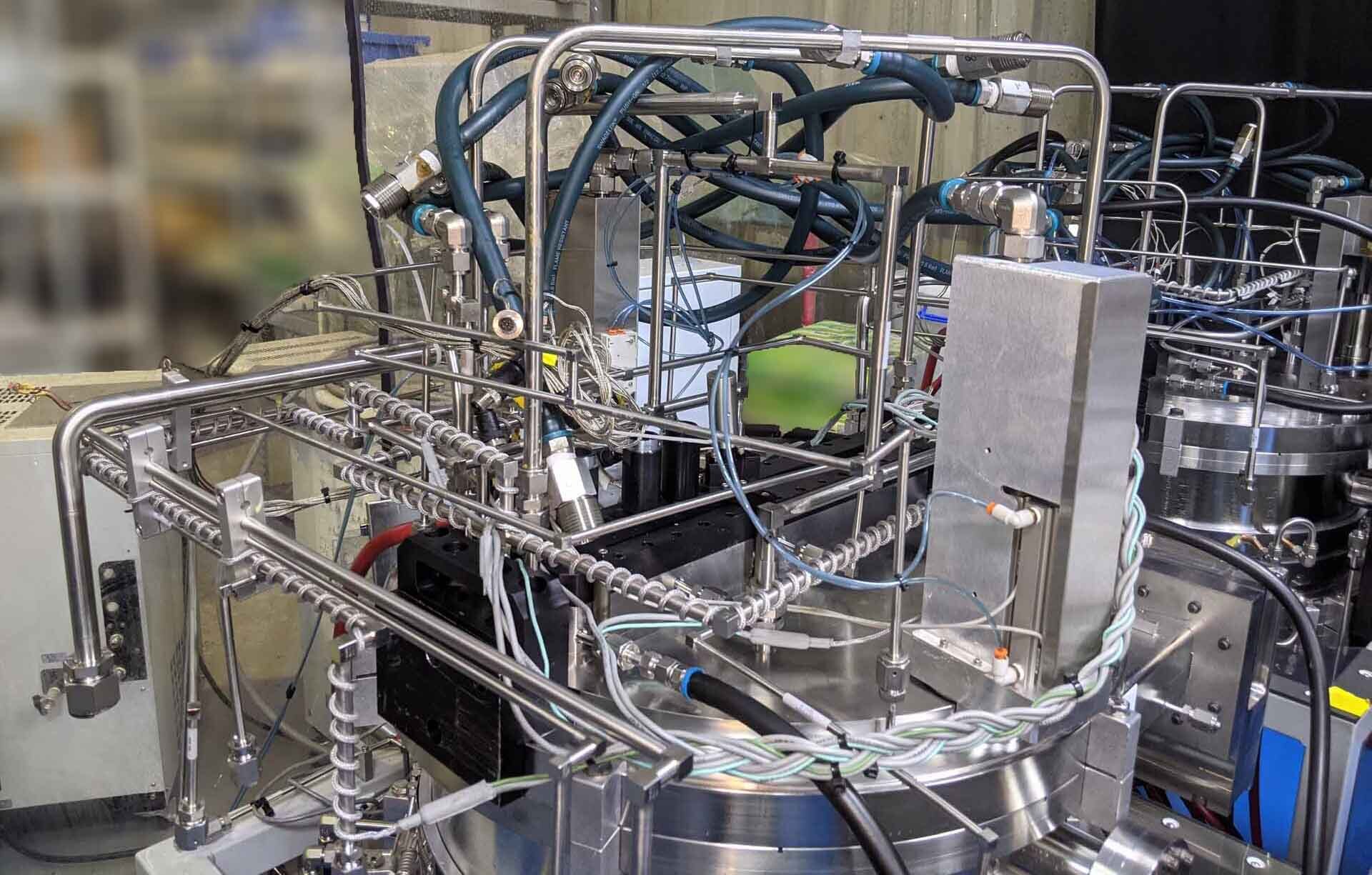

MOCVD System

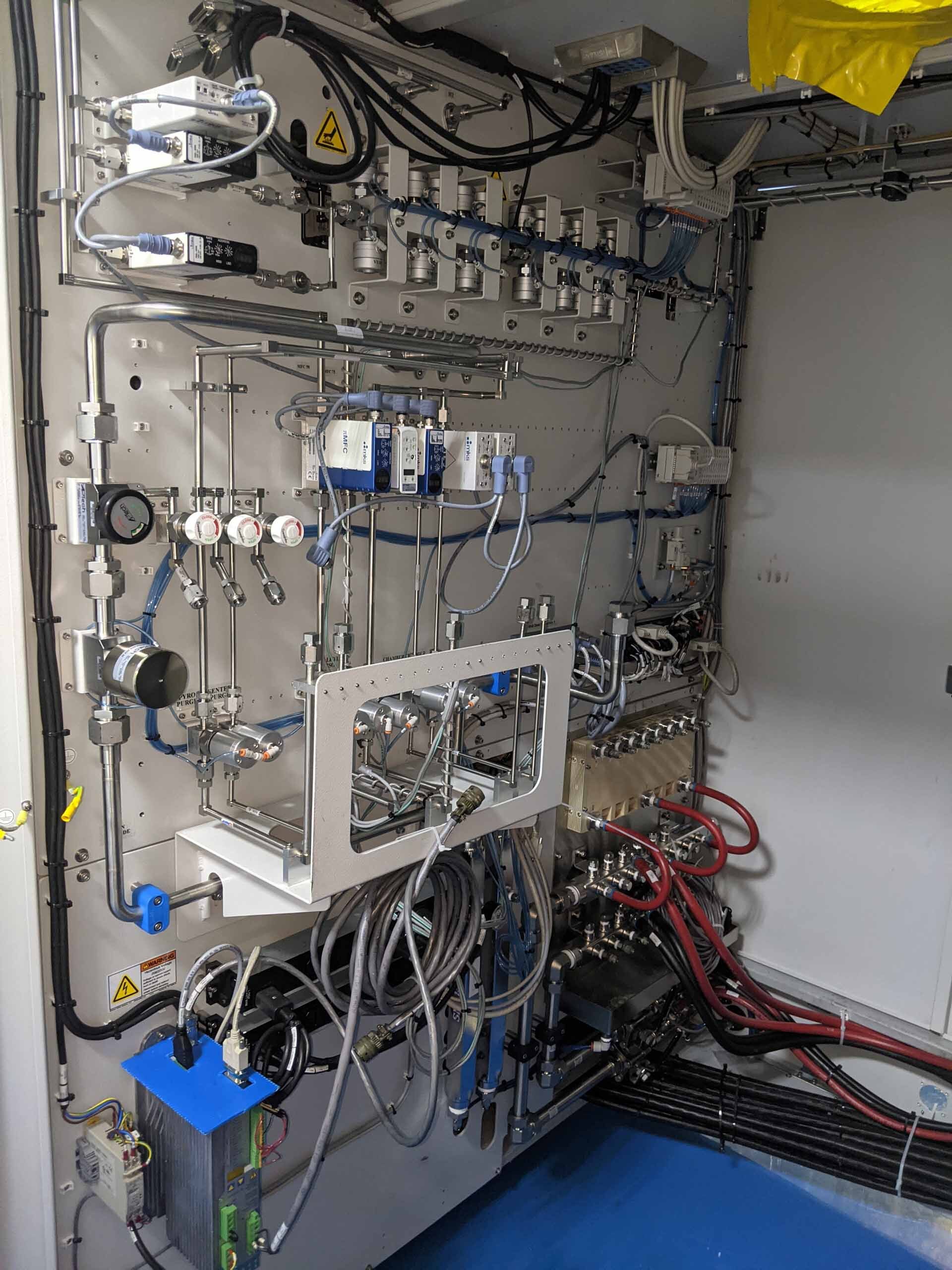

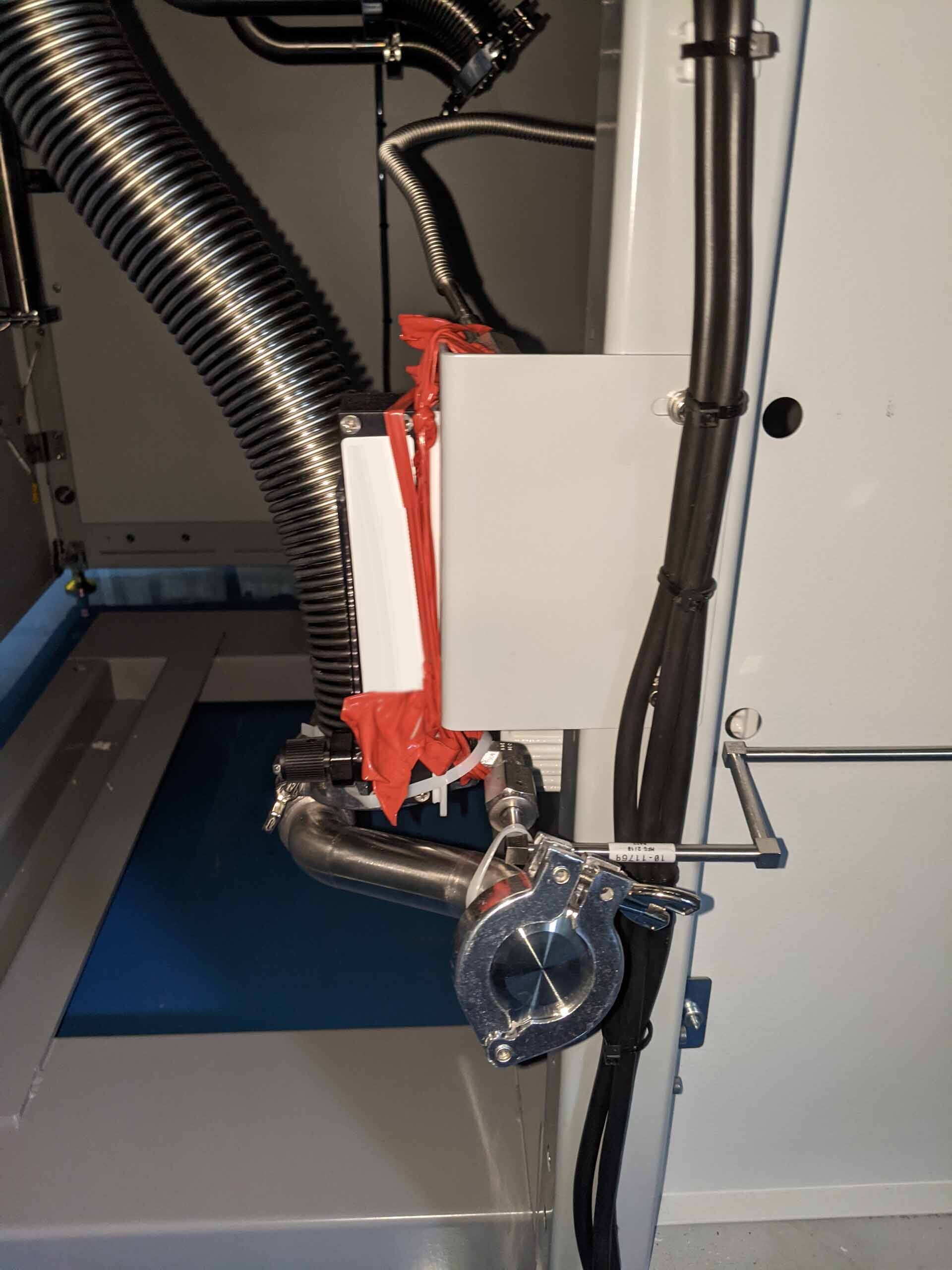

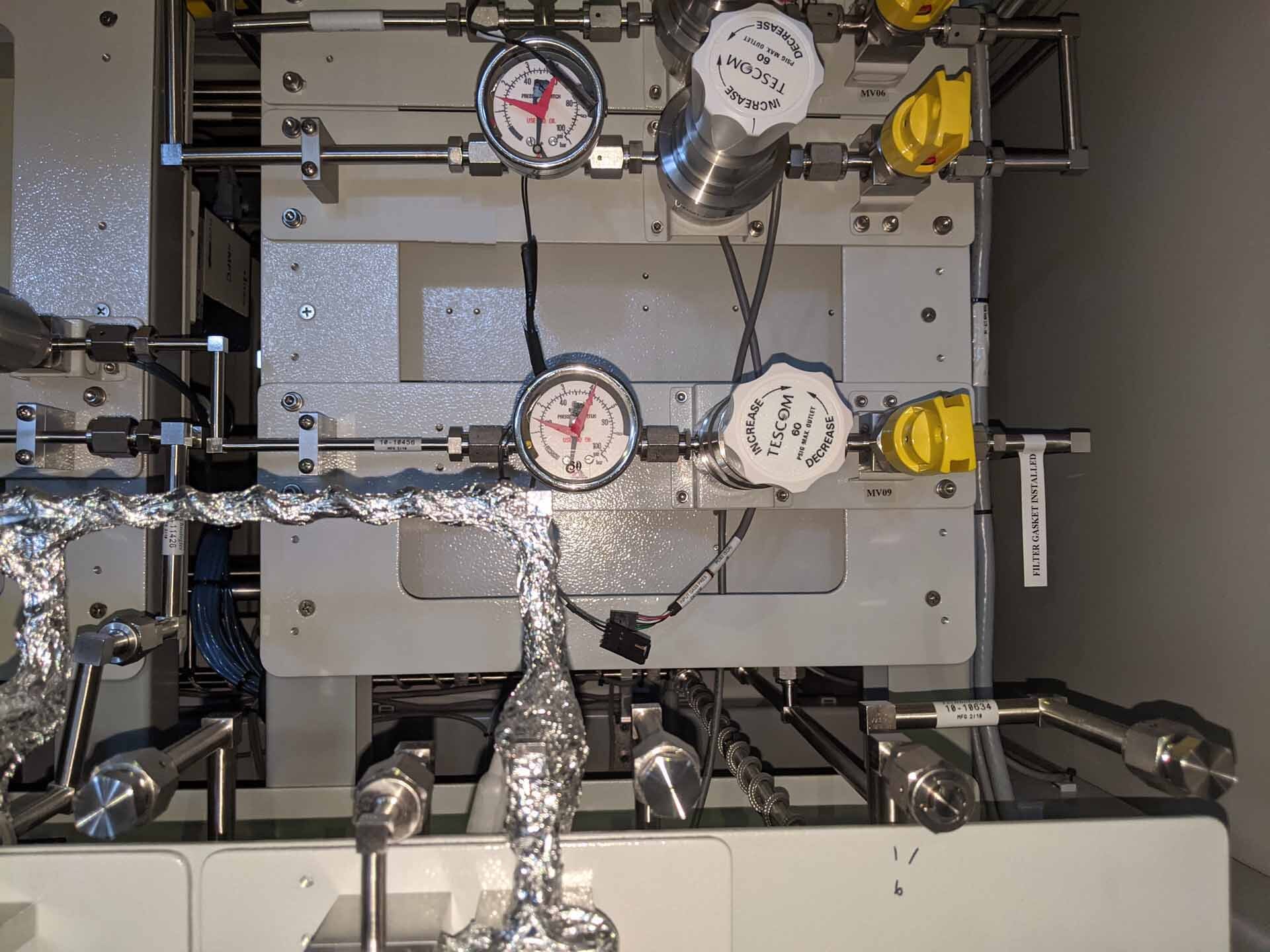

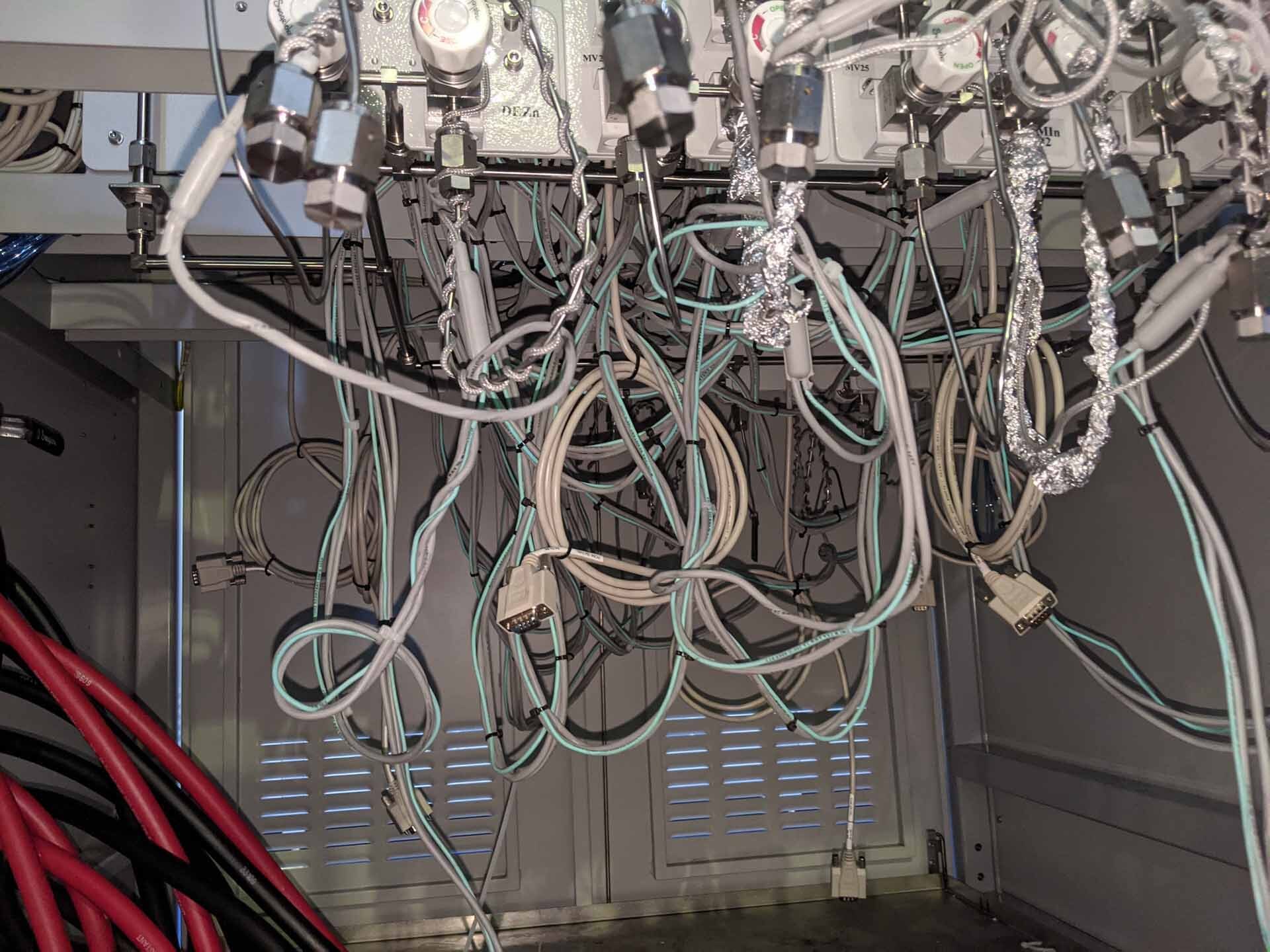

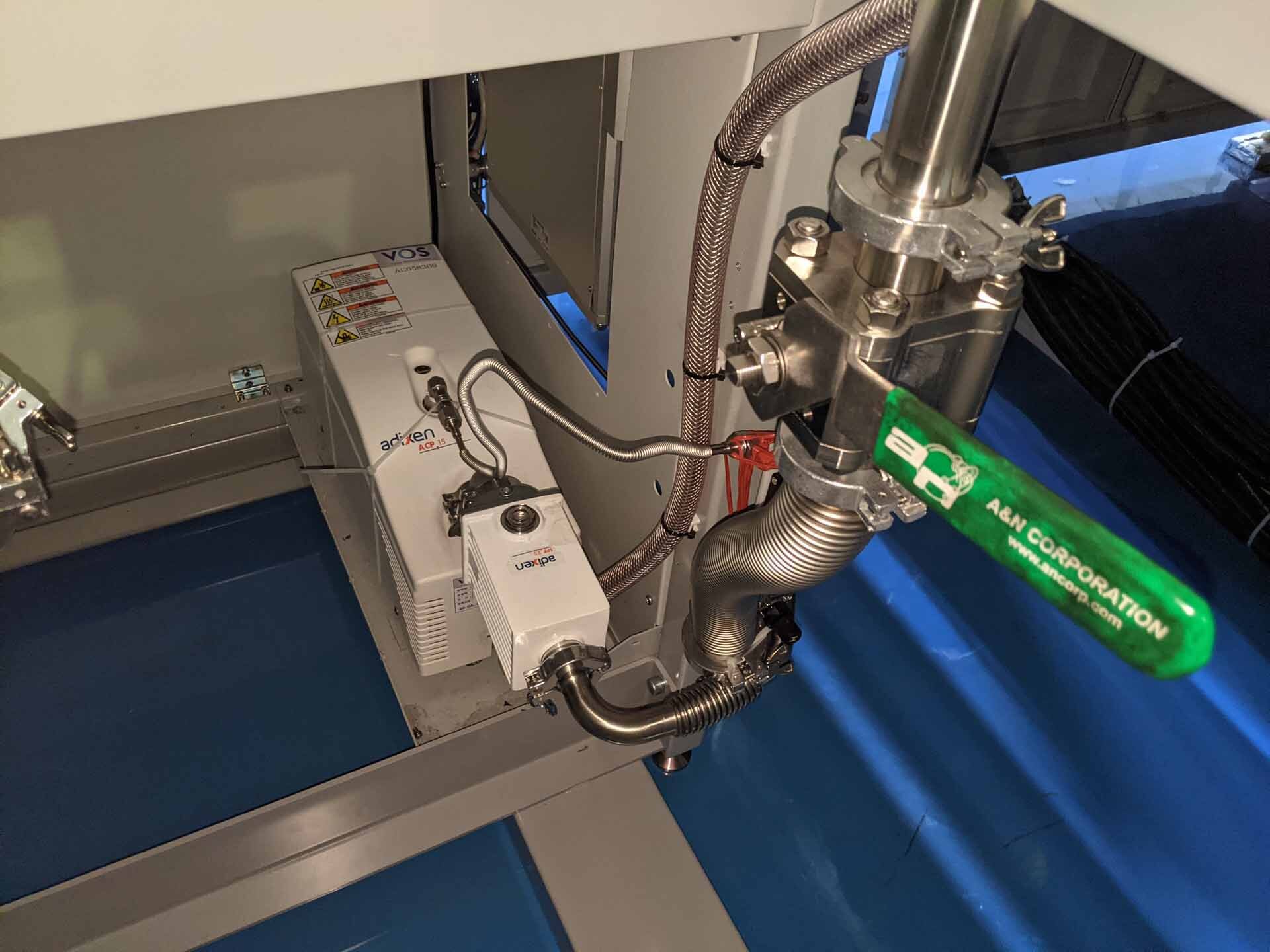

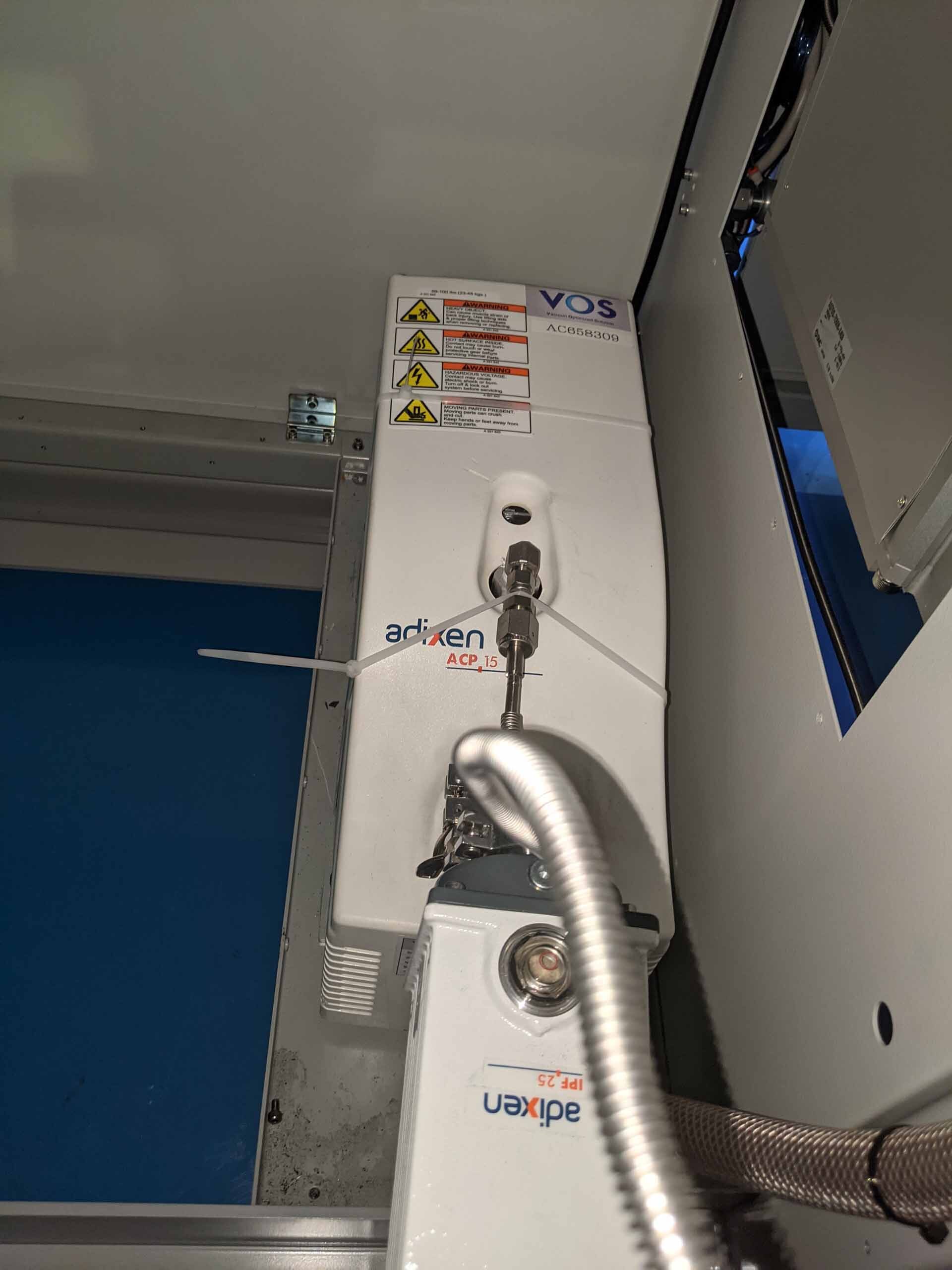

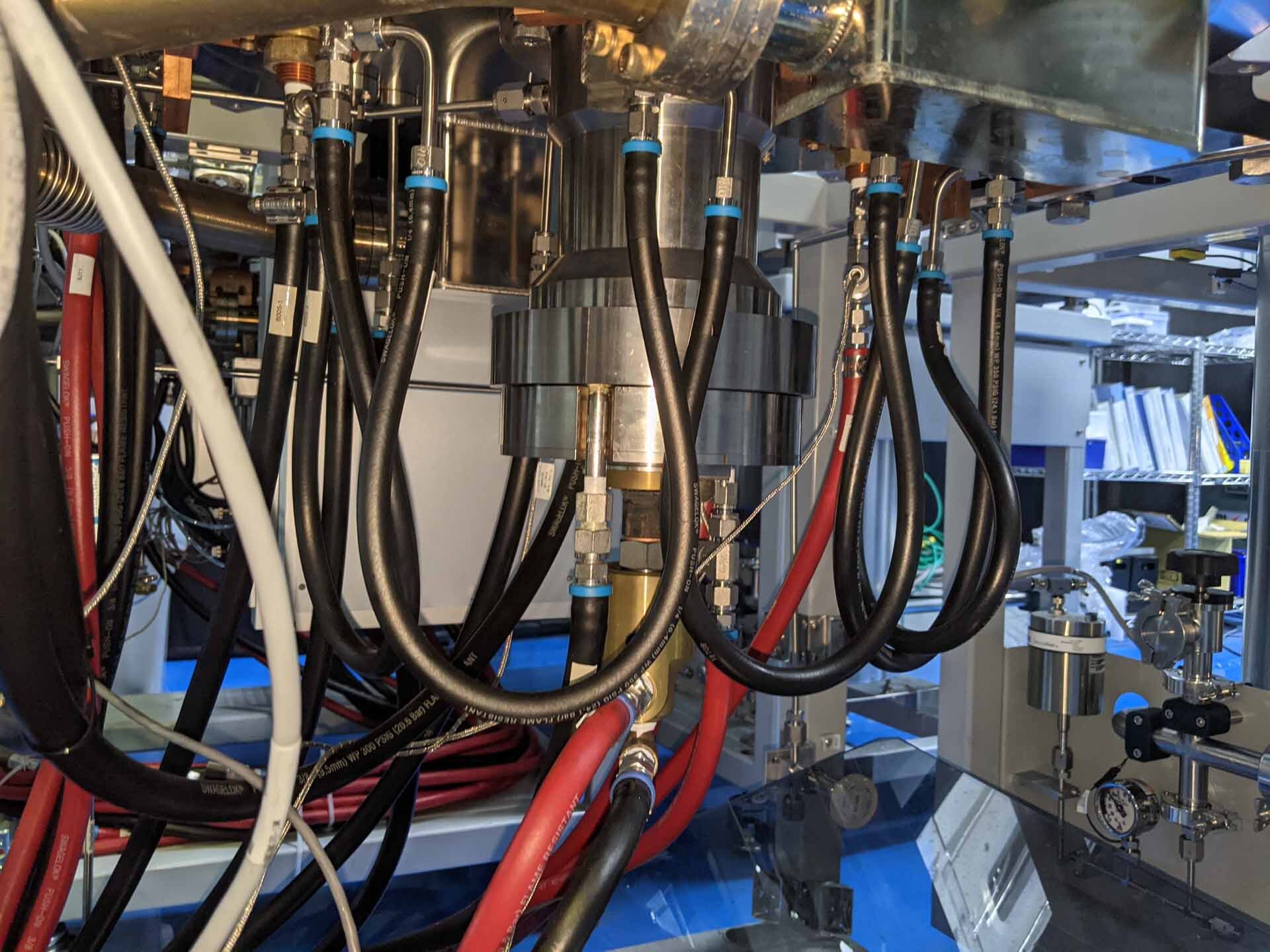

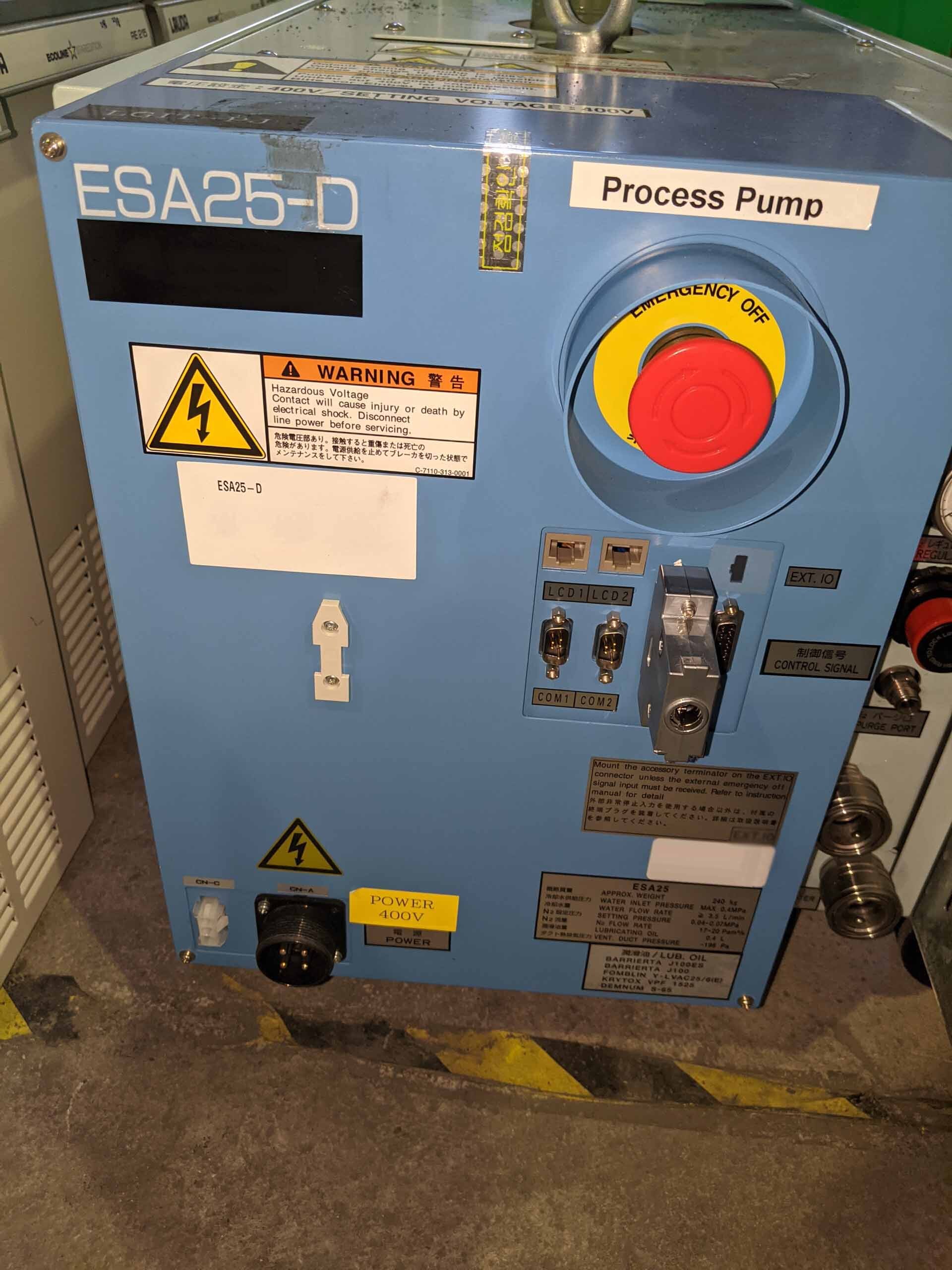

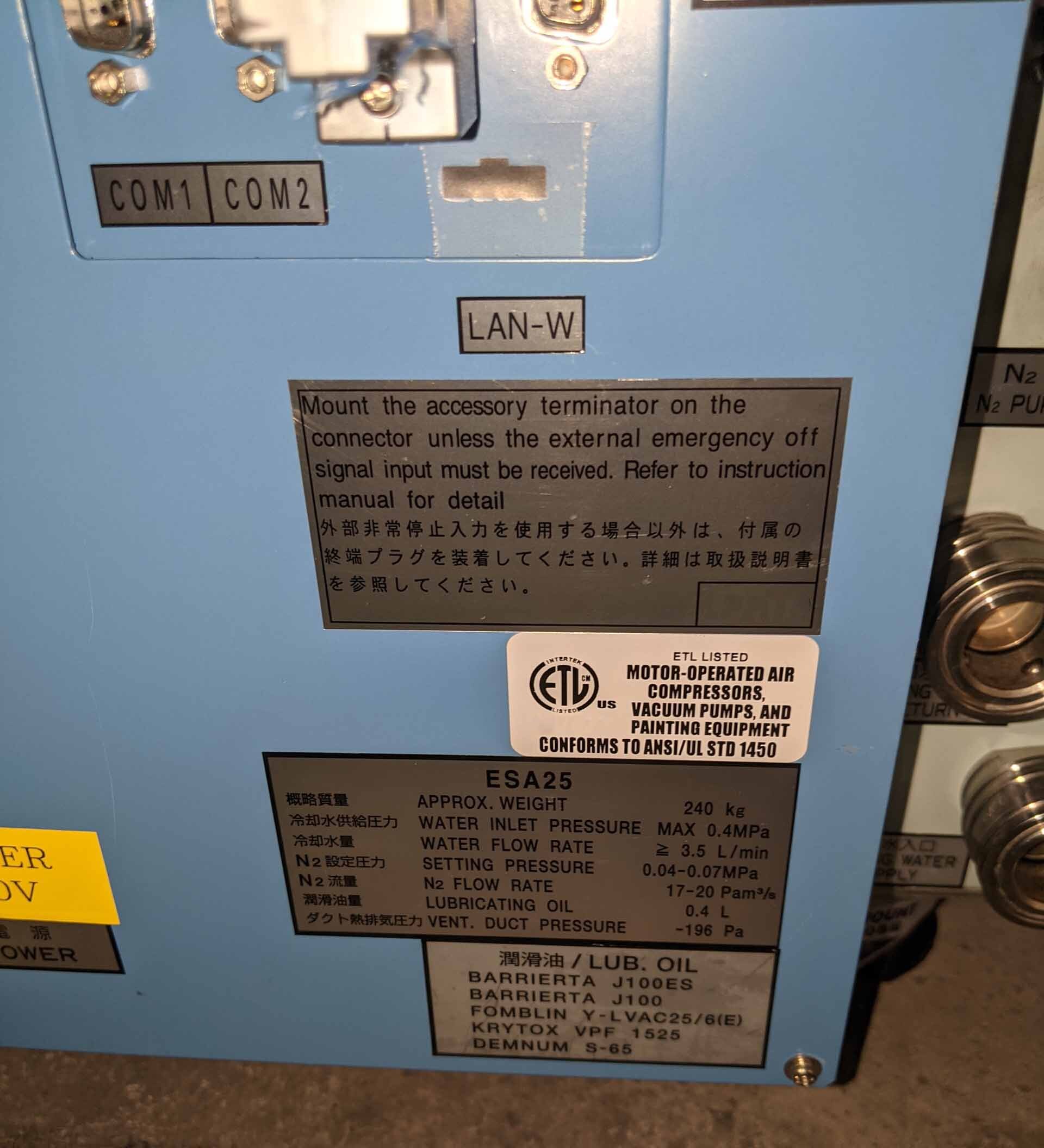

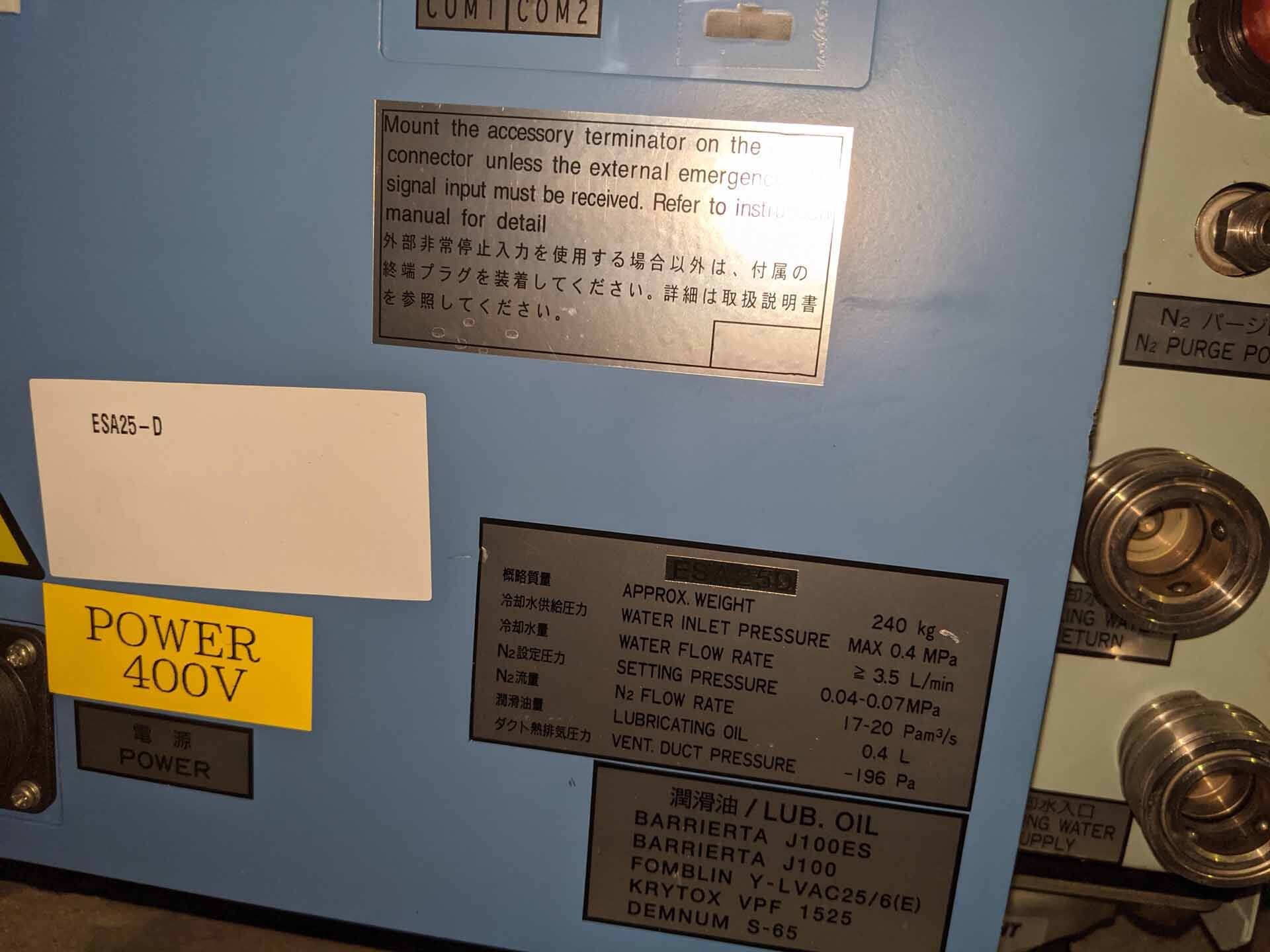

(2) EBARA ESA25-D Dry pumps

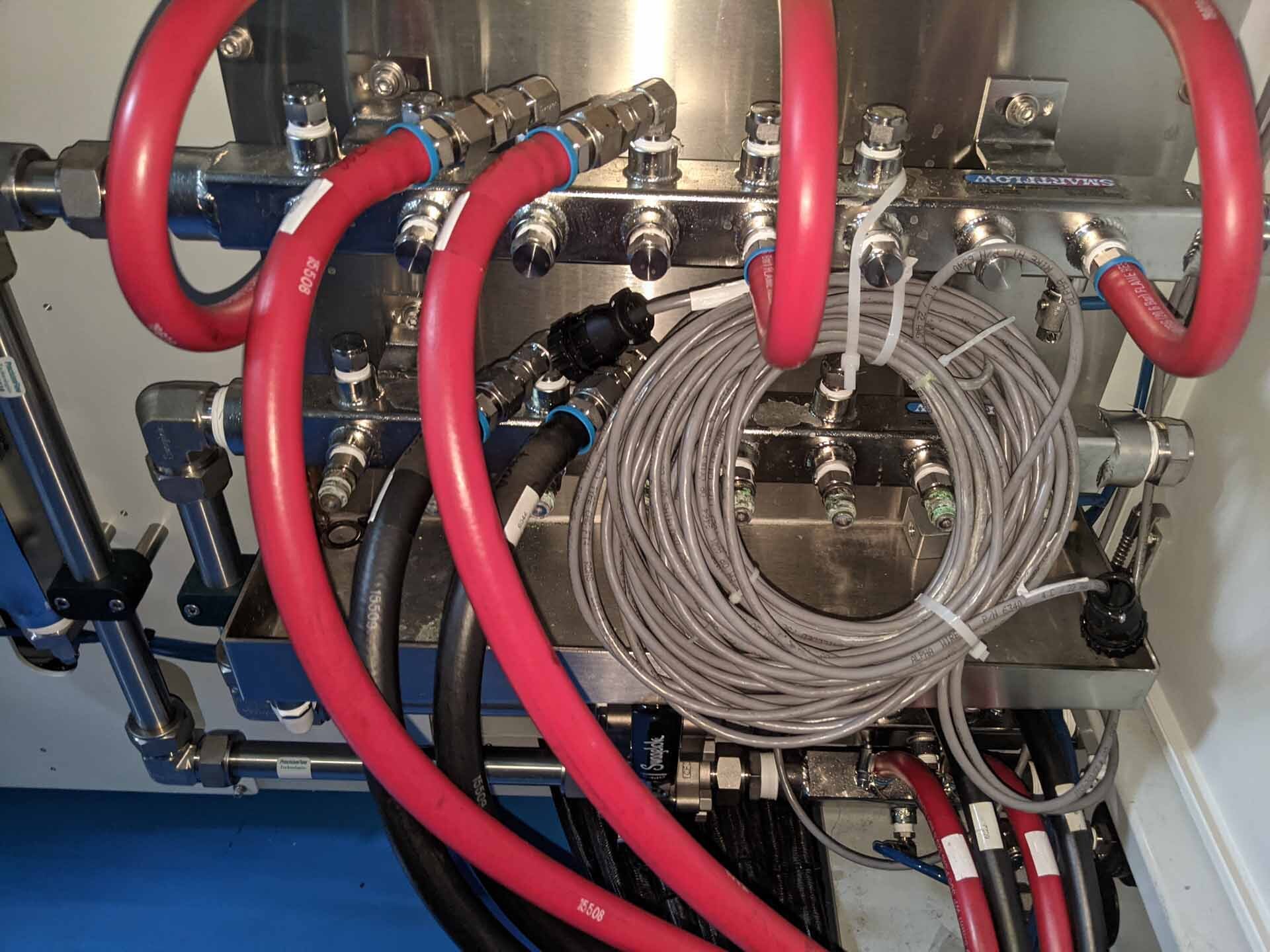

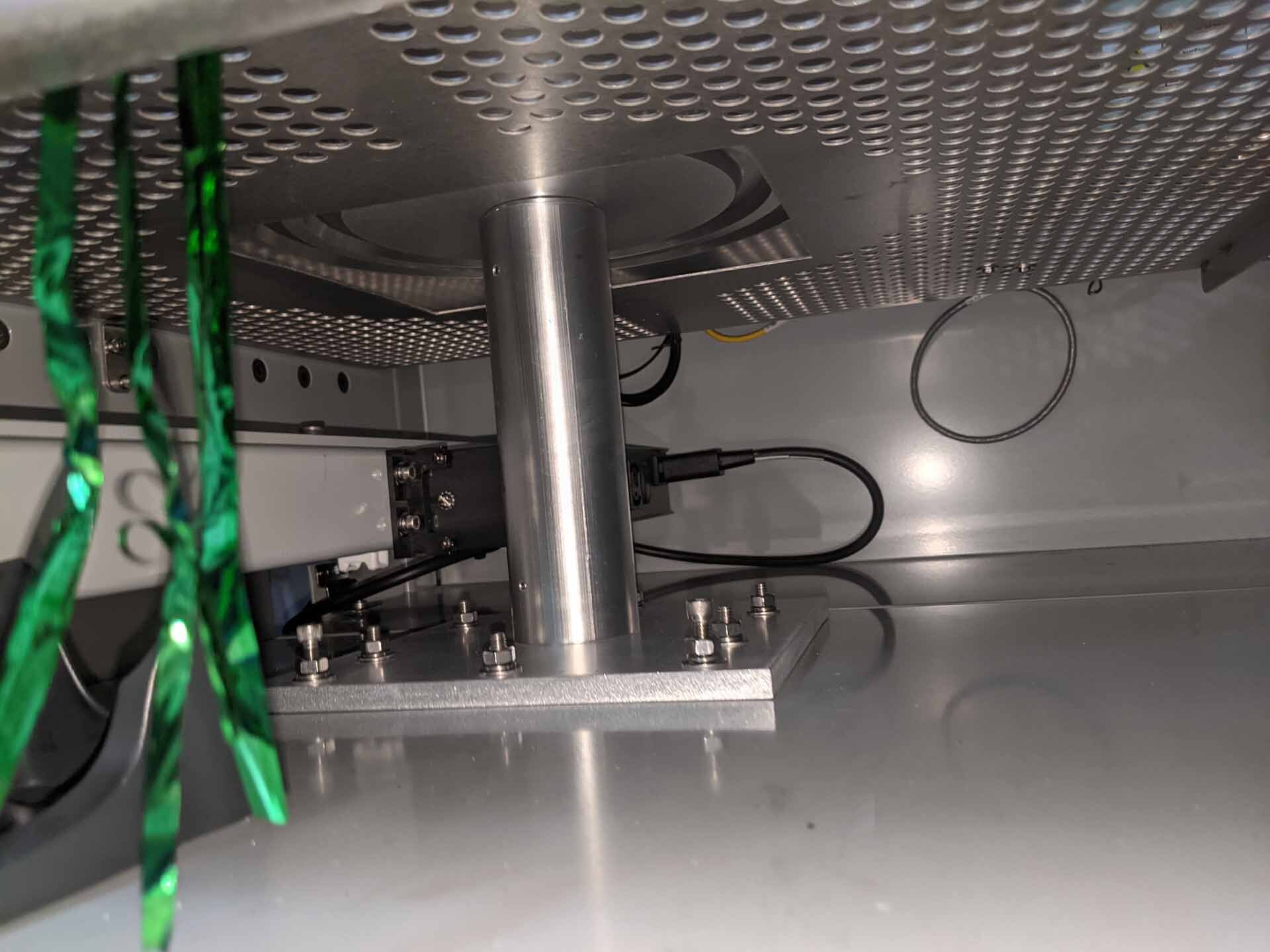

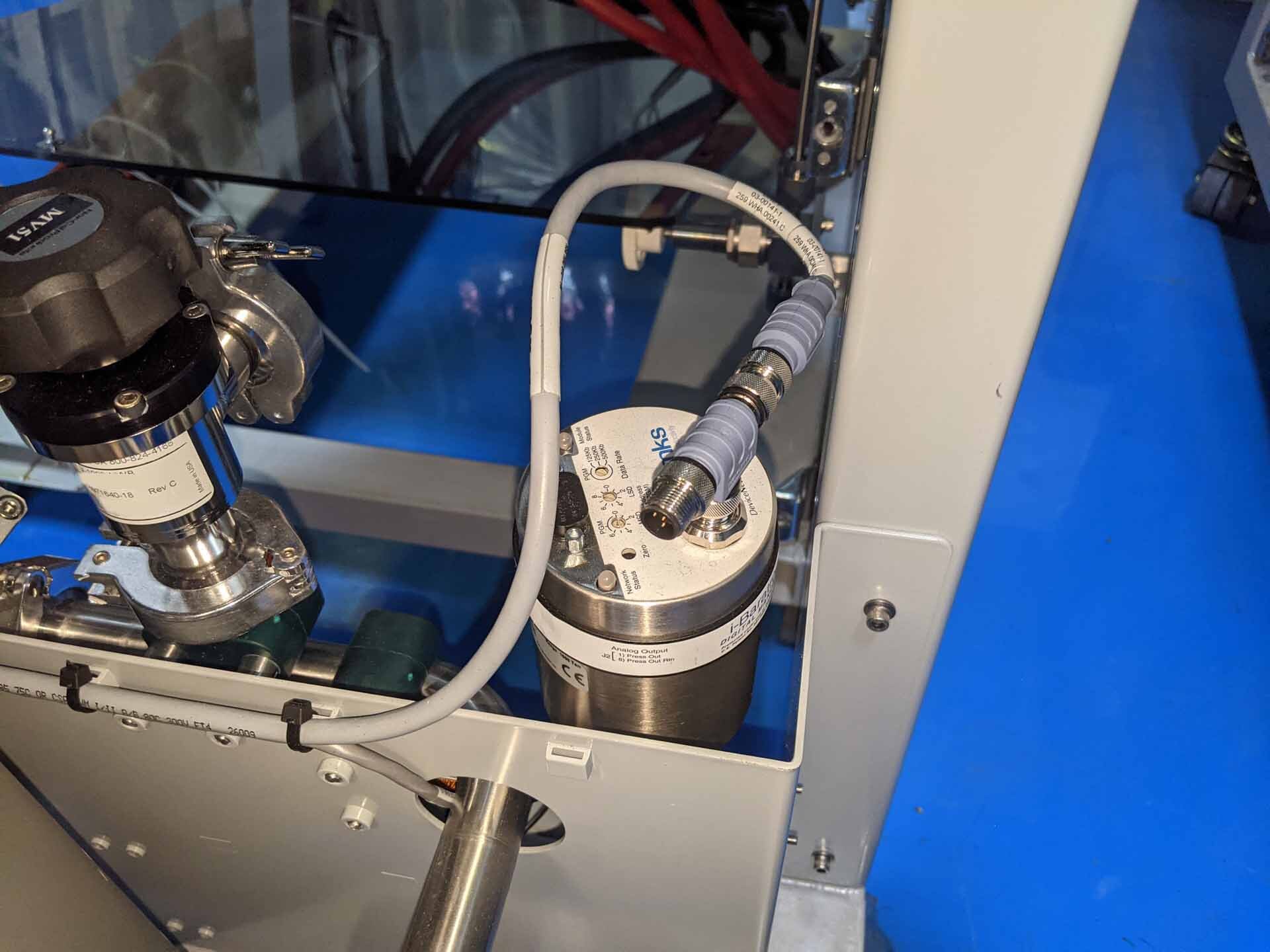

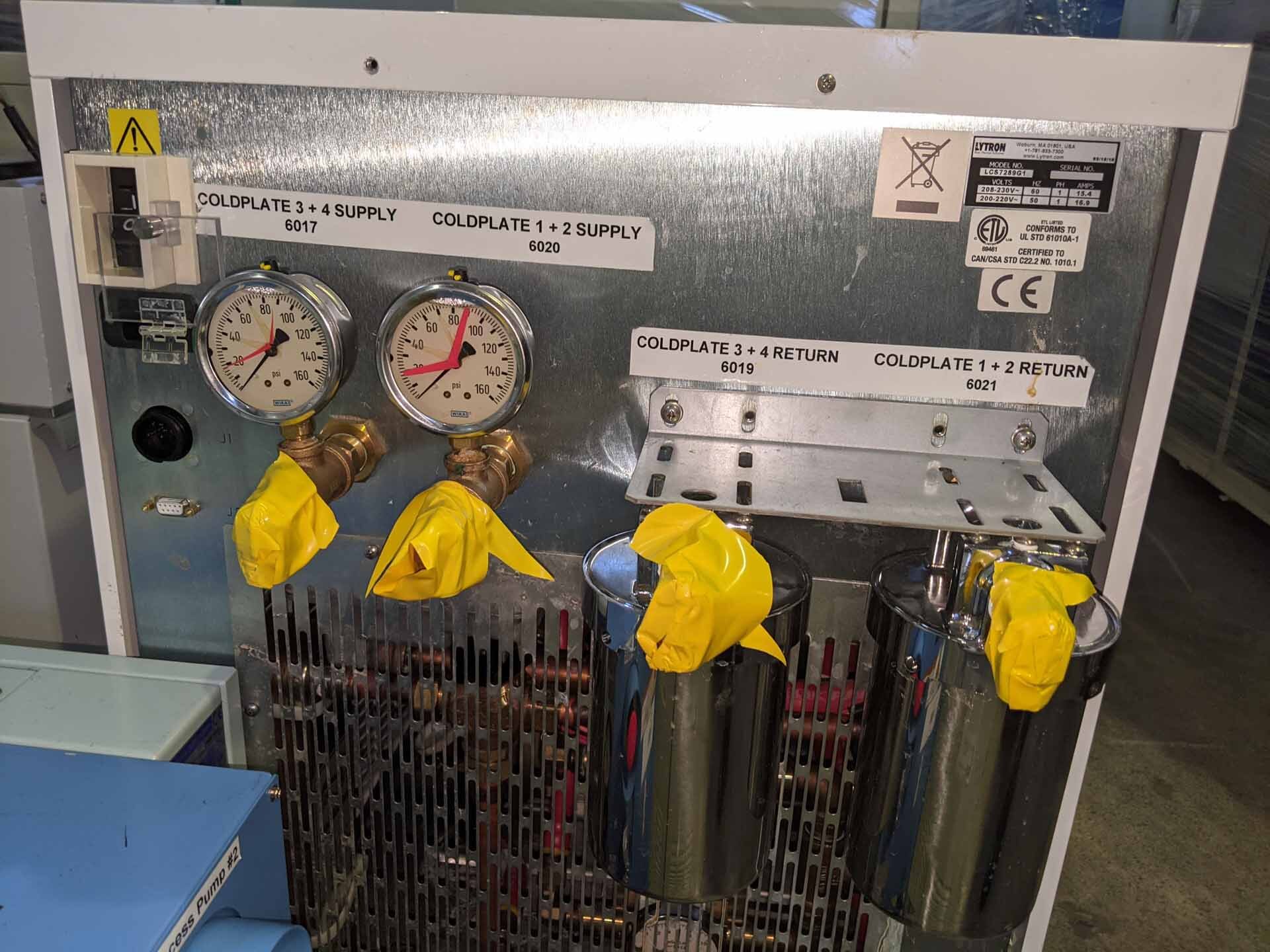

(2) LYTRON LCS7289G1 Chillers

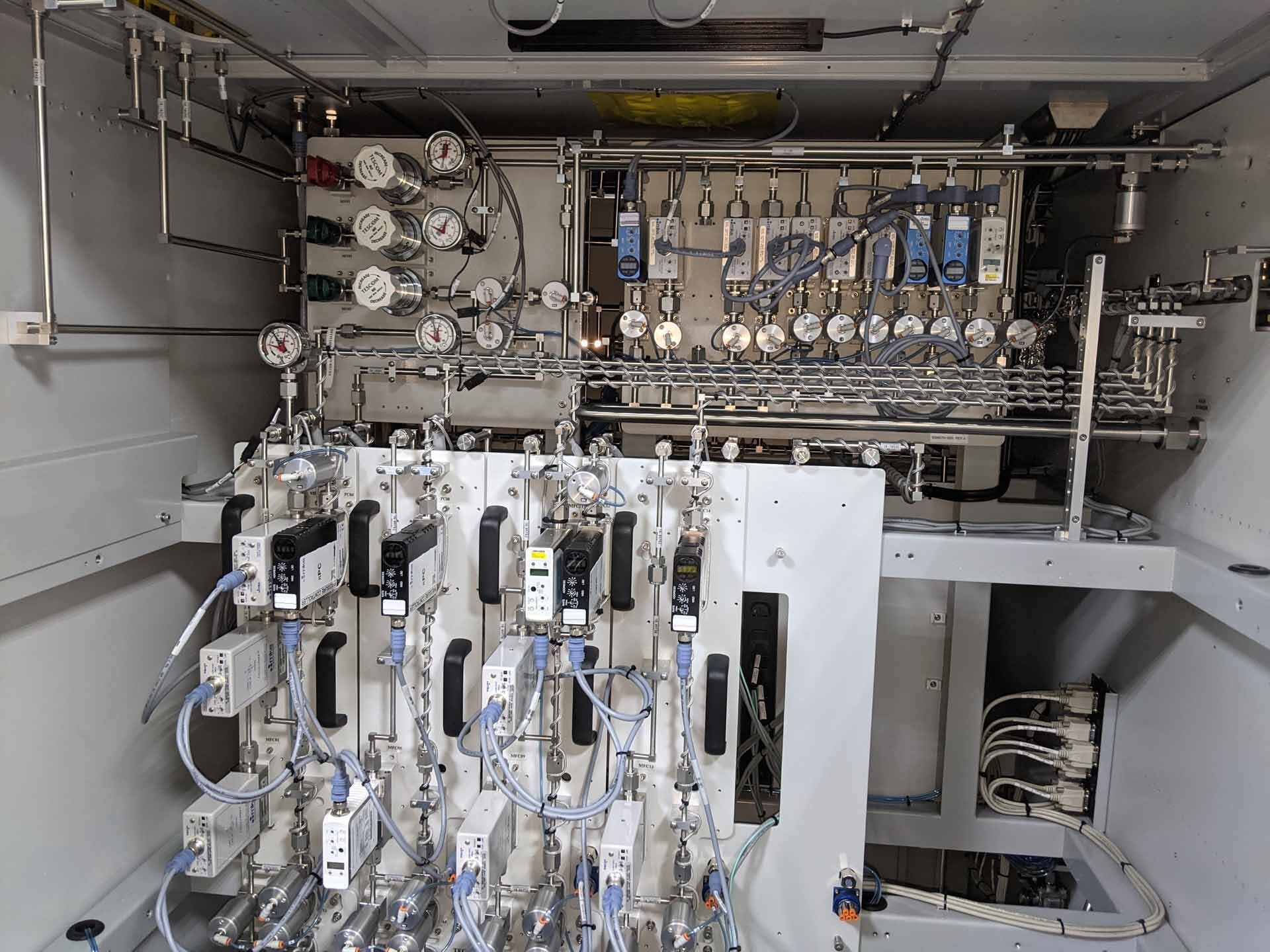

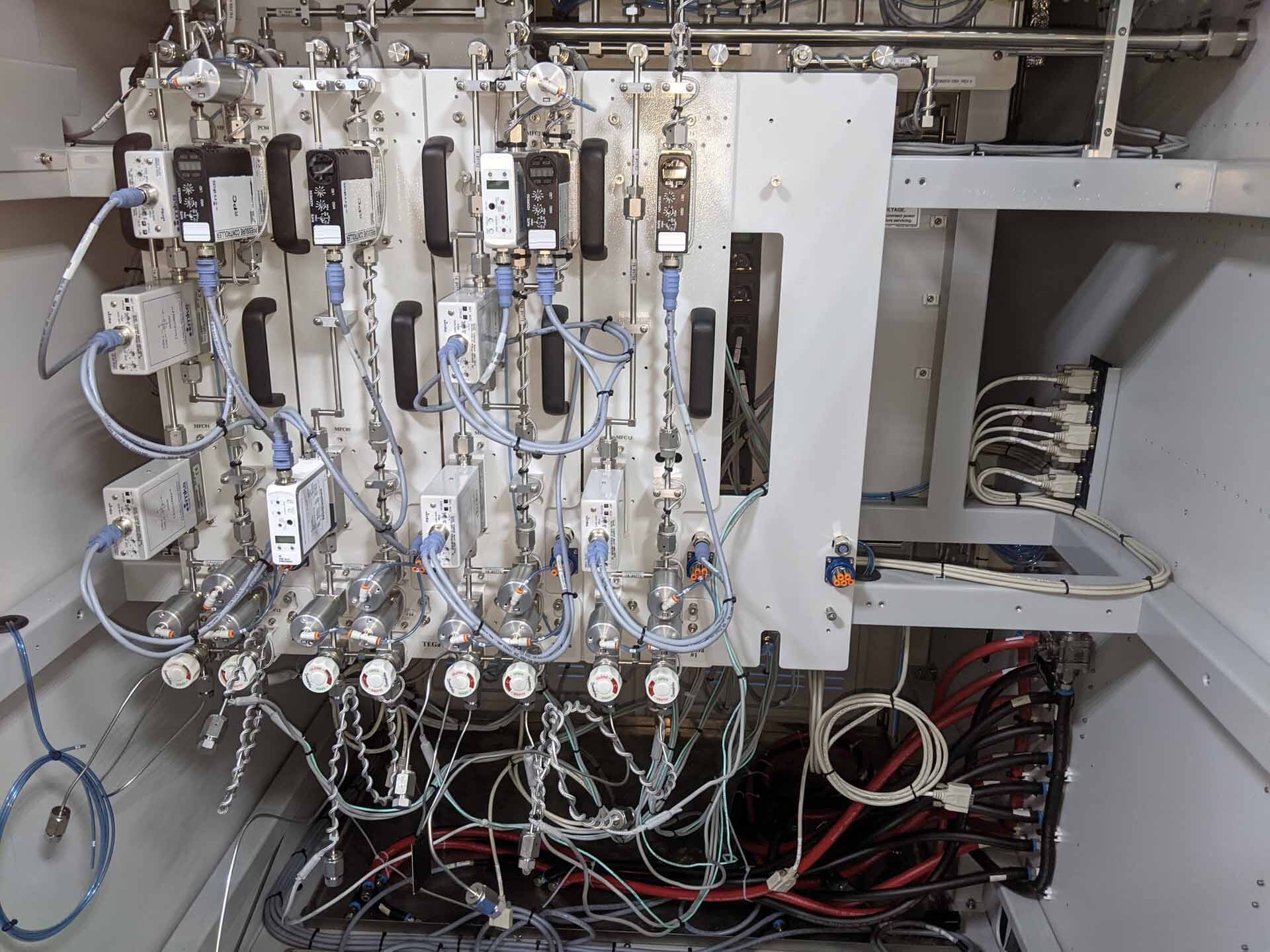

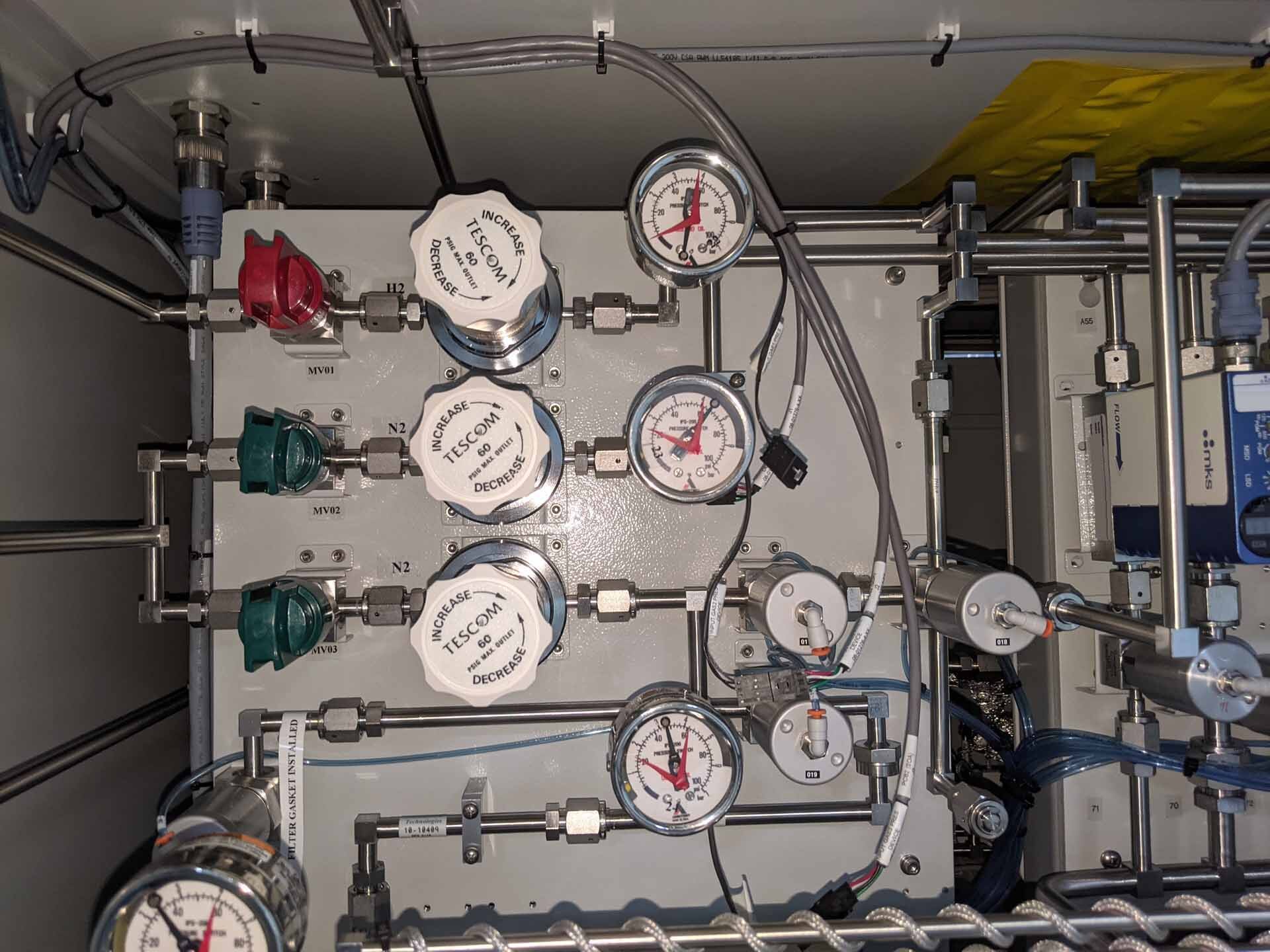

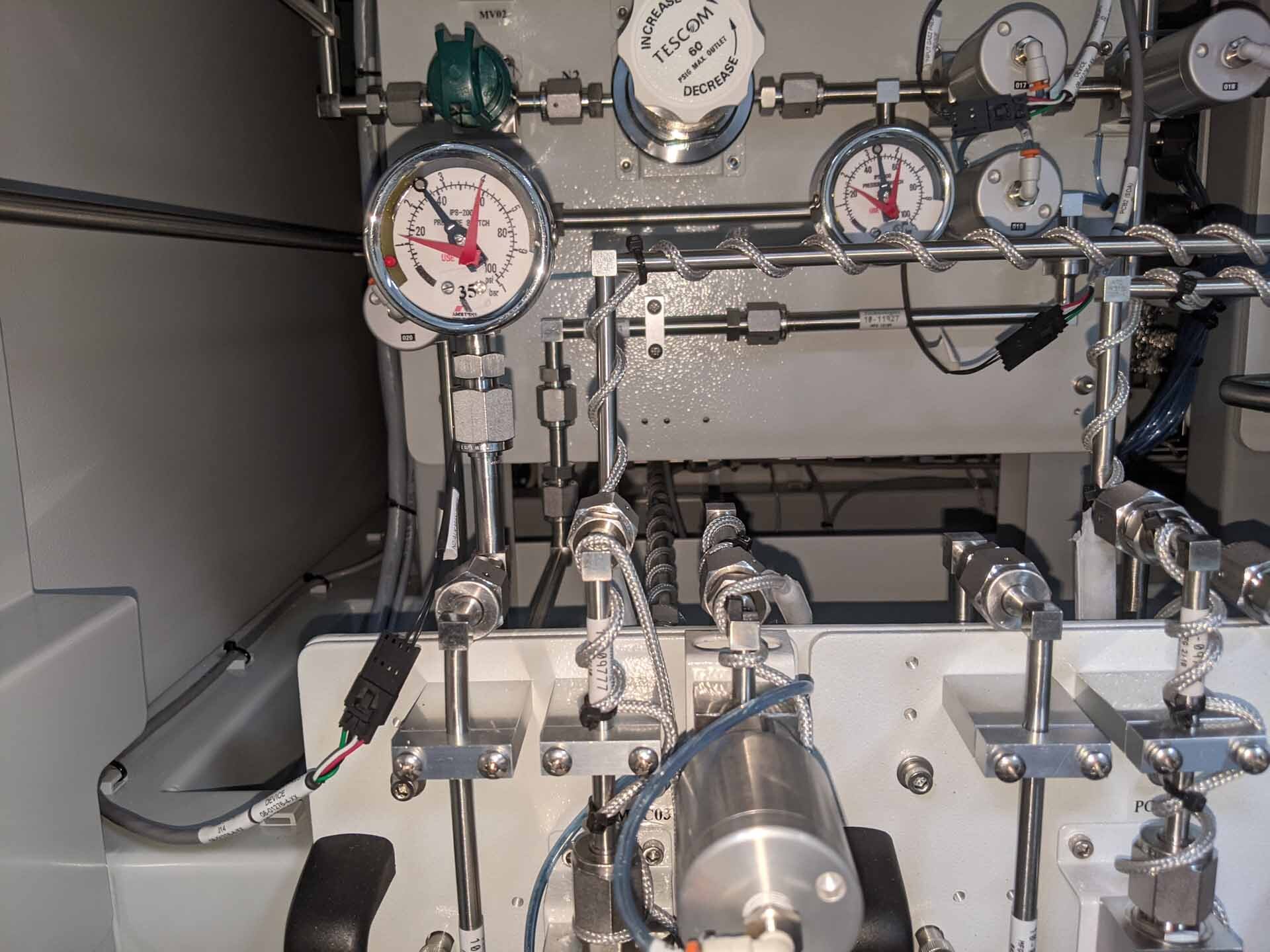

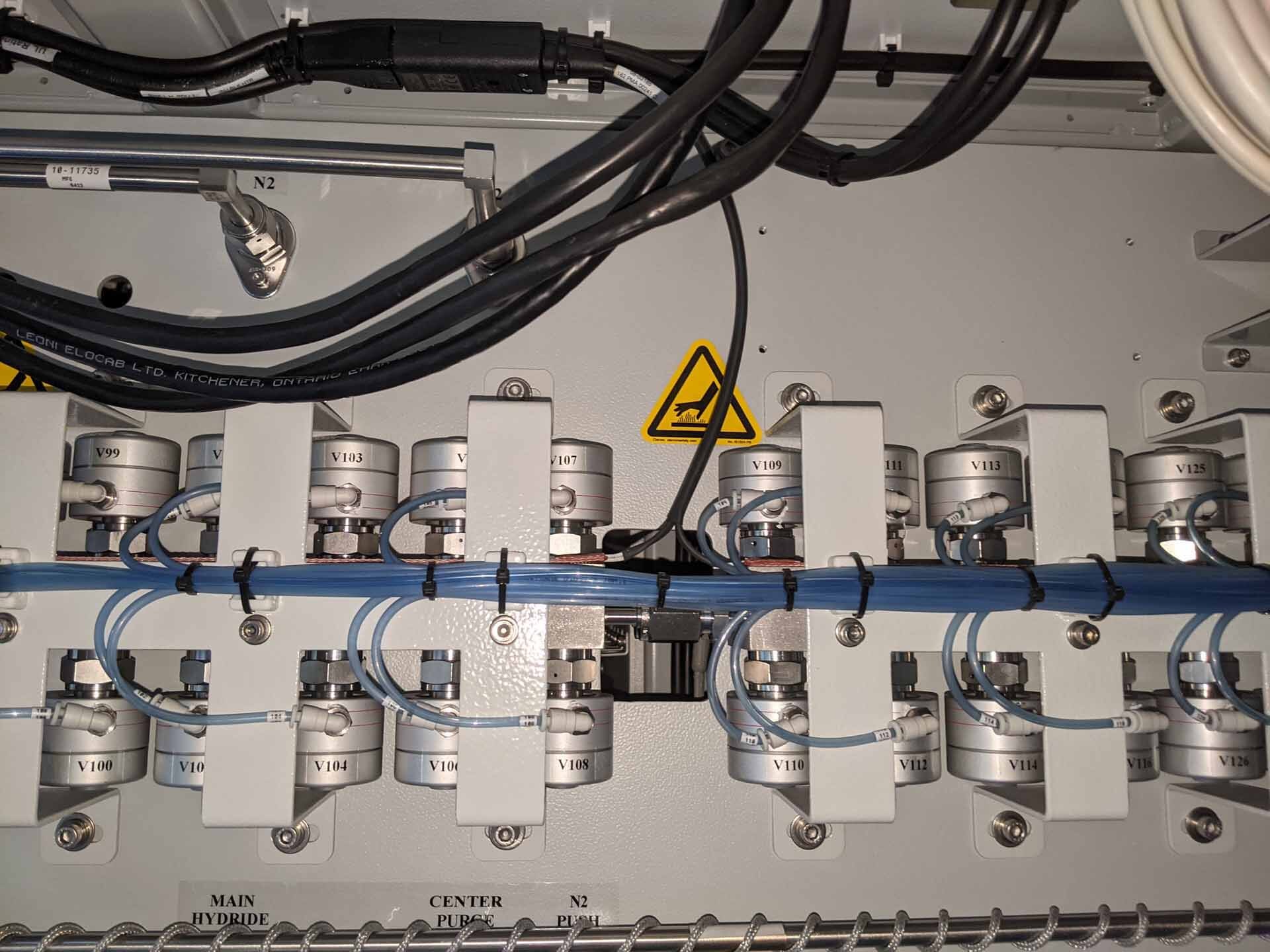

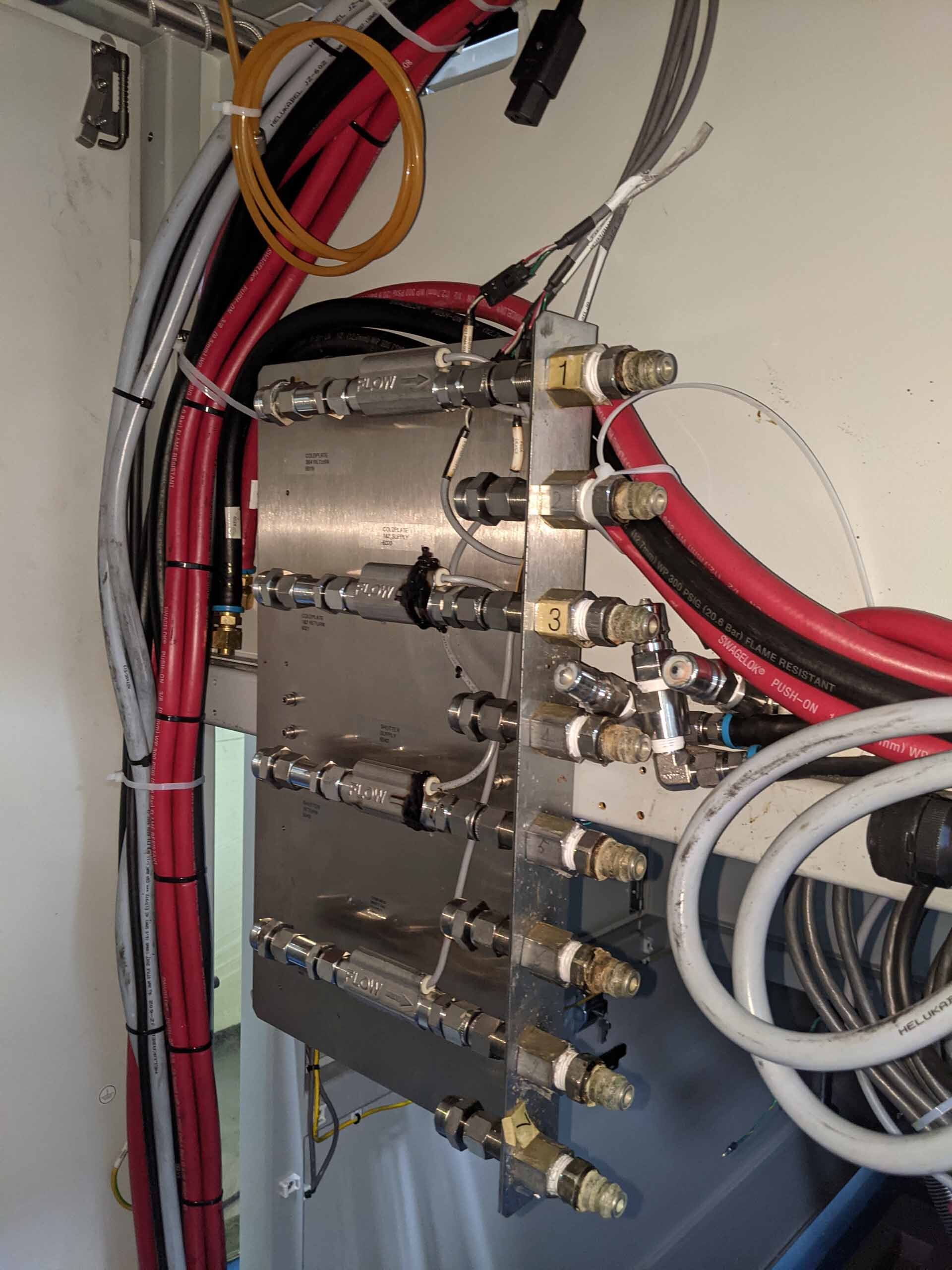

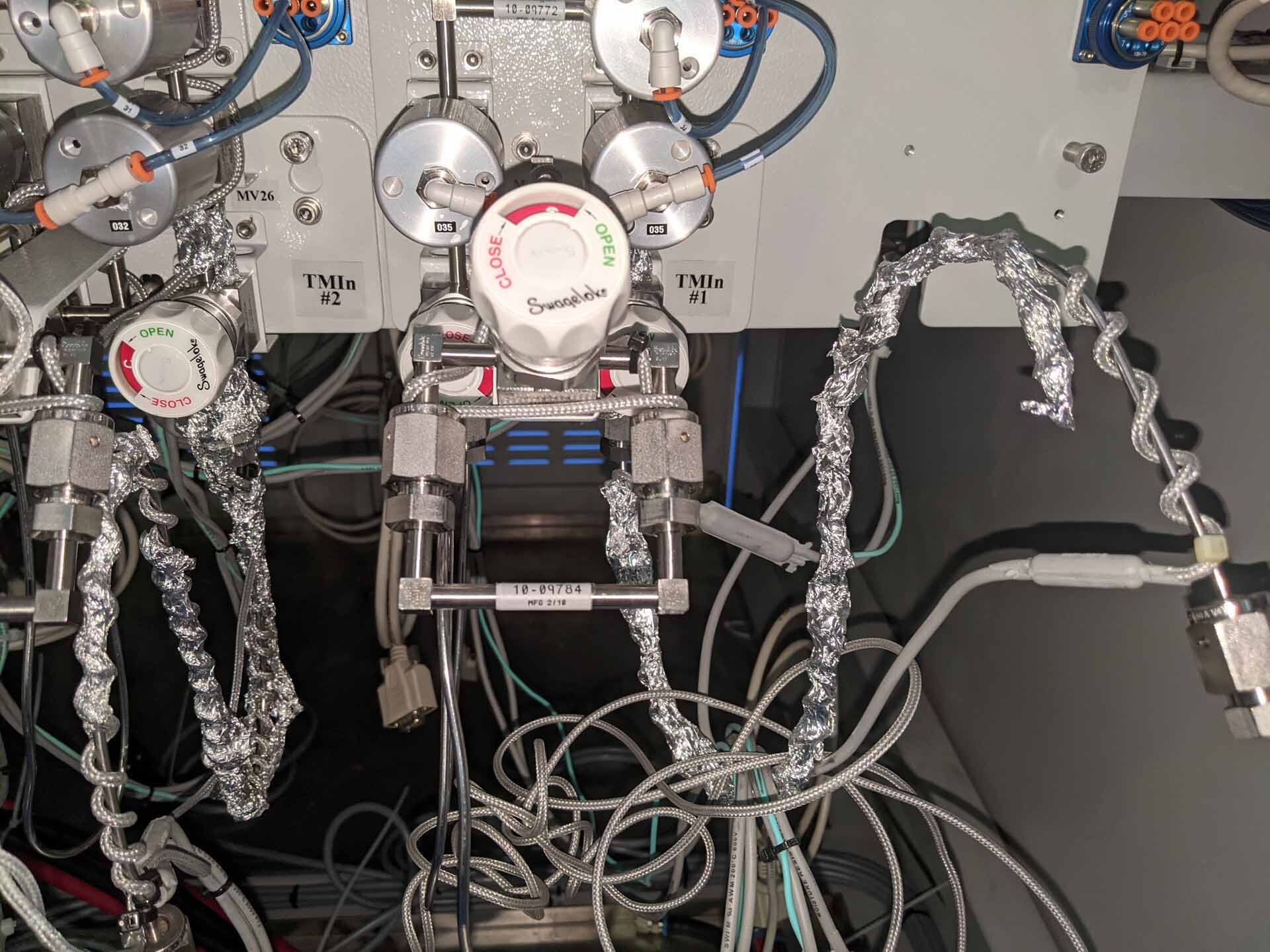

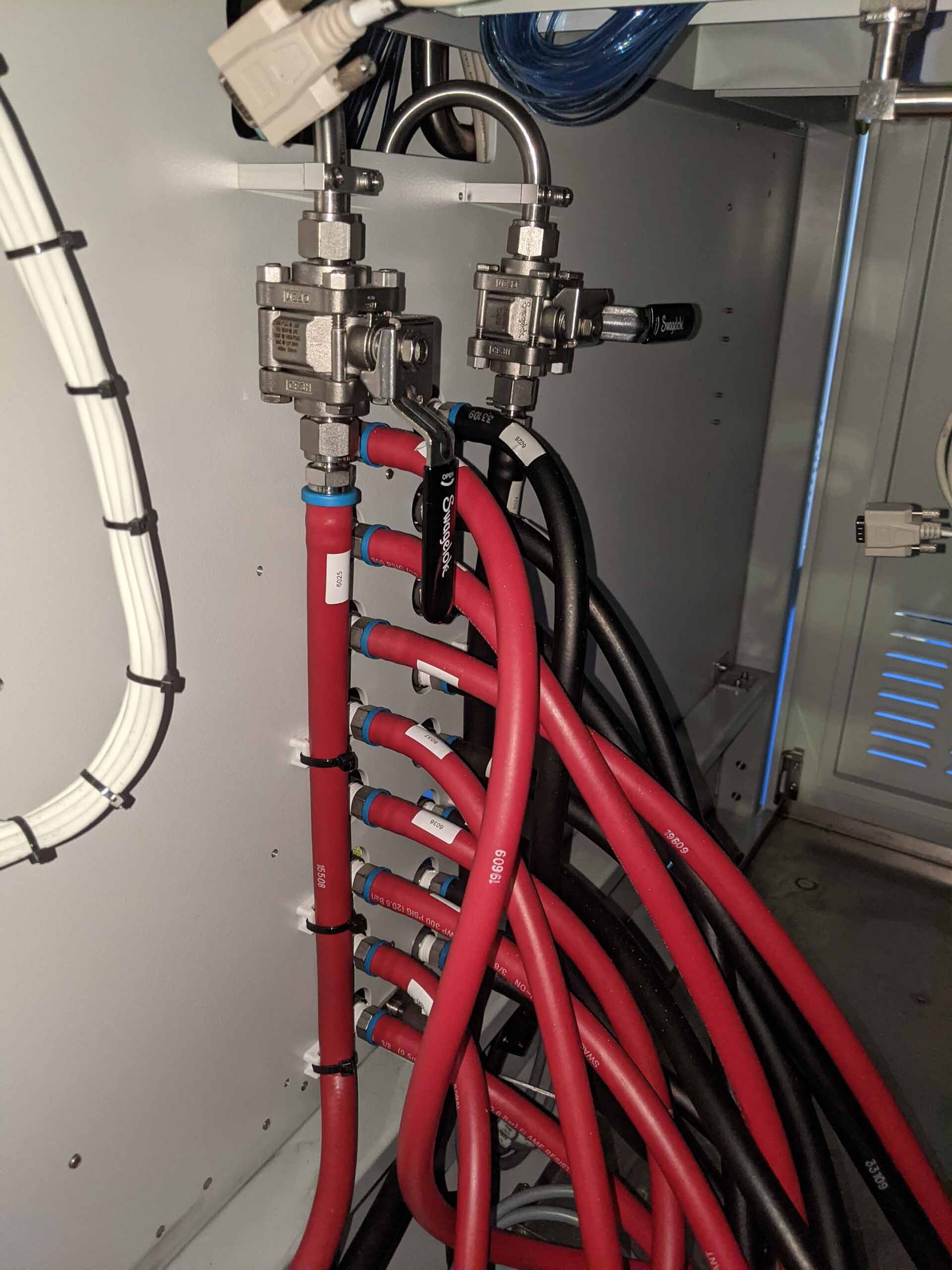

Hydride lines: NH3, SiH4

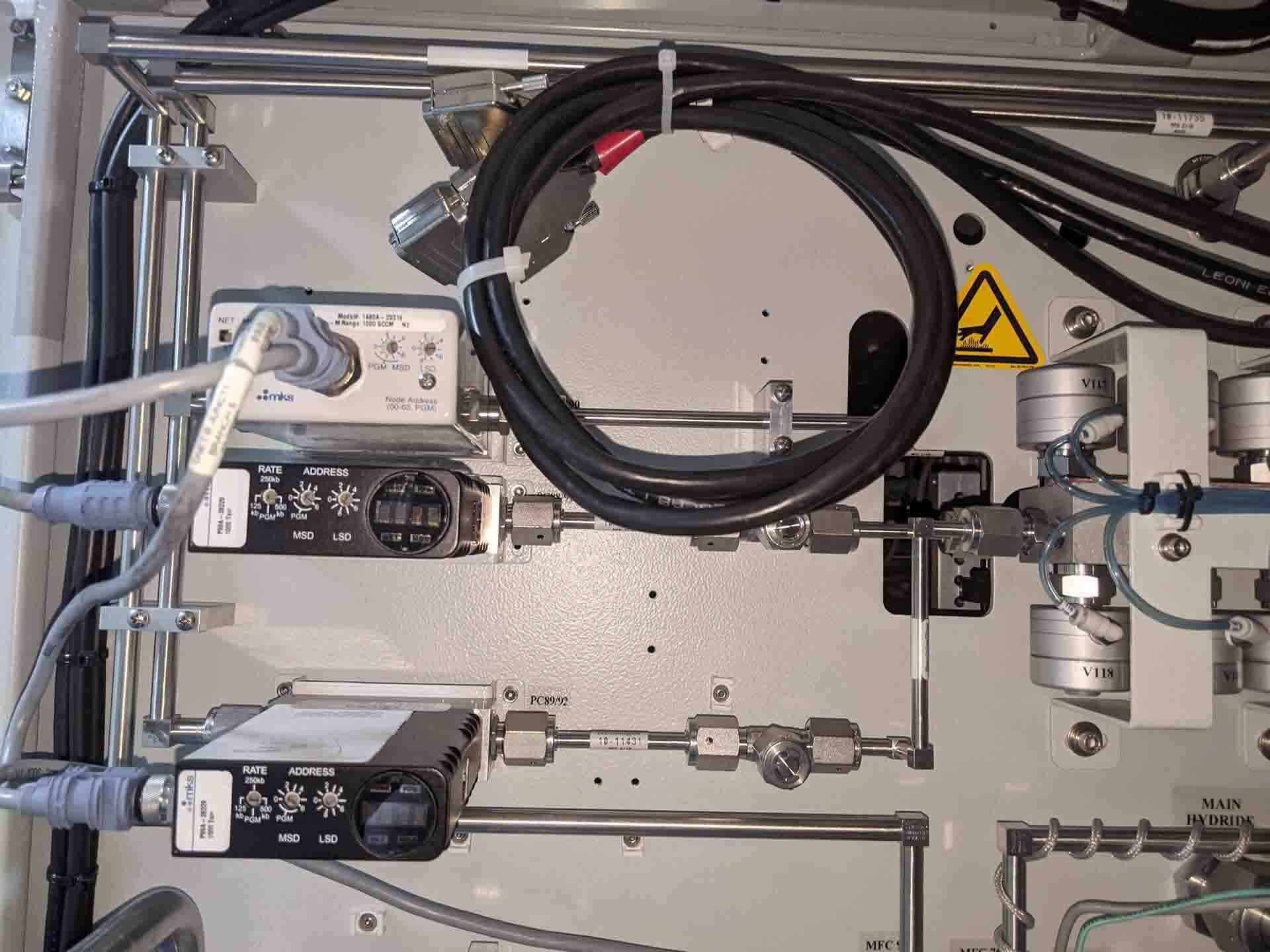

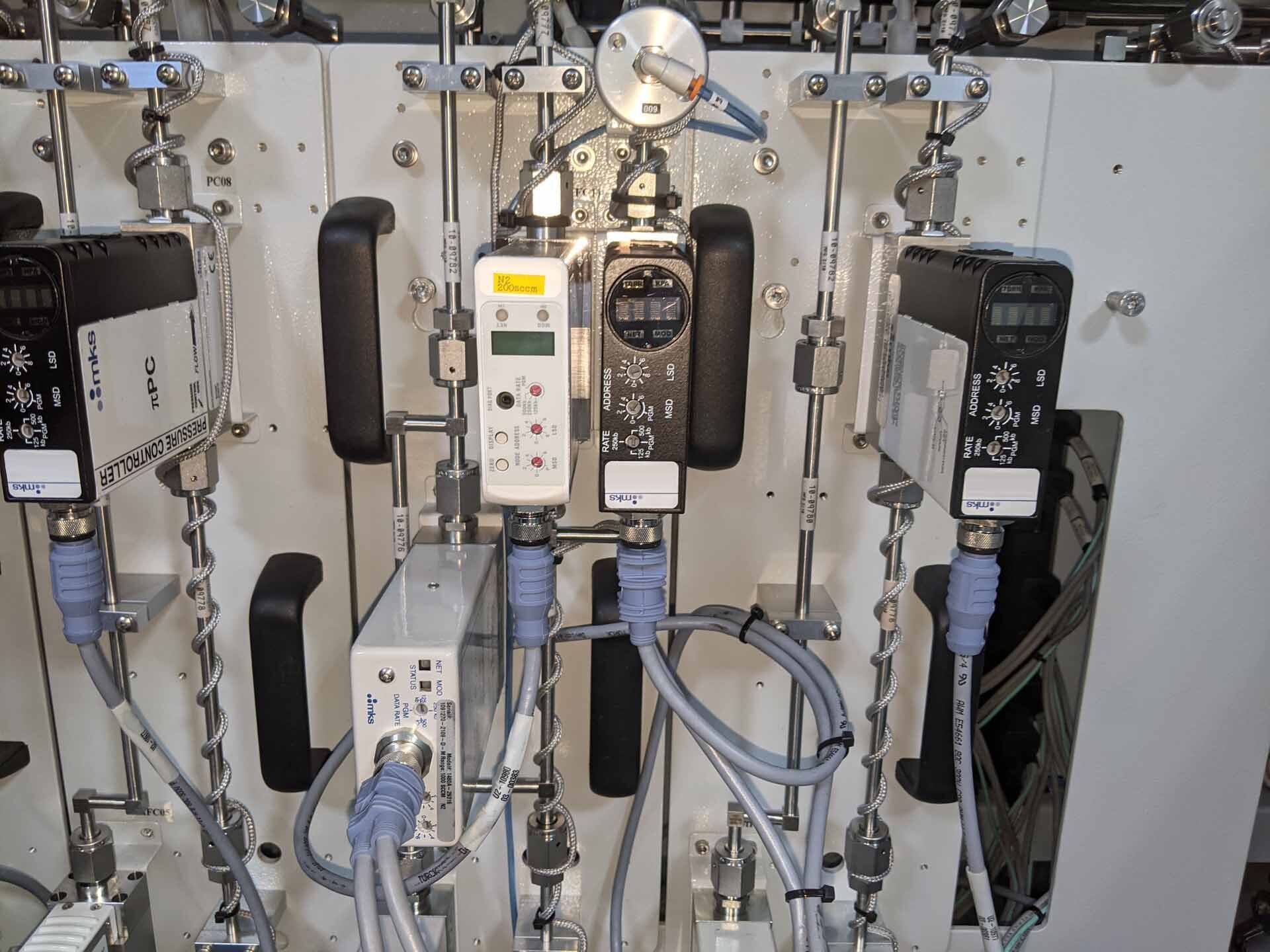

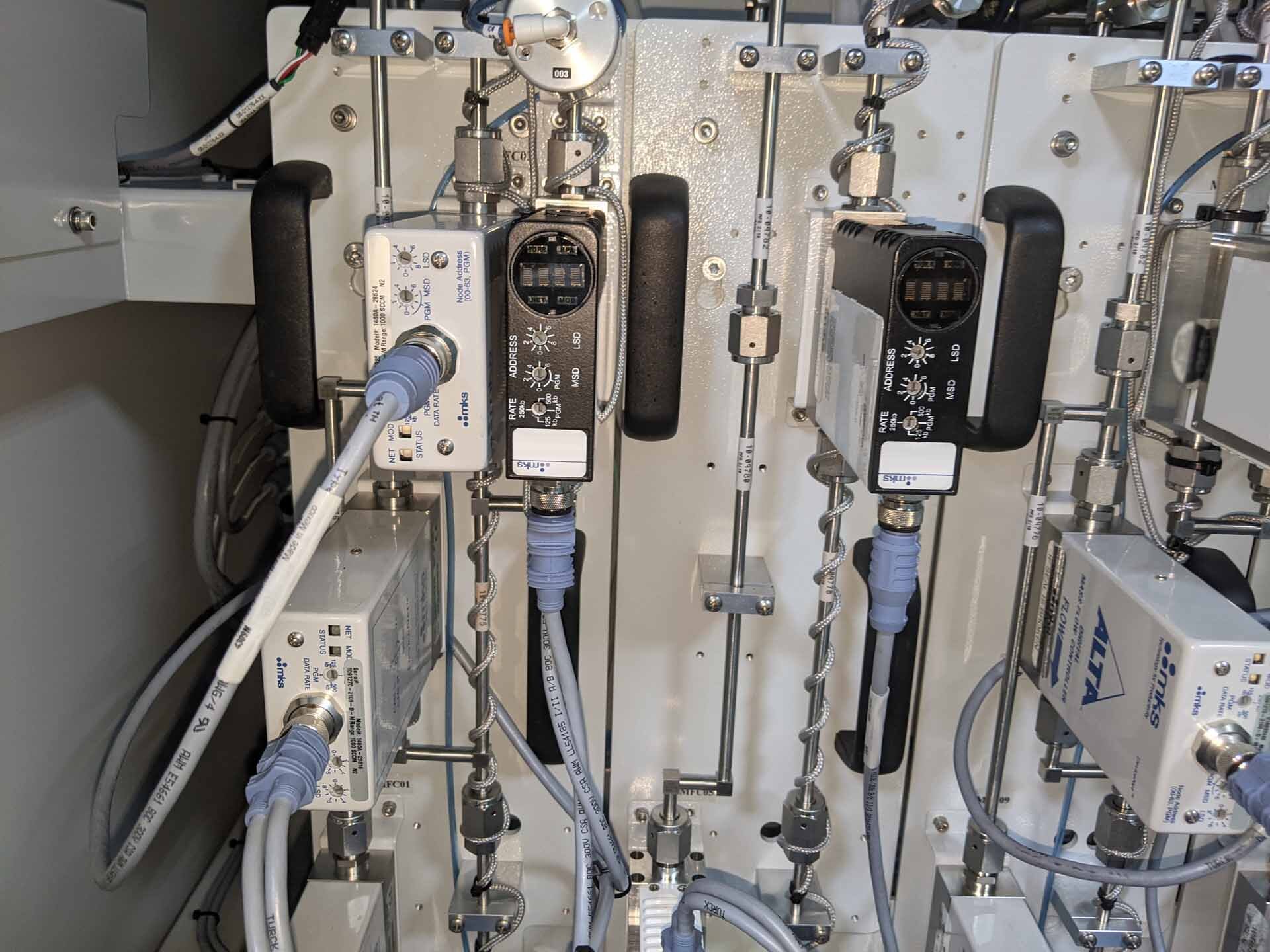

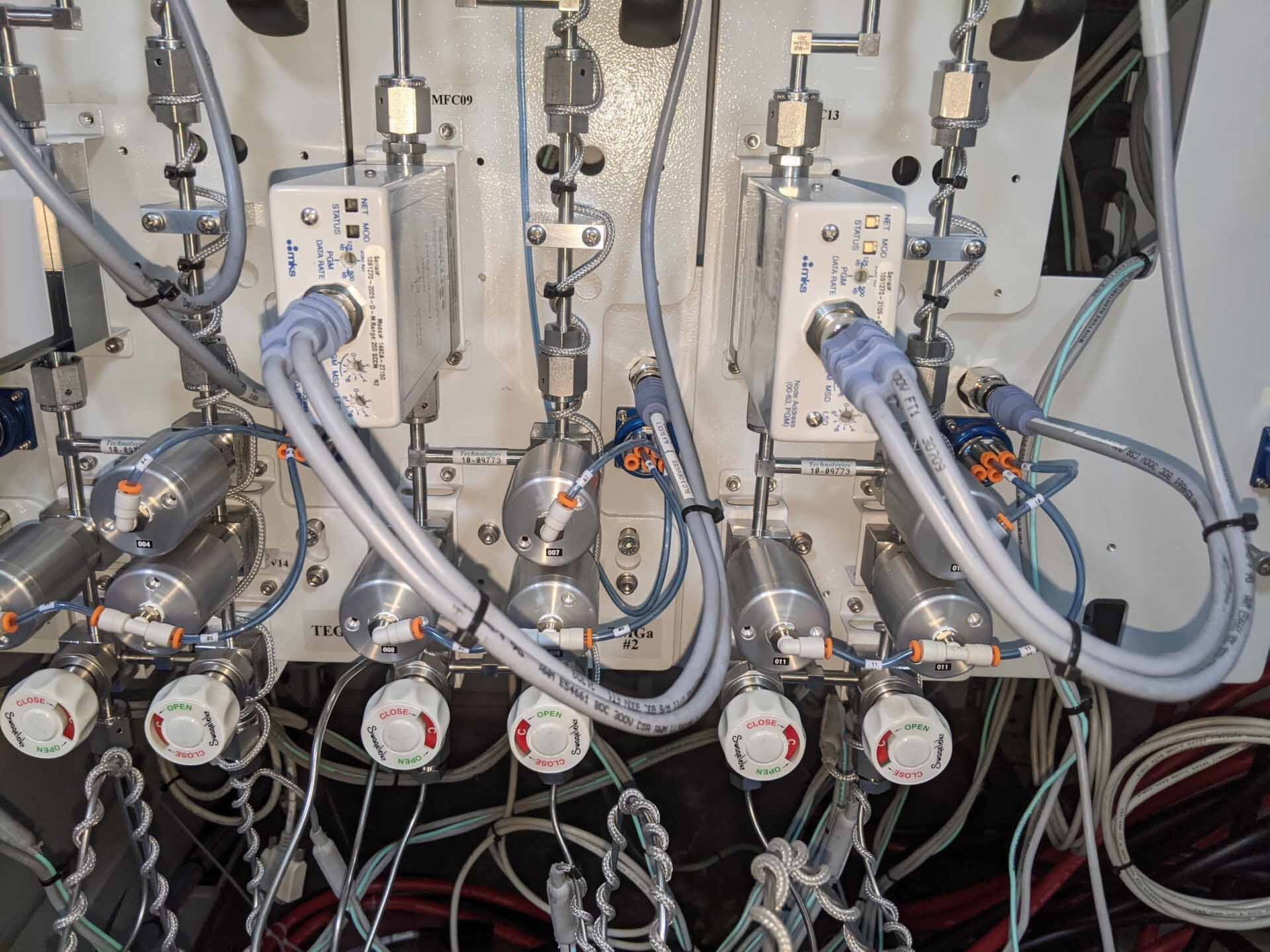

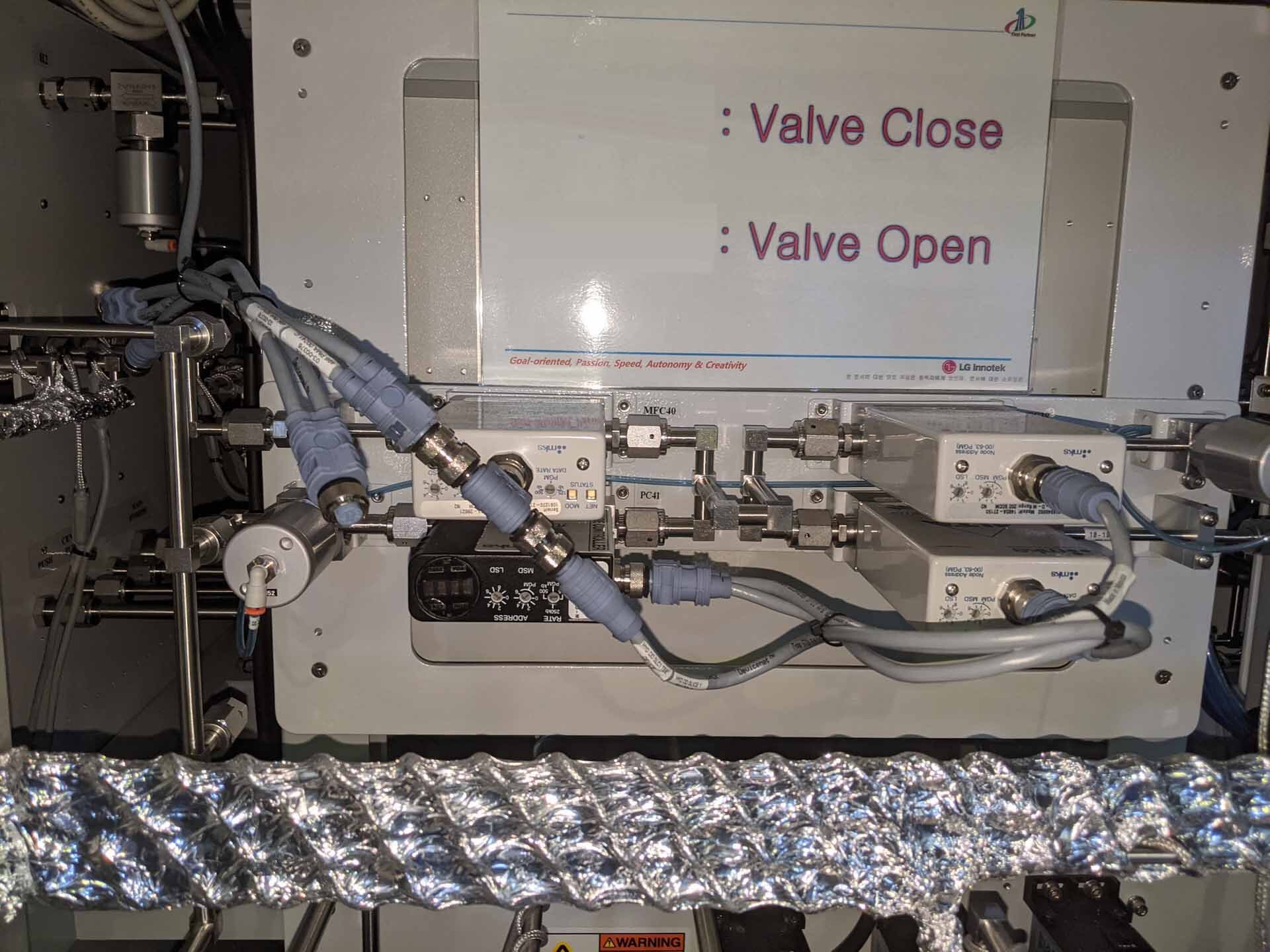

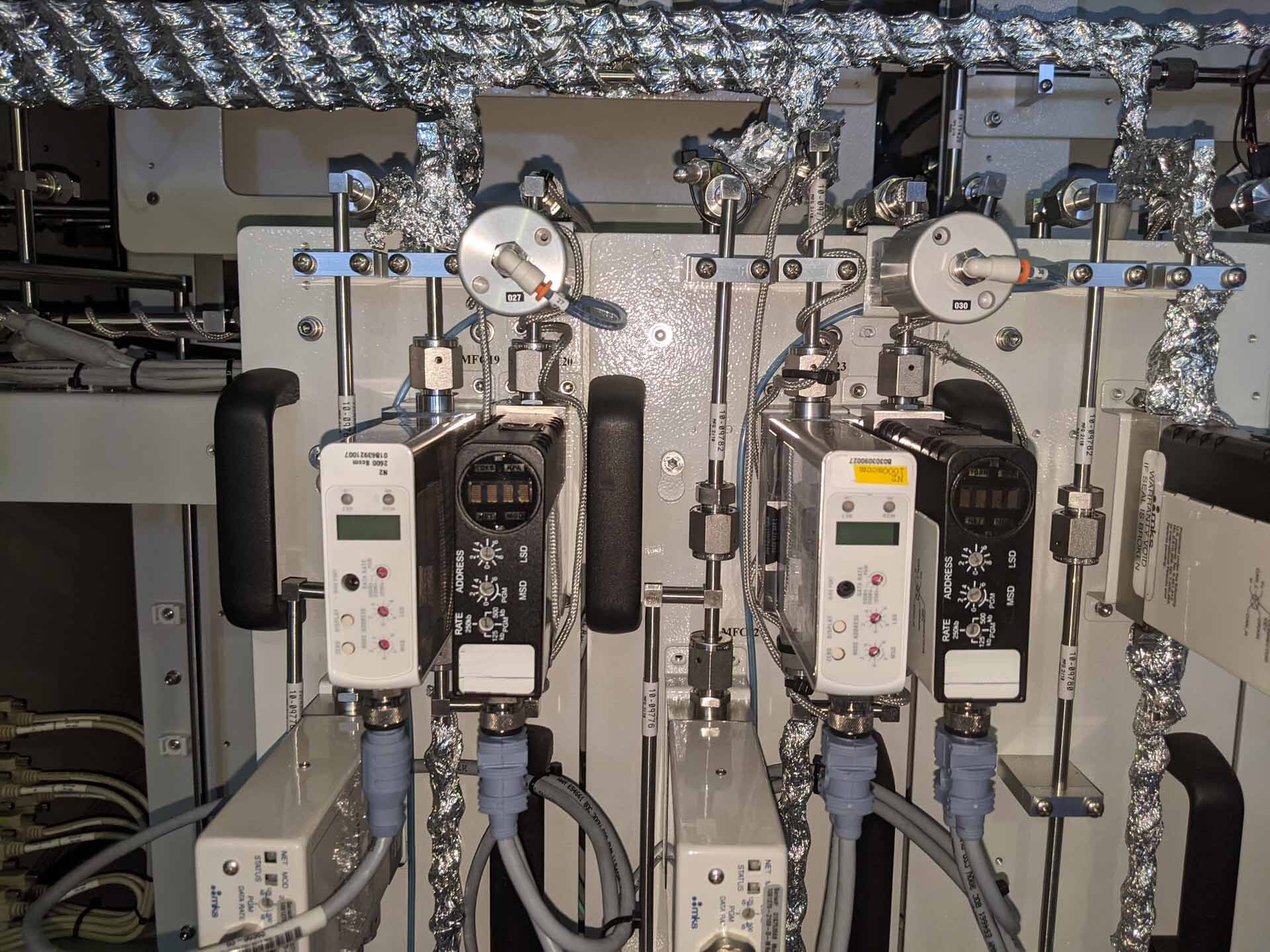

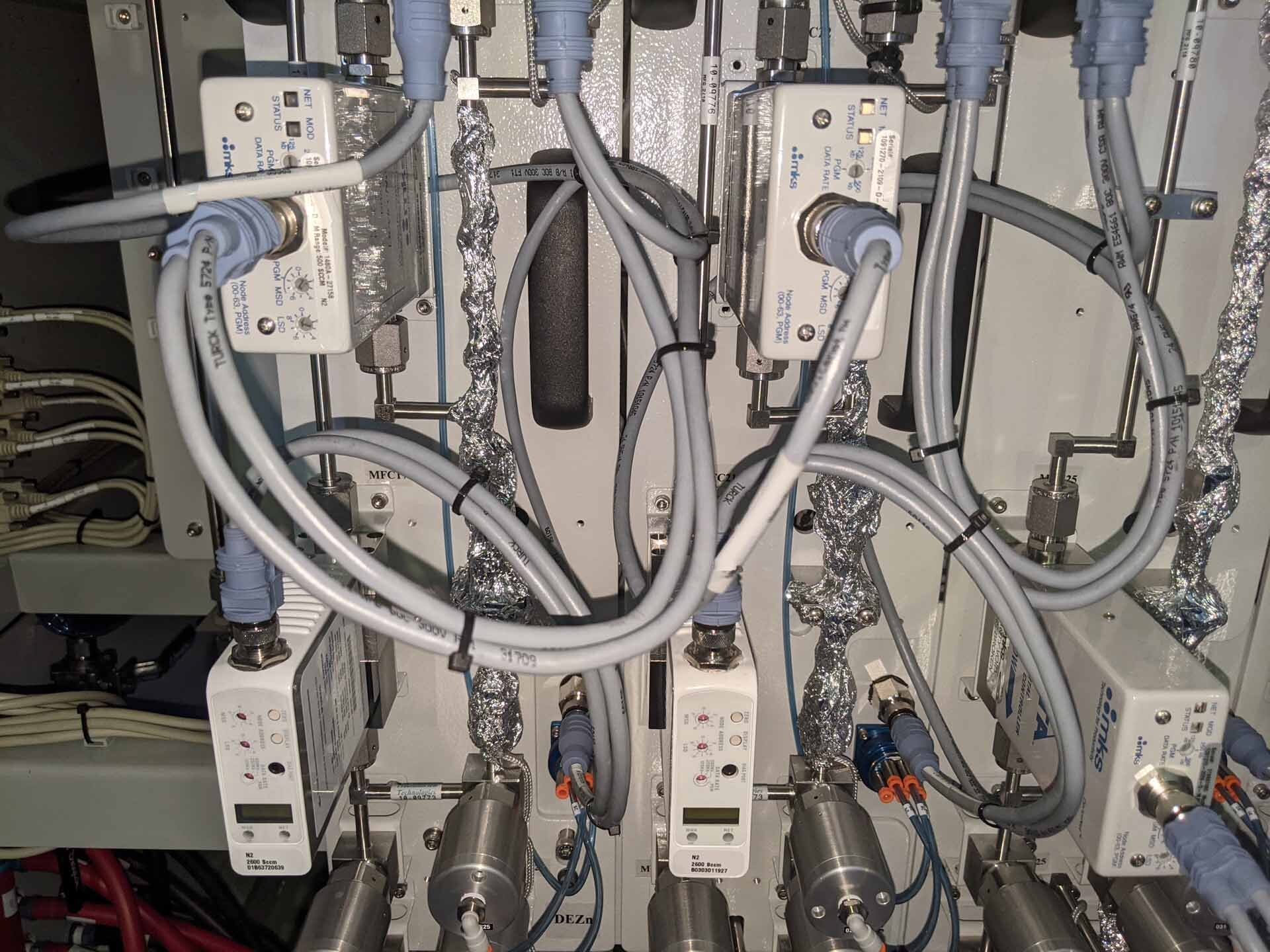

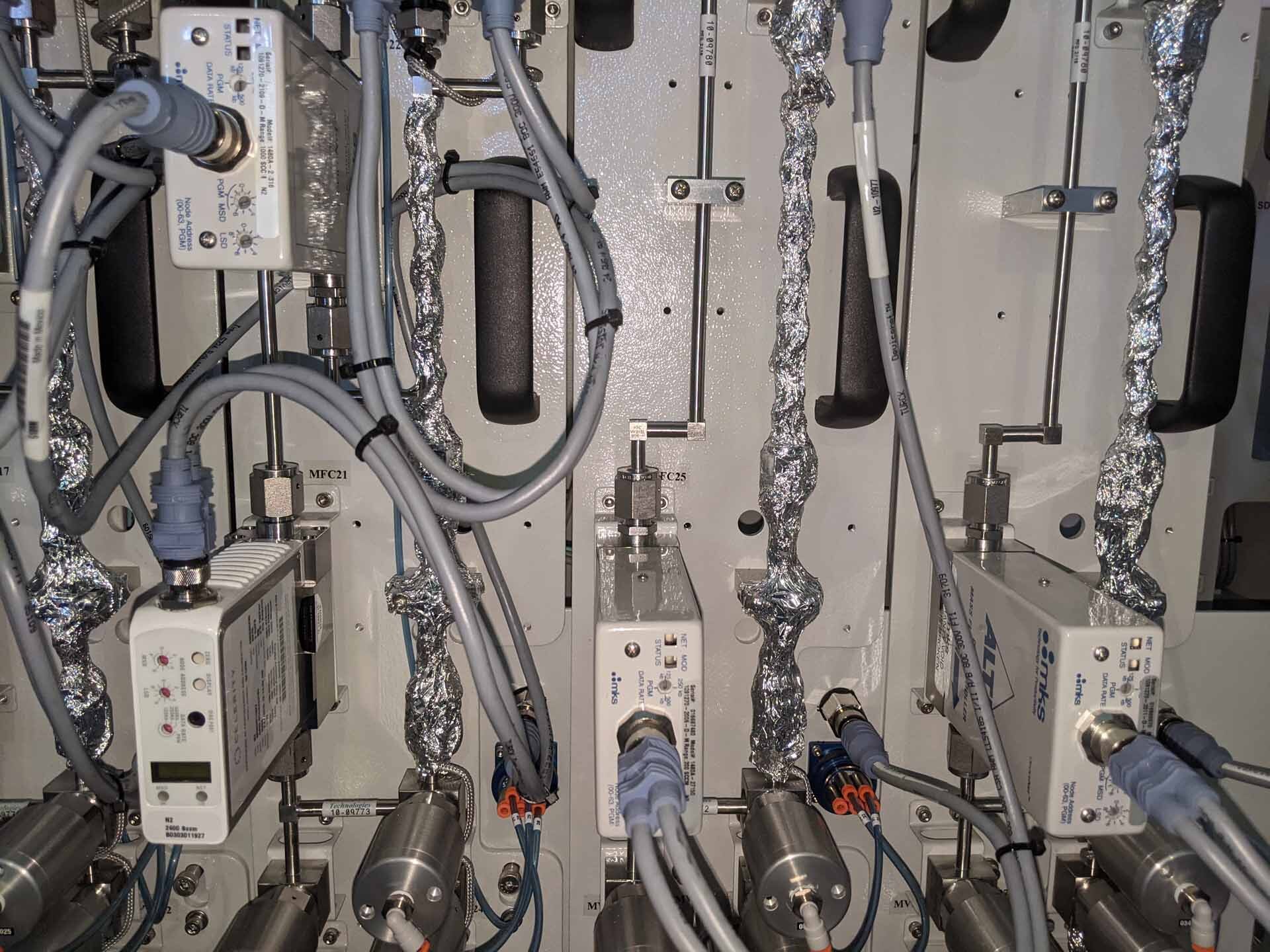

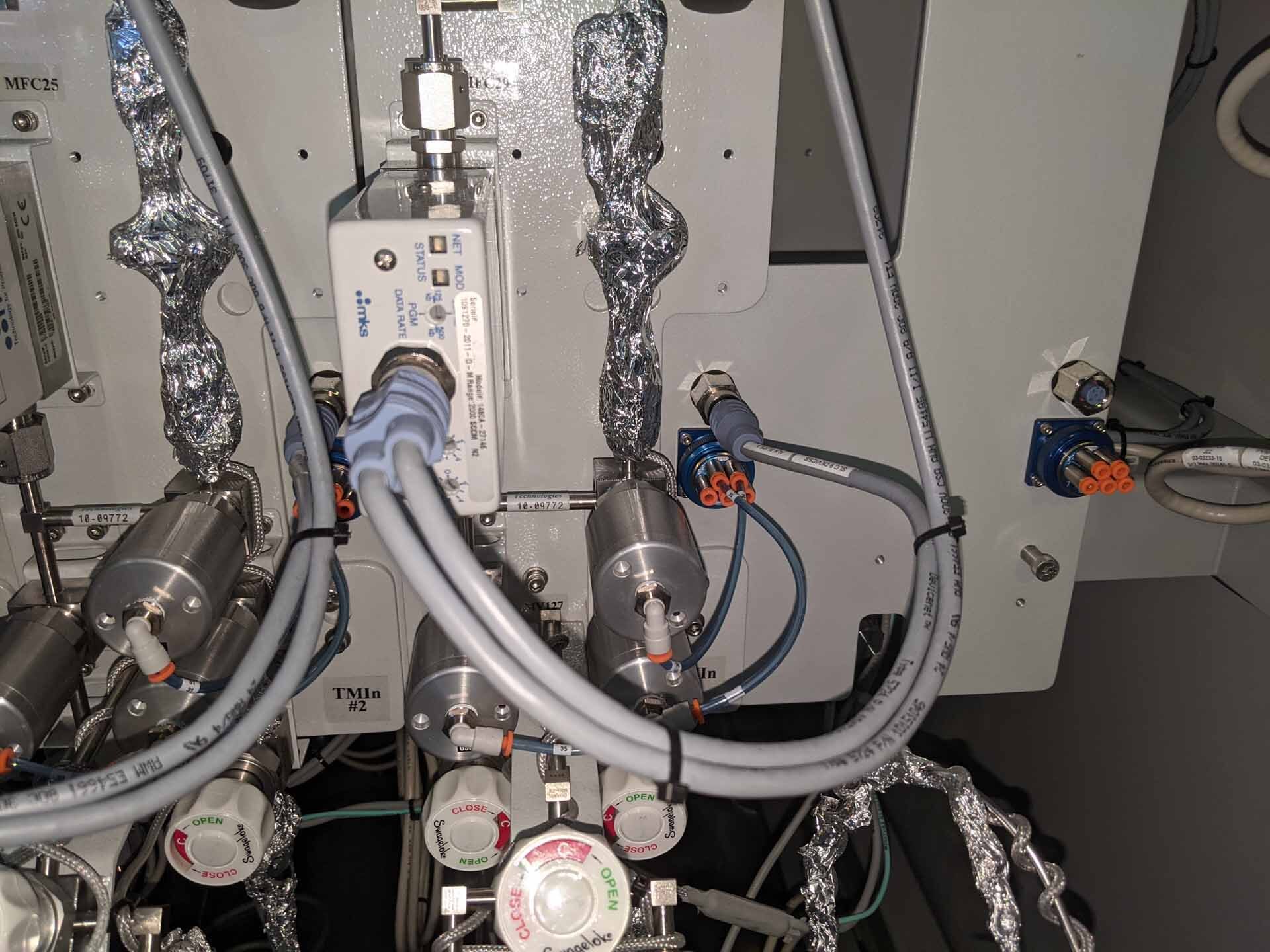

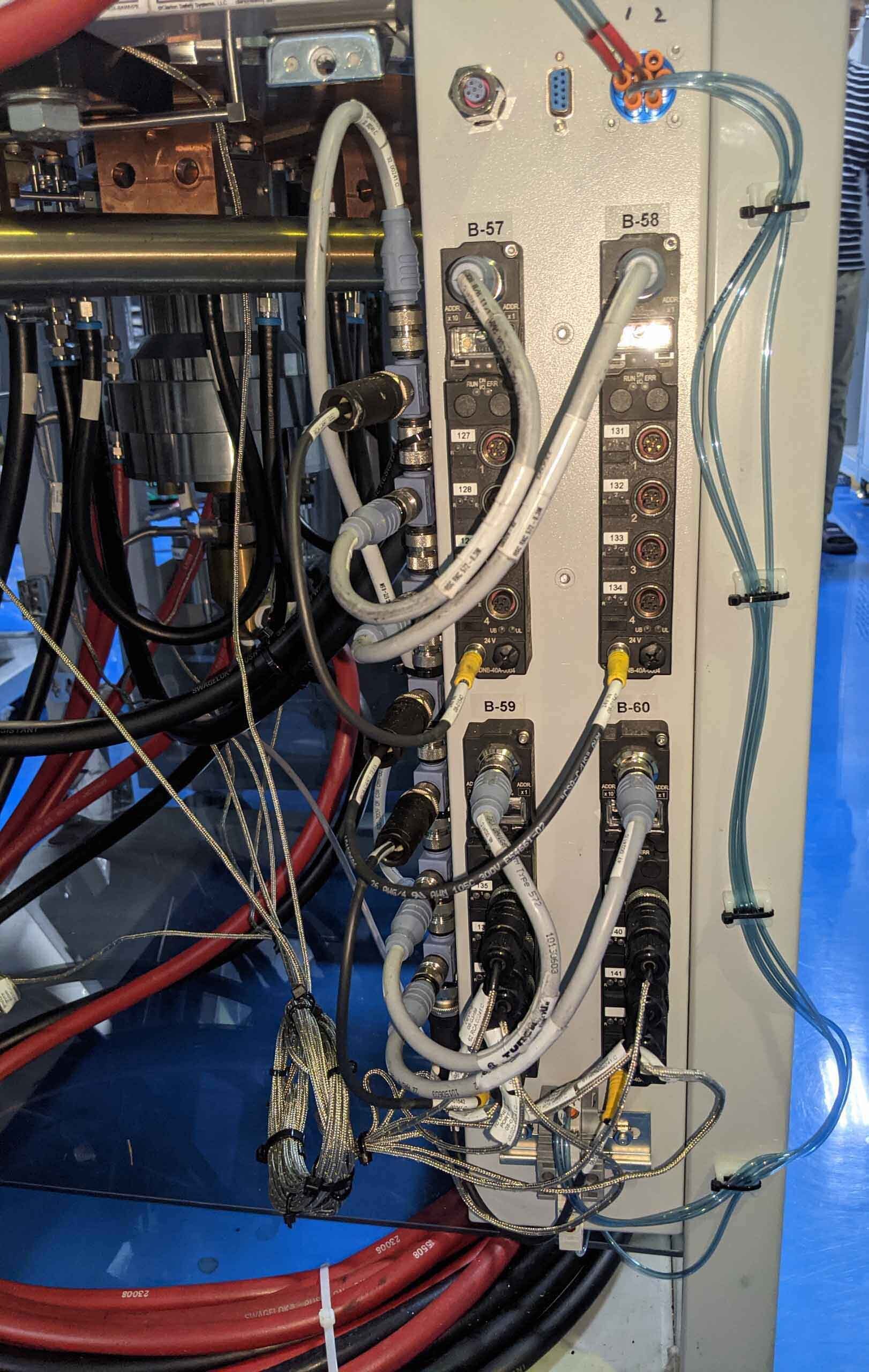

MKS MFC Type

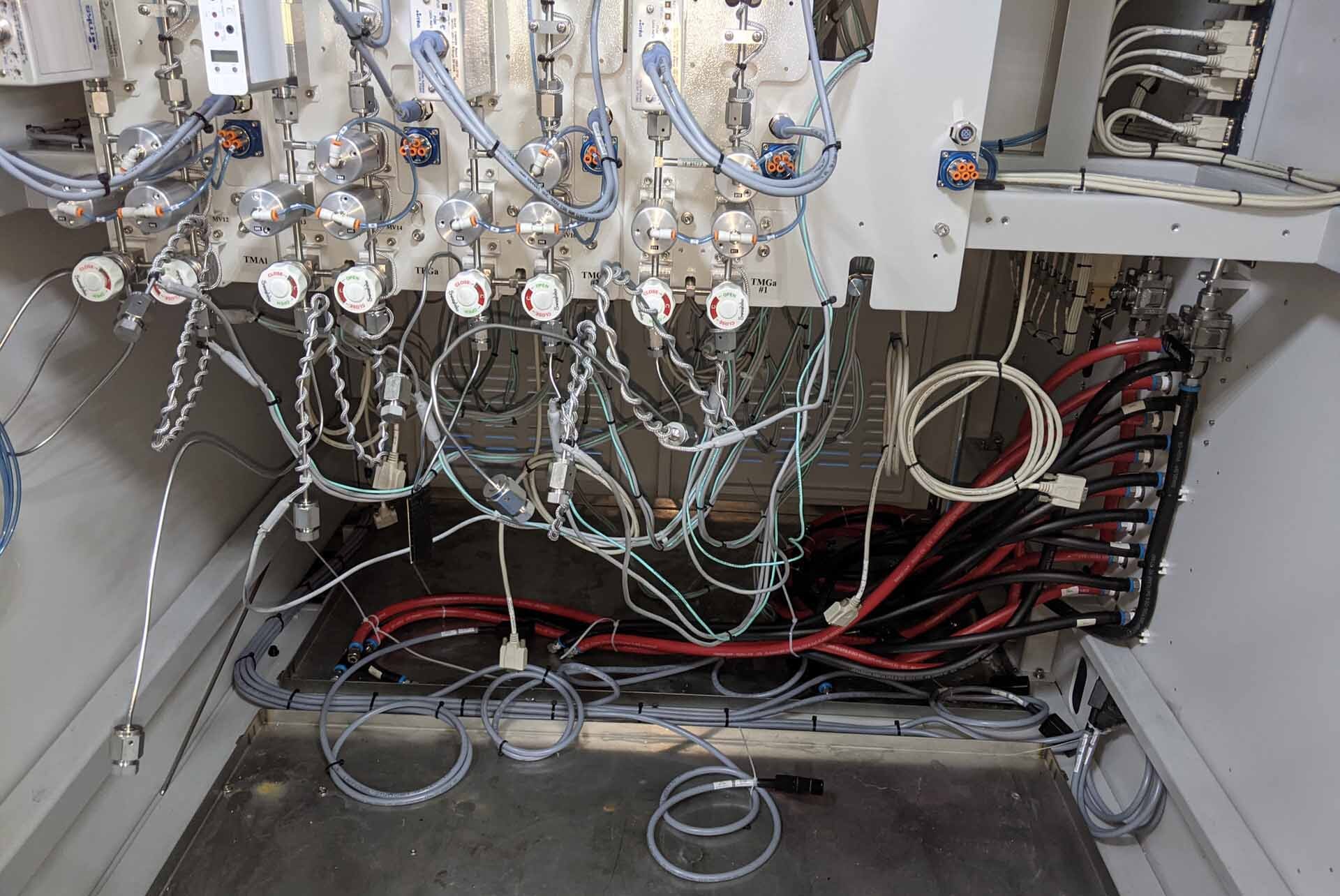

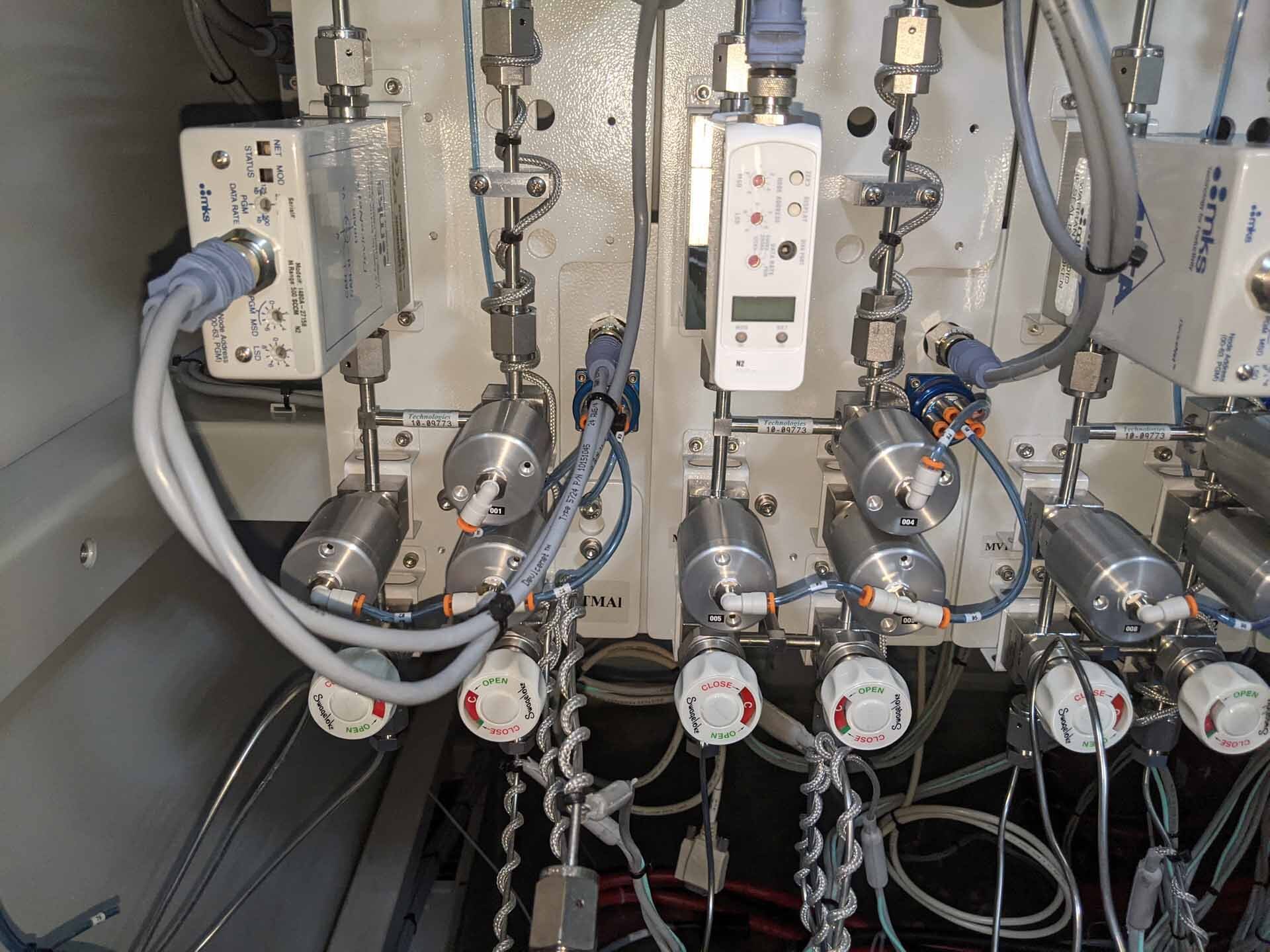

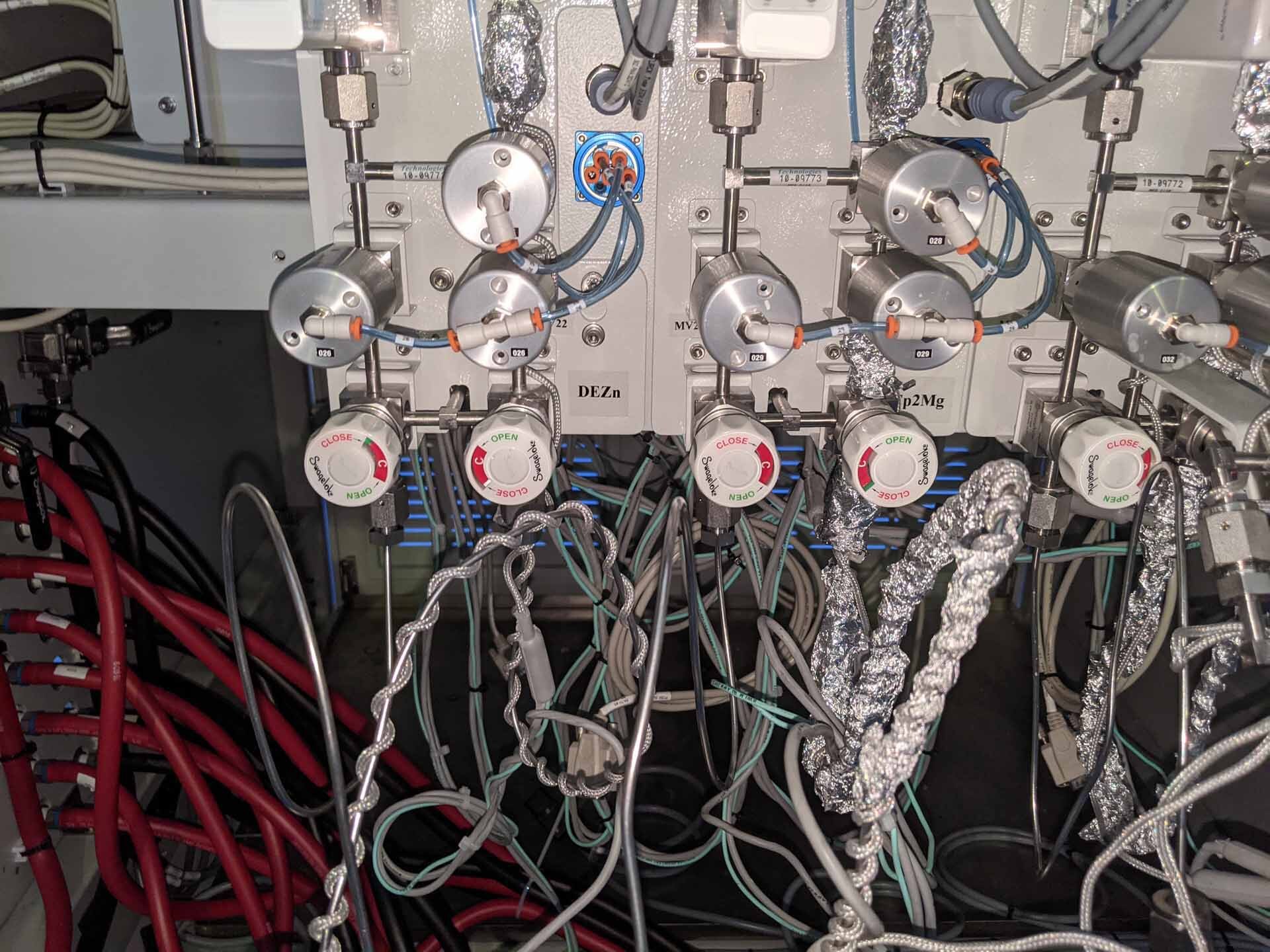

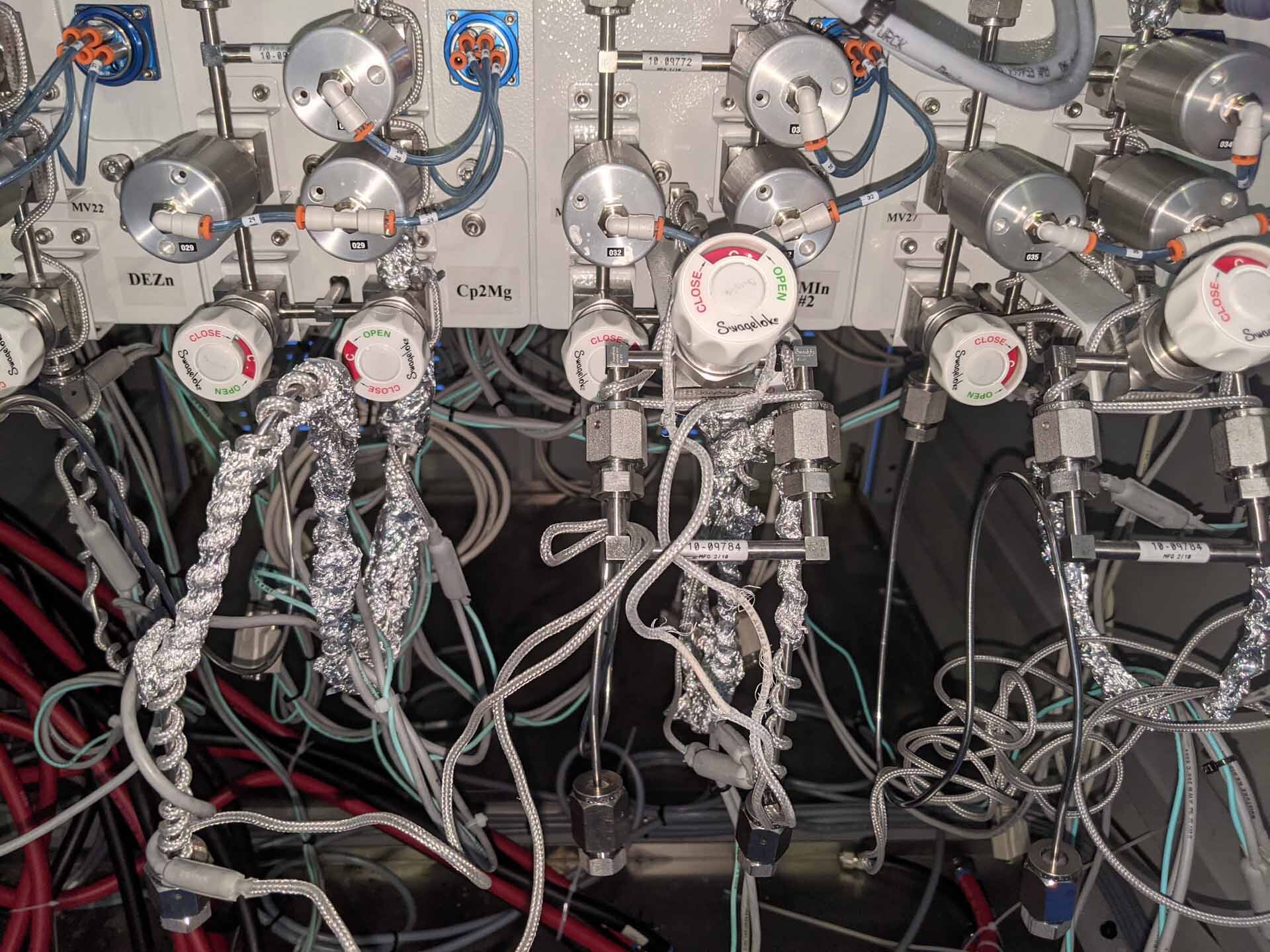

Alkyl lines:

Lines / SCCM

TMIn 1 / 1000 sccm

TMIn 2 / 200 sccm

TMGa 1 / 1000 sccm

TMGa 2 / 200 sccm+1000 sccm

TEGa / 1000 sccm

TMAl / 500 sccm+1000 sccm

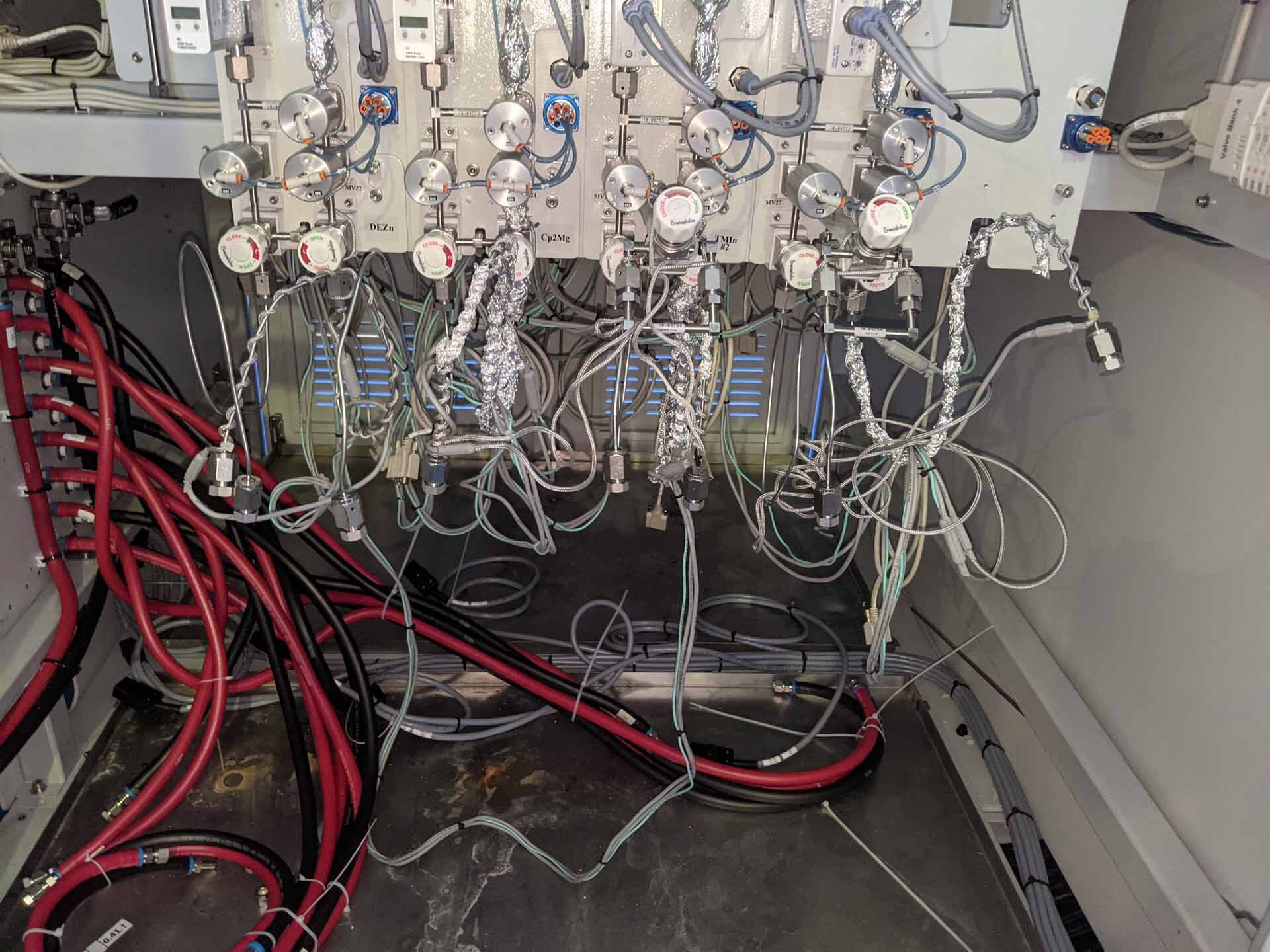

Cp2Mg / 1000 sccm+2600 sccm

DEZn / 500 sccm+1000 sccm

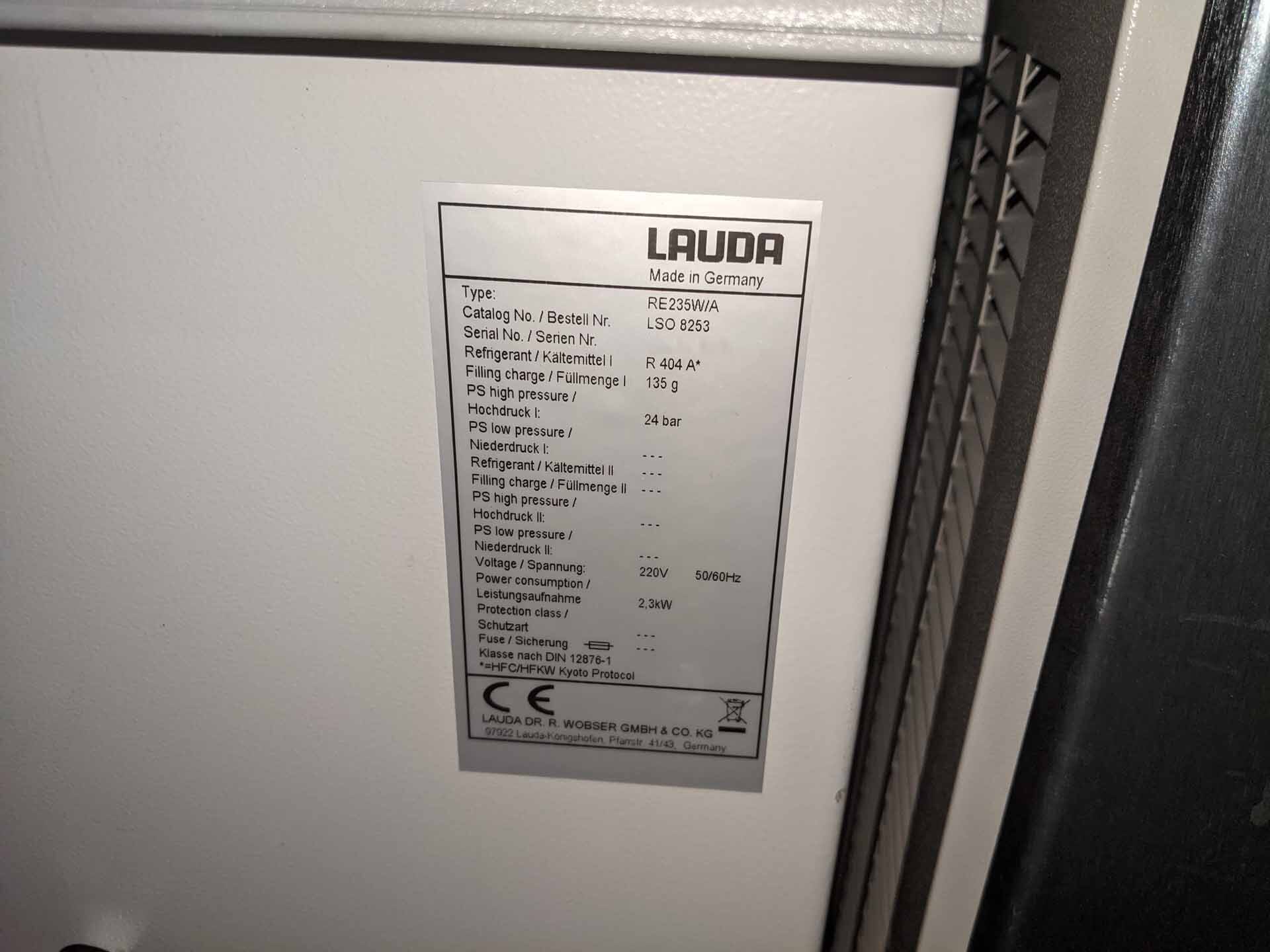

RAUDA Baths:

RE235

(5) RE215

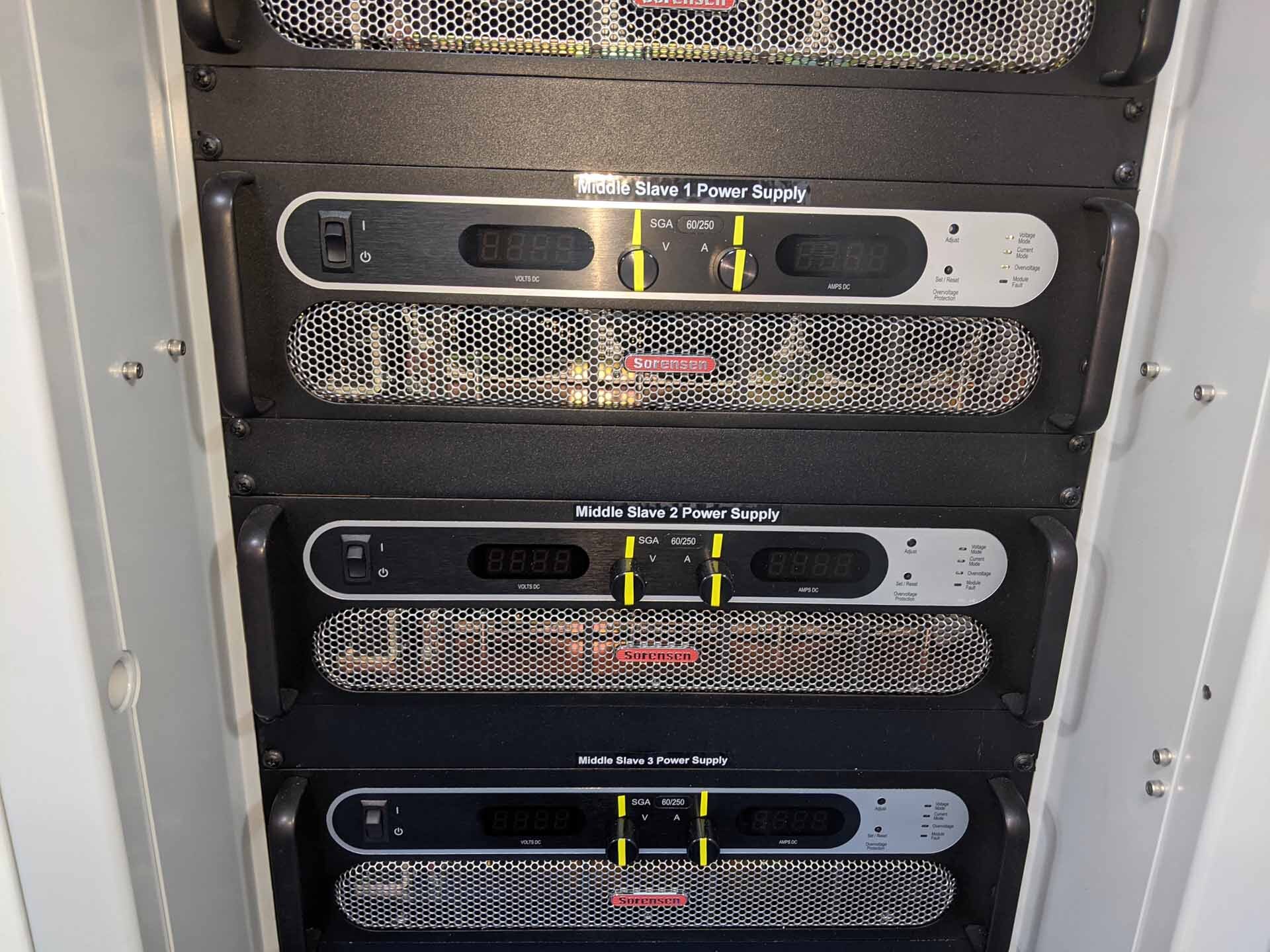

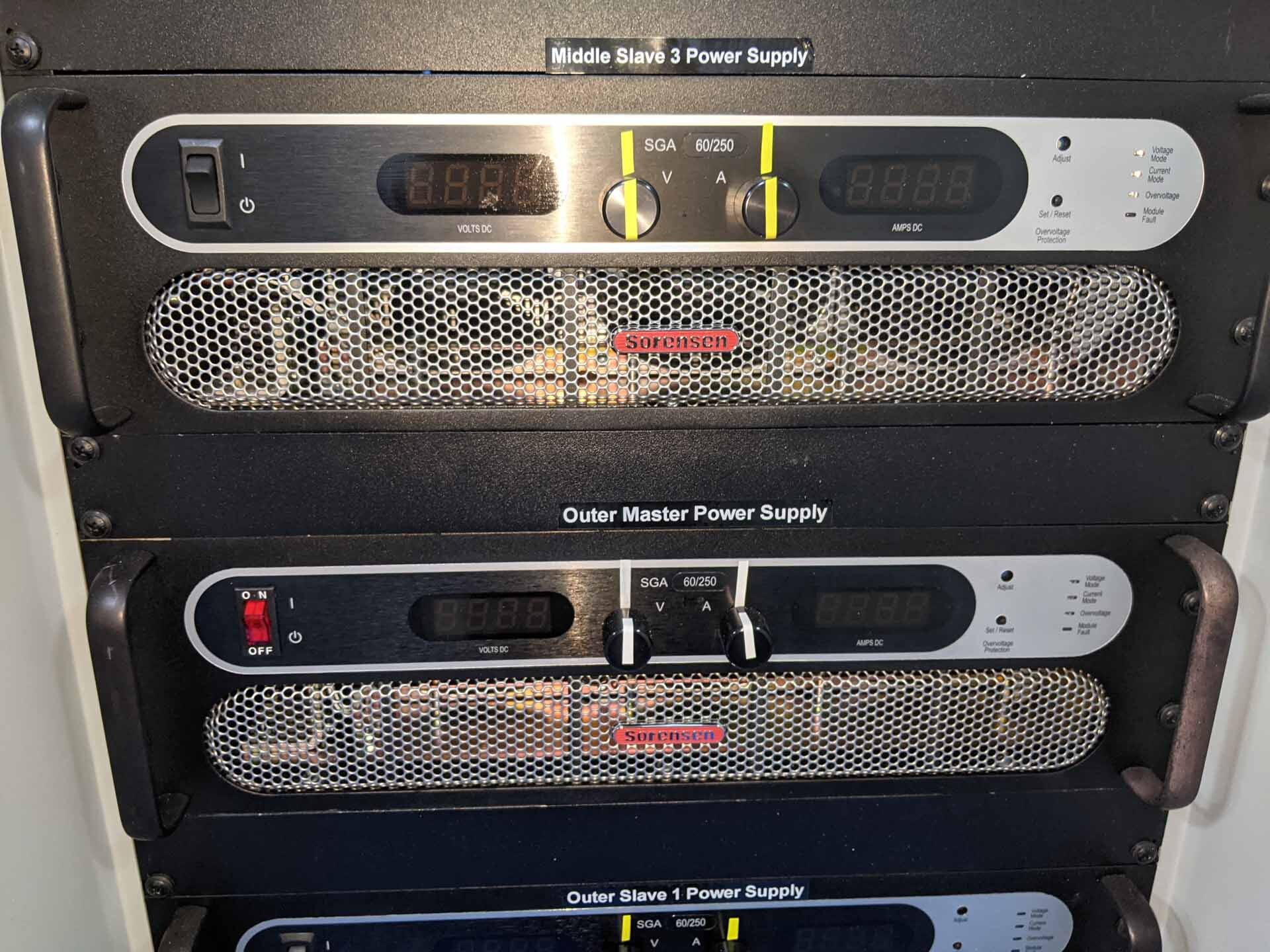

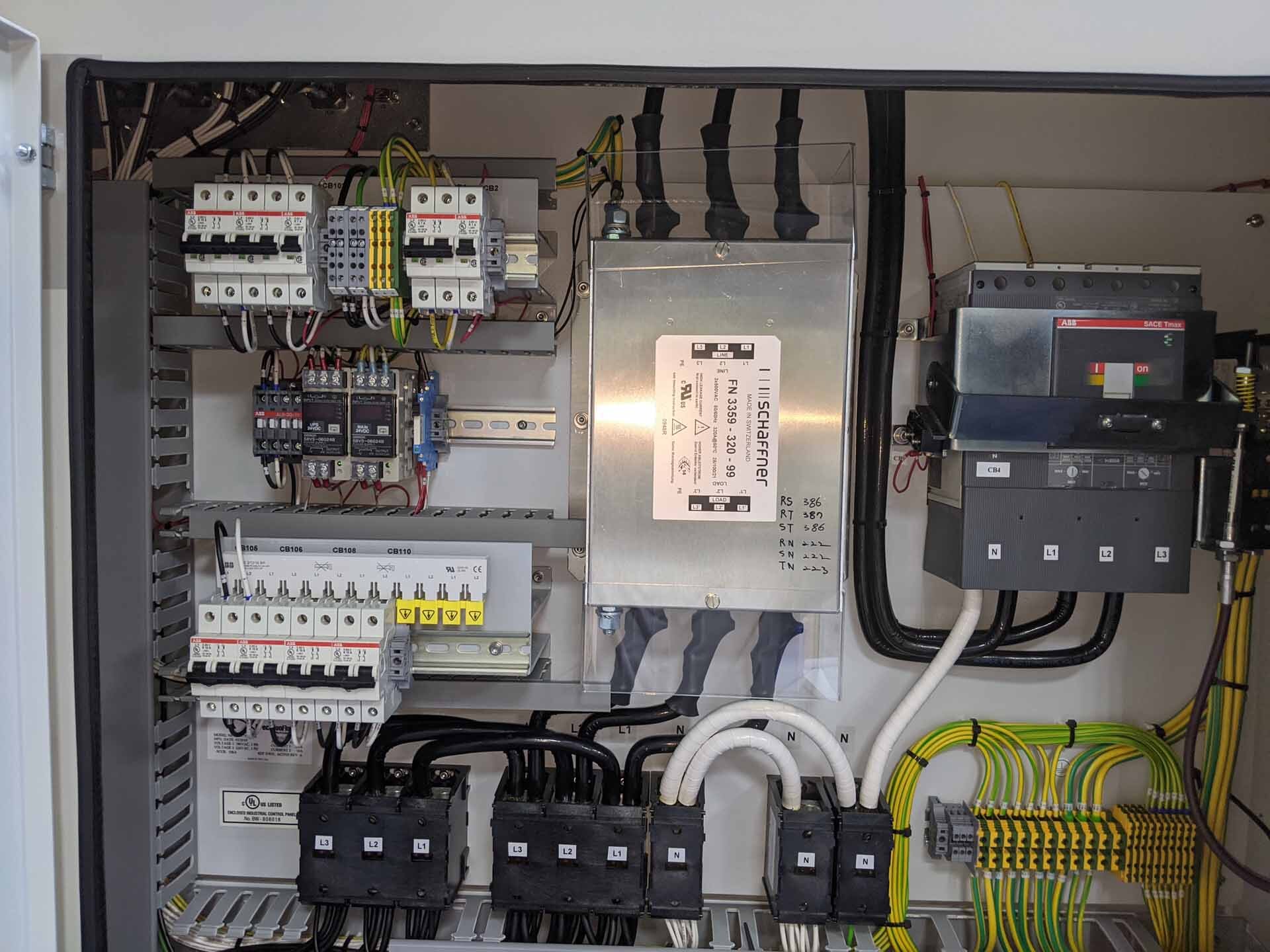

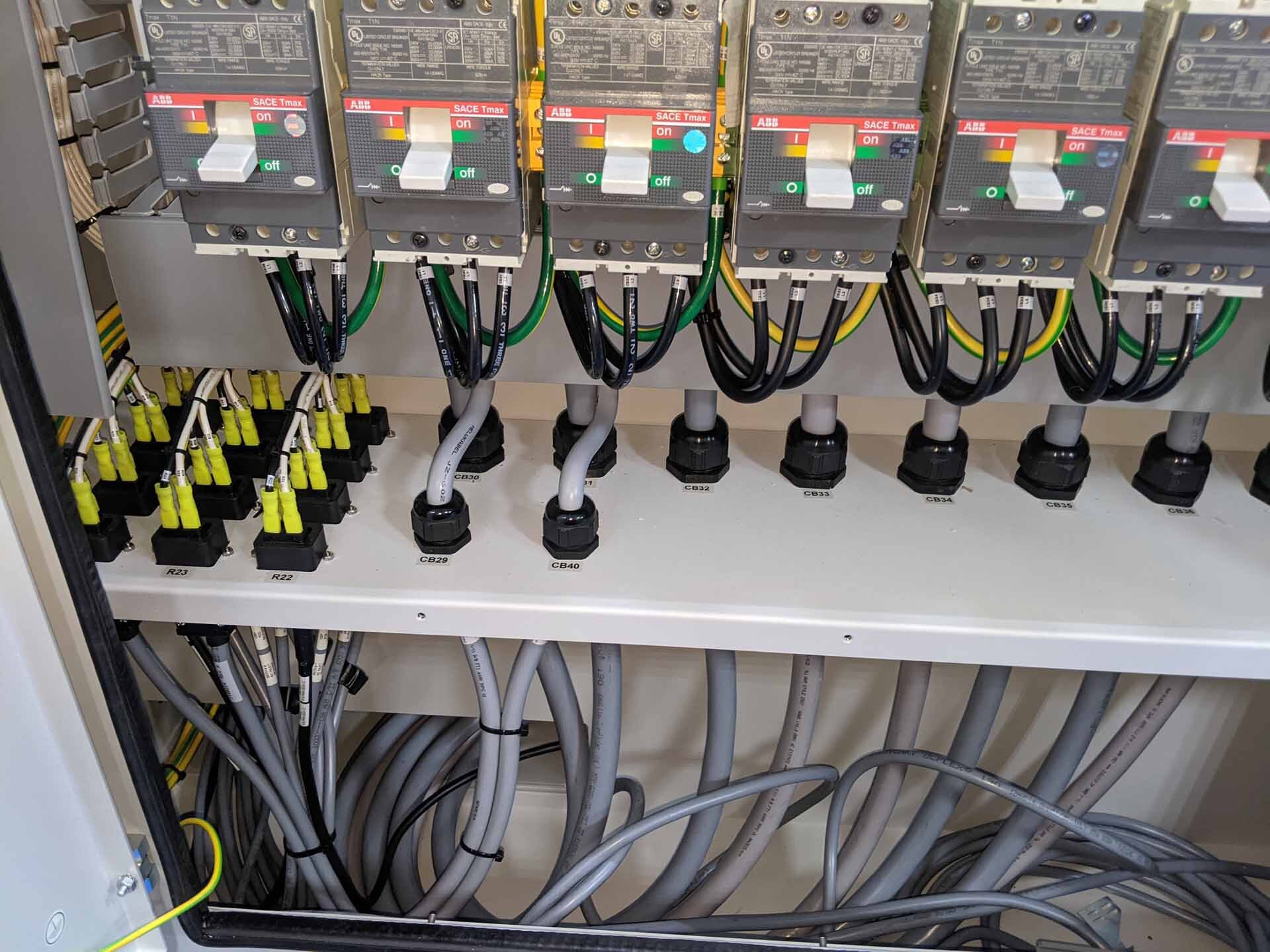

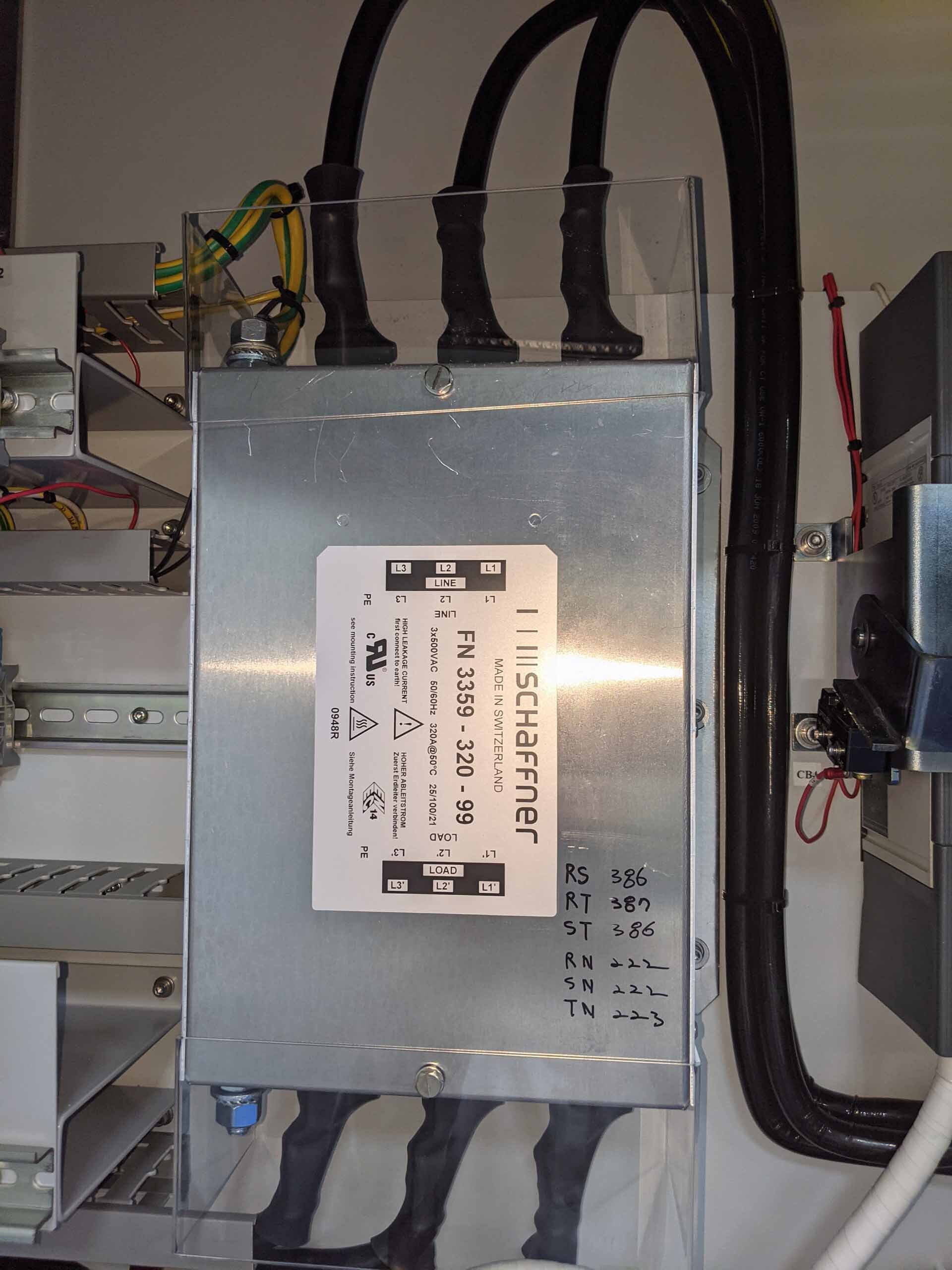

Power supply: 380 VAC, 3-Phase

2010 vintage.

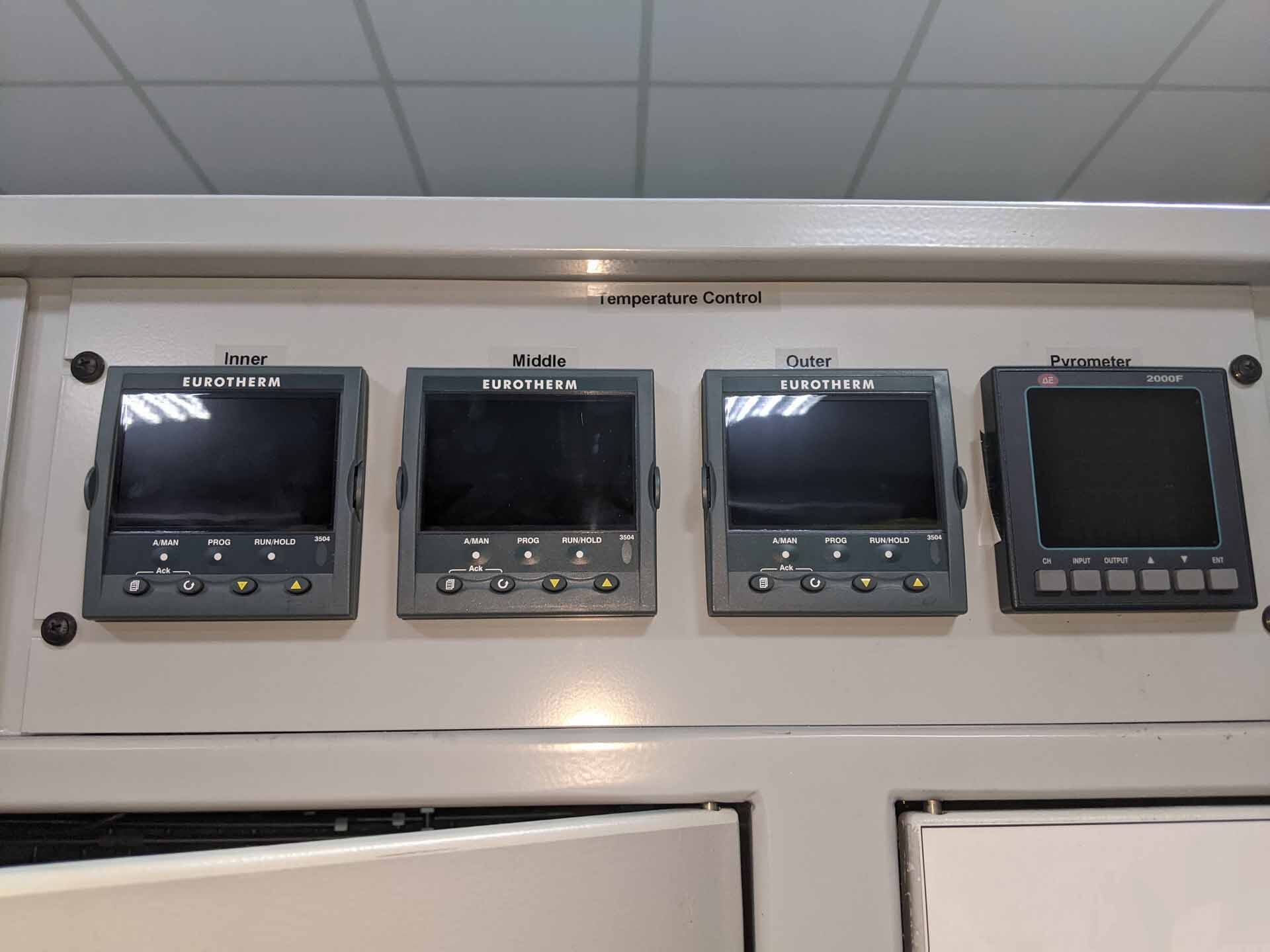

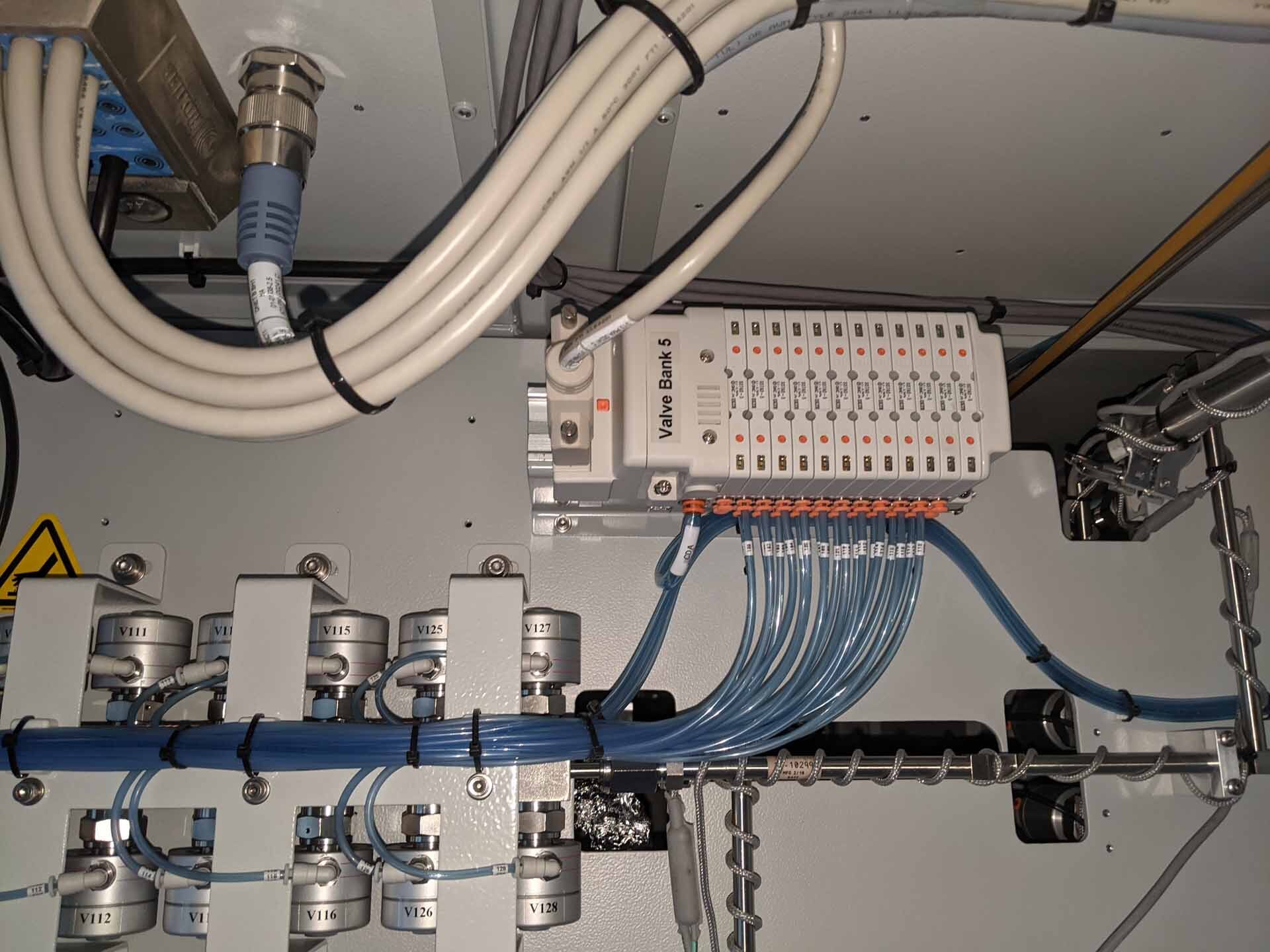

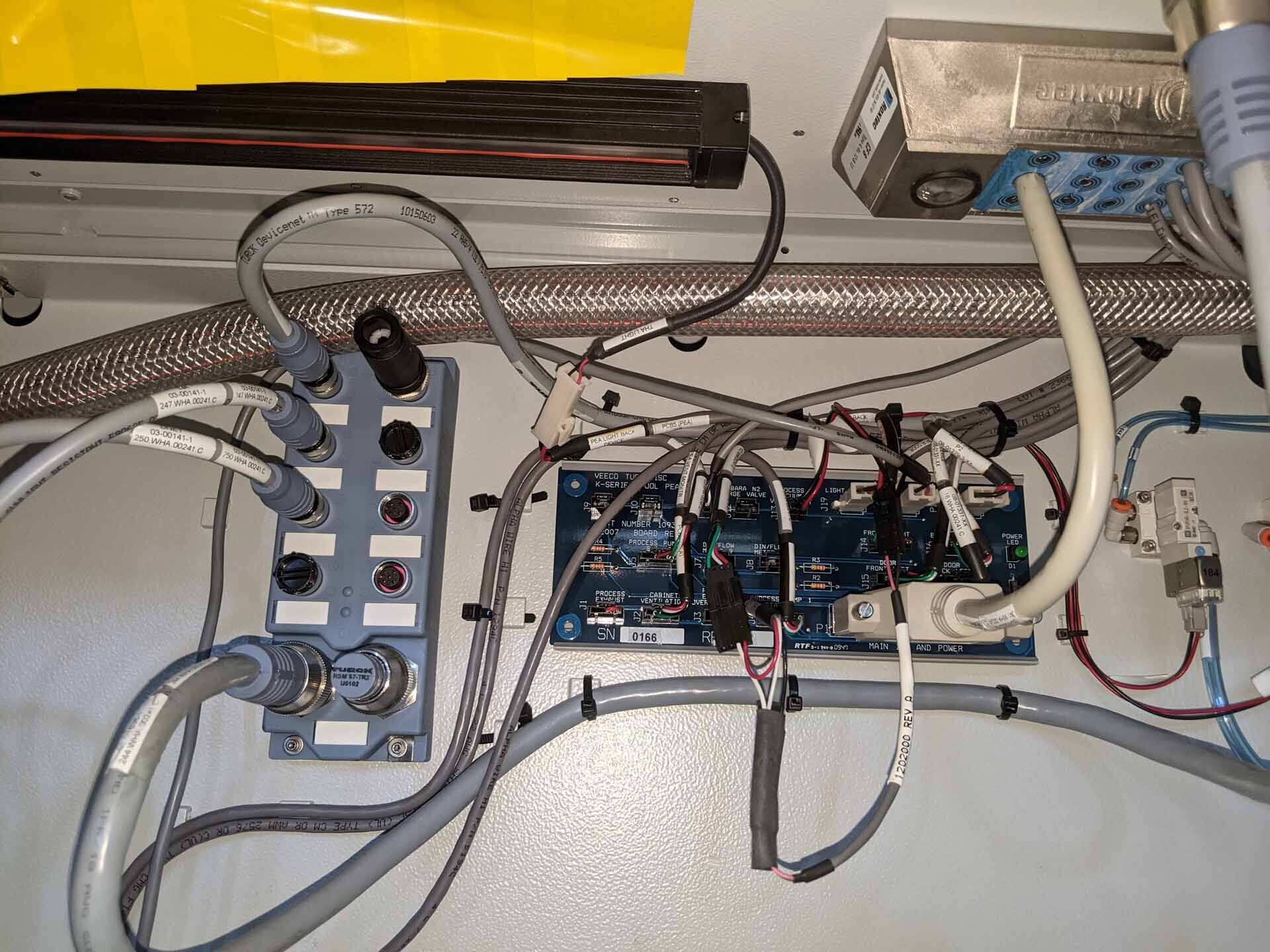

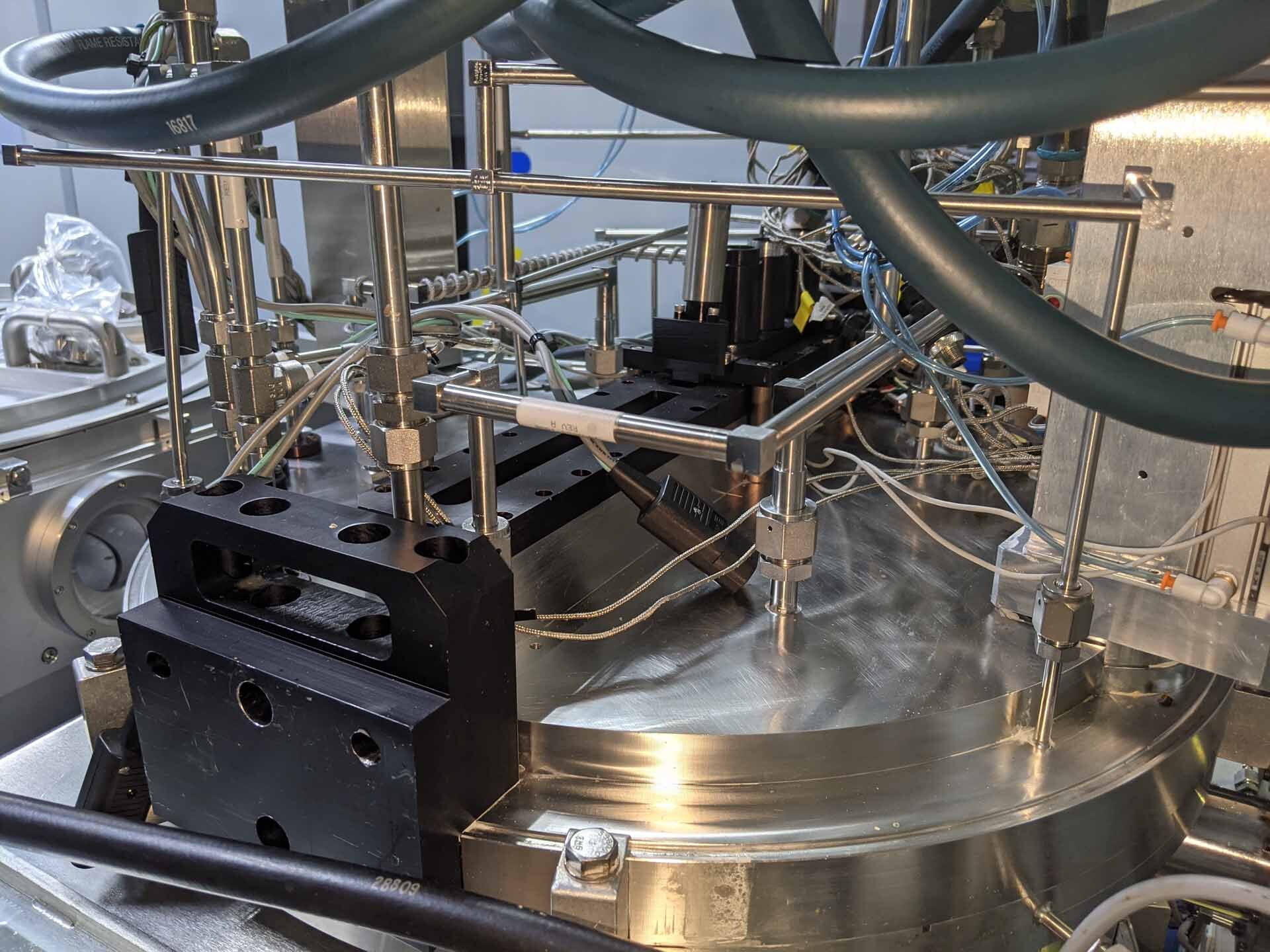

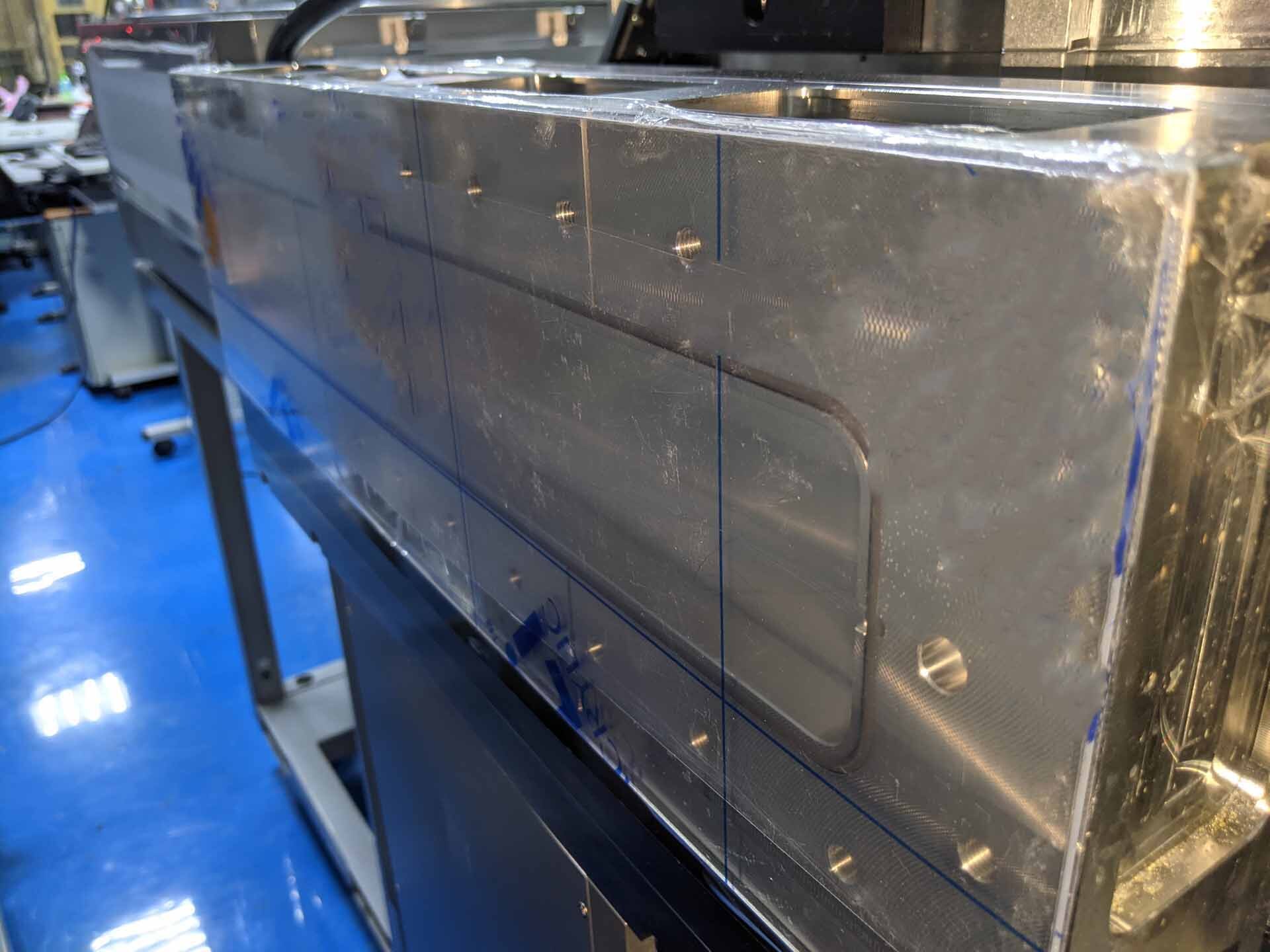

VEECO / DEKTAK K 465 I is a reactor equipment specifically designed for complete processing of substrates. It offers excellent control over the deposition parameters and enables efficient step coverage and uniform film deposition over large areas. It provides superior substrate uniformity and superior manipulation performance while working in the 48 mm X 48 mm work area. The reactor is ideal for growing single, multi-layer and alloy films at nanoparticle scale. The system is designed to meet the needs of a wide range of industries including semiconductor, research, and general laboratory applications. It can be used for processes such as physical vapor deposition (PVD), low temperature oxide deposition (LTO) and chemical vapor deposition (CVD). It also has the capability to simulate a variety of oxide and nitride profiles. The reactor includes a baseplate and a sample holder, a quartz viewport, a spatial distribution port, a shutter, a vacuum unit, an exhaust valve, a growth rate monitor, a sample holder power supply, and a cooling fan. All these components work together to achieve the desired results. Furthermore, the machine is designed with a high-efficiency mechanical shutter, which can reduce the effects of atmospheric air on the tool, resulting in increased accuracy and uniformity of results. The asset is based on a two-tiered approach with a "light chamber" and a "strong chamber". The "light chamber" is the shallowest chamber and has a high chamber pressure, allowing uniform and controlled batch processing with low growth rates. The "strong chamber" provides an increased level of control over the deposition process and allows for uniformity of the layers. By using multiple growth rates and different chamber configurations, the model is able to achieve superior results with step coverage, uniformity and film quality. VEECO K 465 I reactor is also designed with a sample holder power supply, allowing for accurate control of temperature and growth time. The equipment includes a multi-zone control interface, allowing for precise manipulation of deposition parameters. Furthermore, the system is designed with an on-board diagnostic unit, which allows for easy troubleshooting of the machine and its components. Overall, DEKTAK K465I is a sophisticated and advanced reactor tool designed to meet the needs of a wide range of industries and applications. It provides excellent control over substrate processing and ensures superior uniformity and performance. The asset can provide high-quality results with step coverage and uniform film deposition and is designed to meet the most exacting of industrial requirements.

There are no reviews yet