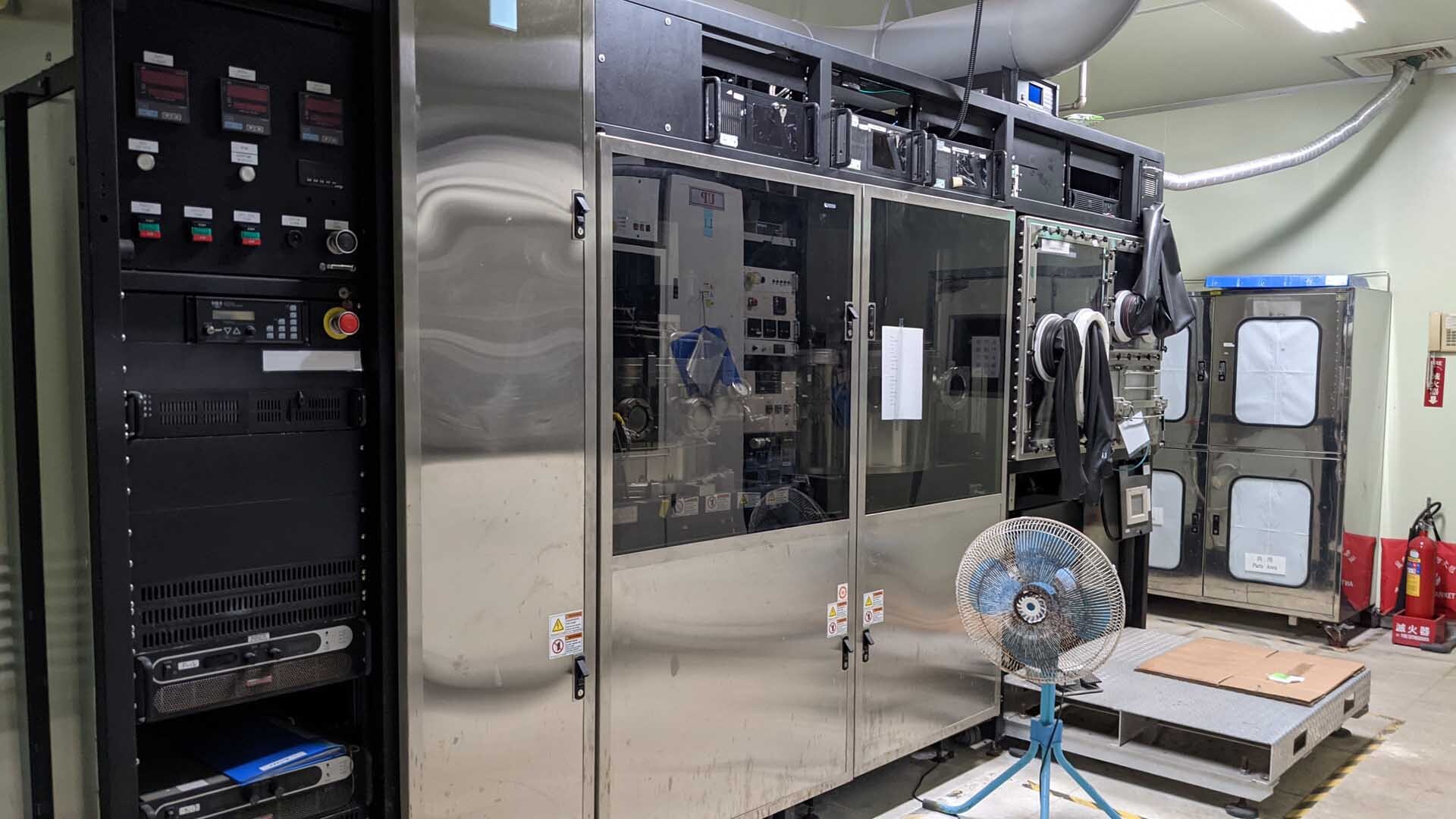

Used VEECO E475 #293641836 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

VEECO E475 Molecular Beam Epitaxy (MBE) equipment is a state-of-the-art molecular beam epitaxy deposition system that enables researchers to perform molecular beam molecular-beam epitaxy (MBE) of thin films for a variety of applications. The unit is capable of introducing multiple beams of atoms and molecules to a substrate surface in a very precisely controlled manner, allowing the deposition of layers in multi-layer structures typically used in the fabrication of semiconductor and optoelectronic devices. E475 machine features a 1000 amu (= 1.67 x 10-27 kg) molecular beam reactor, a turbomolecular pumping tool, a differential pumping asset, eight high current thermal evaporation sources and a variety of vacuum gauges and sensors. The deposition chamber holds two rotation stages, and temperature options of up to 2000°C (3632°F) and a variety of substrates such as single-crystalline substrates, wafers, and nano-ball arrays. VEECO E475 provides a large number of process parameters and can be remotely programmed for in-situ processing and off-line analysis. The high-current thermal evaporation sources in E475 model provide uniform and repeatable deposition of a wide range of materials onto many different substrates with high temperature stability and control. These sources offer variable temperatures up to 2000°C (3632°F) with a precision of 0.01°C (0.18°F). The systems' differential pumping equipment provides a very high level of vacuum performance, enabling the parameters to be maintained with little fluctuation. VEECO E475 system also features a quartz crucible that is designed to contain a maximum mass of 8 g at 2000°C (3632°F). The quartz crucible is specially designed to minimize the re-evaporation of materials that can occur due to sudden changes in temperature. The material produced in E475 unit has low temperature wide-bandgap materials such as carbon nanotubes and polycrystalline films. The aspect ratio of the films can be varied from 1 to 10 and can be obtained with a minimum aspect ratio error of 1%. All the components used in VEECO E475 MBE machine are housed within a stainless steel cabinet that is equipped with air conditioning, dehumidification and a nitrogen purge for maintaining temperatures. It also includes a remote control via Ethernet for easy monitoring and vibration reduction. It also includes safety sensors to reduce the possibility of accidents. In conclusion, E475 Molecular Beam Epitaxy (MBE) tool is an advanced asset that allows for fast, precise and repeatable deposition of thin-film material layers. Its processes can be used for applications in the semiconductor and optoelectronics industries. It features a wide range of features and functions that provide robust, reliable and accurate deposition results.

There are no reviews yet