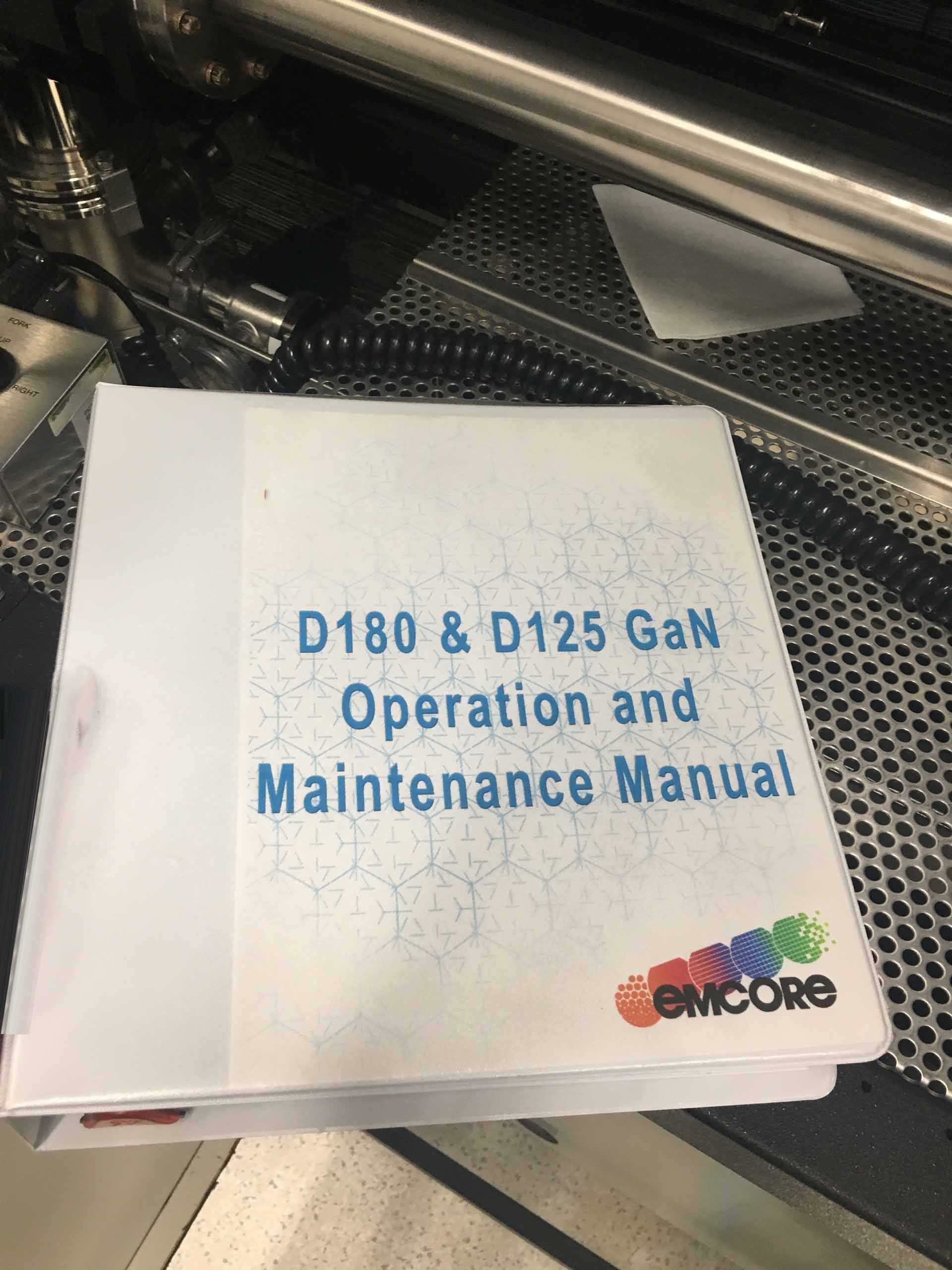

Used VEECO / EMCORE D125 #9212026 for sale

URL successfully copied!

Tap to zoom

ID: 9212026

Vintage: 2003

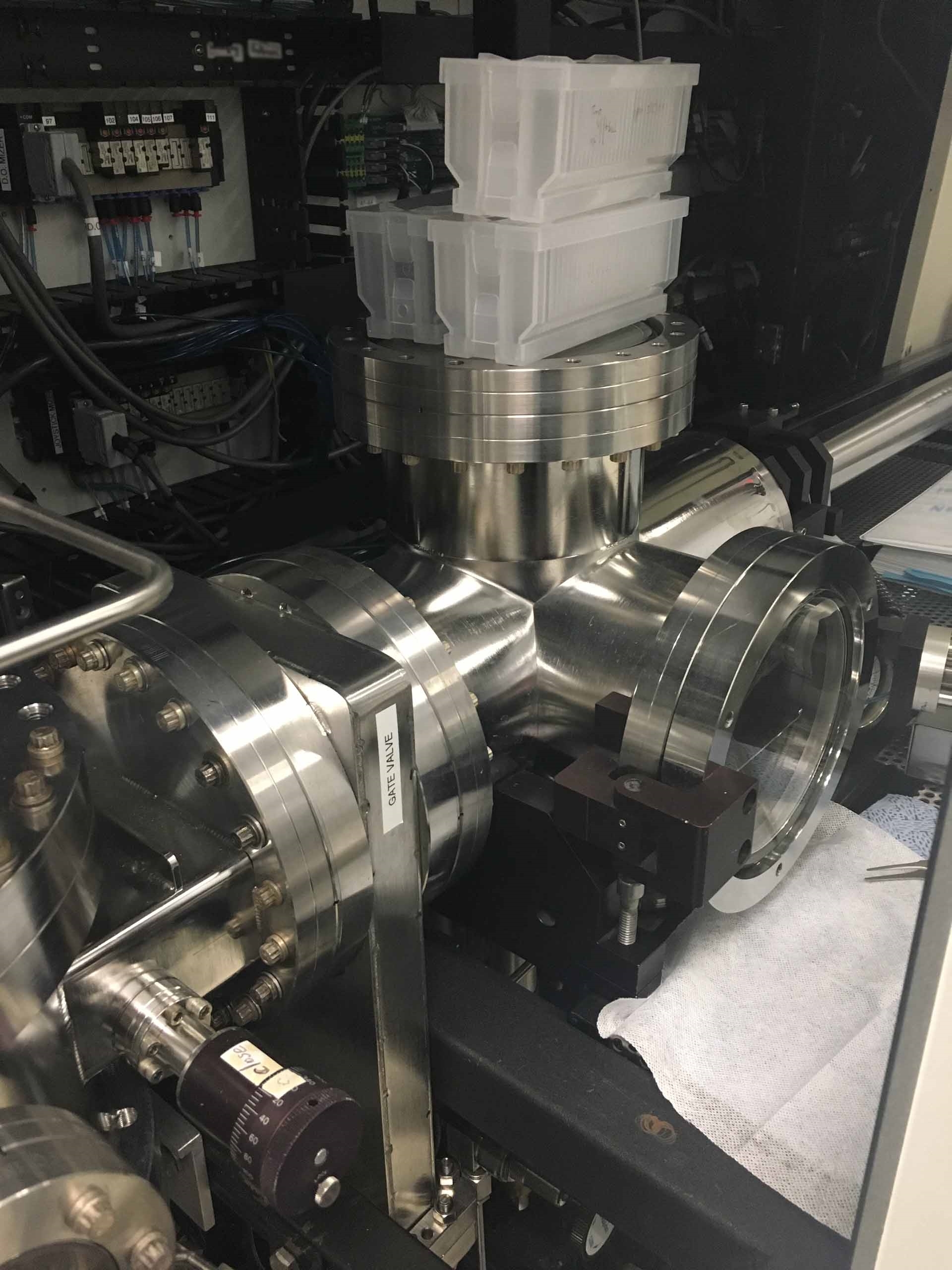

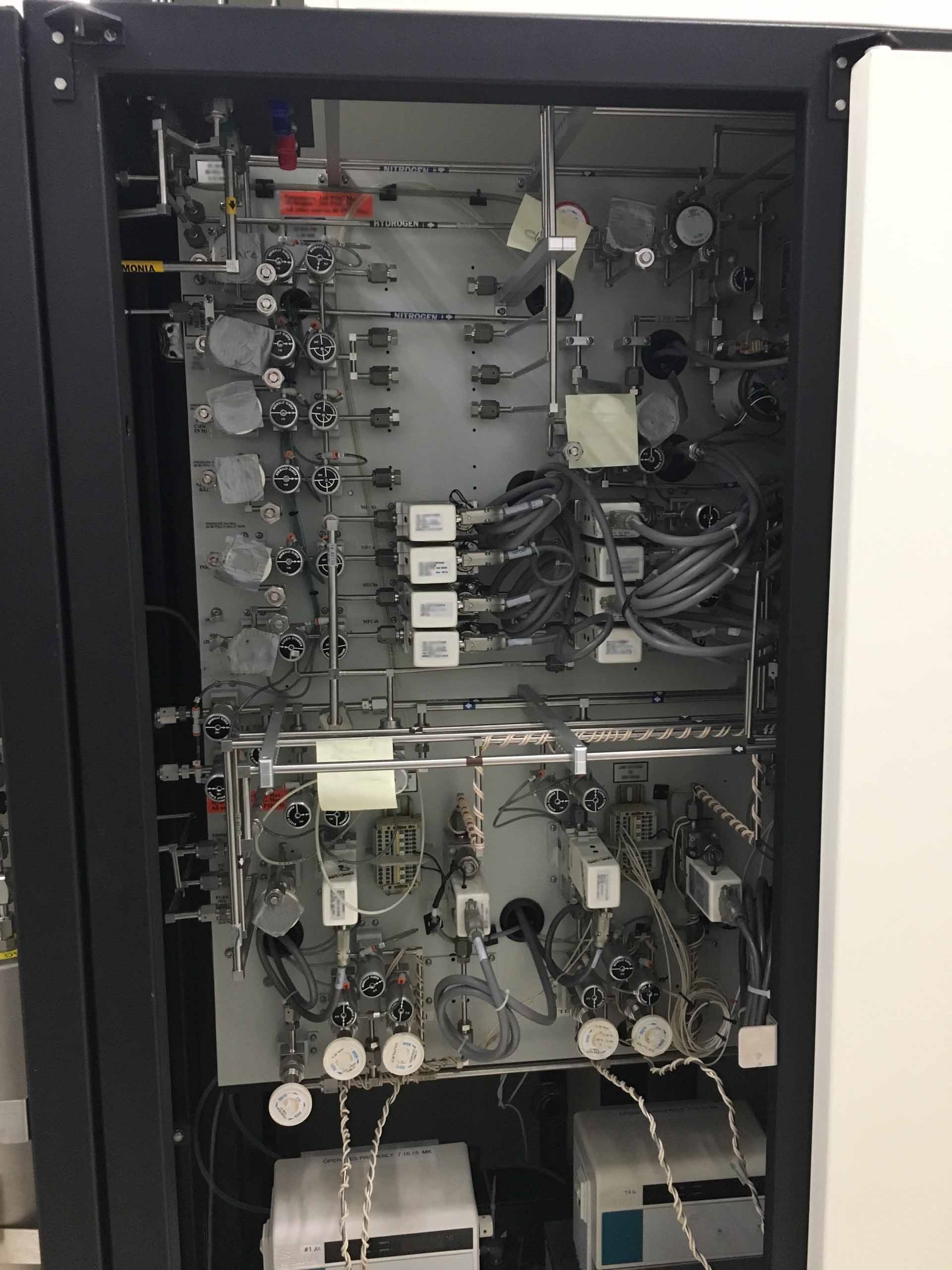

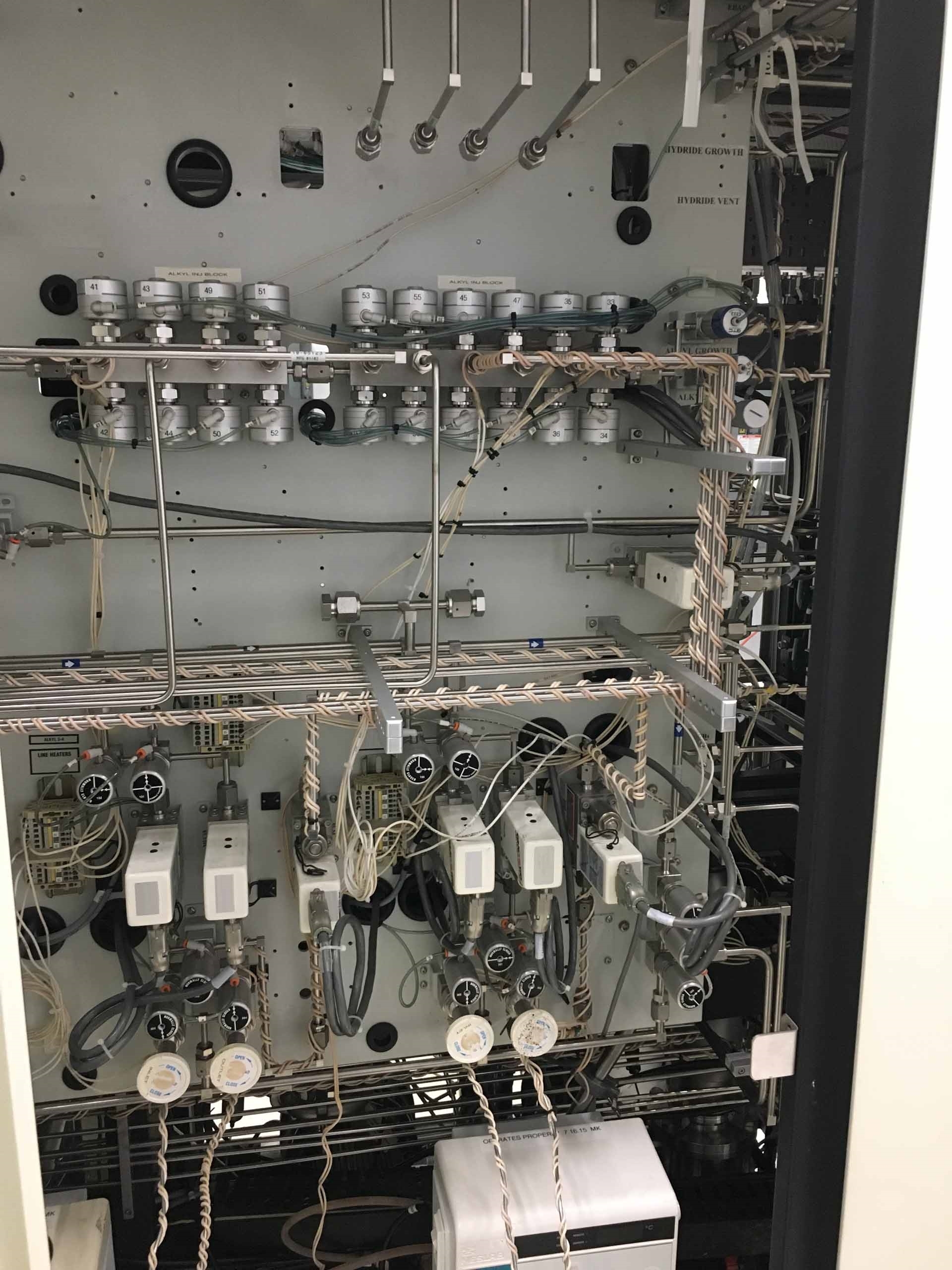

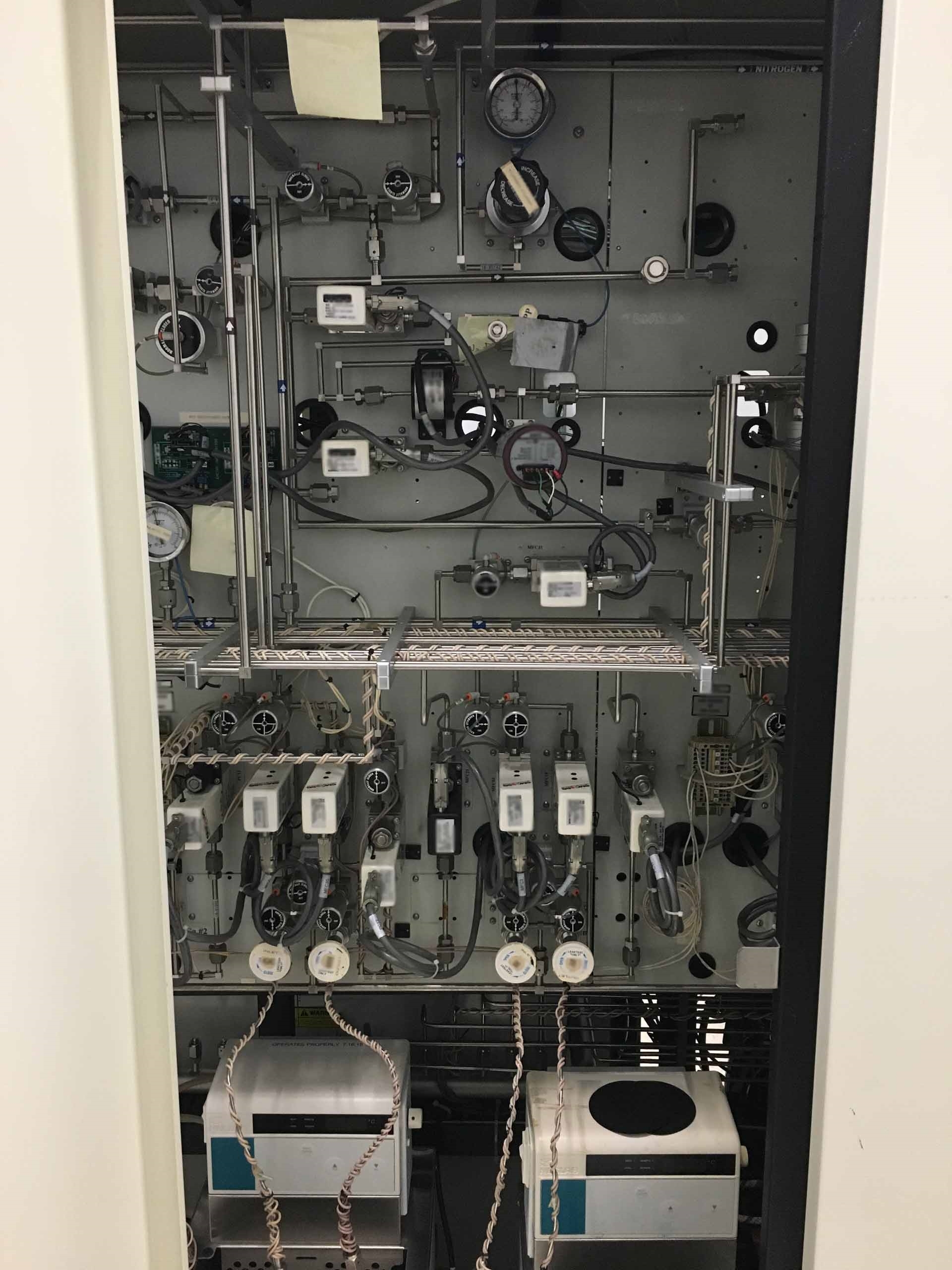

MOCVD System

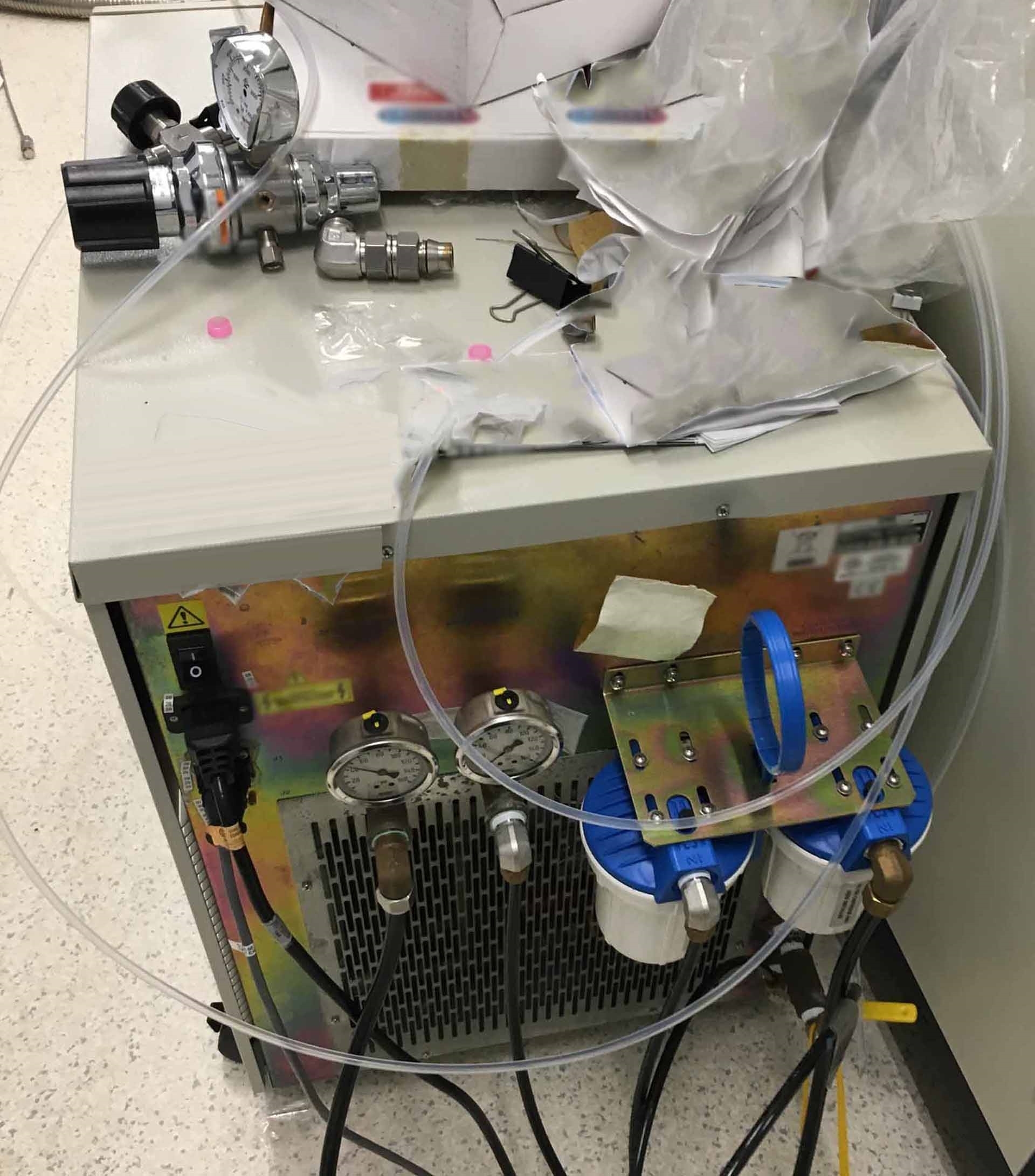

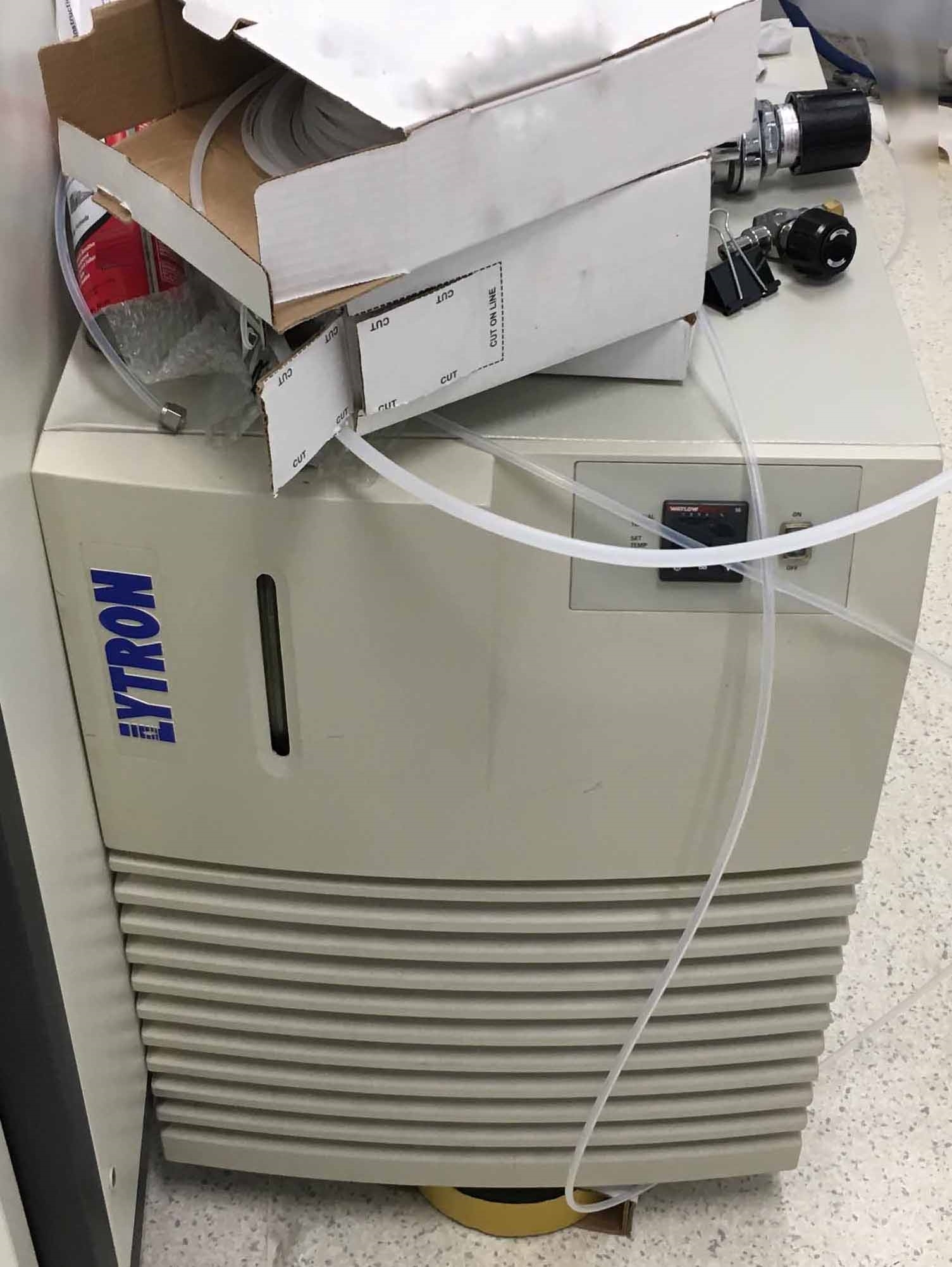

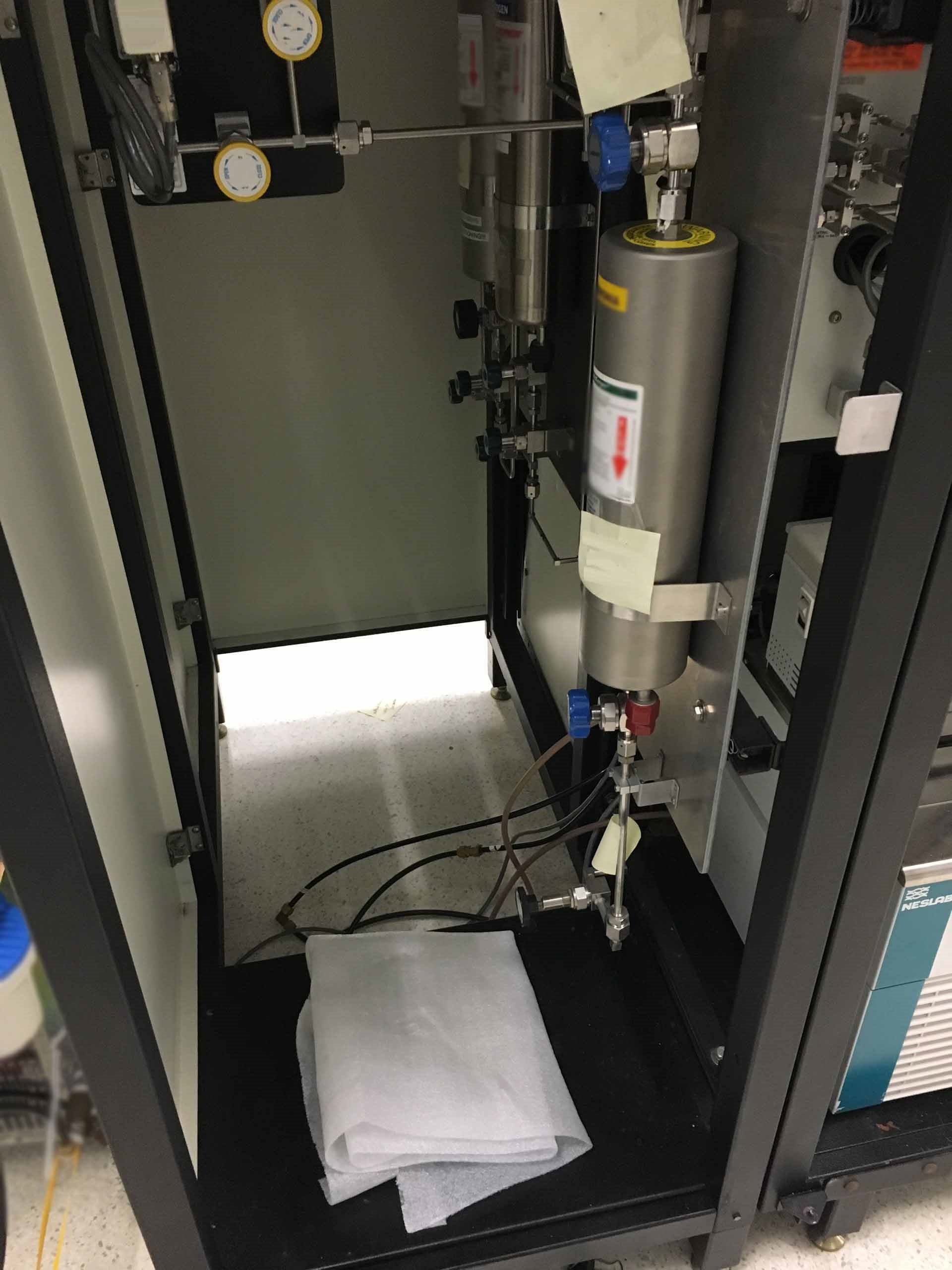

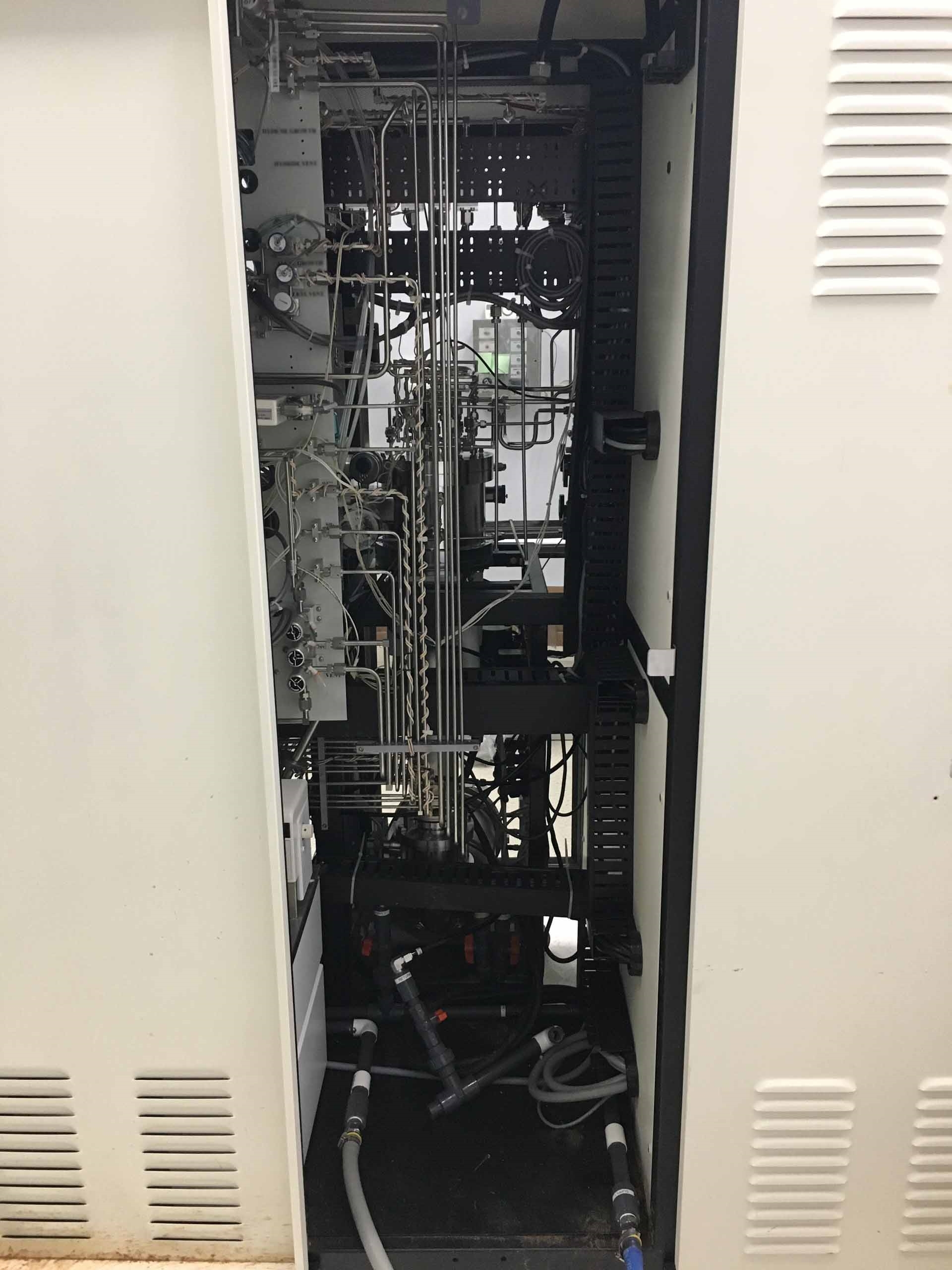

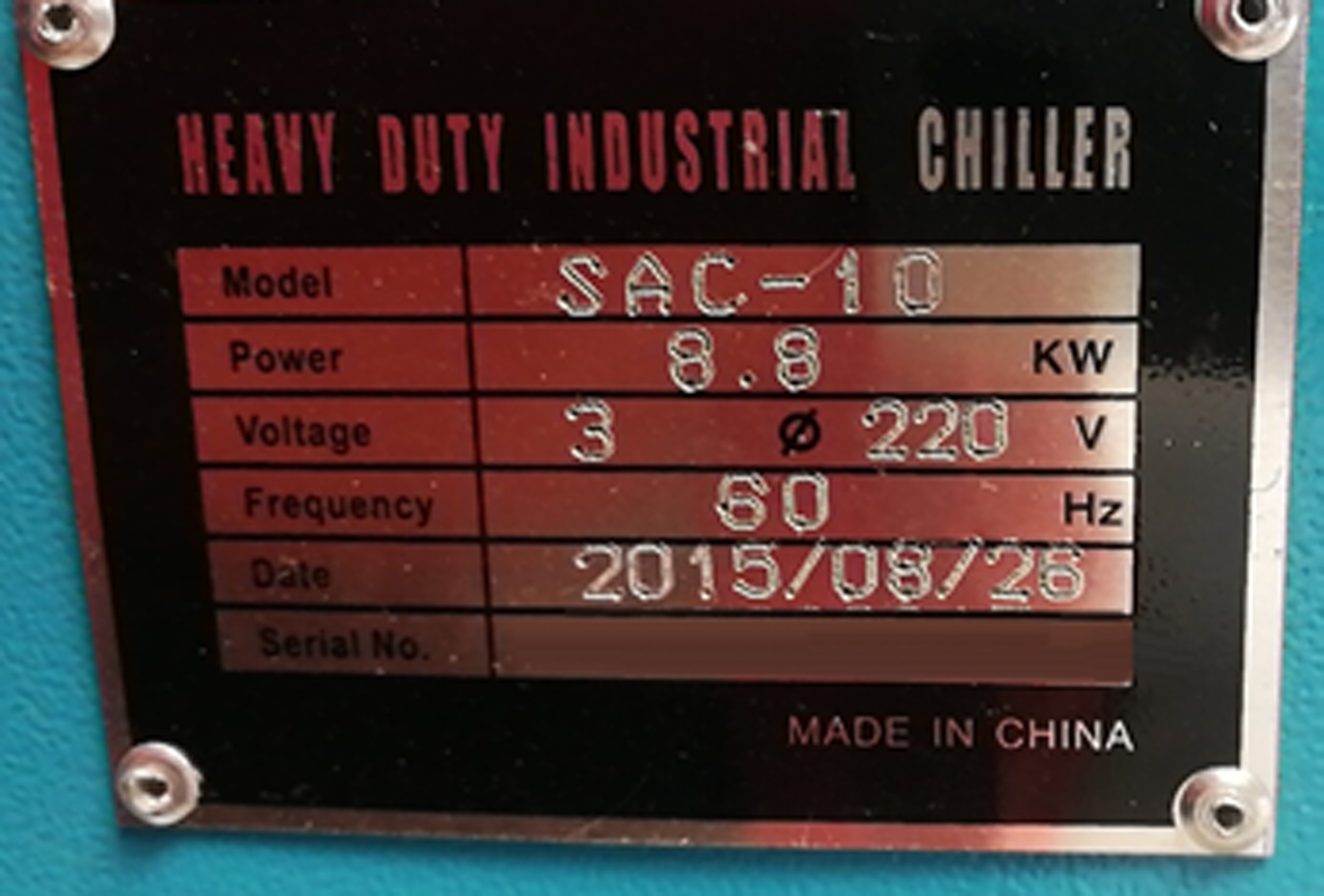

(2) Chillers

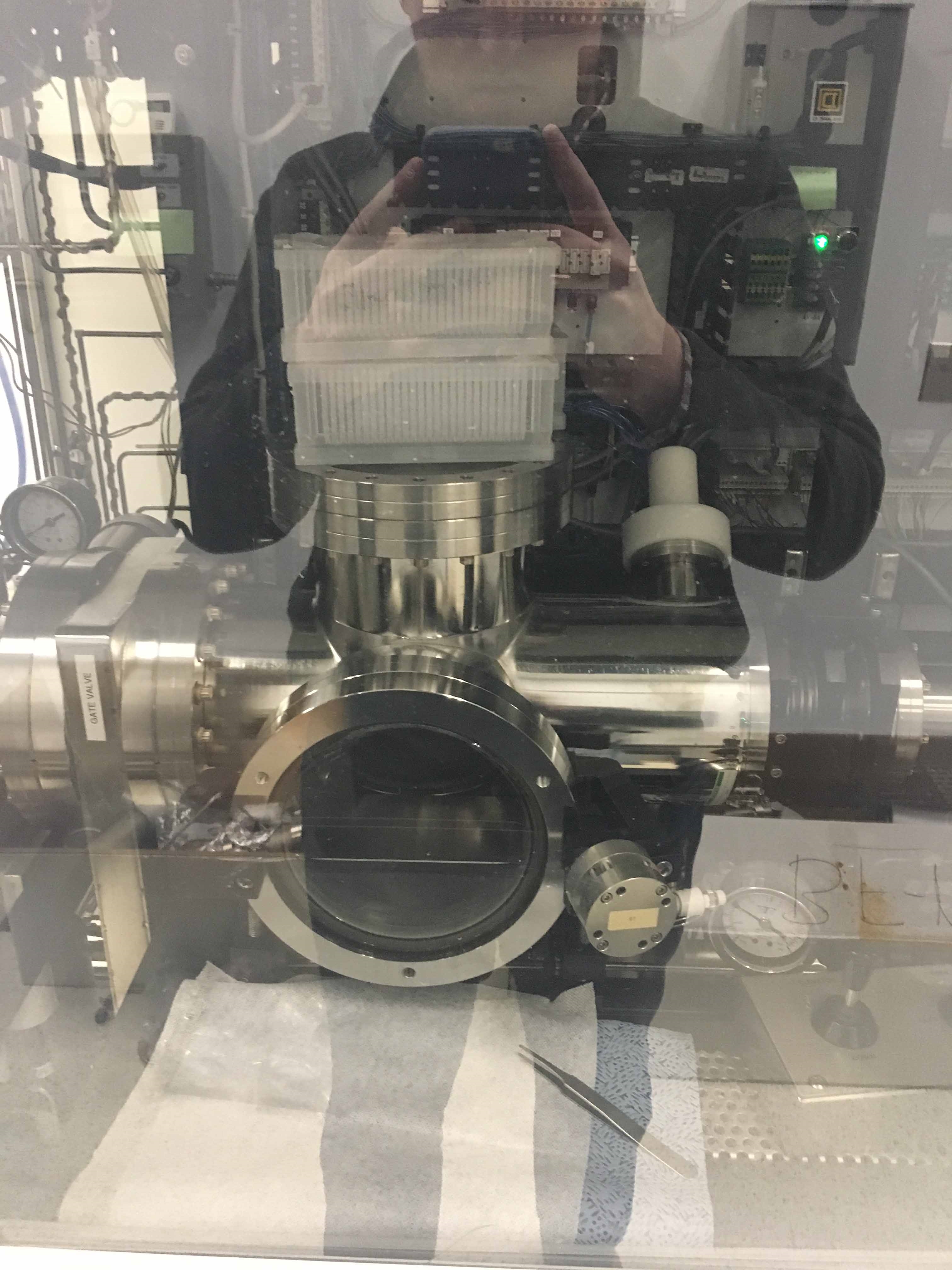

Semi-automatic wafer transfer

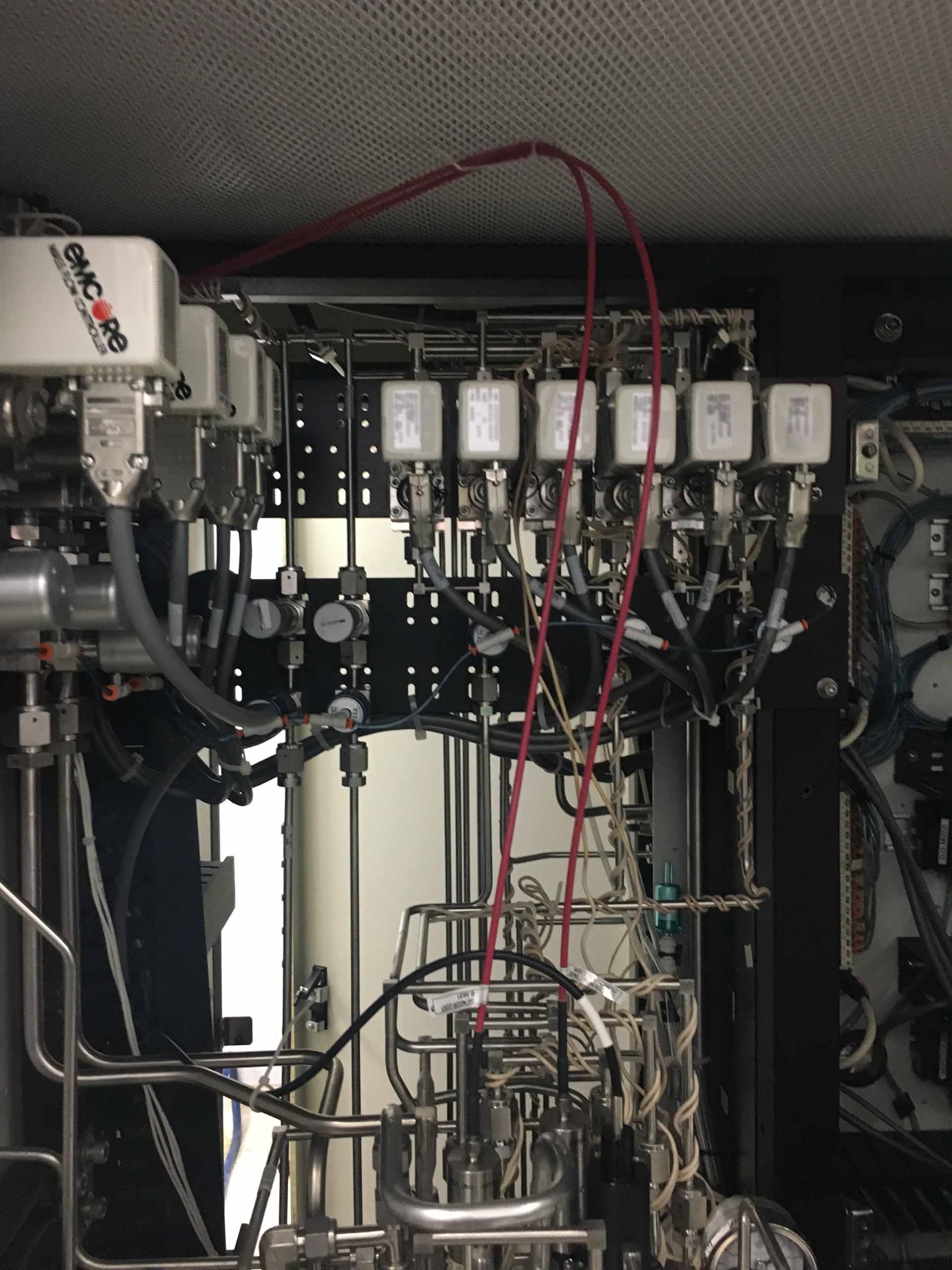

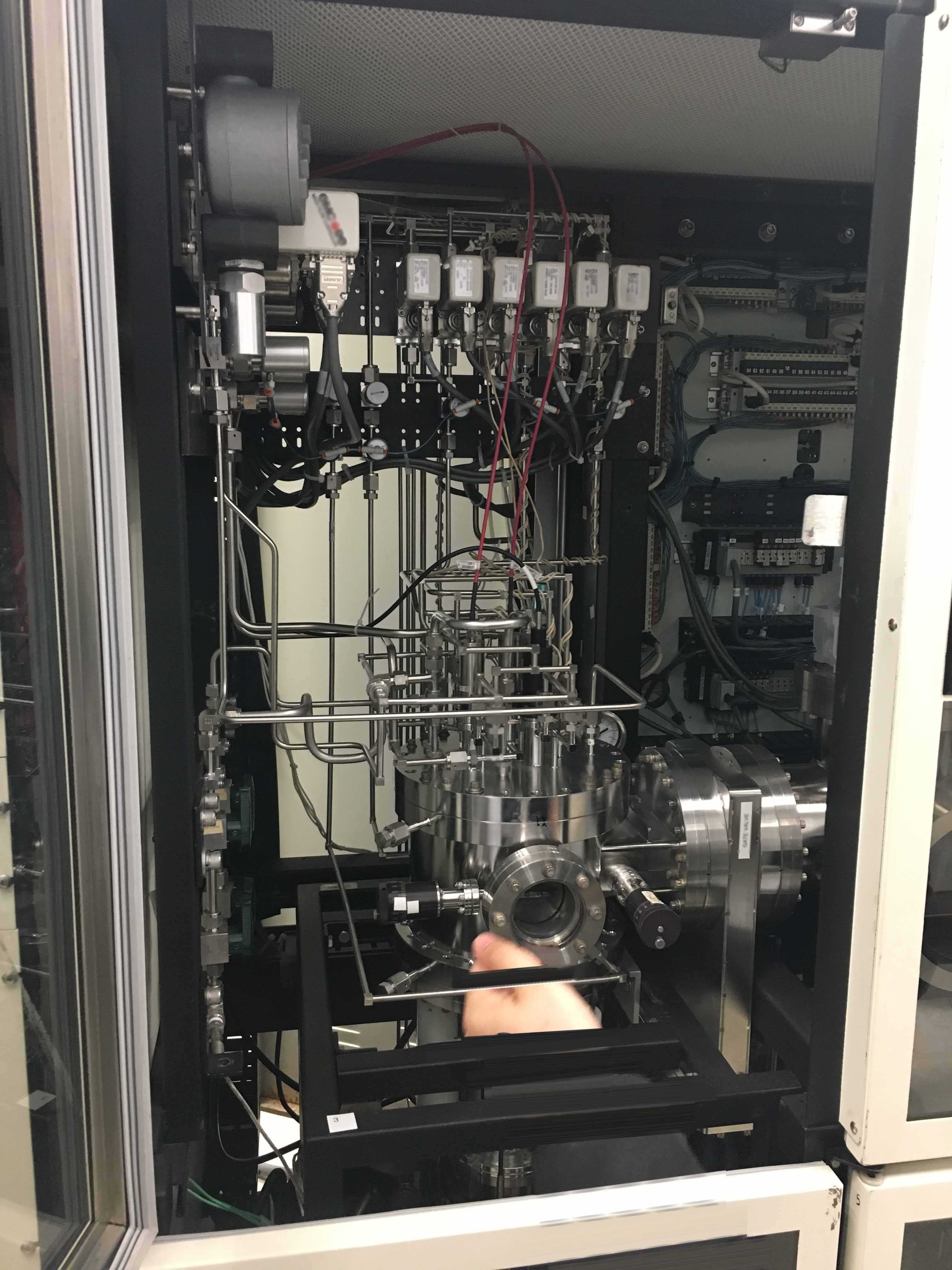

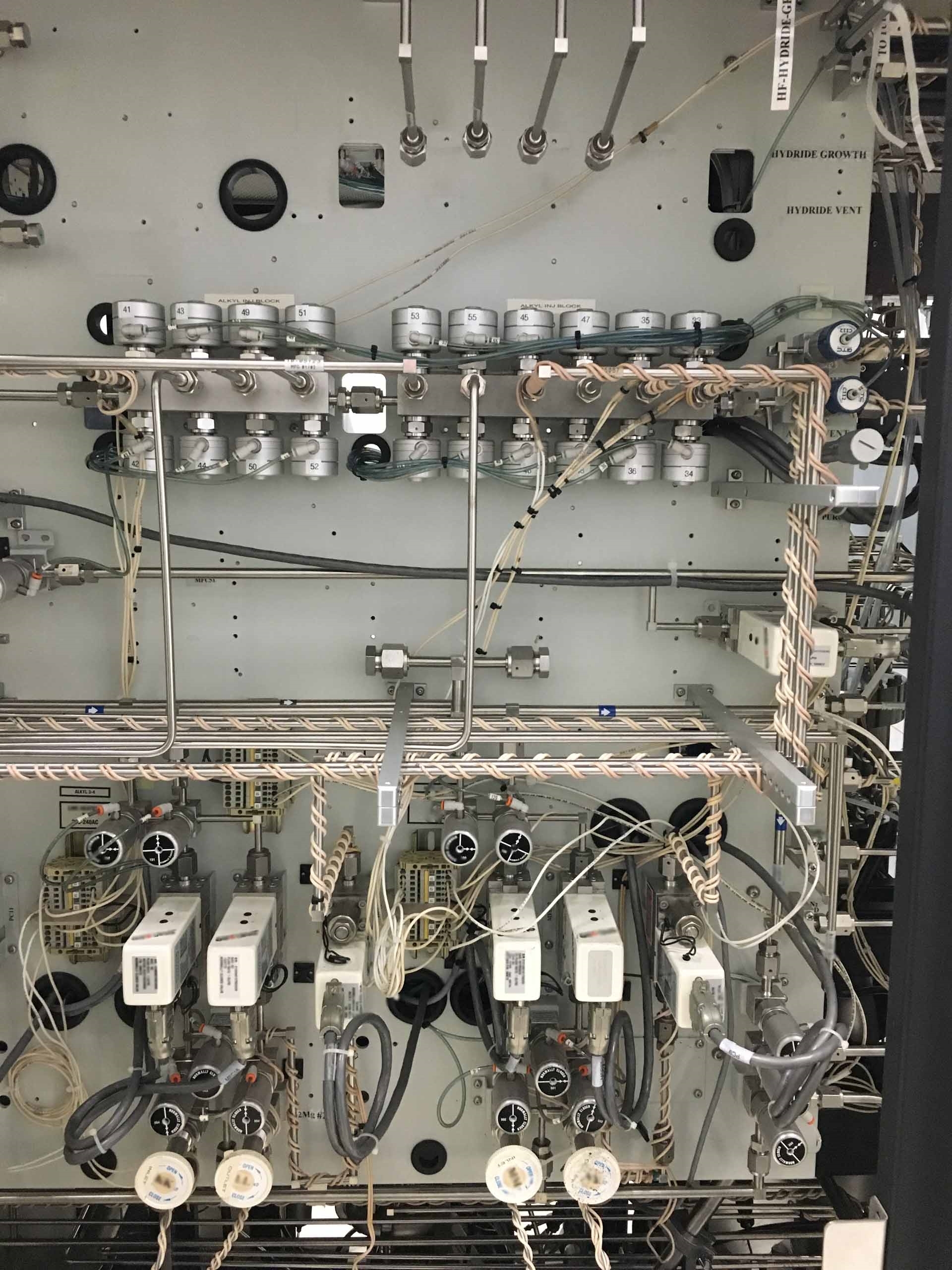

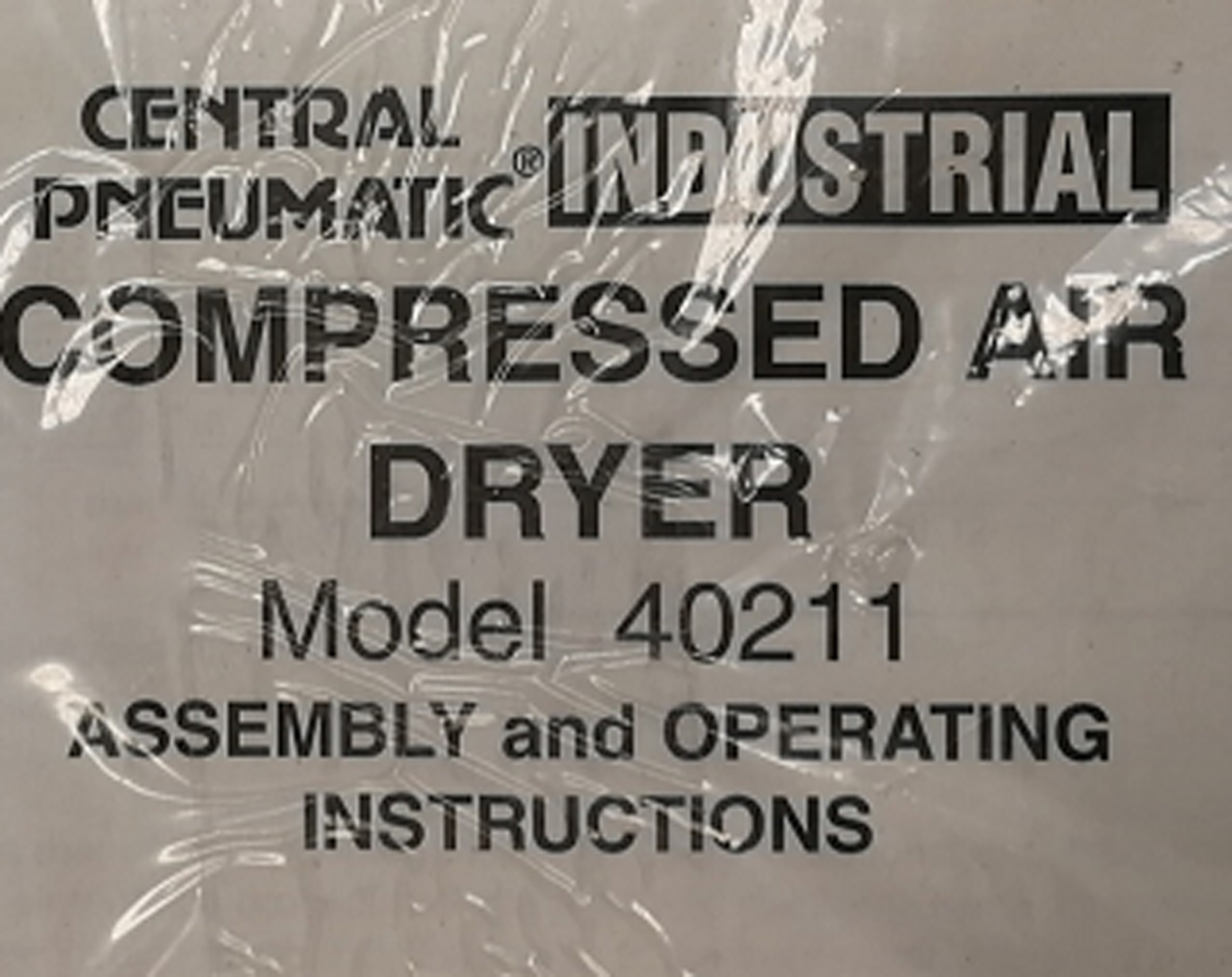

Gas delivery system

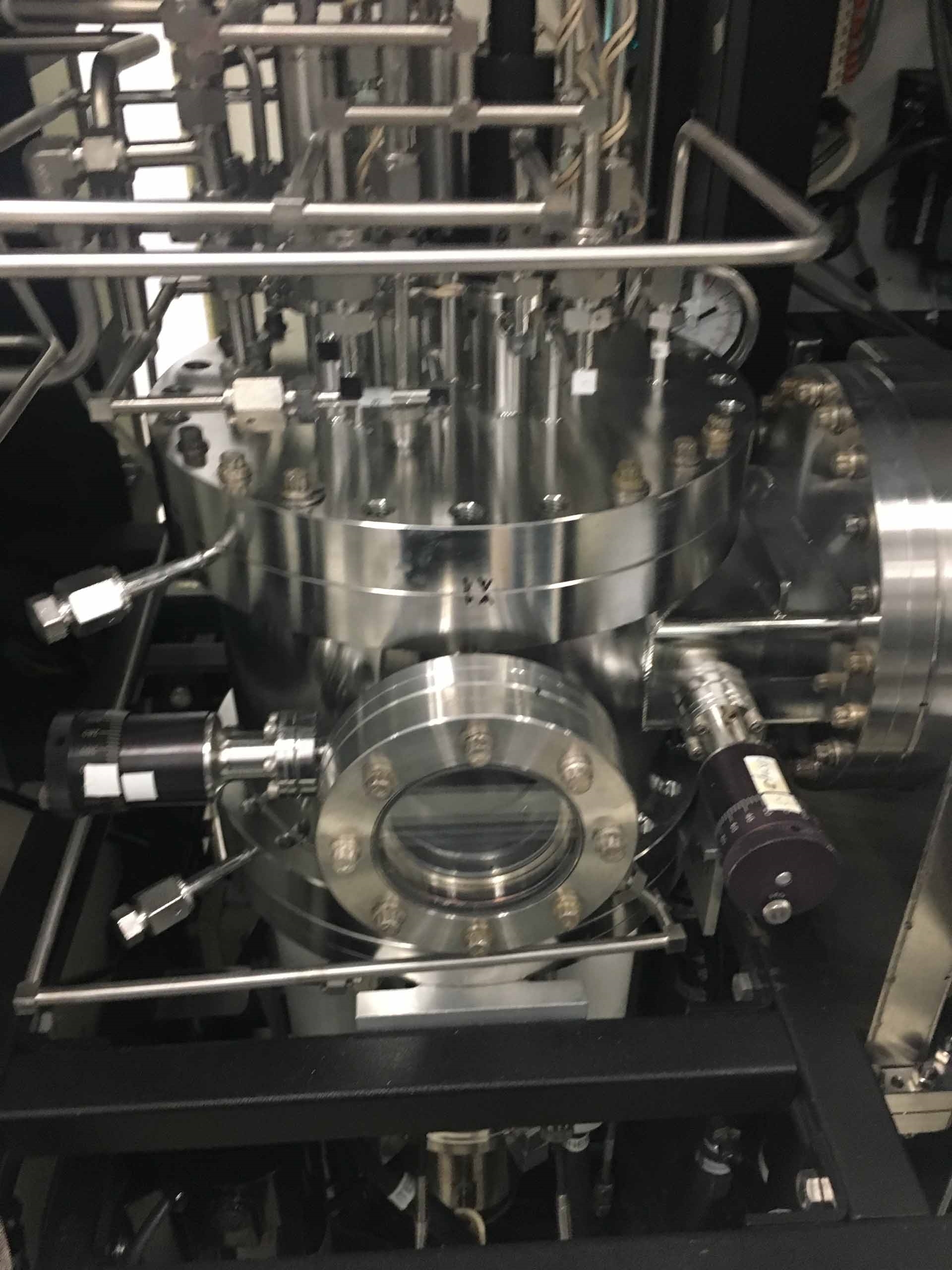

Flanges constructed of 316L stainless steel

Reactor & gas panel: With exhaust vented steel & polycarbonate cabinet panels

HEPA Filtered wafer loading area

With system cabinet

7-8 Metal organic channels (Switchable from N2 to H2 carrier gas)

3-4 Hydride channels

Standard non-emissivity corrected pyrometer included

Up to 3 2"/1 3" wafers per run capability

(4) SiC Coated wafer carriers: (2) Standard 3 x 2" / (2) Custom configurations

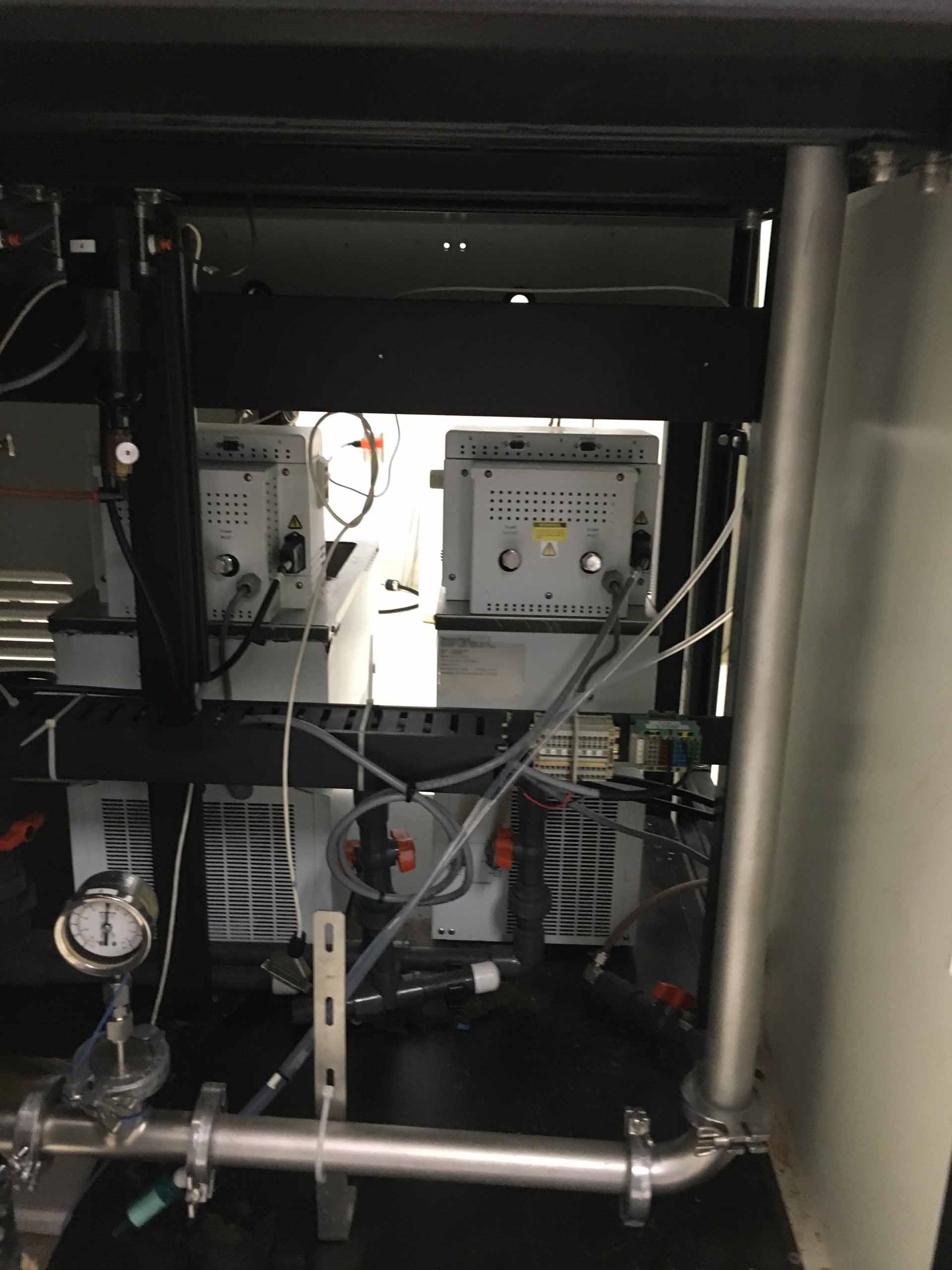

EBARA A70W Process pump

MKS Butterfly reactor exhaust line pressure control valve

With PID control

Turbo molecular pump / Scroll dry pump for load lock

CTC Controller with low noise analog card for T/C channel

MO & Hydride delivery SS lines

Heaters and controls

(5) MO Bath water chillers

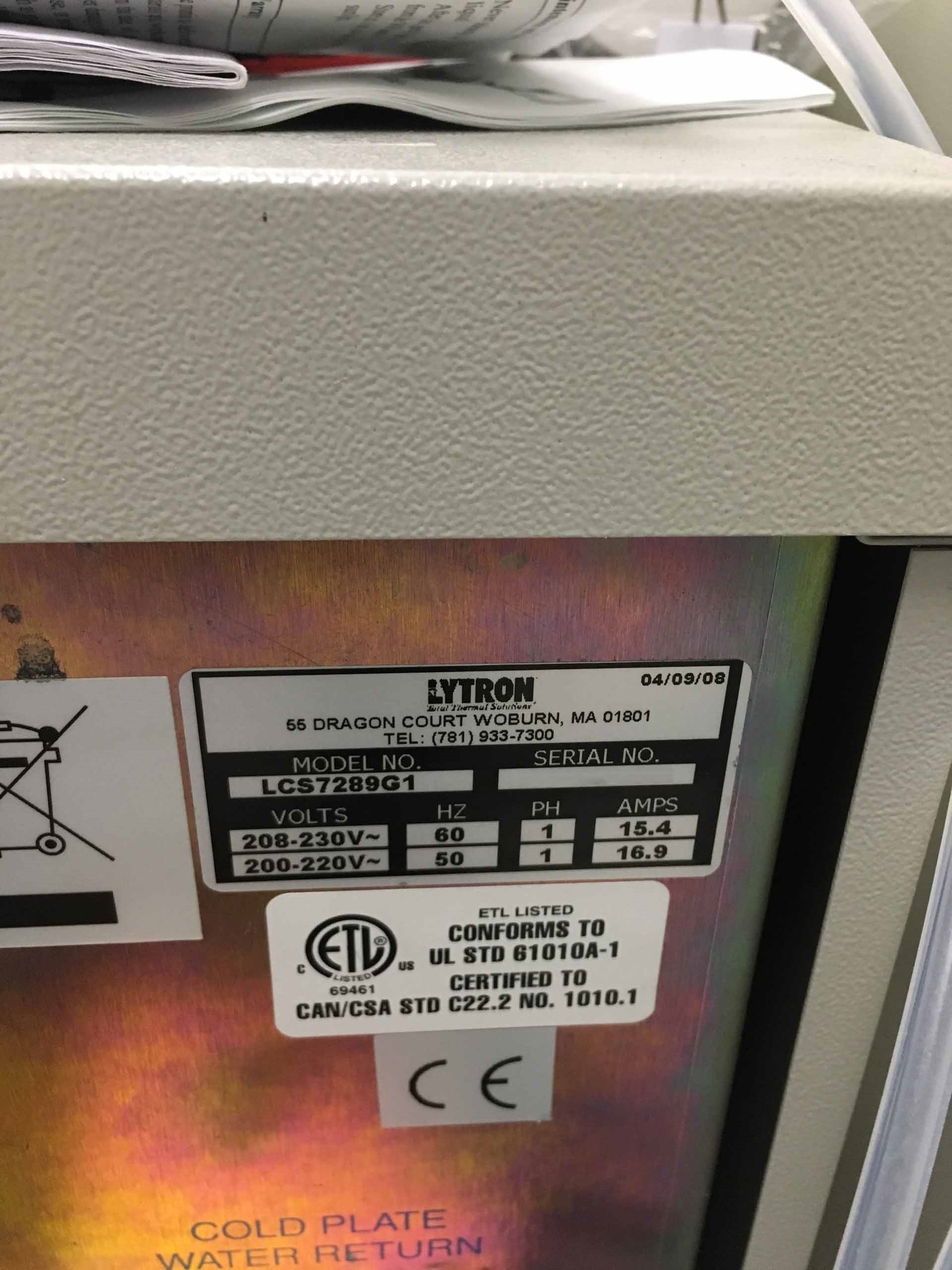

AFFINITY / LYTRON / Equivalent heat exchanger

Turbo rotation: 1500 RPM

Safety alarm system

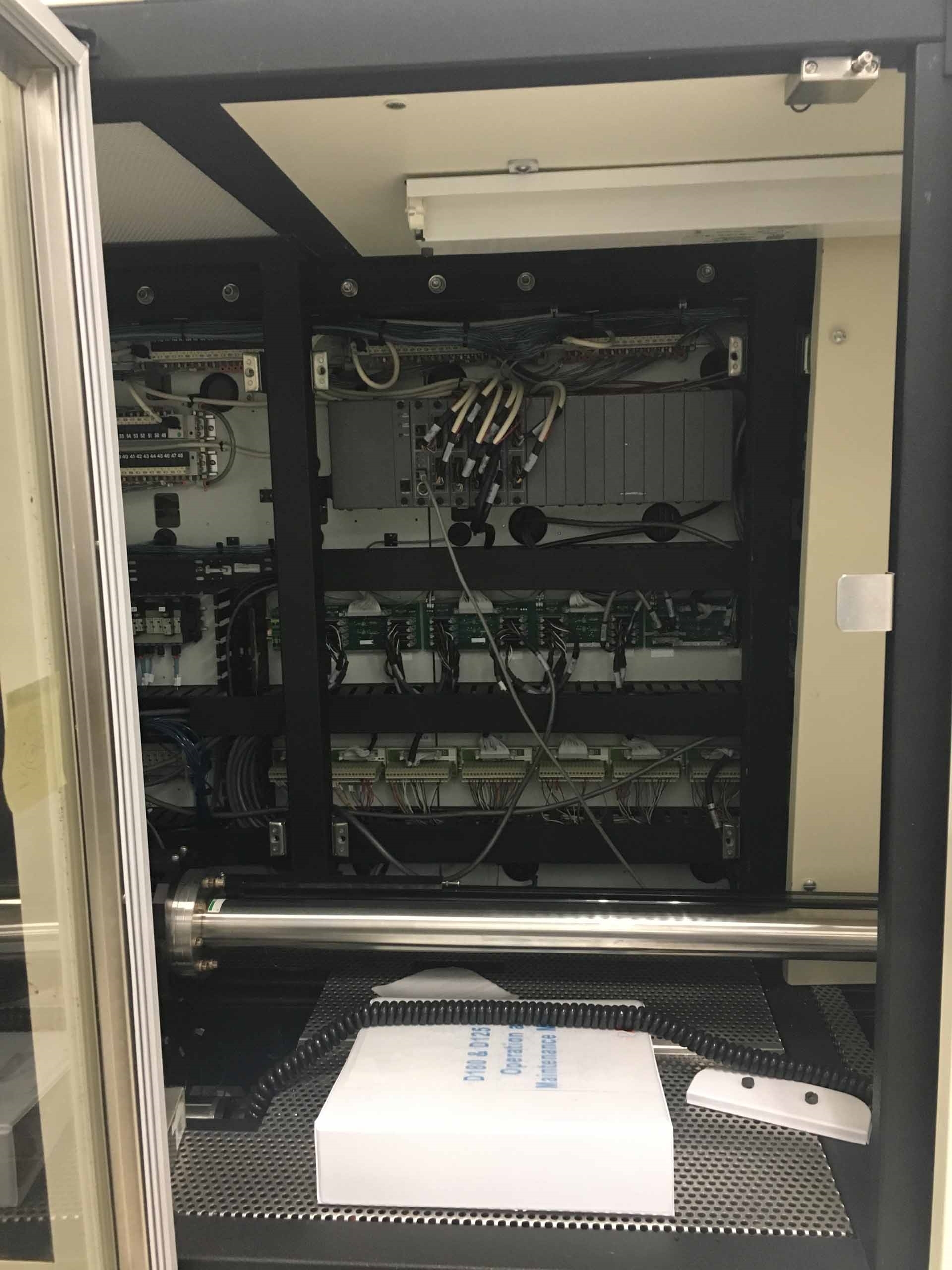

Control system:

Operating system: Windows 7

Personal computer (PC)

With flat panel monitor

Alarms

Routines provide unparalleled control system versatility

Spare parts:

(3) Analog cards

(2) Digital cards

(2) MFC

PCU

Baratron

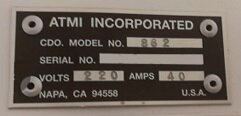

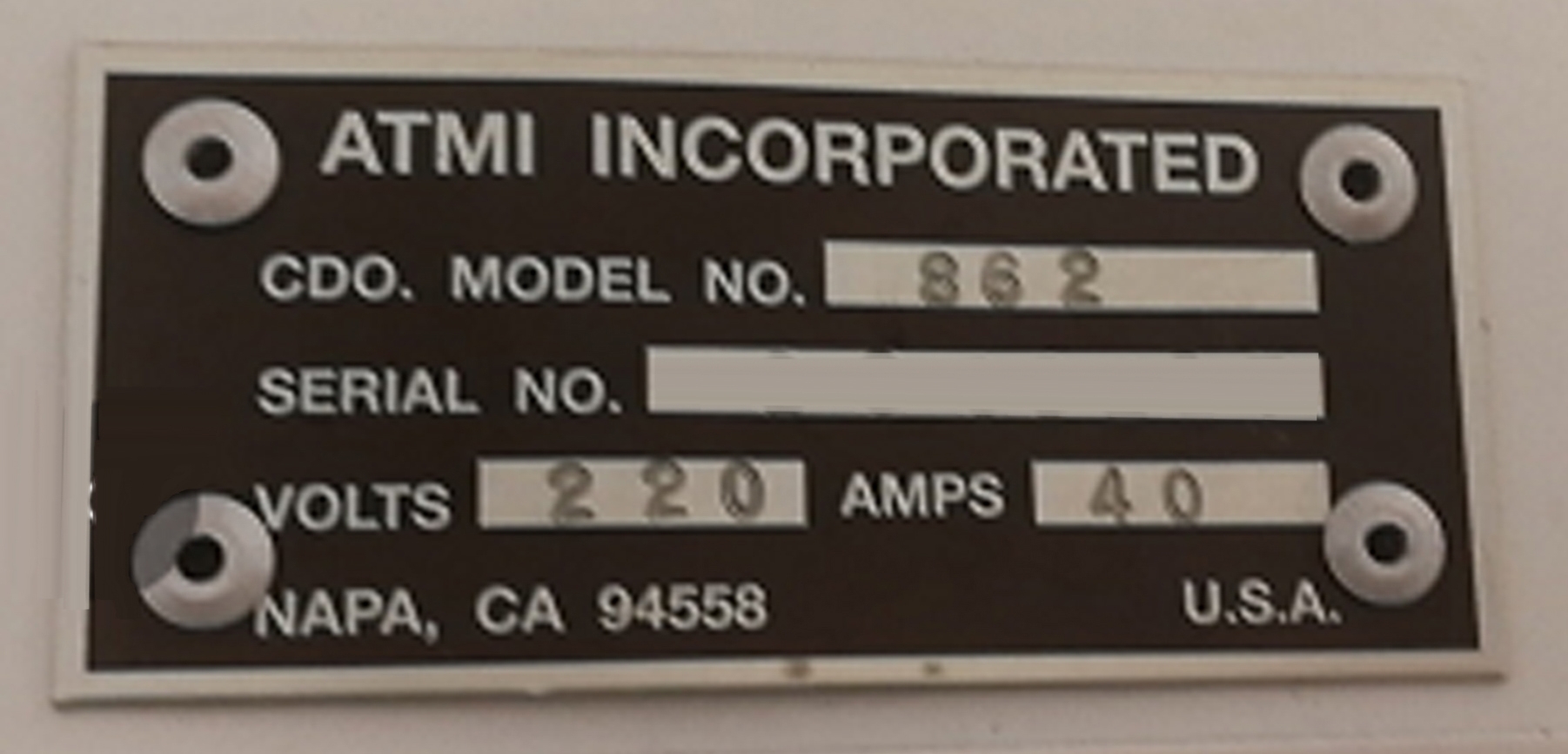

ATMI CDO 862 Abatement system

Combination scrubber and burn-box

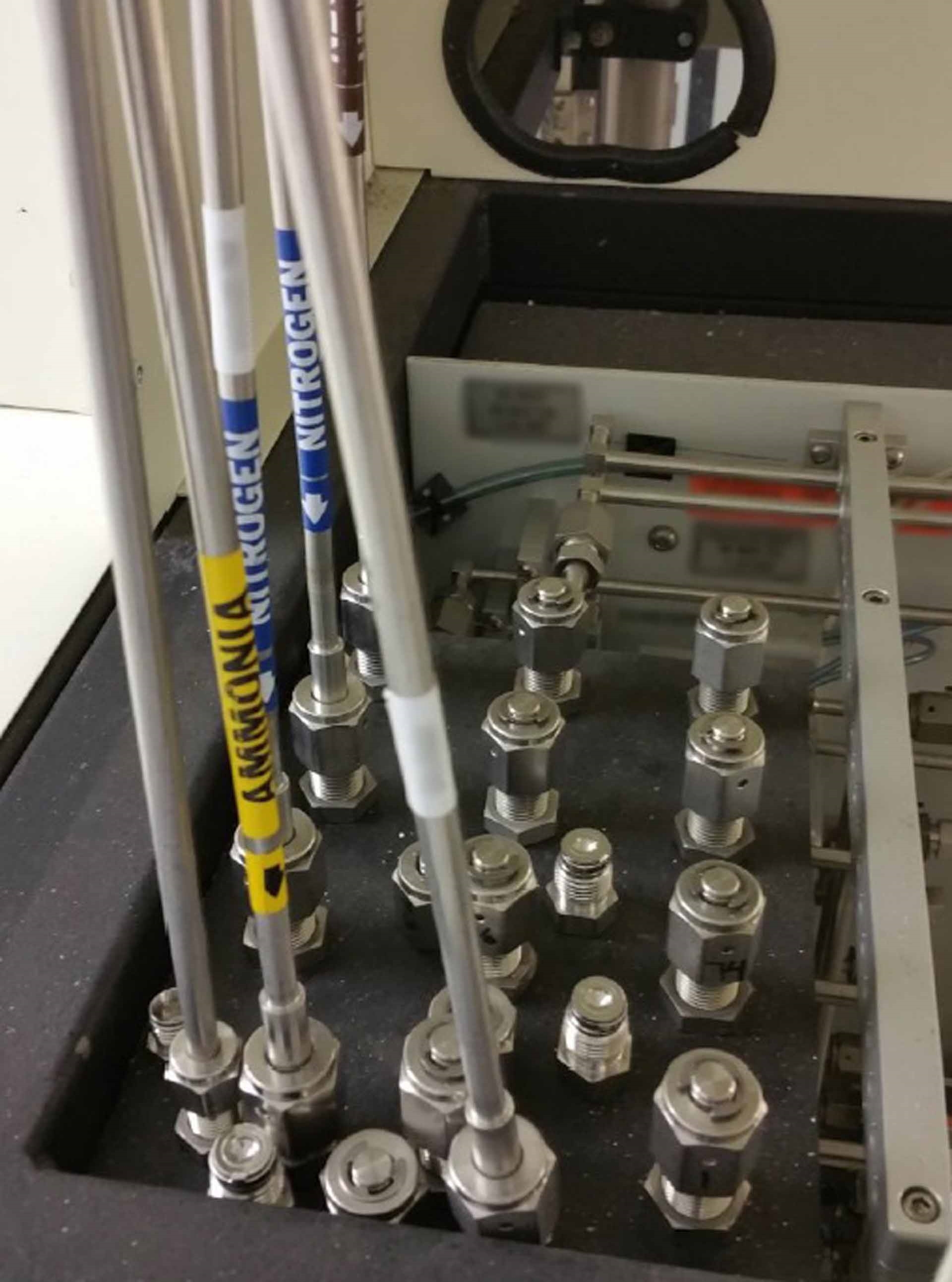

Nitride MOCVD precursors: NH3, H2, SiH4, MOs

Handling maximum D125/D180 gas flows (according to OEM specifications)

Scrubber water: Recirculated in loop

PRAXAIR (3) Bottles ULTRA PURGE ammonia gas cabinet

Internal gas network: ULTRA PURGE Controller

(2) 501b ammonia bottles

Does not include nitrogen purge bottle

Air products AP10, 24" silane gas cabinet

Touch screen controls

(2) SILANE Bottles

Indoor gas distribution panel for hydrogen and nitrogen:

Anodized aluminum: 3 ft. x 4 ft./ Smaller gas panel

Cylinder banks and nitrogen purge: Manifold with (2) hydrogen inlets

(2) Pressure regulators

(3) Check valves

(2) Inline particle filters

(8) Manual valves

High purify 1/4 inch tubing

Tees

Weldments (Orbital welding)

(2) Pressure gauges

Leak checking and certification of leak integrity

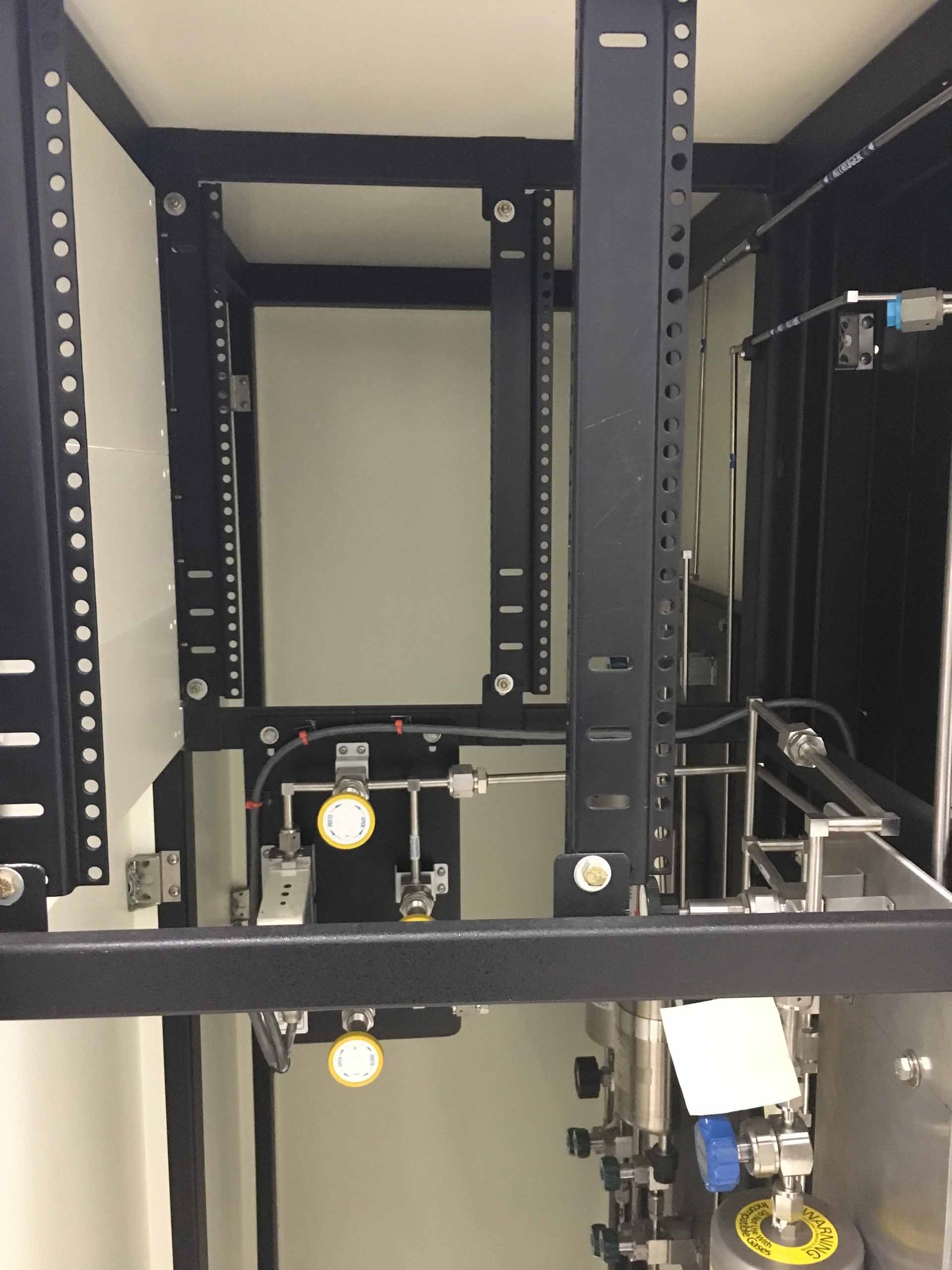

Outdoor gas distribution panel for hydrogen with nitrogen purging capability:

36 in x 9 in / Smaller anodized aluminum gas panel

Purging & switching manifolds for (2) six pack cylinders

Manual valves and (2) check valves

UHP 1/4 inch Tubing

Weldments (Orbital welding)

(2) Pressure gauges

Leak checking & certification of leak integrity

System electrical specification:

208 / 220V

50 or 60 Hz

3 φ 150 A per φ

5 Wire with GND

Gas supply specification

Type / Rating / Max flow / Mean flow

Purified H2 / 30-40-100 PSIG / 65 SLM / 30-40 SLM

Purified N2 / 80-100 PSIG / 70 SLM / 20-40 SLM

N2 House feed / 80-100 PSIG / 50 SLM / 25 SLM

CDA/N2 for pneumatics / 80-100 PSIG / 50 SLM / < 15 SLM

NHa / 40-60 PSIG / 30 SLM / -

100 ppm SiH« in UHP H2 / 20-30 PSIG / 22 SLM / -

2003 vintage.

VEECO / EMCORE D125 is a general-purpose reactor equipment designed to support advanced process development, academic research, and production-scale manufacturing operations. VEECO D125 integrates advanced hot-wall technology commonly used in heterogeneous catalytic processes and nanomaterial applications. The reactor system is specifically optimized to enable precise temperature, pressure, and residence time control, while also providing highest yield productivity for a wide variety of processes. The modular design of EMCORE D125 allows for custom configuration to best serve the user's application needs. It features an integrated heated-wall facility with maximum temperatures up to 220°C and internal pressures up to 22 bar. The heated wall consists of annular slits which allow for efficient heat transfer from the wall to the process. The adaptable, modular architecture, allows for modification of the device to support both batch and continuous processing. Furthermore, the overall design and adjustment of the reactor is straightforward and can be easily configured to accommodate different reactors sizes, temperatures, pressures, and residence times. D125 provides users with a variety of process control options, ranging from manual to automated controls, enabling ease and flexibility in the development of complex processes. Automated control systems may be incorporated to monitor key parameters, adjust settings, and data logging yielding reproducible outcomes. Process timeline simulations can be programmed for repetitive strategies such as cyclic temp ramping, and pressure increases/decreases. For operations requiring a high-process sensitivity, VEECO / EMCORE D125 can be ably configured to provide full hazard-control and measures beyond those typically provided, such as a safety shutdown. VEECO D125 has a wide range of applications across industries and applications. It can be deployed in UV-Vis spectroscopy, scintillation counting, and plating processes. Additionally, the unit is used in mass spectrometry, chromatography, and electrochemical characterization and drug discovery. EMCORE D125 is well-suited for the manufacture of pharmaceuticals, carbon nanotubes, and other proteins in the biochemical industry. And its advanced technology is especially useful for nanomaterials synthesis, which often require either very high-temperatures, high-flow rates, or extended reaction times. Overall, D125 is a flexible, robust, and reliable reactor machine optimized to support advanced process development, academic research, and performance-driven production applications. The high-performance, modular design provides integrated control, precise temperature, pressure, and residence time control, enhanced productivity, and improved safety features ensure reliable, reproducible, and repeatable process outcomes.

There are no reviews yet