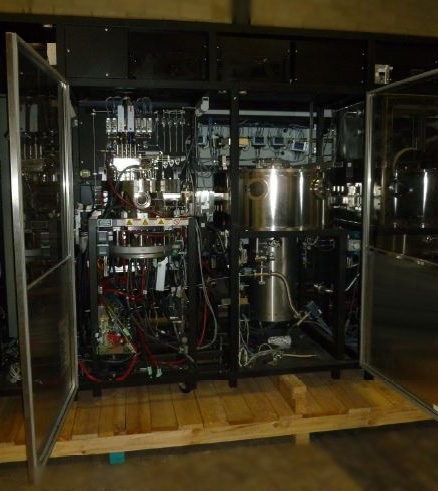

Used VEECO / EMCORE E300 GaN #9245409 for sale

URL successfully copied!

Tap to zoom

ID: 9245409

Vintage: 2005

MOCVD Ganzilla system

Throughput: 21" x 2" / 8" x 3"

Pass-through glovebox

With load anti-chamber

Components:

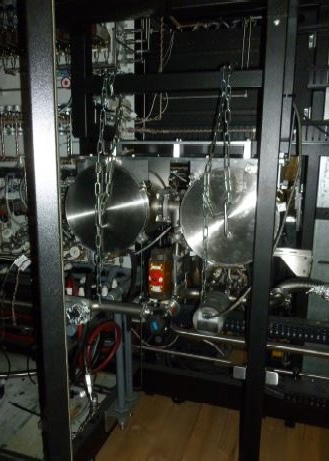

Gate valve

Gauges

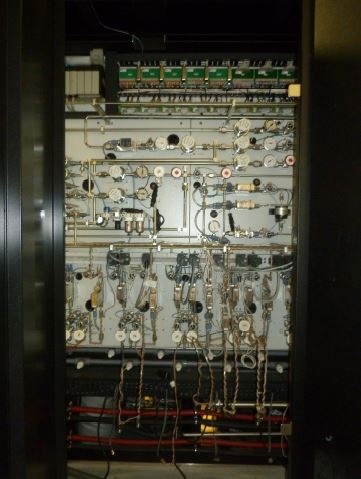

Valves

MFC Pressure controllers

(3) YOKOGAWA Temperature controllers

(5) DC Power supplies

(5) Gas lines

(8) Bubbler manifolds

Gas line purifiers:

Hydrogen

Inter

Hydride

EBARA A70W Series Multistage vacuum pump

(2) Real temperature pyrometers

(3) Sekidenko Pyrometers

Includes:

GaN

InGaN

AIGaN

Missing parts:

Primary heater

Filaments

~2005 vintage.

VEECO / EMCORE E300 GaN is a high performance, compact reactor designed for applications such as deposition and etching of Gallium Nitride (GaN) and other materials requiring high deposition rates and uniformity. The E300 is ideal for producing high quality thin film coatings and nanoscale structures. The E300 utilizes low-pressure inductively-coupled plasma (ICP) sources, operated at a maximum power of 300 W. These sources are designed to achieve more uniform and consistent process temperatures and ion energies, thereby providing higher deposition rate and improved uniformity. The low-pressure ICP sources provide a key advantage over sub-atmospheric deposition systems that require large volumes of gas and lengthy cycle times. The E300 is able to accurately control substrate temperature, allowing for precise and predictable temperature control for a wide range of applications. The bottom of the chamber is equipped with a heated stage, allowing temperature control in the range of ambient to 500°C. This allows for low-temperature growth of sensitive materials, such as GaN and other III-nitrides. The equipment is also equipped with an electrostatic energy source, which can be used to subject the substrate to a range of process conditions, varying the energy of ions incident upon the substrate and the surface properties of the resulting film layer. This allows for unique etching and deposition processes such as energetically selective deposition (ESD), and provides greater flexibility when processing nanopatterns. The E300 features a state-of-the-art control system, with real-time data monitoring, providing precise and reliable process control, even in high-temperature applications. The integrated software allows for fully automated operation, and can be configured to meet the specific needs of the user. Overall, VEECO E300 GaN is a compact and high performance unit engineered specifically for GaN processing. Its ability to accurately control substrate temperature, as well as its integrated range of sophisticated control systems, makes it an ideal machine for complex deposition and etching processes, such as the growth of high-quality GaN thin film coatings and nanoscale structures.

There are no reviews yet