Used VEECO / EMCORE E300 #9265829 for sale

URL successfully copied!

Tap to zoom

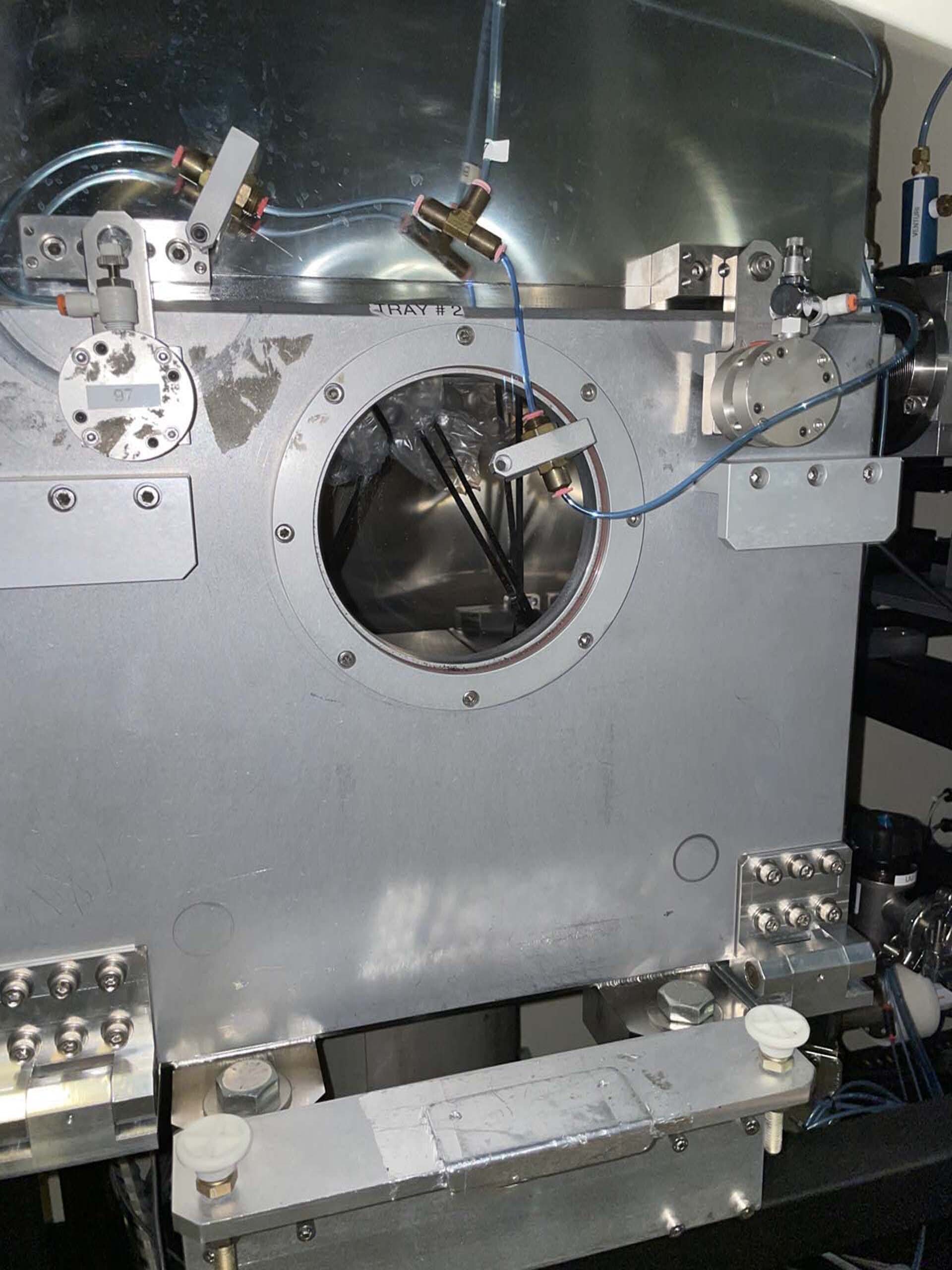

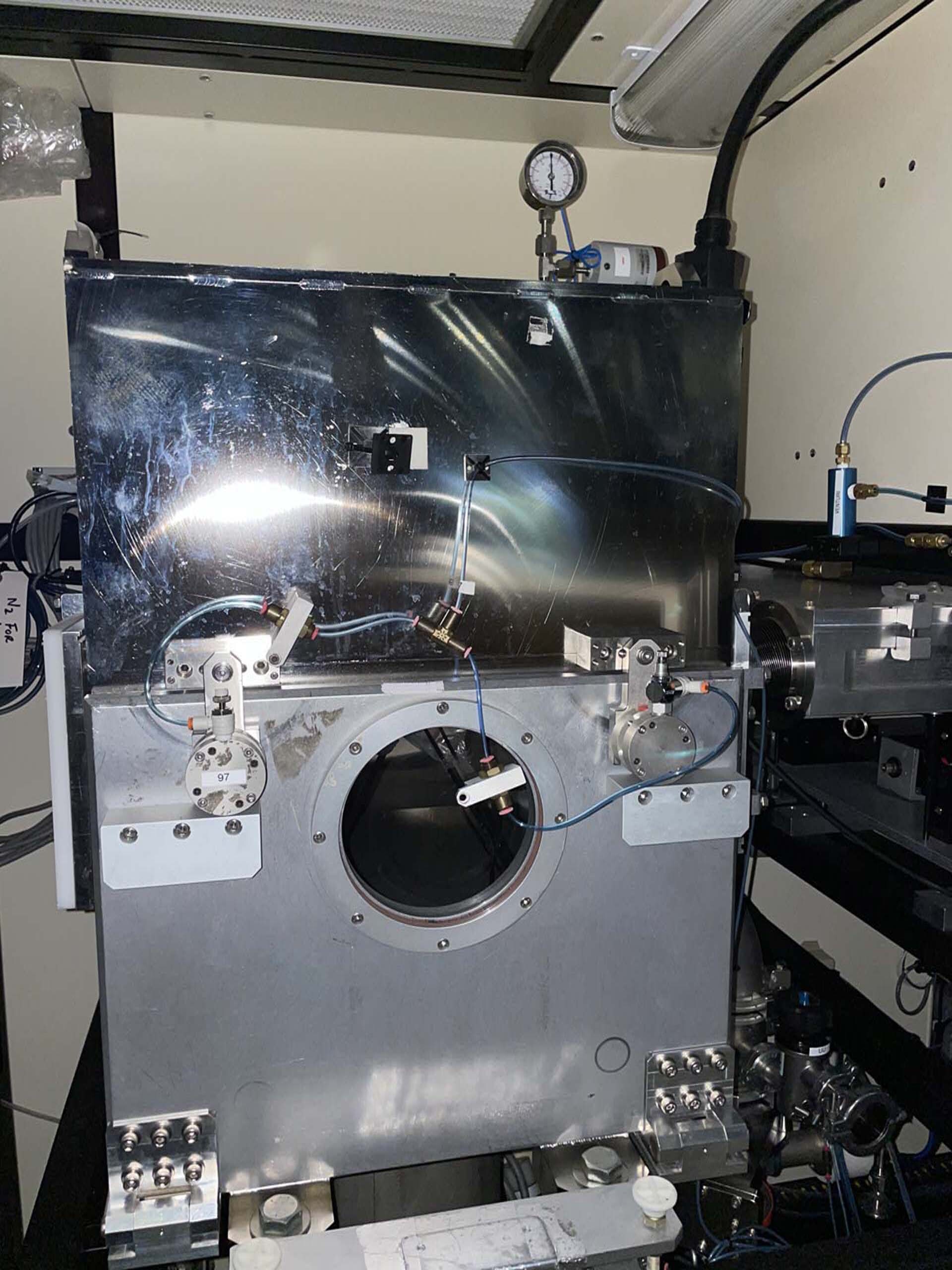

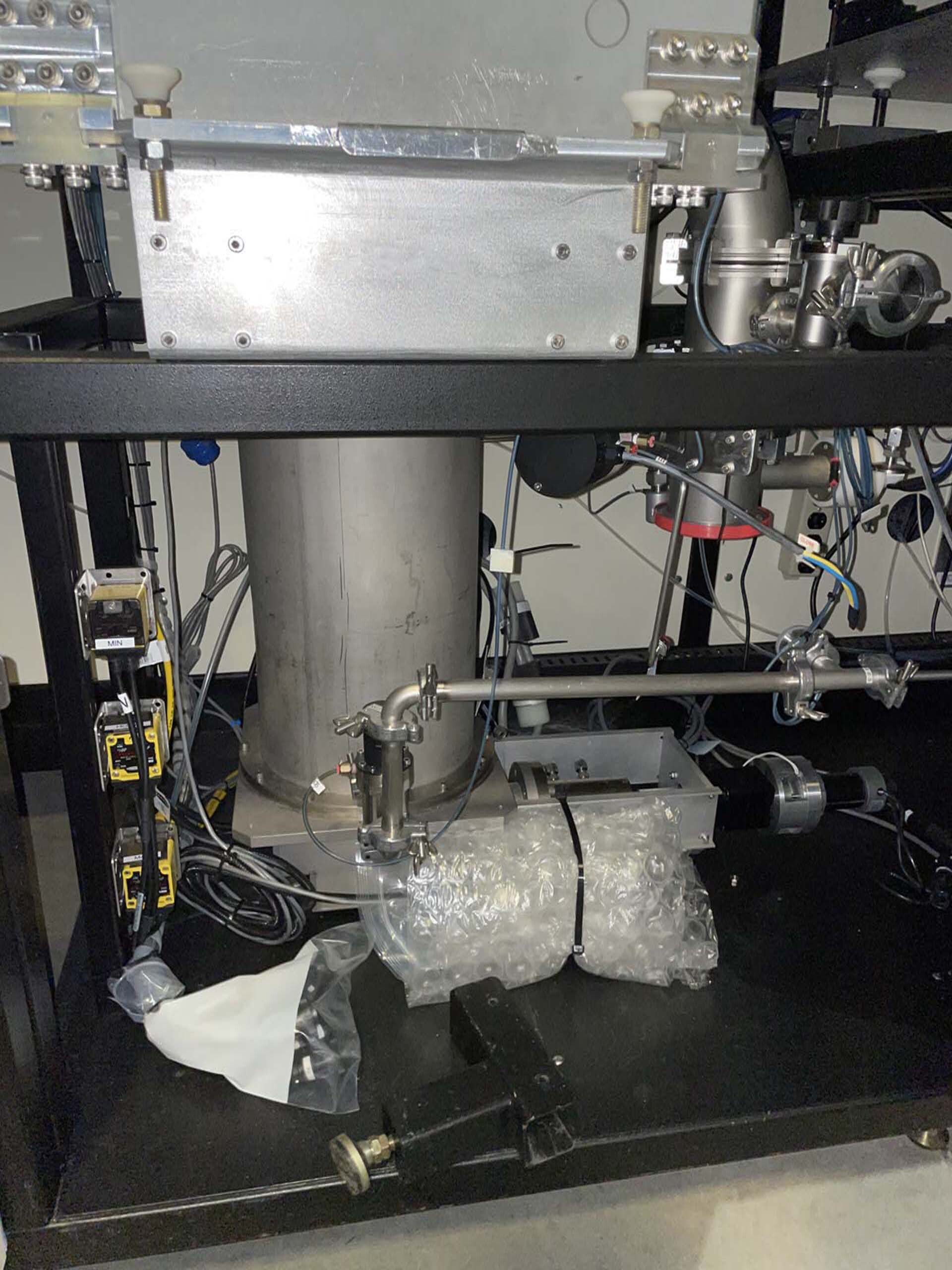

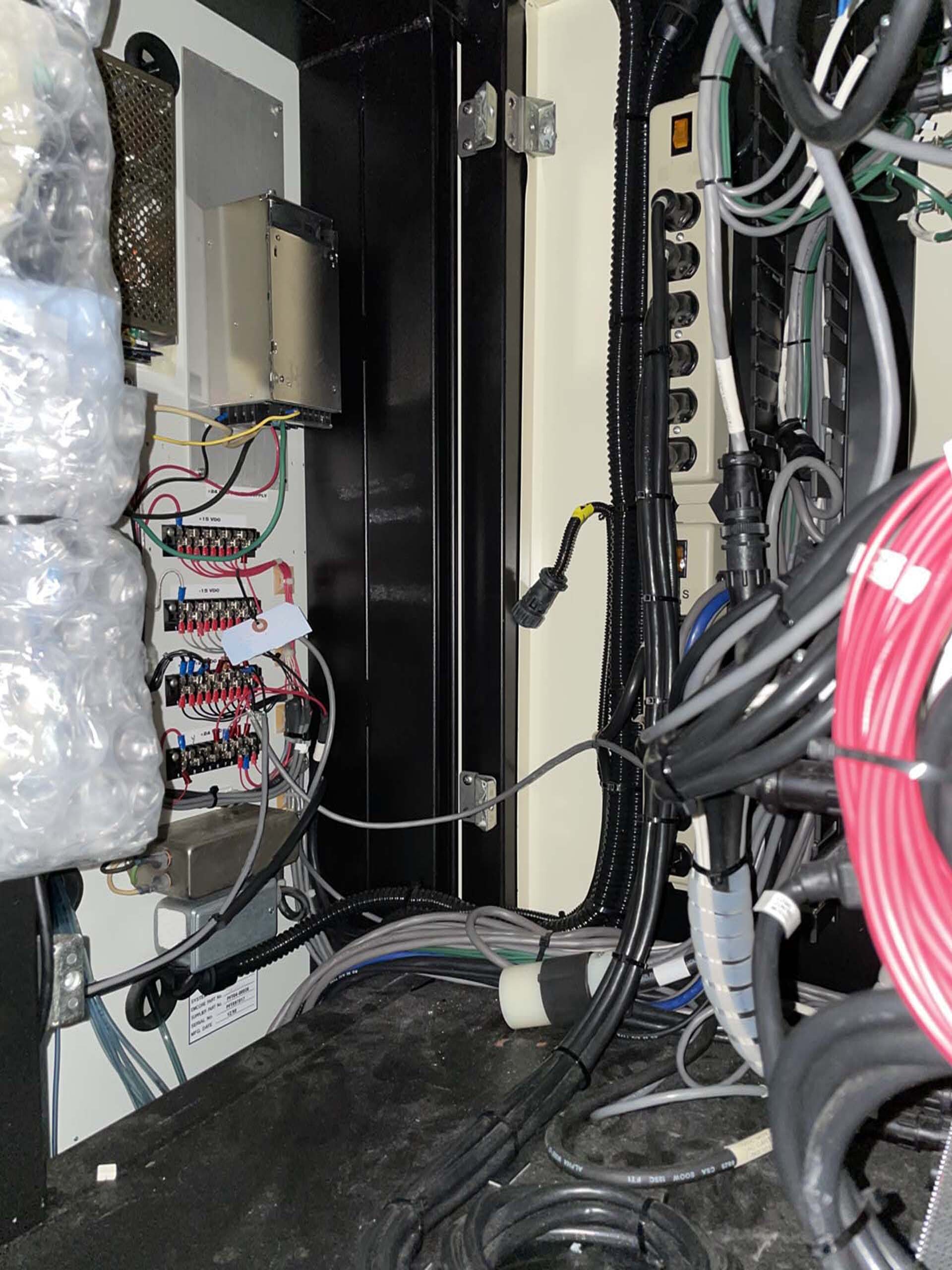

VEECO / EMCORE E300 is a reactor designed for chemical vapor deposition applications and other types of epitaxial deposition. This reactor is capable of producing a wide range of high purity materials from various compounds. VEECO E300 reactor is an inert, horizontal tube-type reactor made of stainless steel and other materials capable of withstanding high temperatures. The reactor interior is sealed from outside air, preventing contamination. It has a heated susceptor, or crucible, for material deposition. The susceptor can be heated to a high temperature. It is also equipped with a unique vacuum source. A step-scanning mass spectrometer can be connected to this reactor for monitoring reaction processes. EMCORE E300 has a wide range of uses in the manufacture of semiconductors such as gallium arsenide, indium phosphide, III-V compounds, silicon carbide and similar materials. It has a low-contamination design that enables these materials to be produced in pure form. E300's capacitance-coupled plasma (or CCM) approach allows for precise control of the deposition process, and its flexible geometrical configuration allows for the deposition of thick films. VEECO / EMCORE E300 offers a high process rate, allowing for greater productivity. Its design allows for optimization of processes such as material layer growth, surface passivation, and etching. It can also eliminate particle-eroding effects. The reactor includes efficient cooling to minimize overheating and thermal destruction of products. It is equipped with diagnostic monitoring systems that allow for efficient control of the deposition process. The reactor also includes a nitrogen input, which helps ensure a clean, inert environment during deposition. VEECO E300's precise control of the parameters and processes involved in material deposition makes it well suited for the manufacture of high purity compounds. Its simplicity of operation and high precision also make it suitable for research. All the parameters used in the deposition process can be adjusted and monitored in real-time, allowing for optimized quality control.

There are no reviews yet