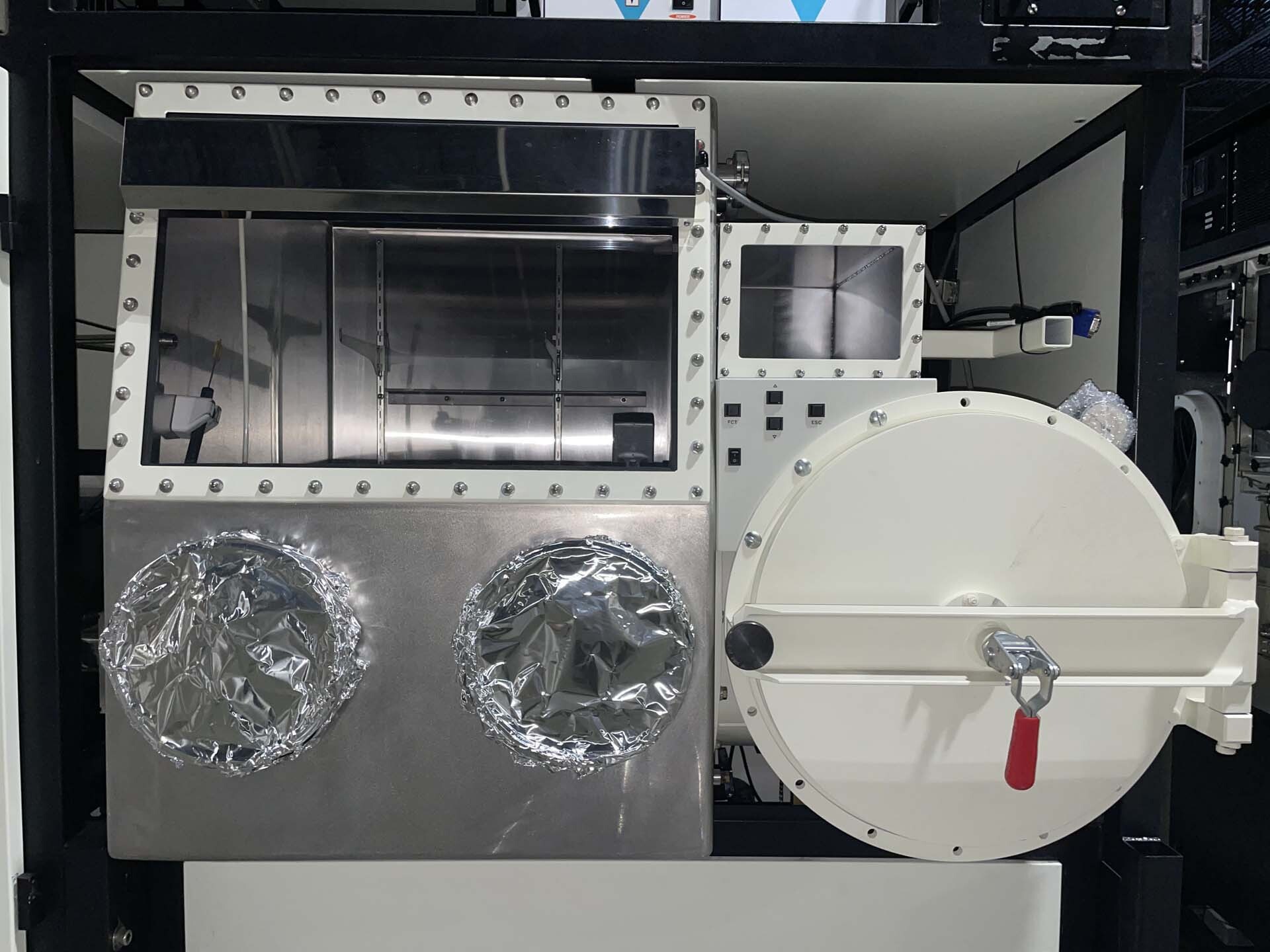

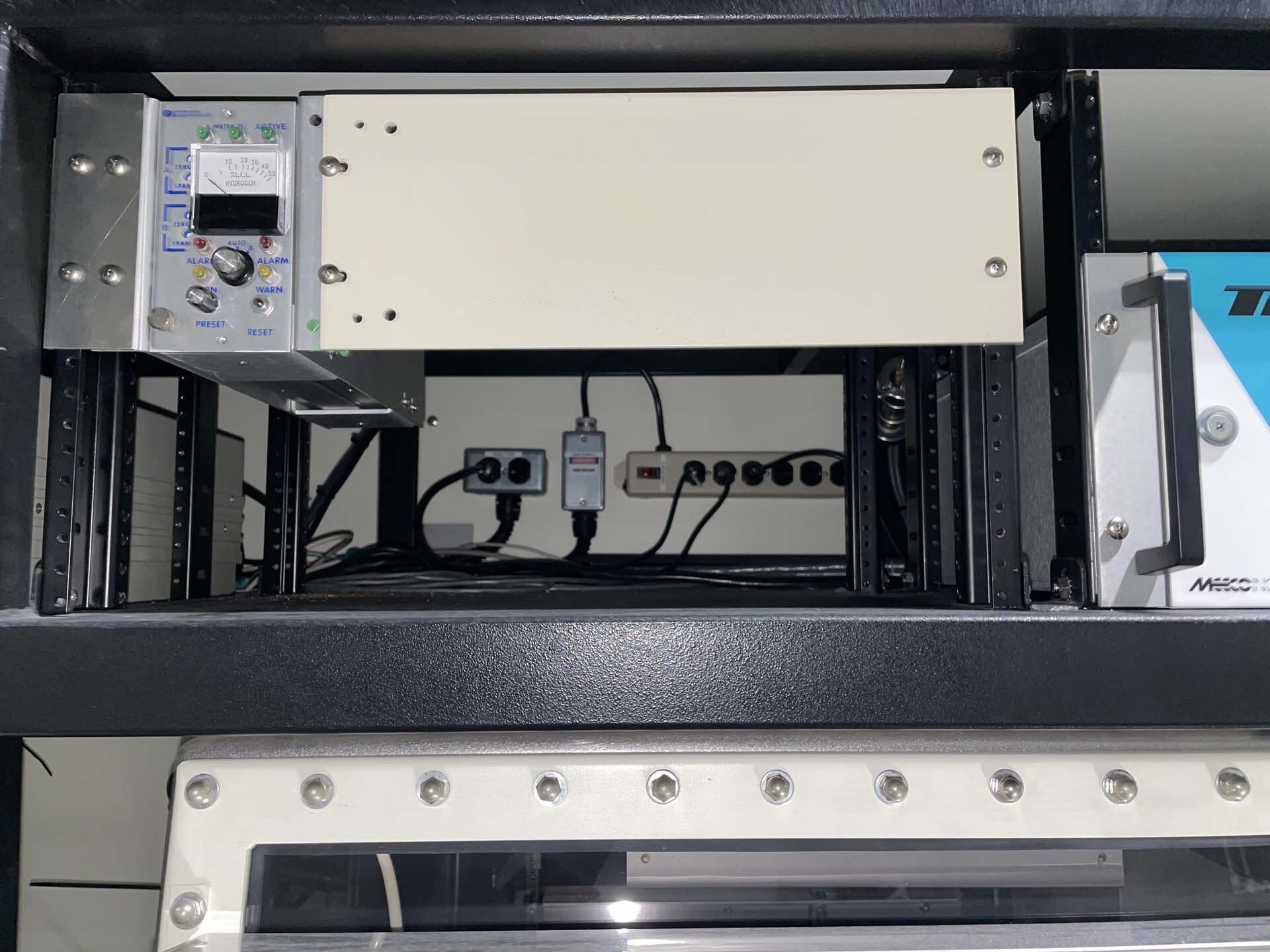

Used VEECO / EMCORE E300 #9283630 for sale

URL successfully copied!

Tap to zoom

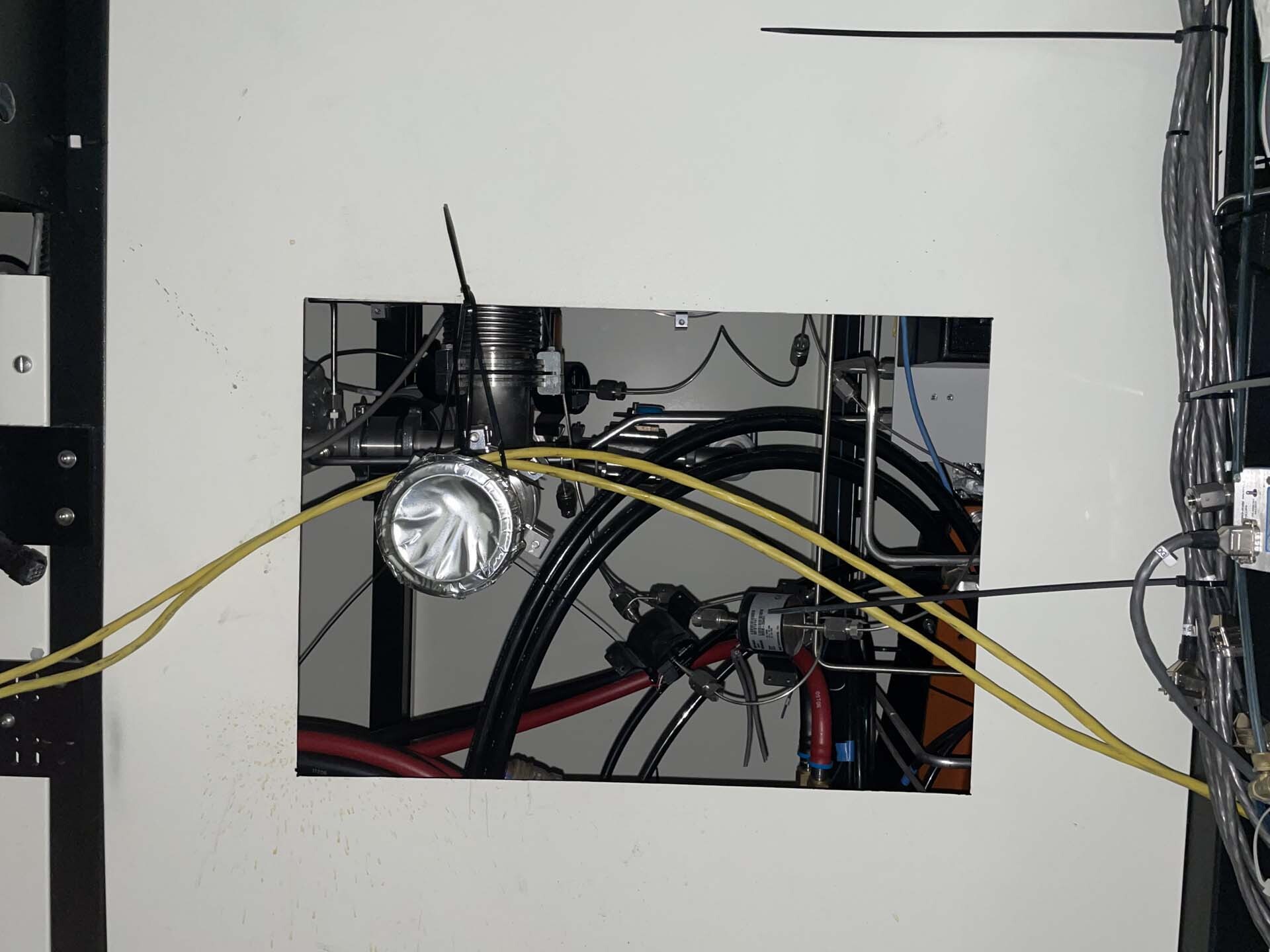

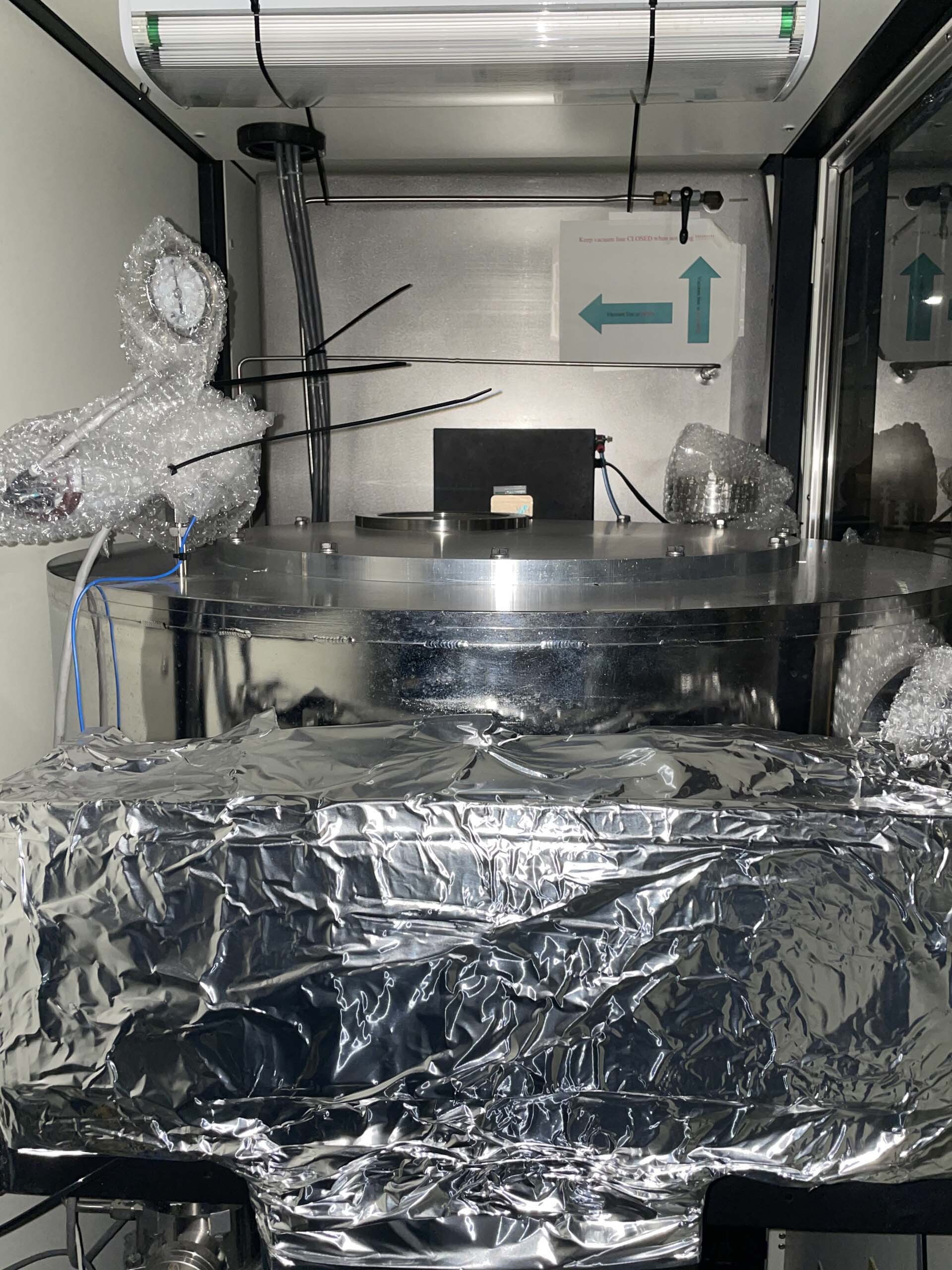

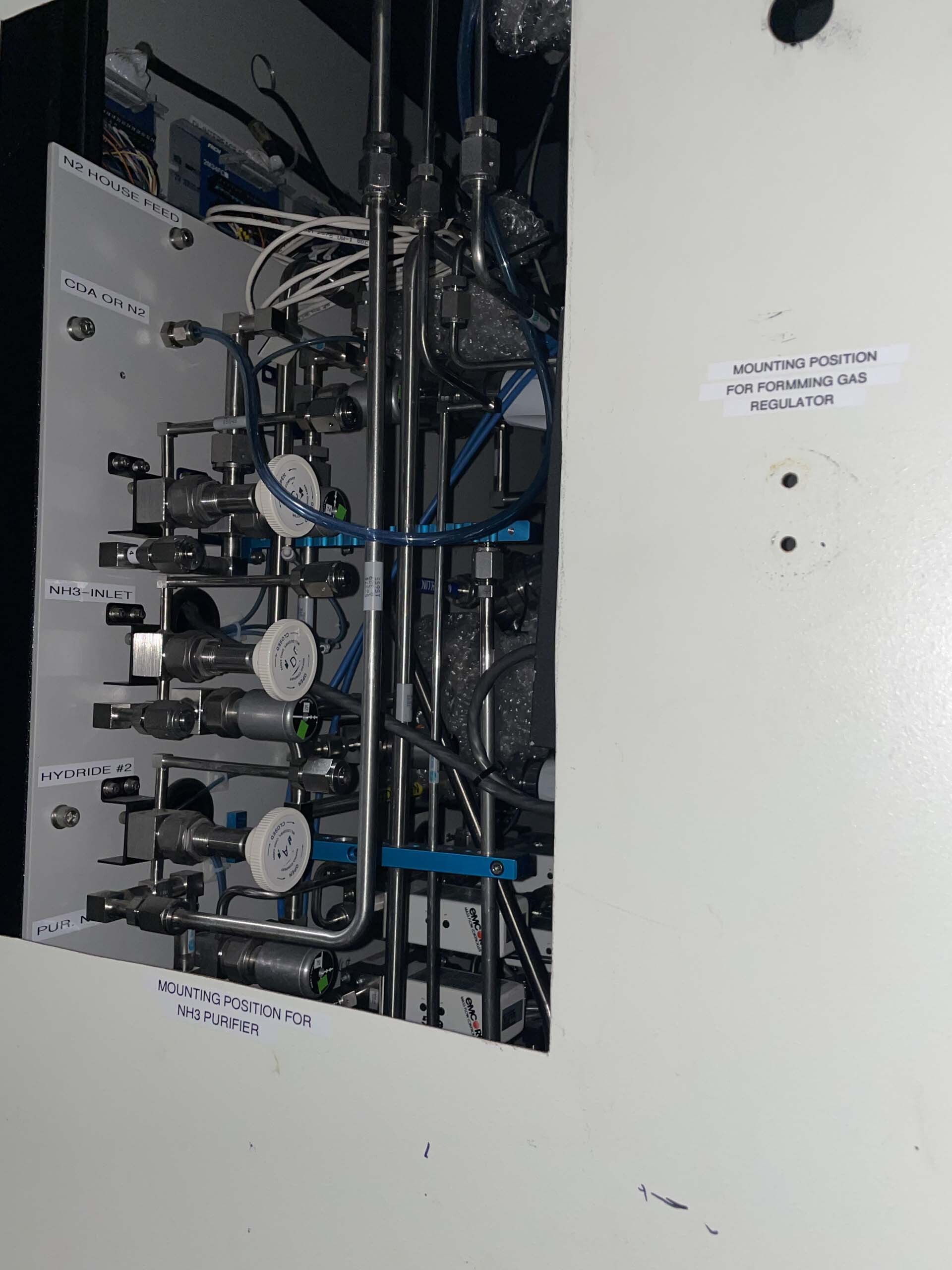

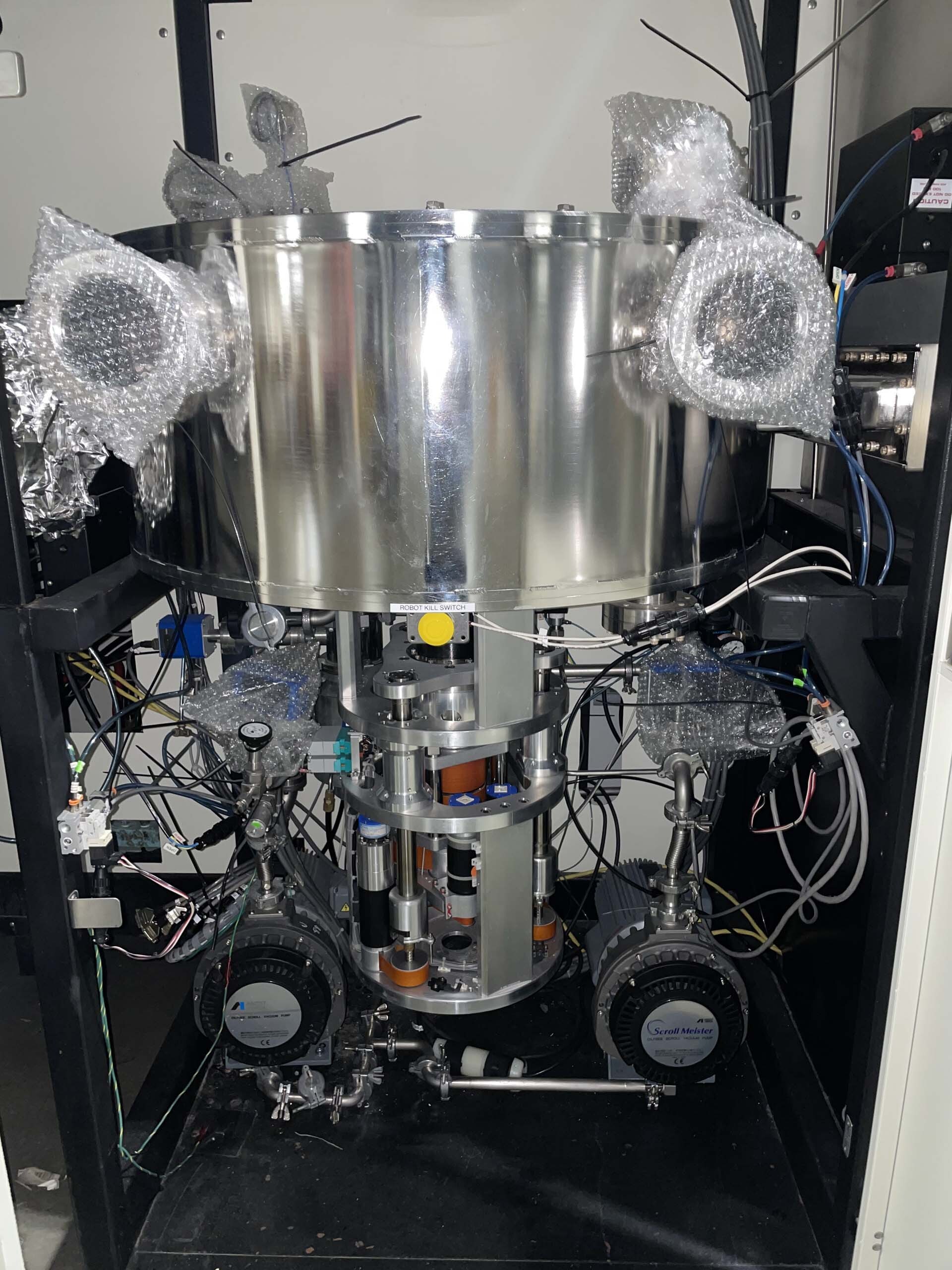

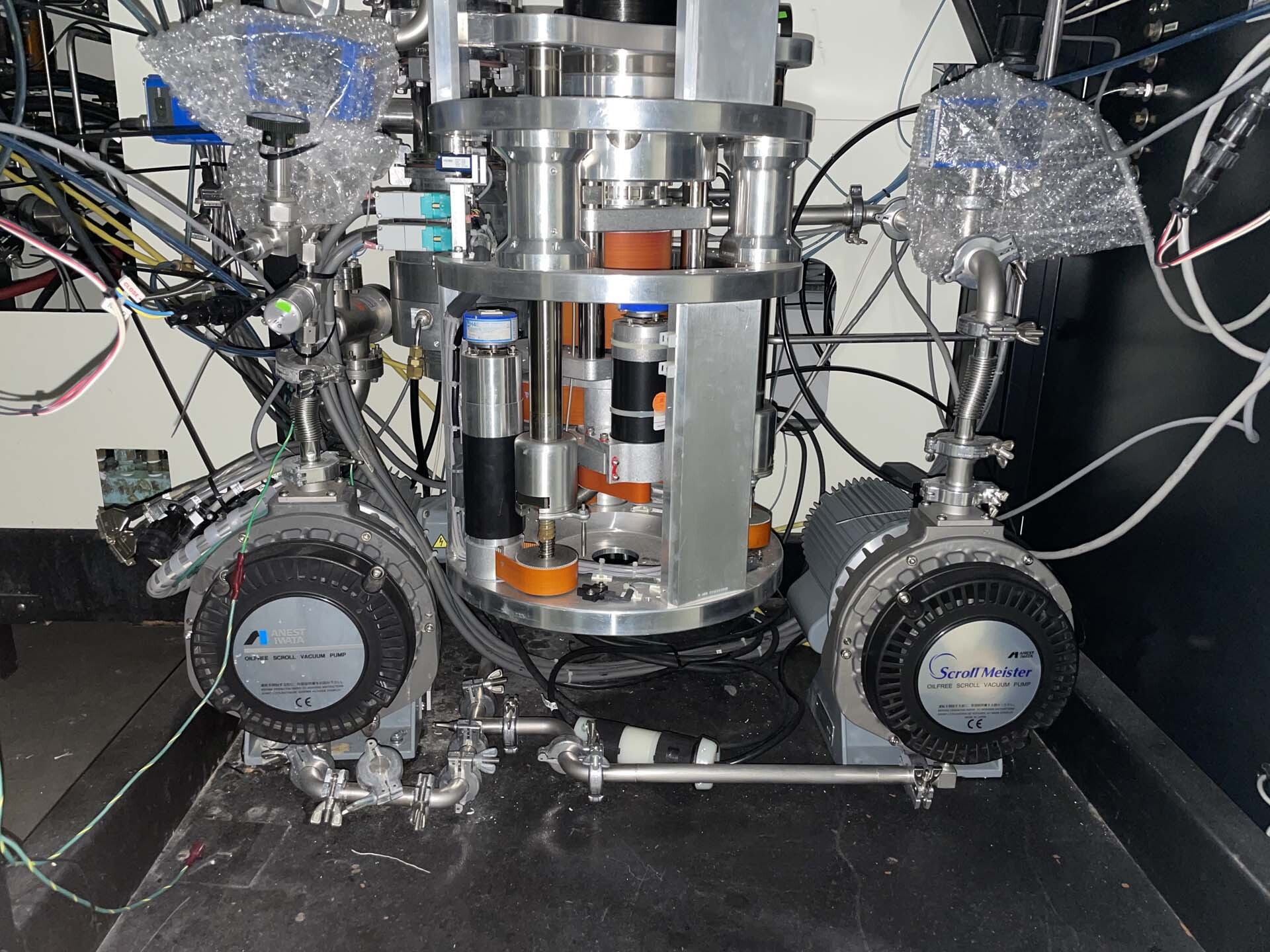

VEECO / EMCORE E300 is a research-level, low pressure, inductively coupled, plasma processing reactor designed for etching silicon and other Group IV materials. The reactor utilizes a 13.56 MHz generator to create an electron cyclotron resonance (ECR) in addition to a low-pressure (1 mTorr to 100 mTorr) inductively-coupled plasma (ICP) for etching and deposition processes. The reactor is suitable for etching, deposition, and etching/deposition with rapid thermal annealing (RTA) and also offers low-pressure EC and rapid thermal oxidation (RTO) processes. VEECO E300 has a gas box for up to nine gases that includes two ICP injectors and a remote gas control unit. The gas box provides precise control of the plasma ion and radicals densities, which are necessary for successful etching of silicon and other group-IV materials, with different materials requiring different plasma densities. The advanced RF generator in EMCORE E300 can be finely tuned to attain optimal process results on different materials. While the 2kW power supply provides a process chamber pressure of 1 mtorr to 100 mtorr, a novel nitrogen RF bias control feature gives the user the ability to tune the density of the plasma in the process chamber and also enhances the uniformity of the process. The generator is also optimized for high-power deposition processes. In addition to the RF generator, E300 offers pressure control in the form of a turbo molecular pump (TMP) that can be used to maintain the desired processing pressures. A dual-pump design allows for more stable operation with faster pumpdown times and better pressure control. VEECO / EMCORE E300 also features a unique split-chamber design that separates the main plasma reaction and deposition chambers from the cooling chamber. This allows for rapid thermal annealing (RTA) and other high-temperature processes without the need for dual cooling plenums. The reactor also includes an integrated UV monitoring system to ensure that the etching process is in optimal conditions. The system includes an advanced optical emission spectroscopy chamber to monitor etch depth and uniformity. Overall, VEECO E300 provides a cost-effective, research-level system designed for processing a wide range of materials for different applications, from etching, deposition, and etching/deposition with RTA to low-pressure EC and RTO processes. Its superior RF generator and the split-chamber design offers exceptional etching uniformity, improved device yield, and process reproducibility.

There are no reviews yet