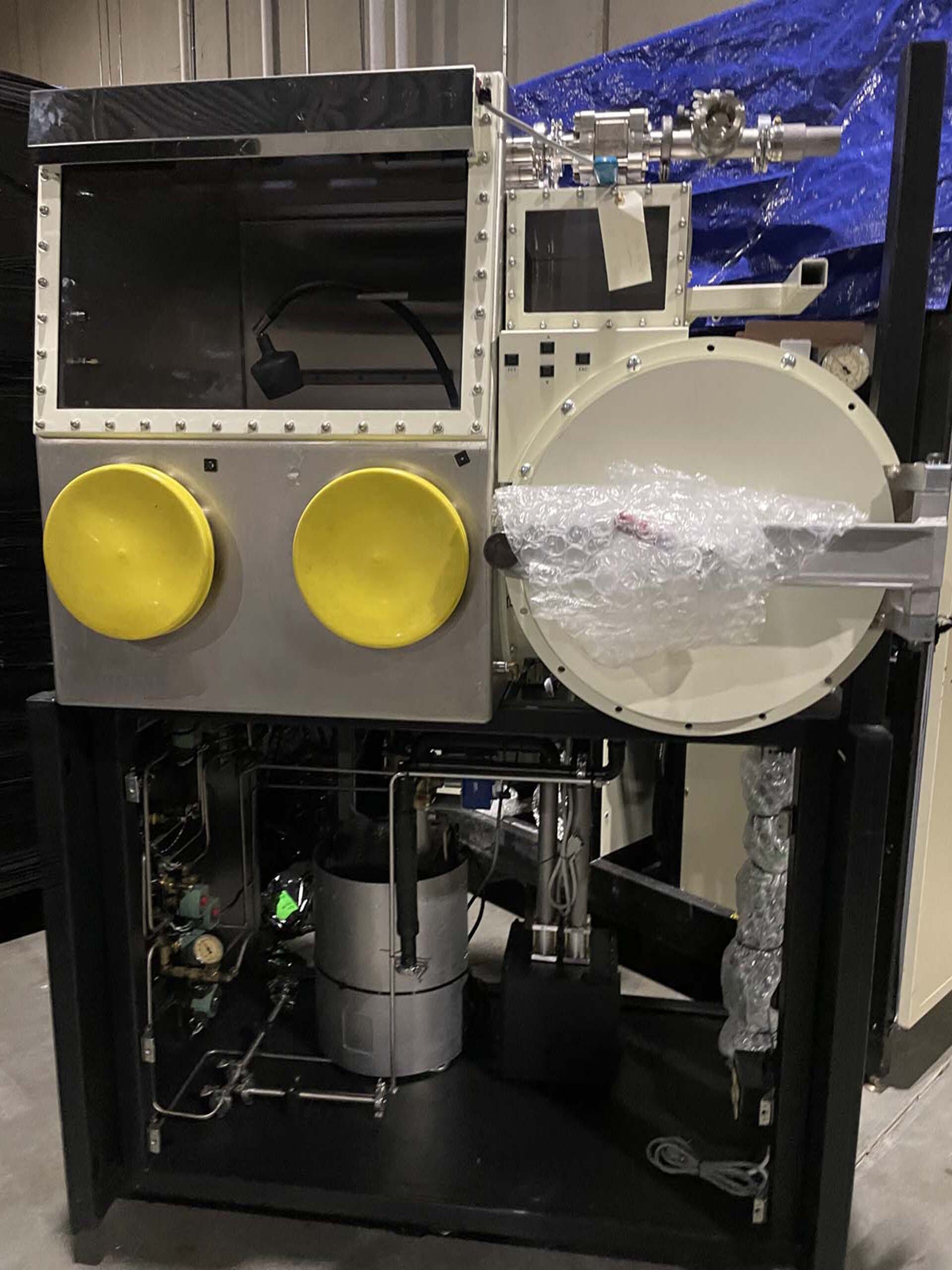

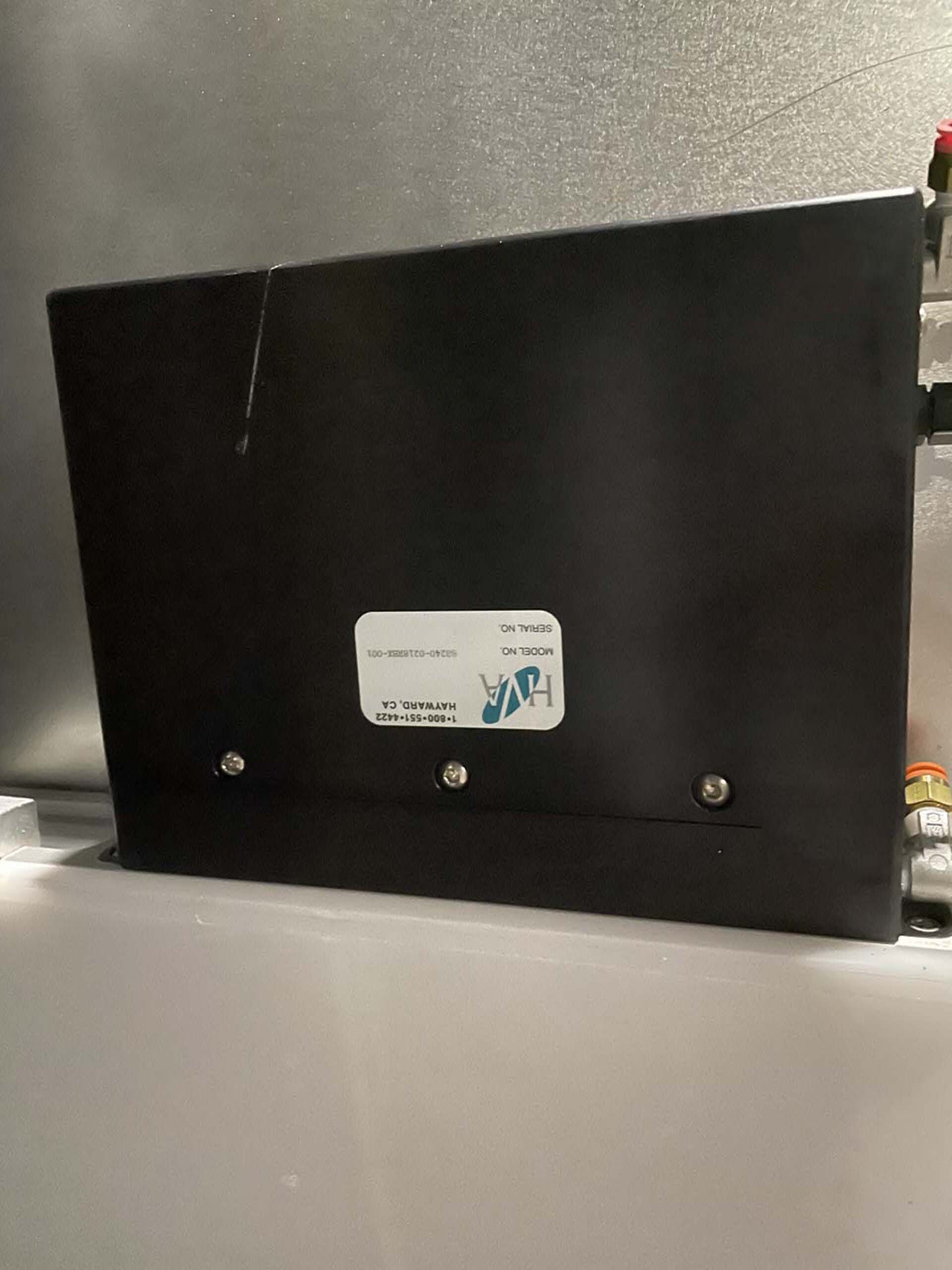

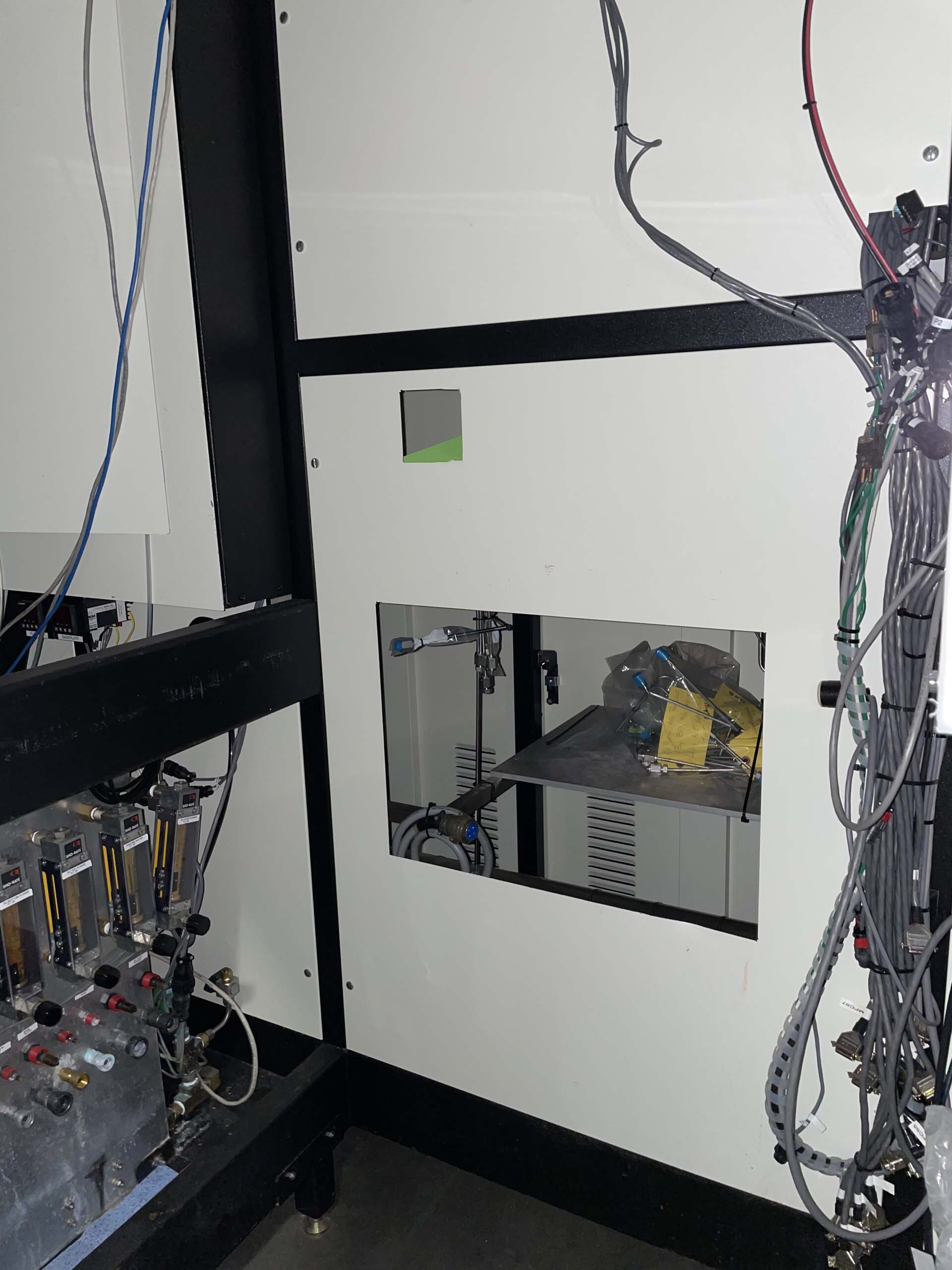

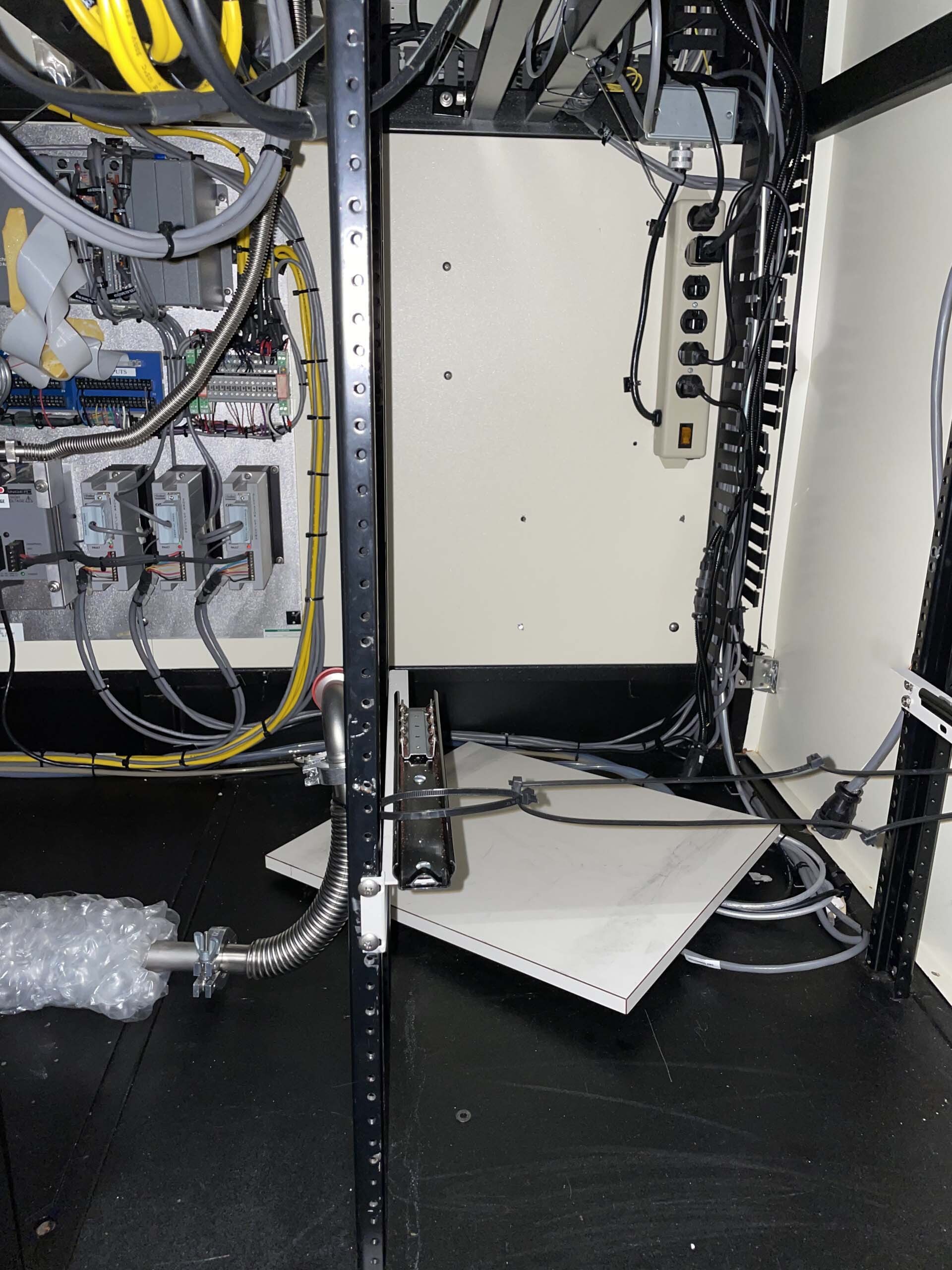

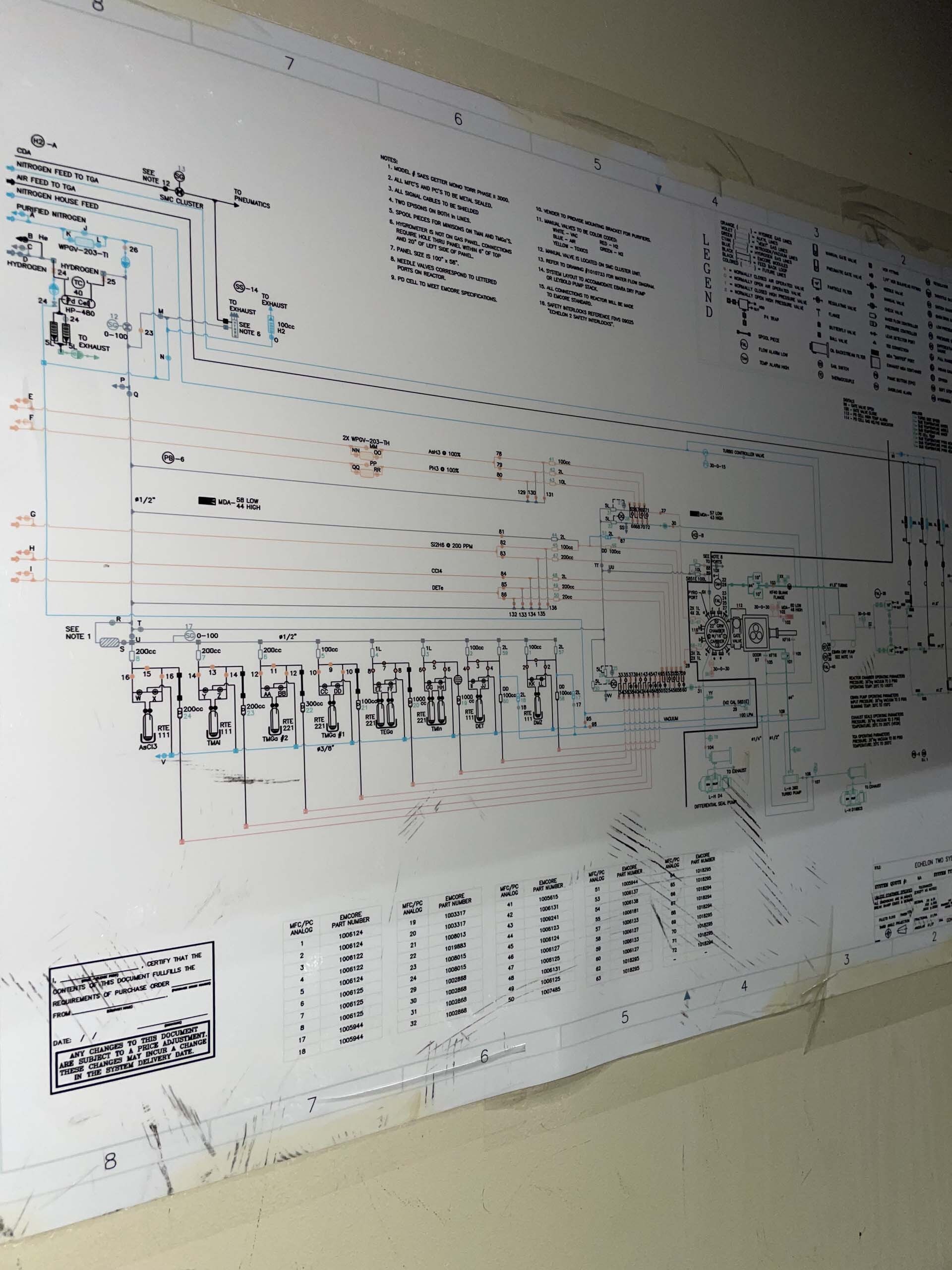

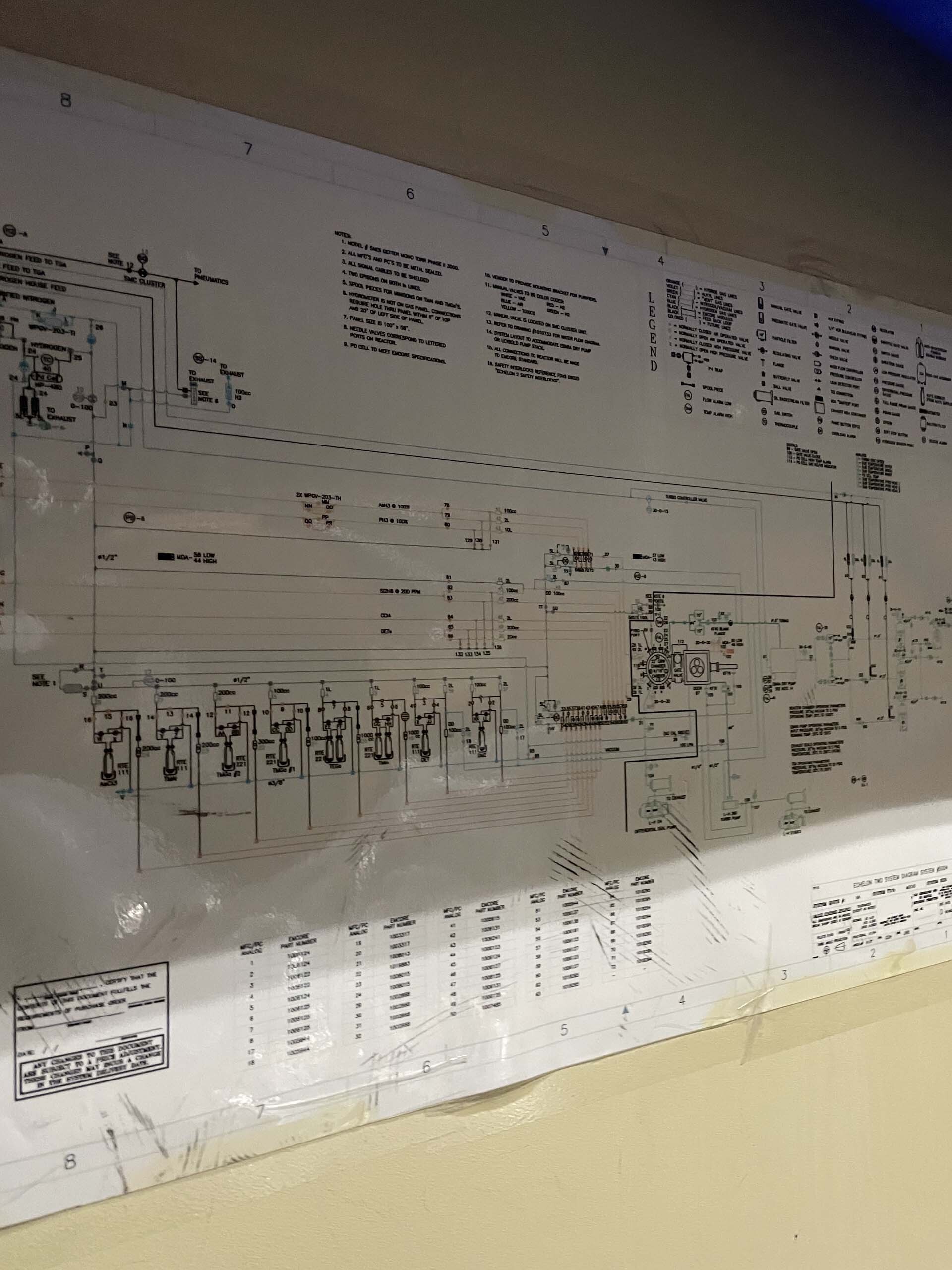

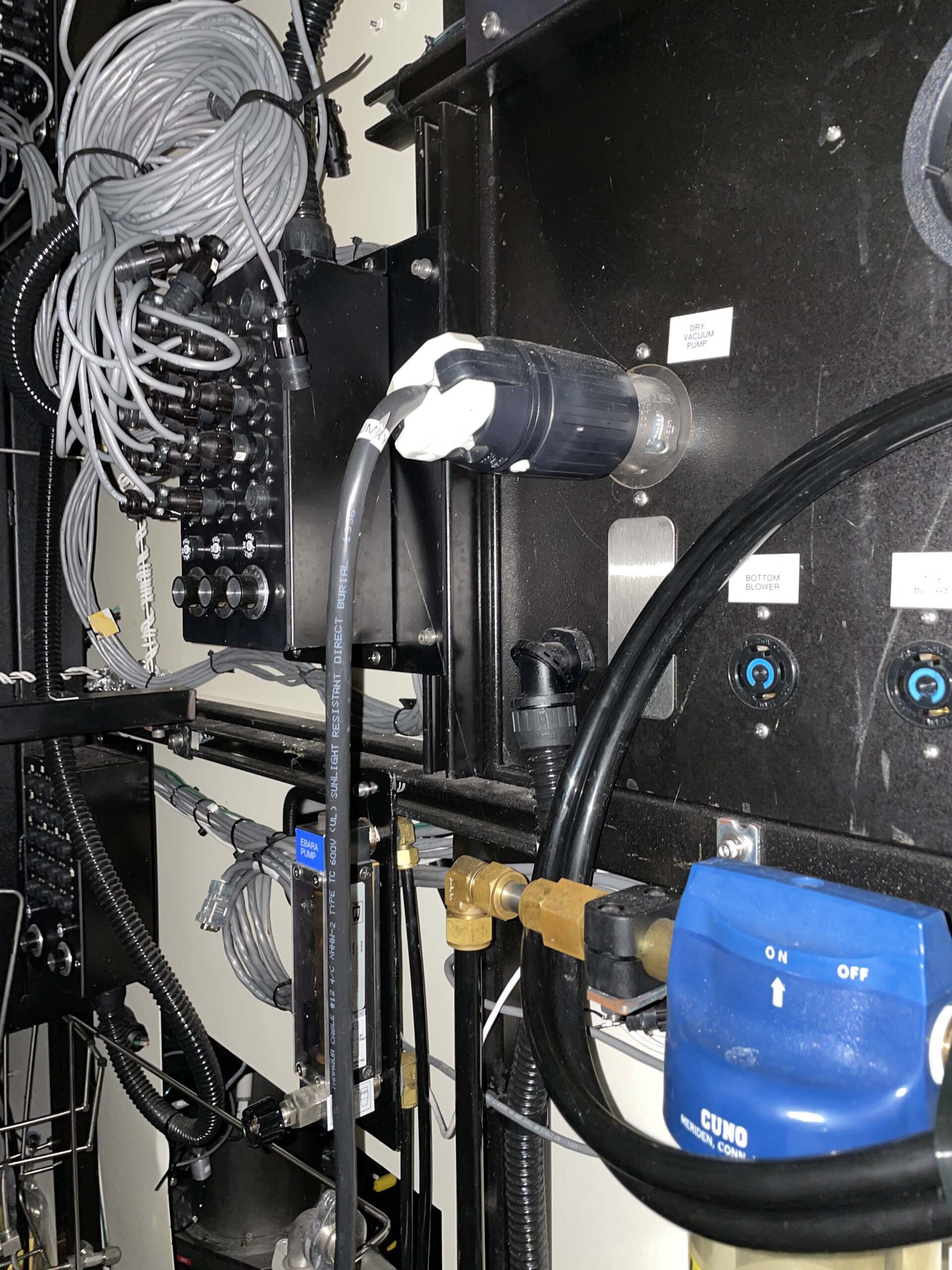

Used VEECO / EMCORE E400 #9265828 for sale

URL successfully copied!

Tap to zoom

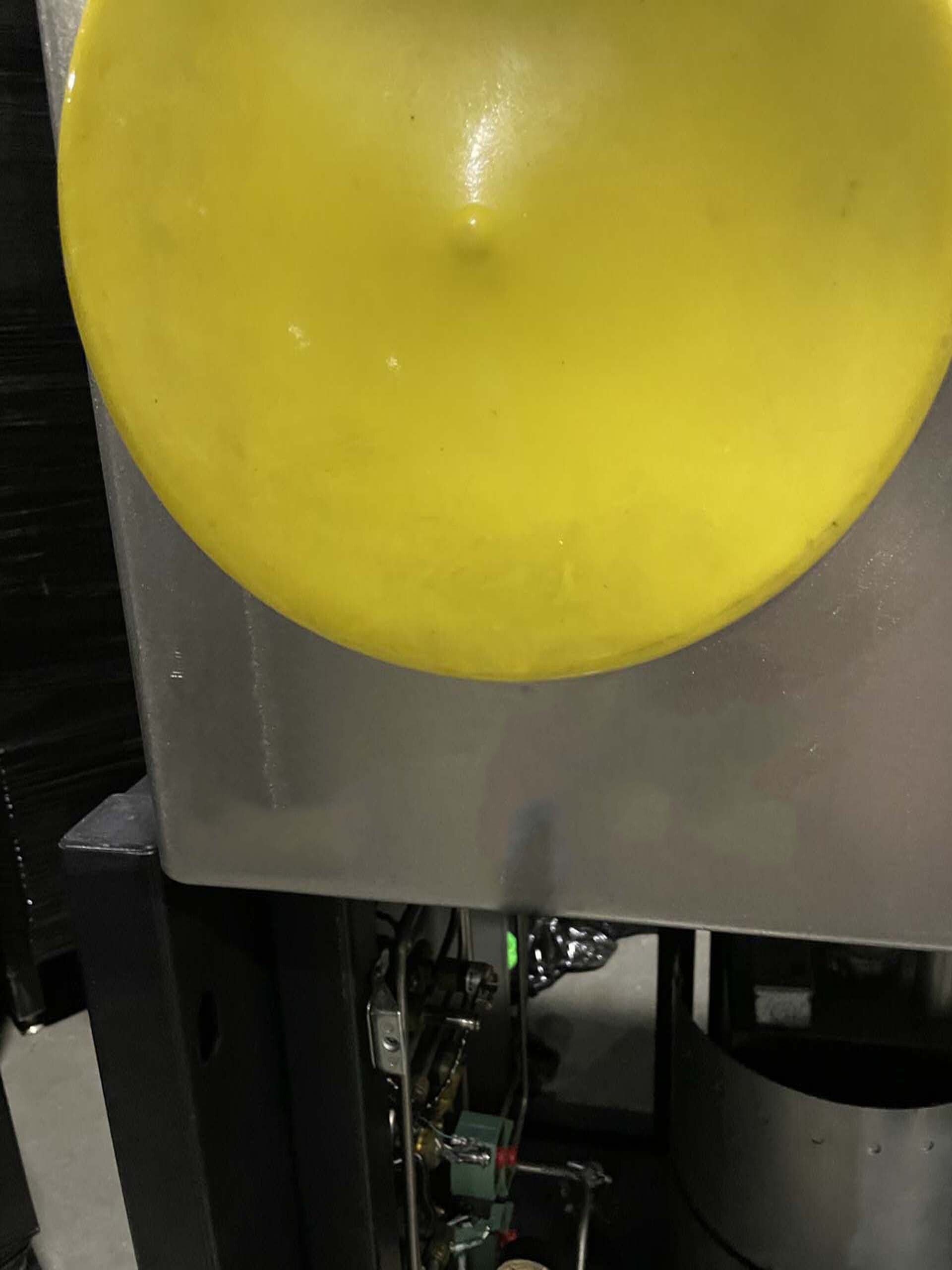

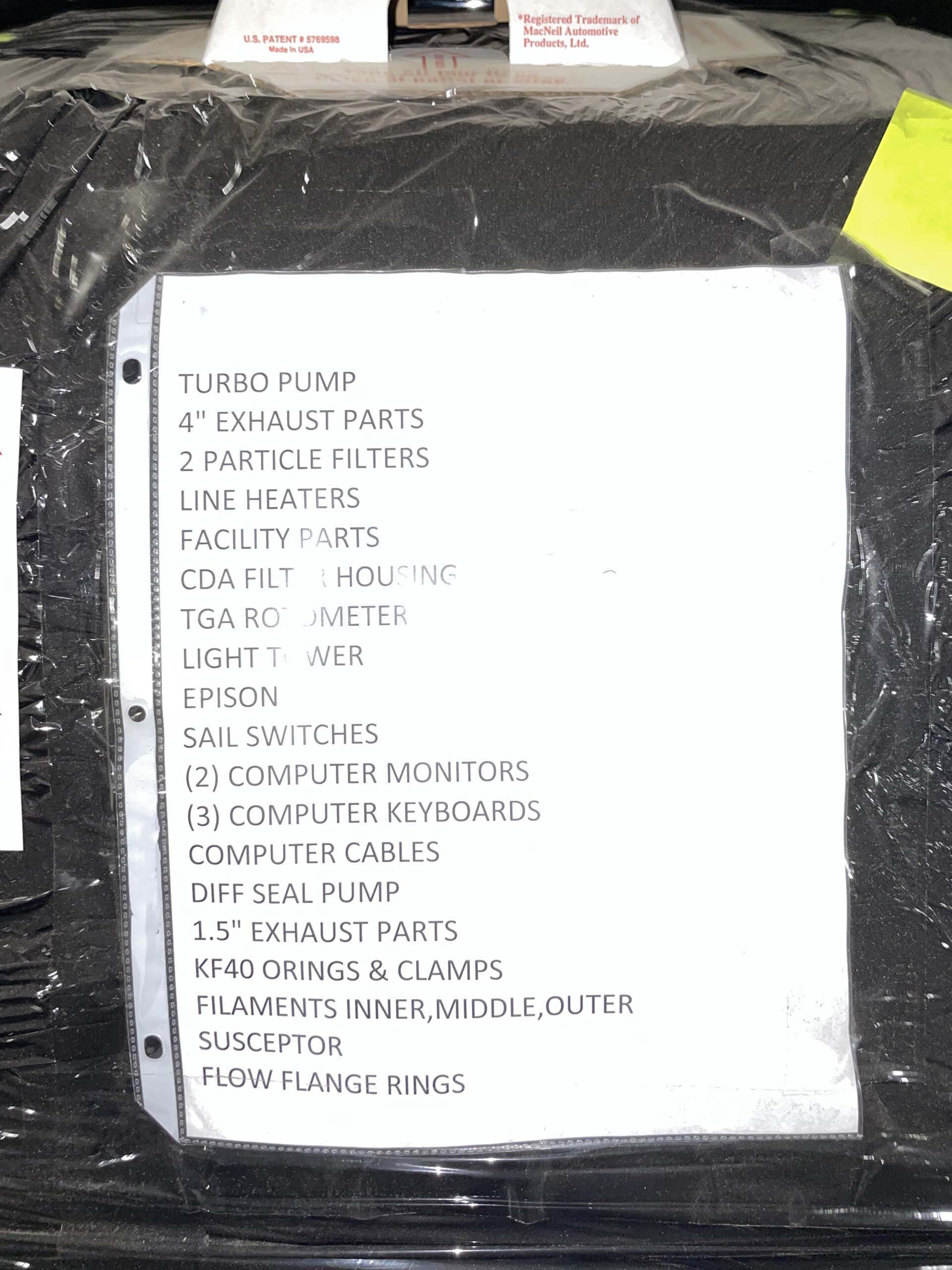

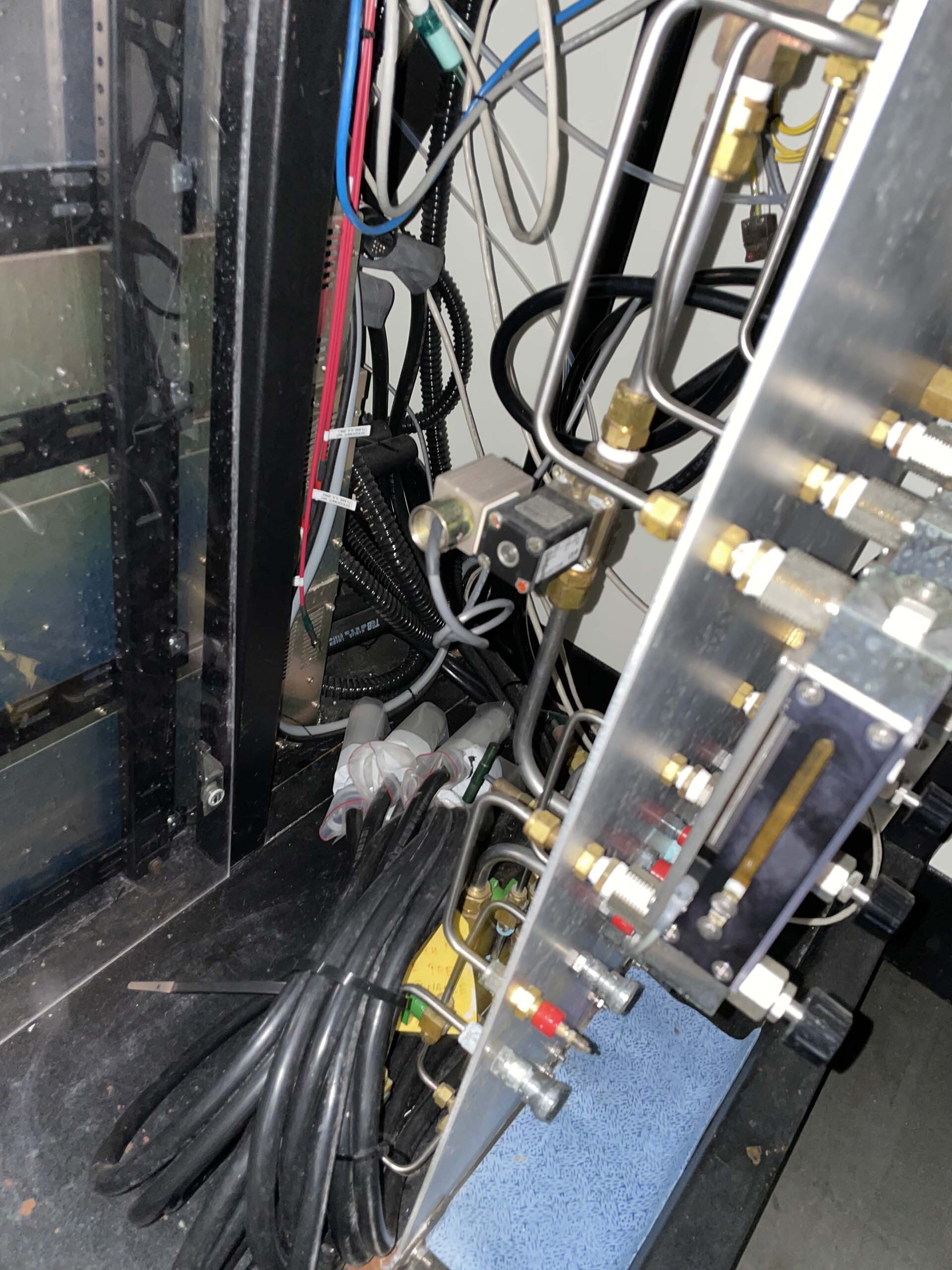

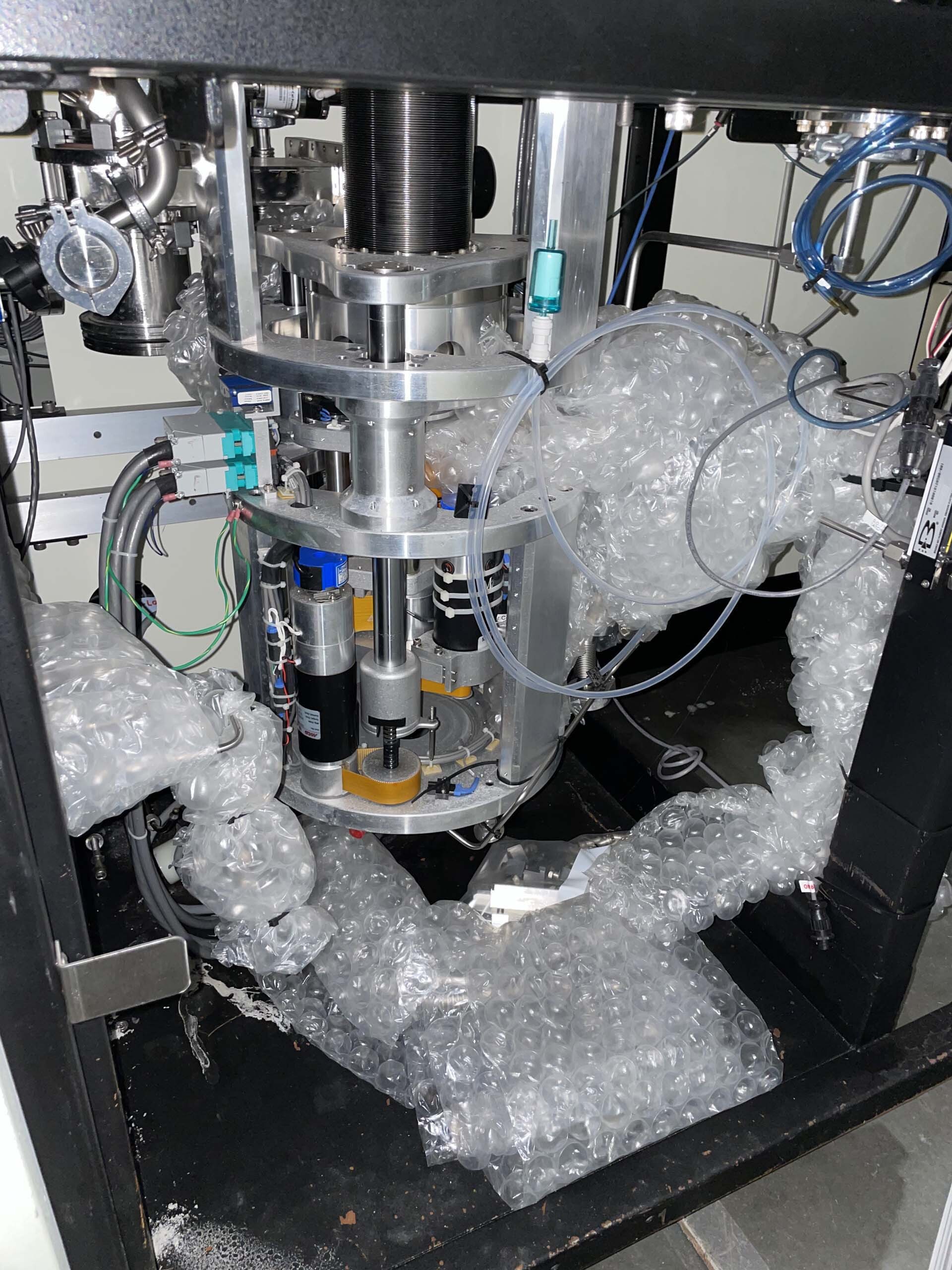

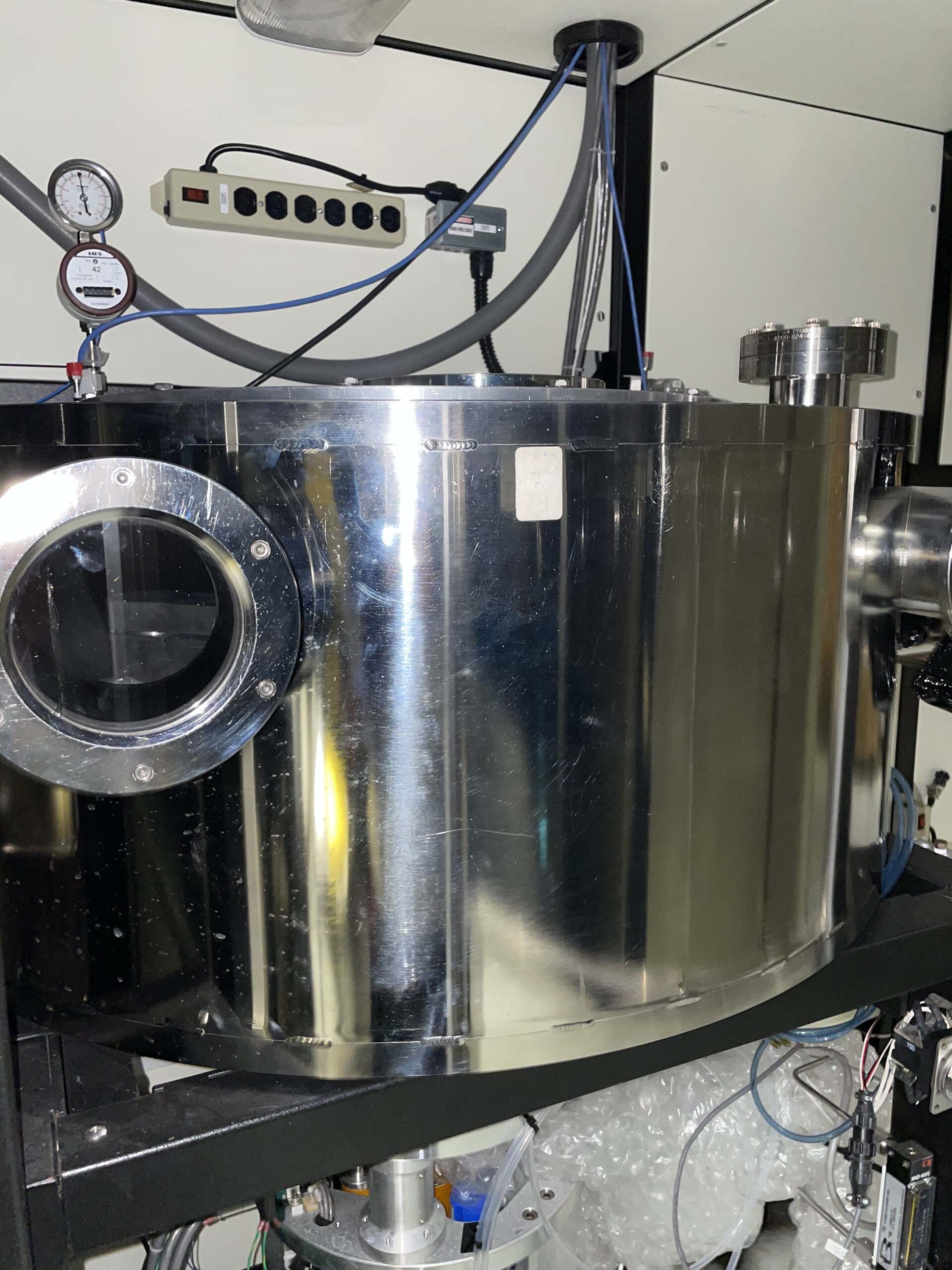

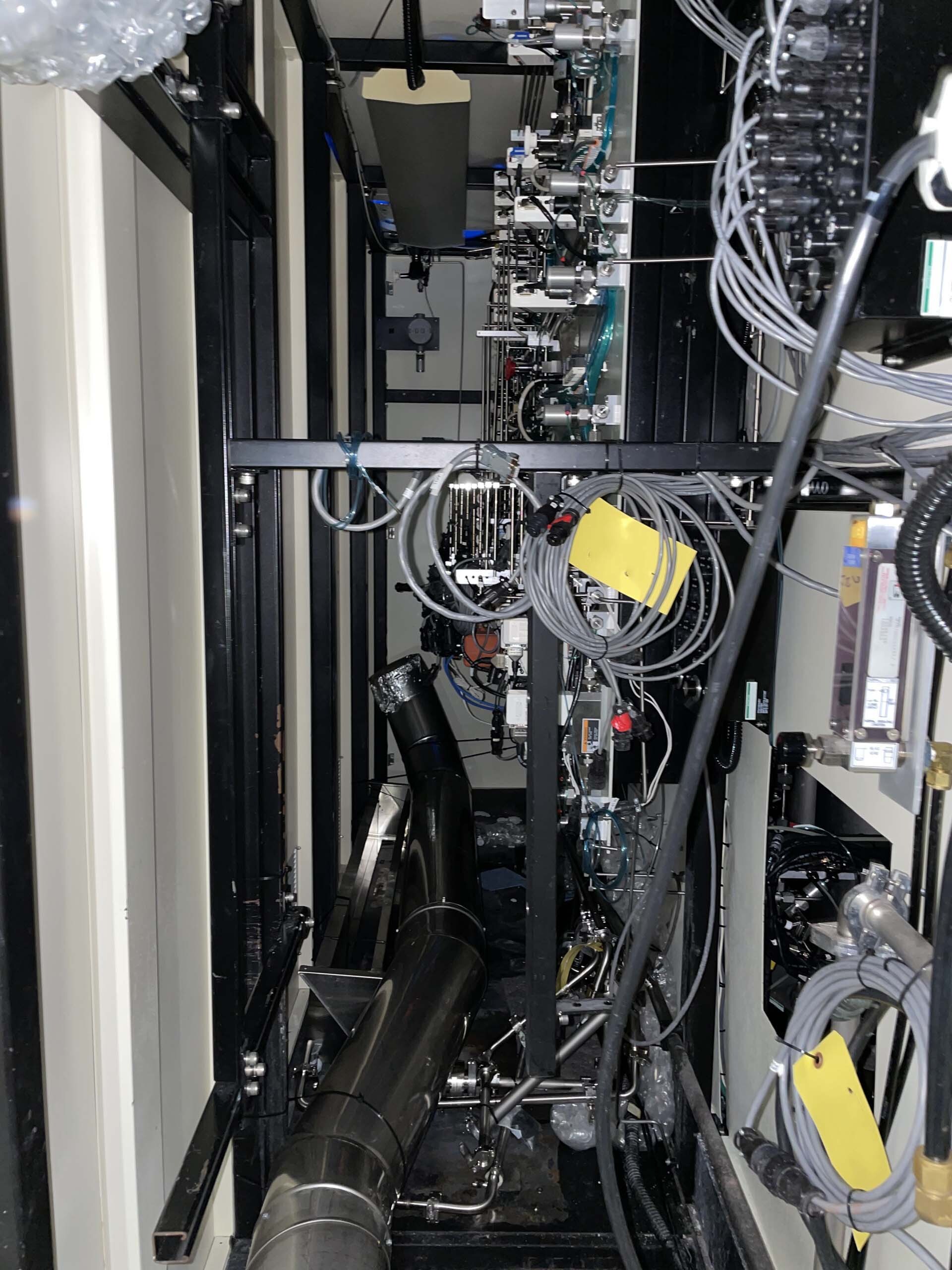

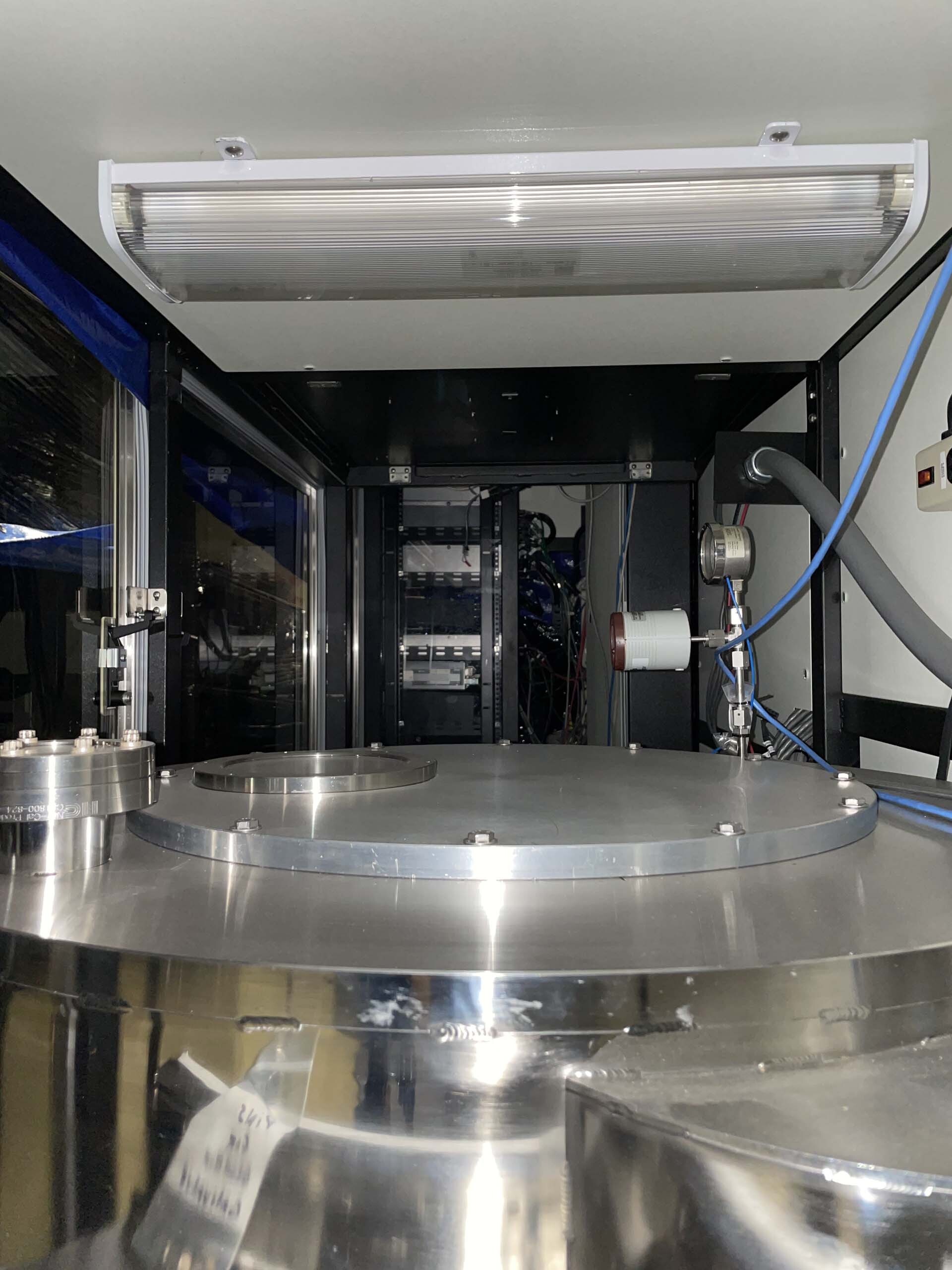

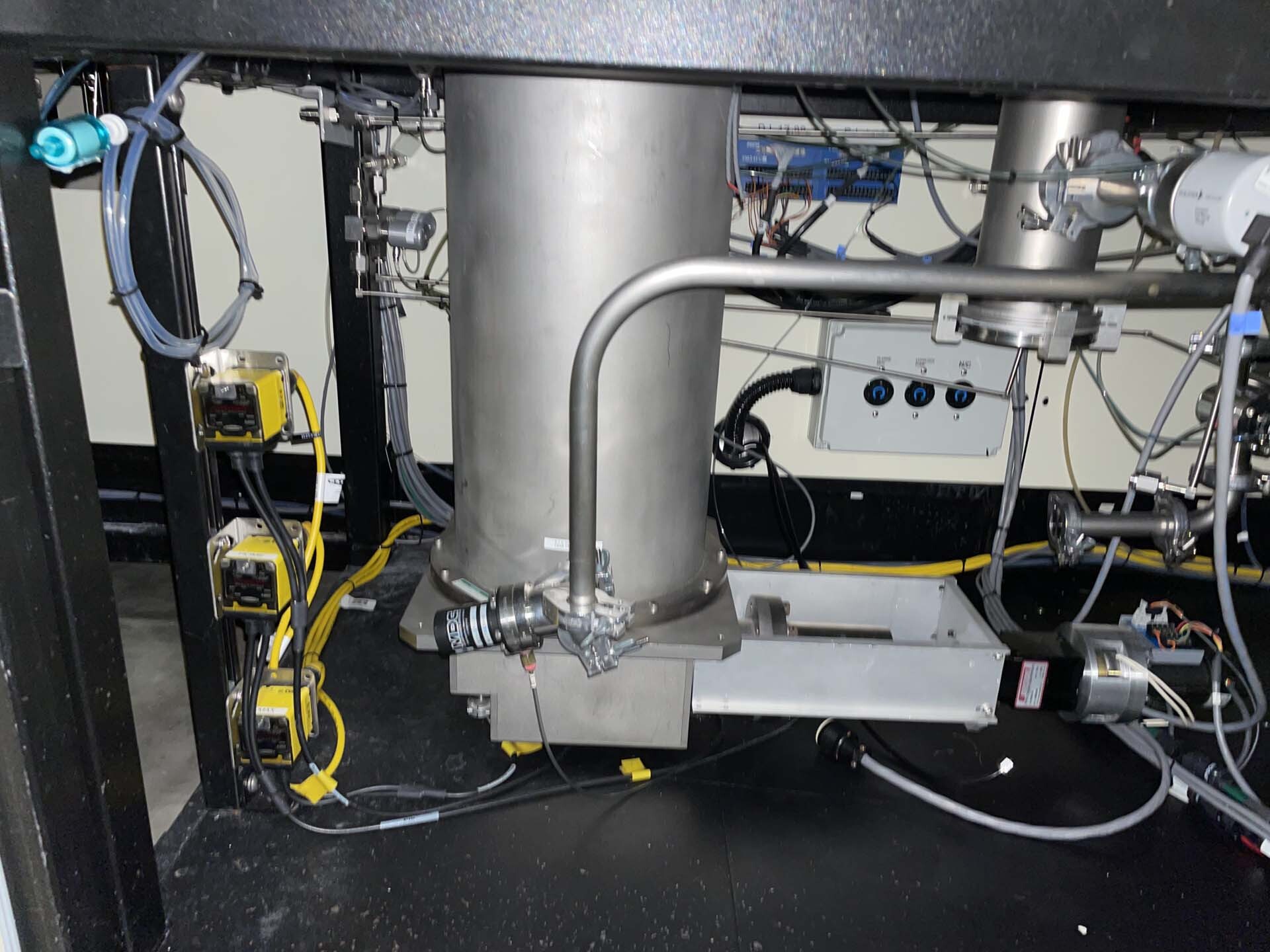

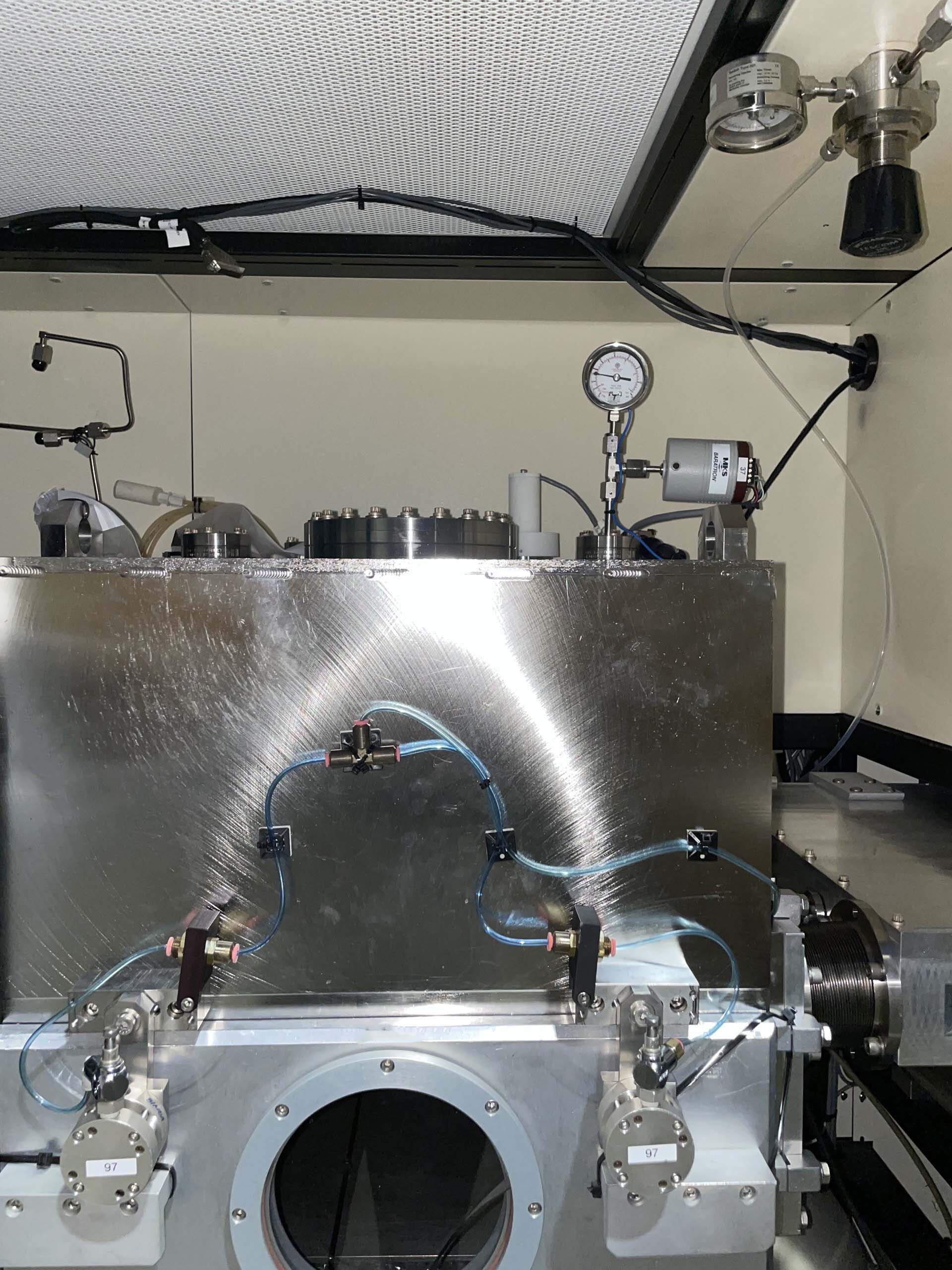

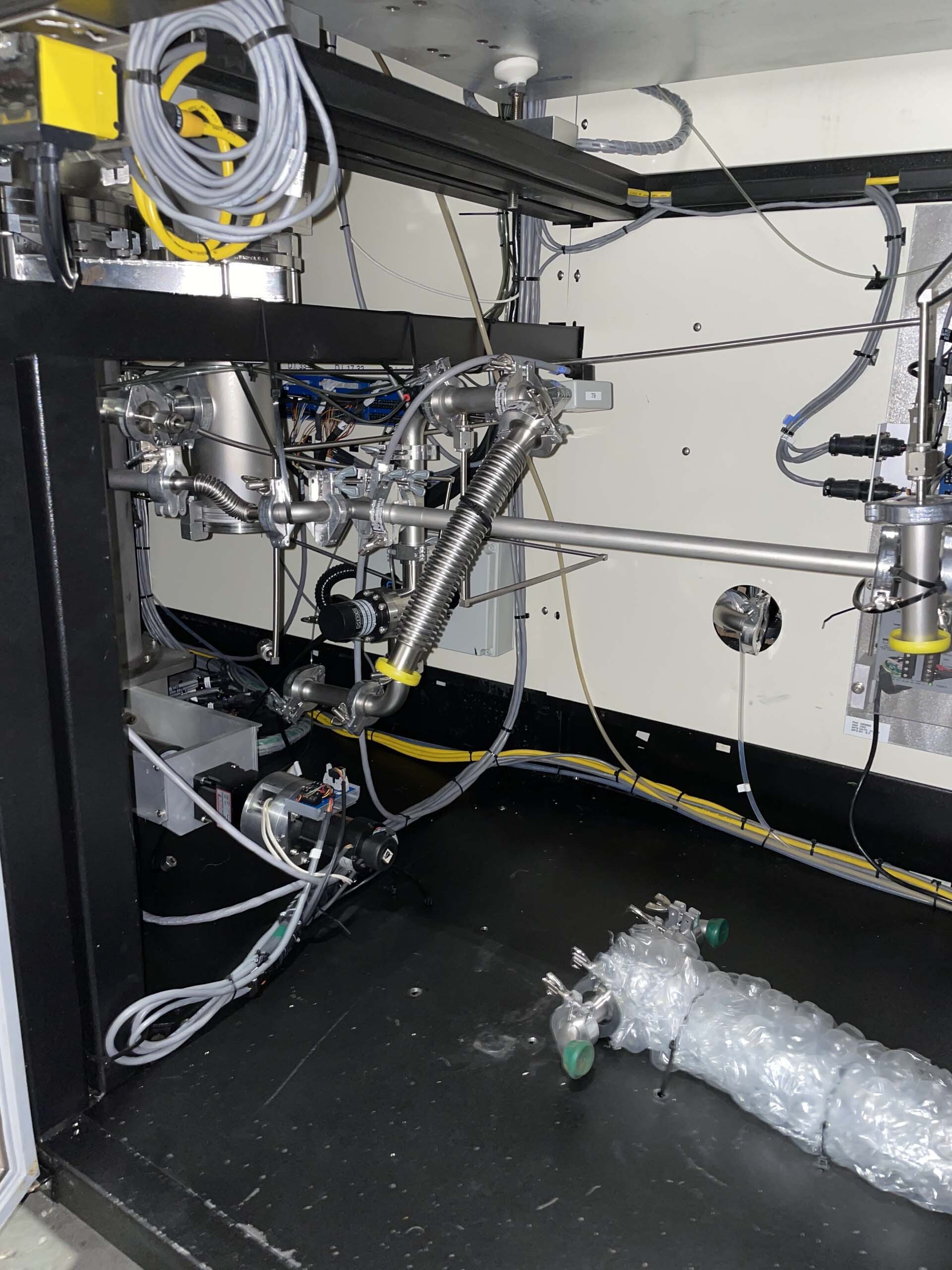

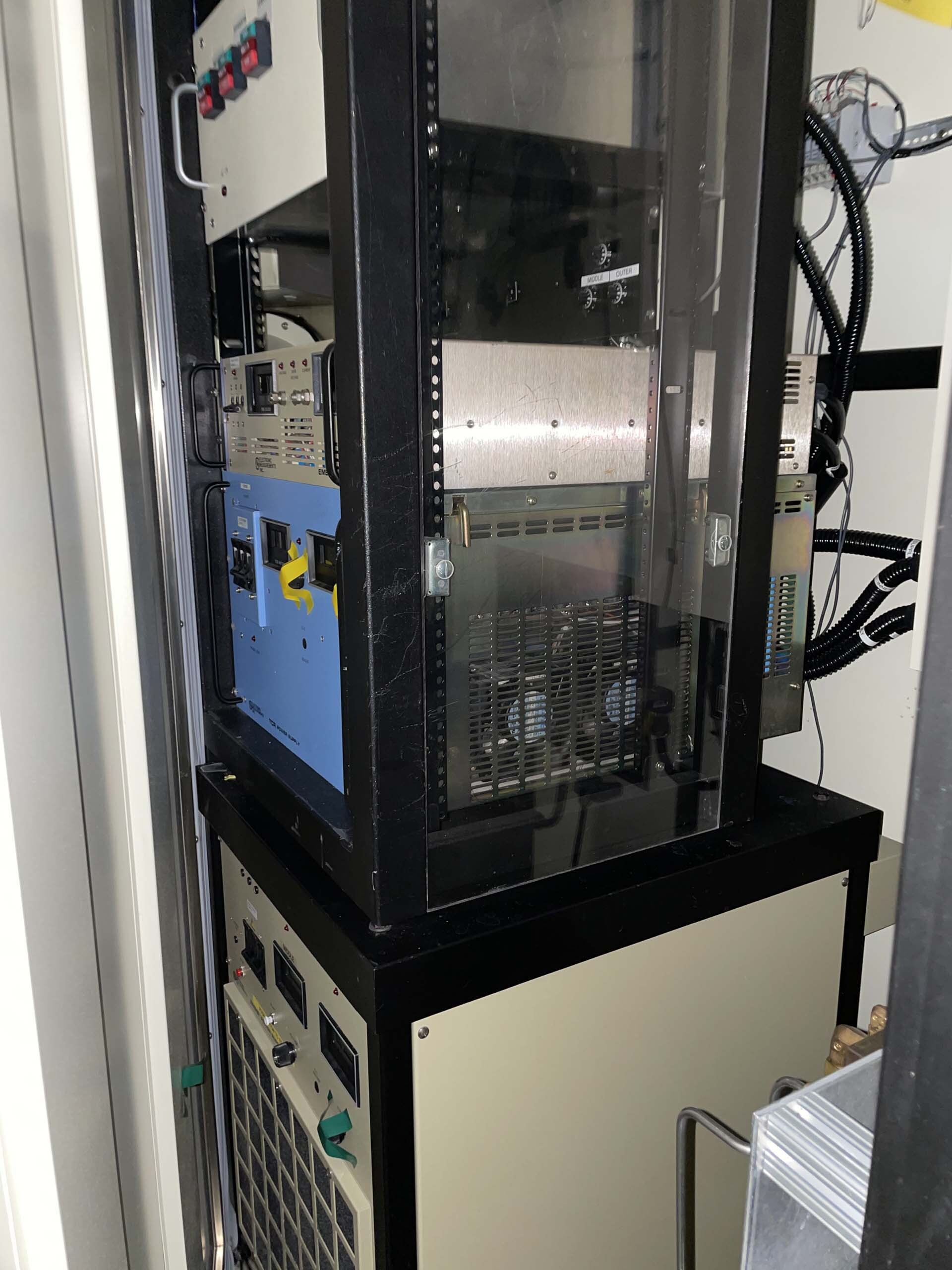

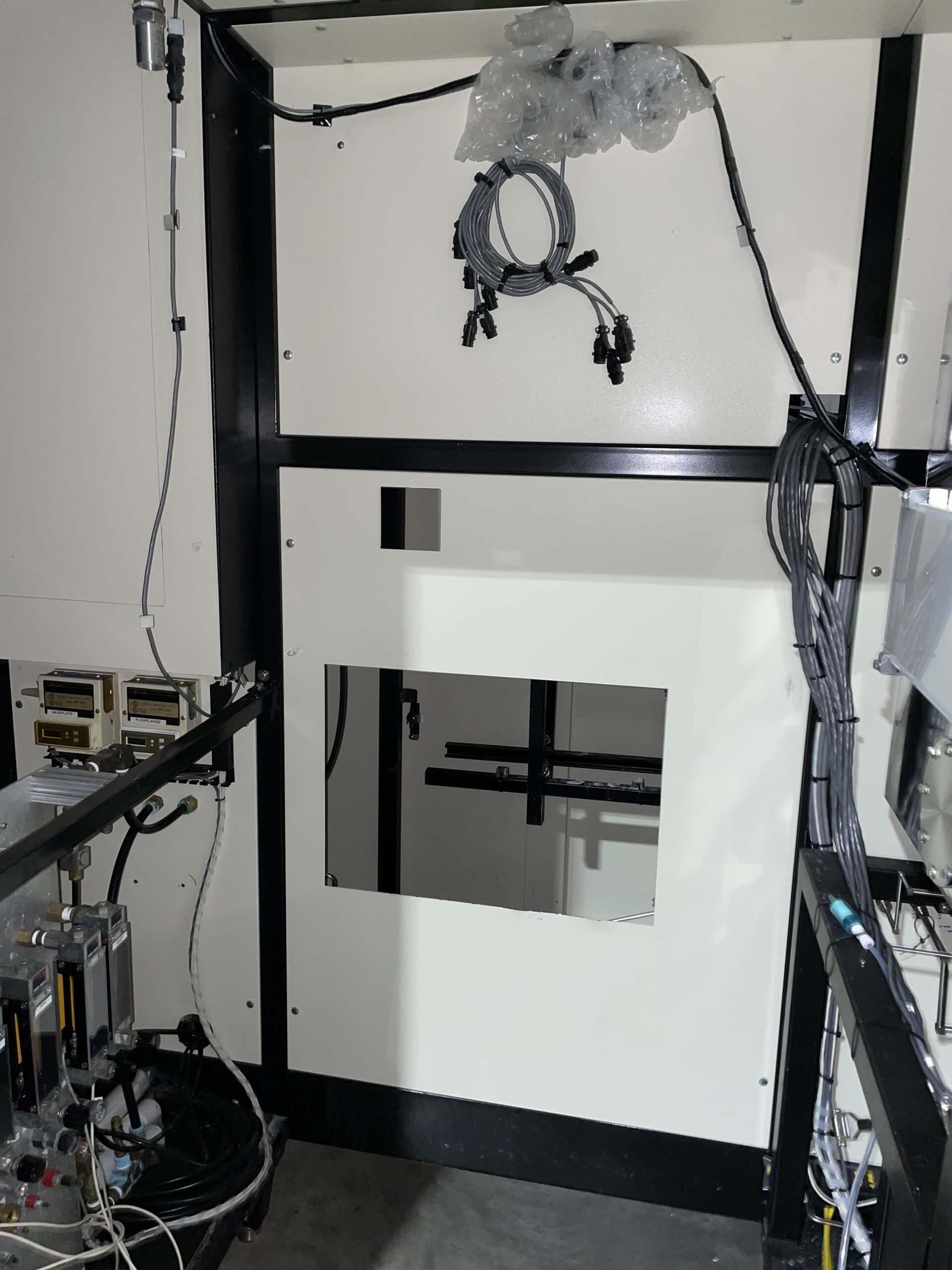

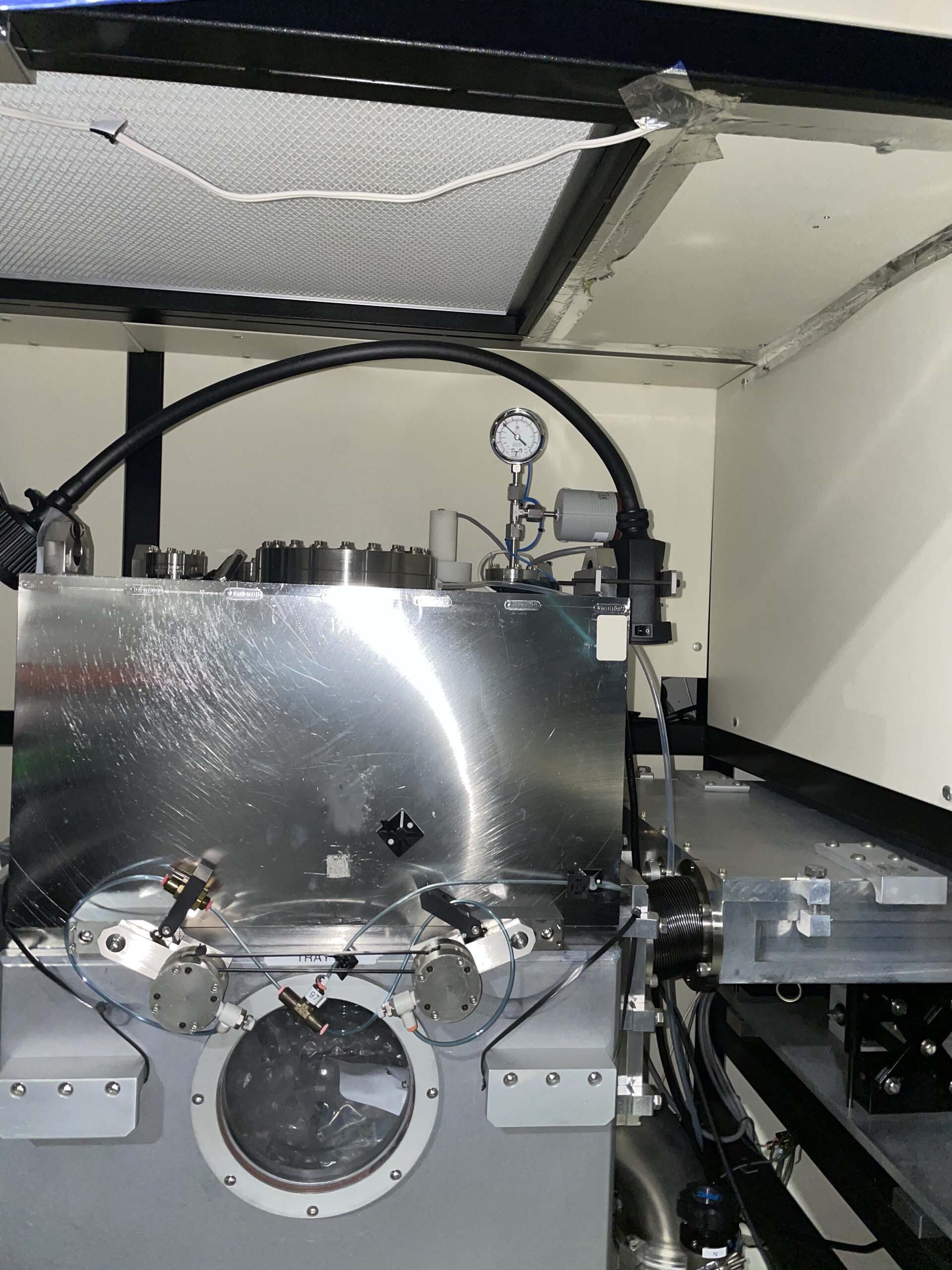

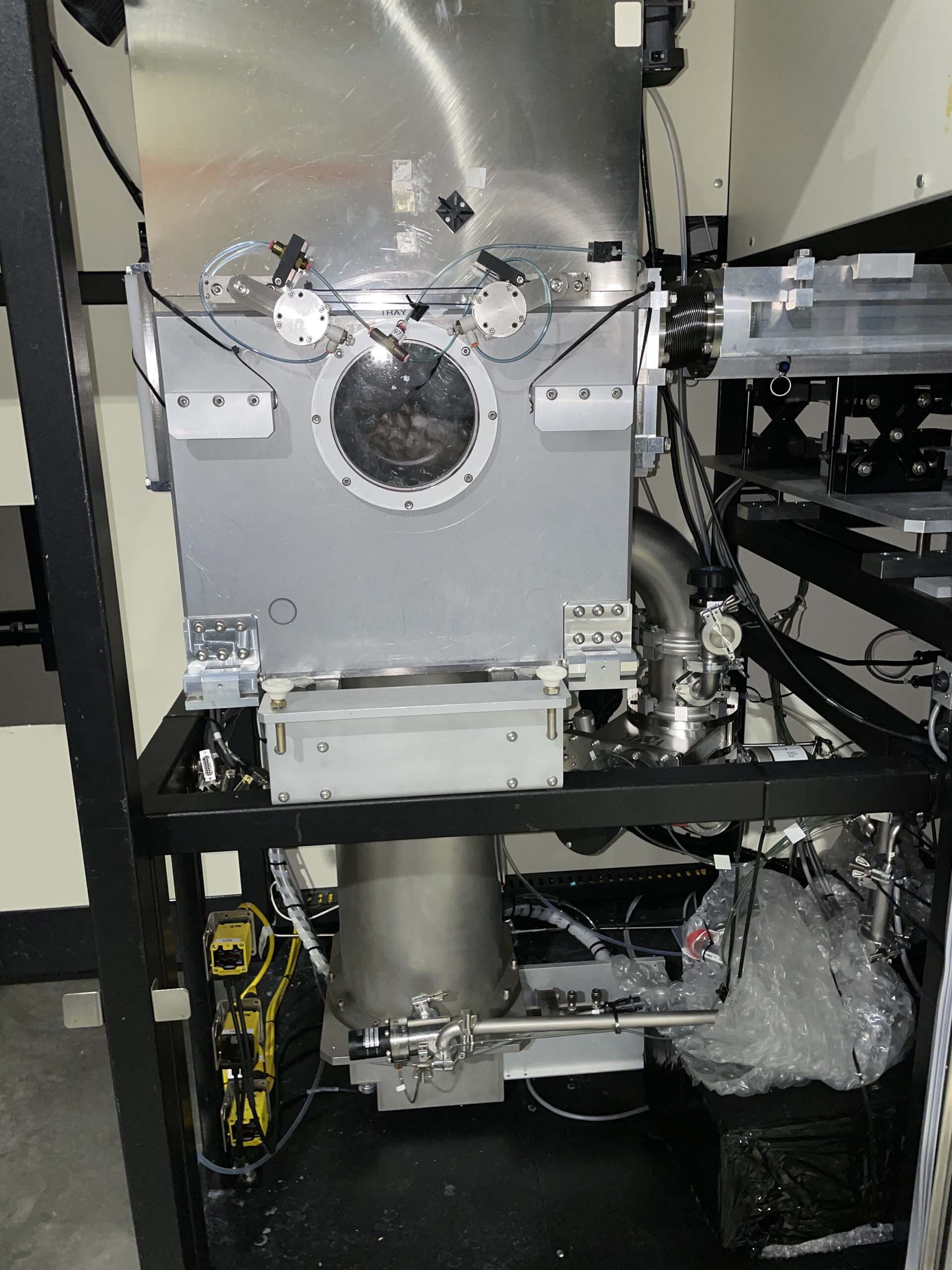

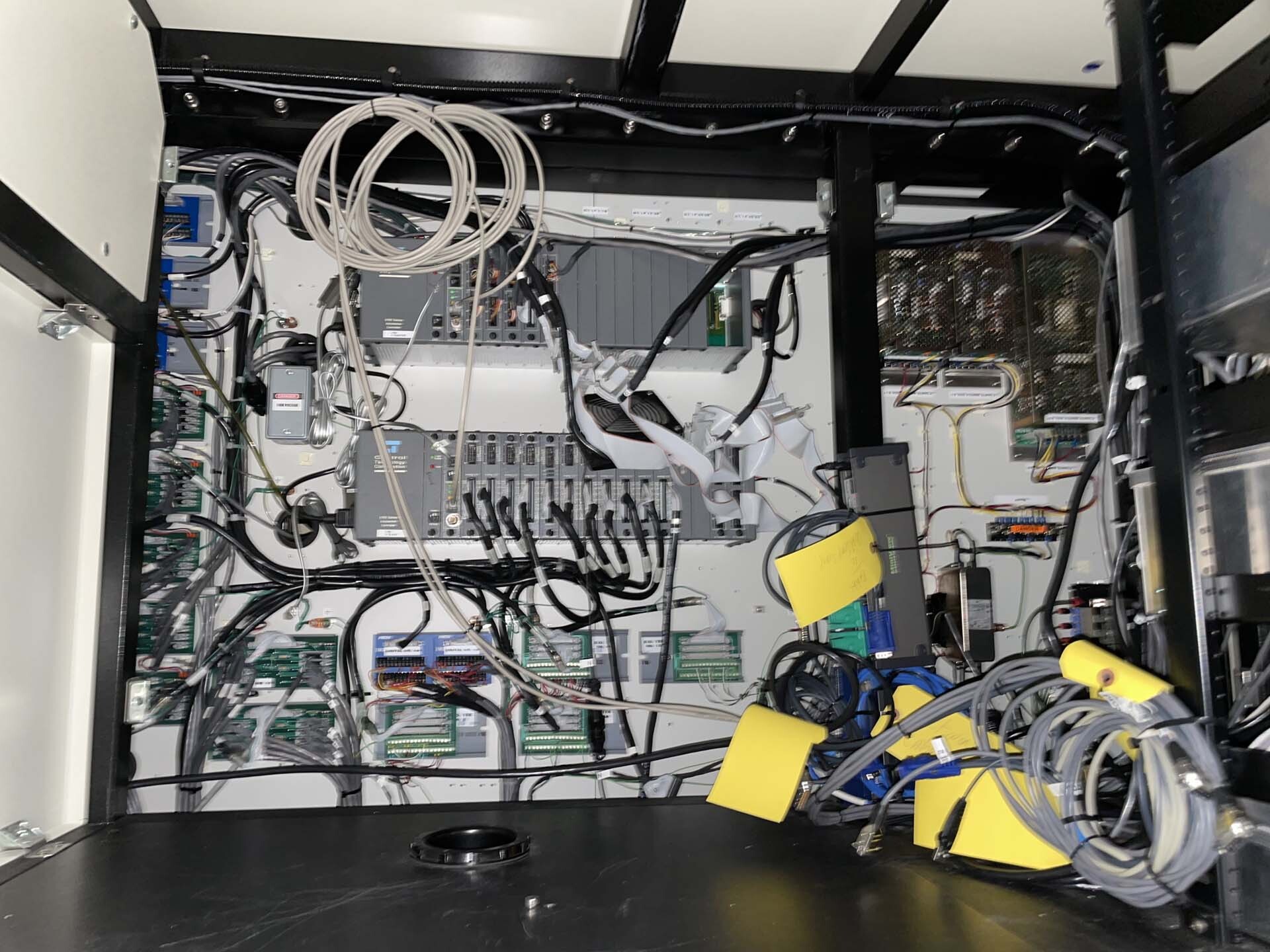

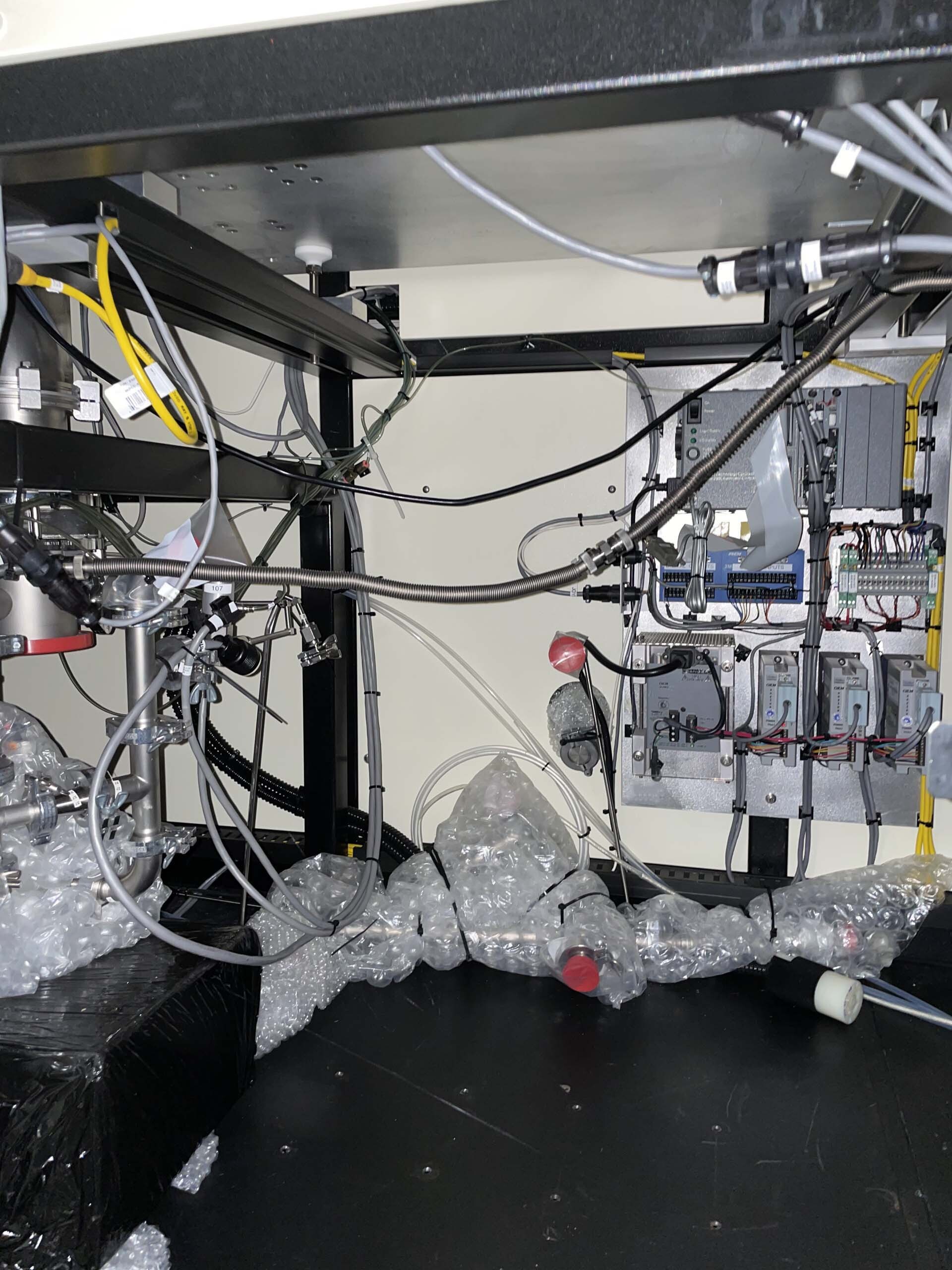

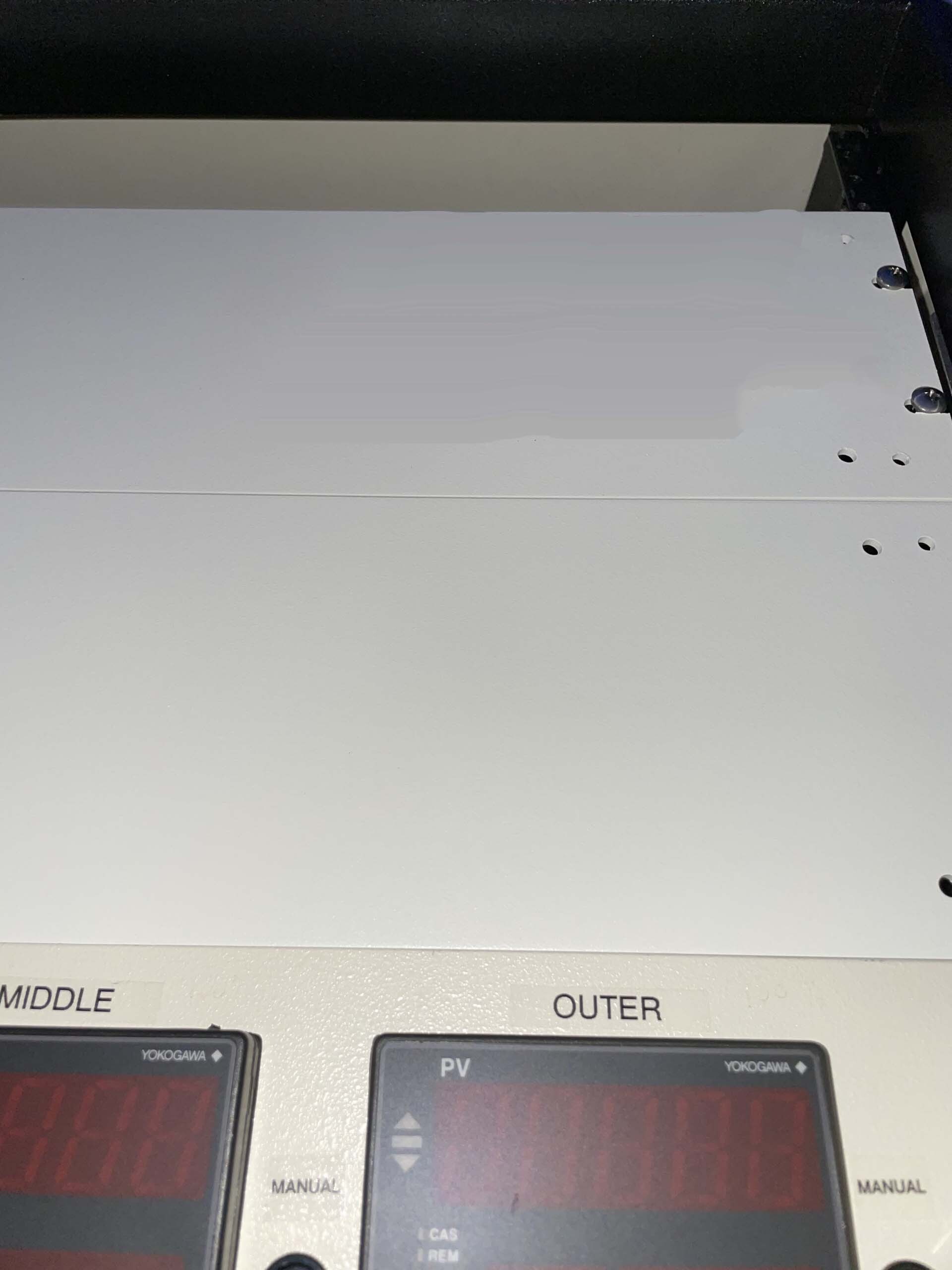

VEECO / EMCORE E400 is an electron-beam (e-beam) vaporization based alternately pulsed laser deposition (APLD) reactor. This advanced deposition equipment enables the precise and repeatable deposition of thin films and hetero-structures for a variety of applications including spintronic and optoelectronic devices. The system provides a high-speed, robust, and reliable platform for thin-film deposition with a high degree of control over factors such as deposition rates and substrate temperature. The unit features an electron beam source for vaporizing the target material and a pulsed laser source for controlling the deposition rate. VEECO E400 utilizes a unique Alt Process Control Machine (APCS) to accurately control the pressure, vacuum, temperature, deposition rate, and other related parameters. It features an advanced thermoelectric stage-controller and an Adaptive Growth Rate Control (AGRC) which provide a high degree of control over the growth rate. The APCS utilizes a feed-forward mechanism to continually adjust the growth and pressure conditions to conform to the desired growth rate. The e-beam source is integrated into the chamber and features a three-axis manipulator, allowing for precise motion control suitable for substrates of different sizes and shapes. The tool's 11-axis manipulator features real-time control of the deposition parameters and provides feedback information that allows for quick, easy, and reliable thin films deposition. The APLD ensures reliable and repeatable deposition of thick layers to sub-nanometer thickness. The device also allows for the deposition of a variety of materials including metals, oxides, nitrides, polymers, and other organic materials. EMCORE E400 is equipped with various in-situ monitoring systems such as scanning electron microscopy (SEM) and time-of-flight secondary ion mass spectra (Tof-SIMS). This ensures in-depth characterization of the deposited material and allows for optimization of the deposition parameters. The combination of APLD and SEM allows for high-precision and repeatable stacking of layers of different materials and height, as well as the study of micro-structures of the deposited material. In conclusion, E400 is a versatile deposition tool which enables controlled and detailed deposition of thin films and heterostructures on a variety of substrates. Its advanced process control asset combined with its versatile manipulator and in-situ characterization systems provide a reliable platform for e-beam deposition. This model is an ideal choice for many applications, enabling high-speed, precise and repeatable deposition of thin films for spintronic and optoelectronic devices.

There are no reviews yet