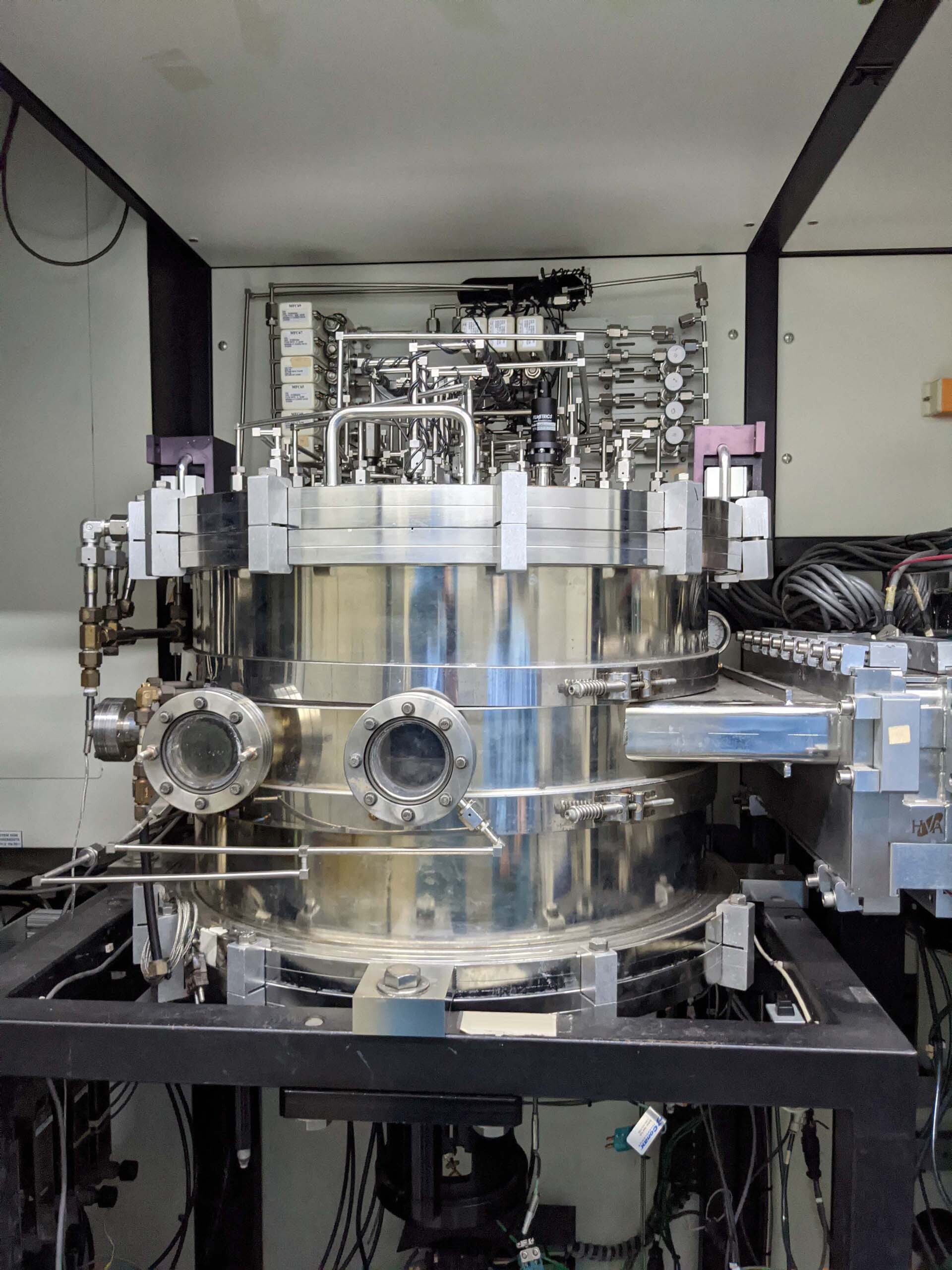

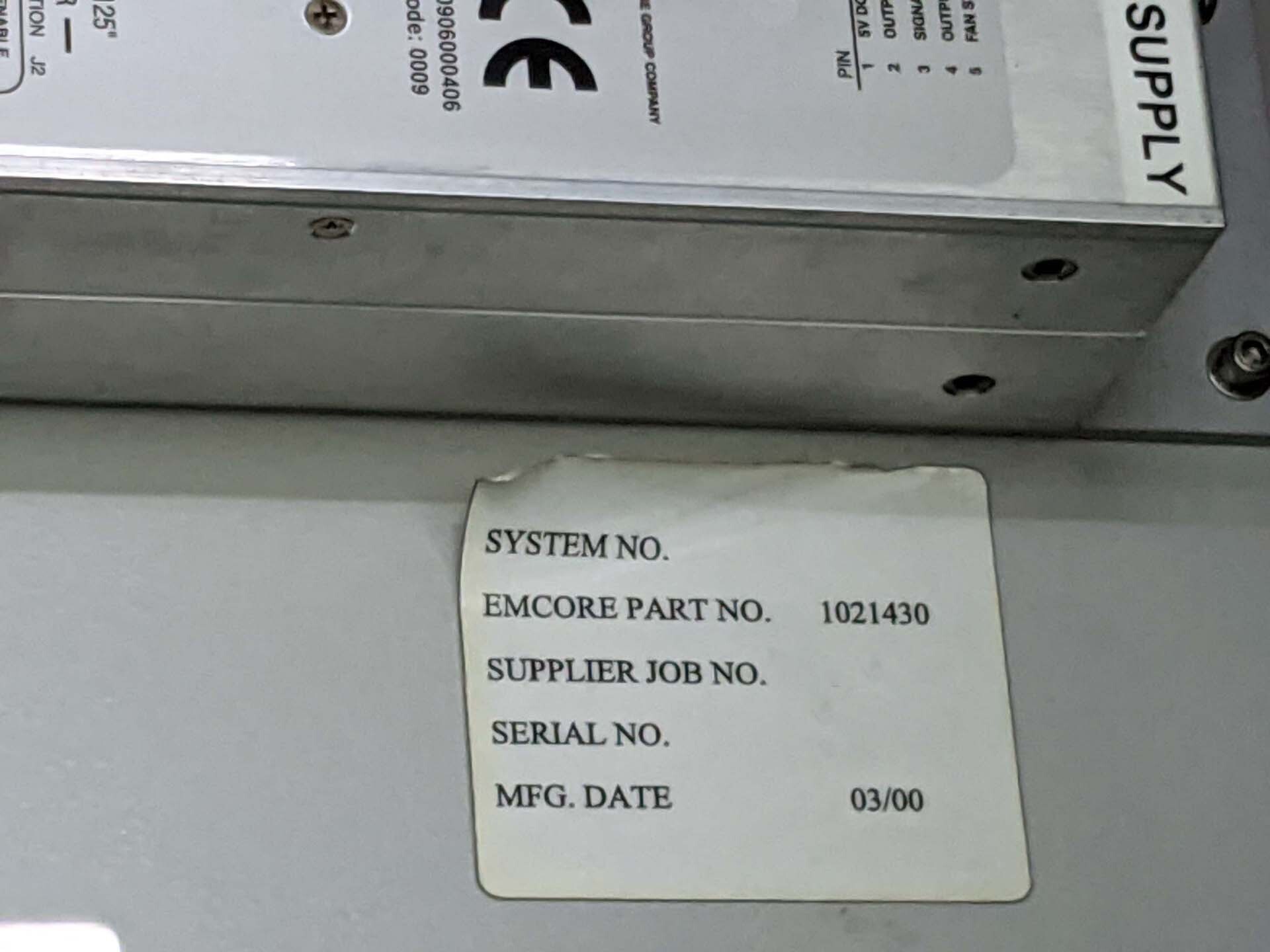

Used VEECO / EMCORE E400 #9395073 for sale

URL successfully copied!

Tap to zoom

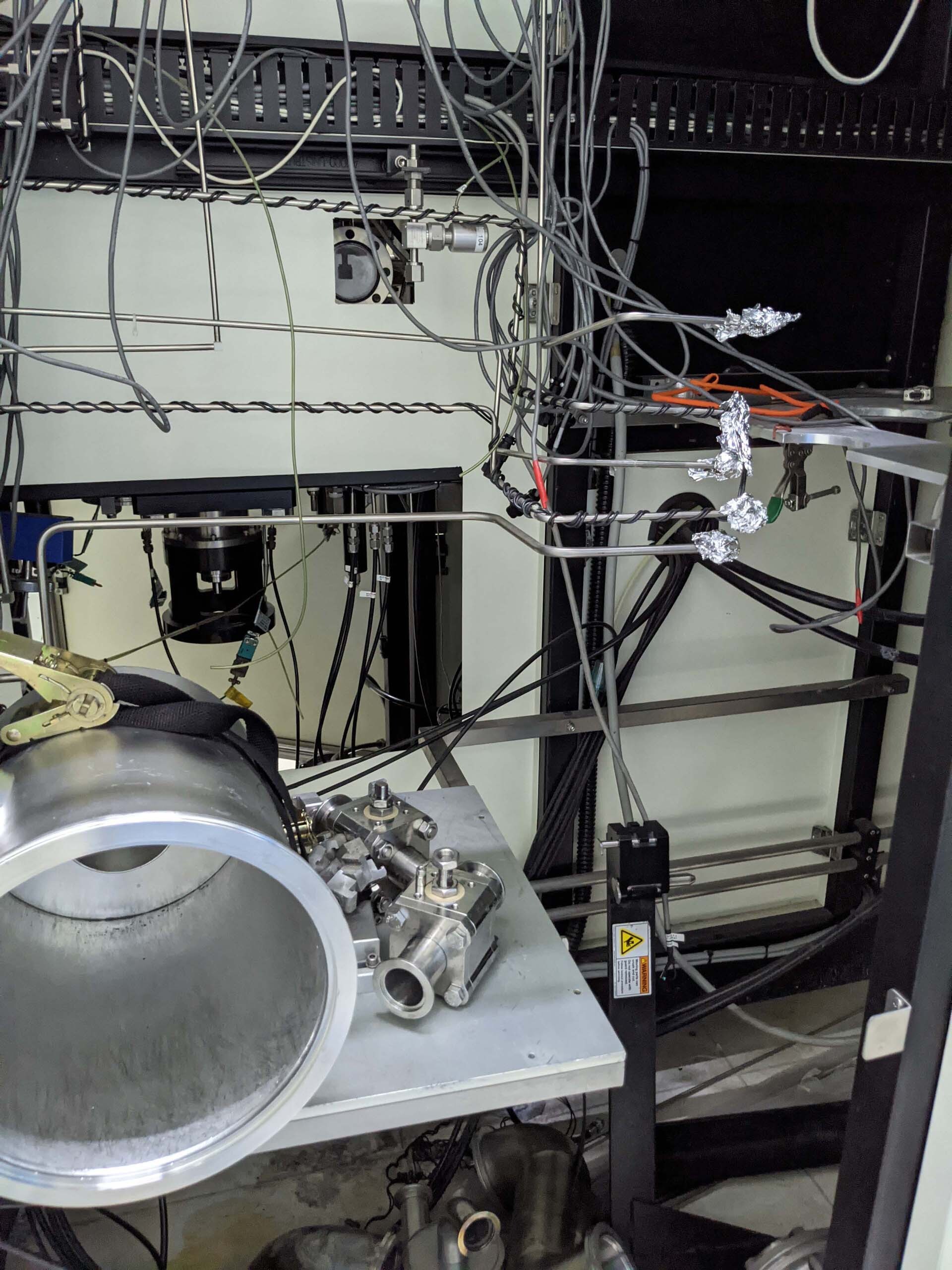

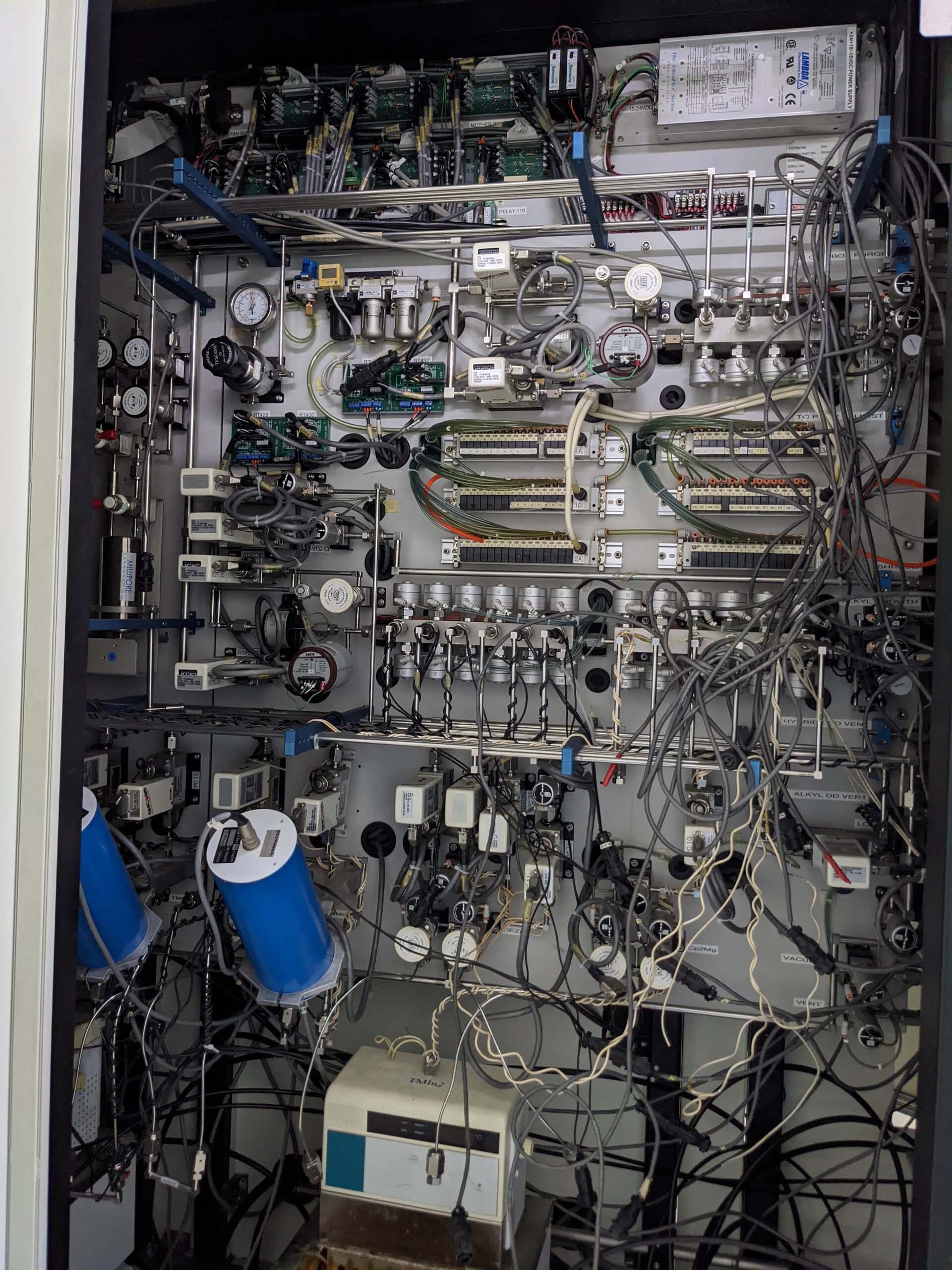

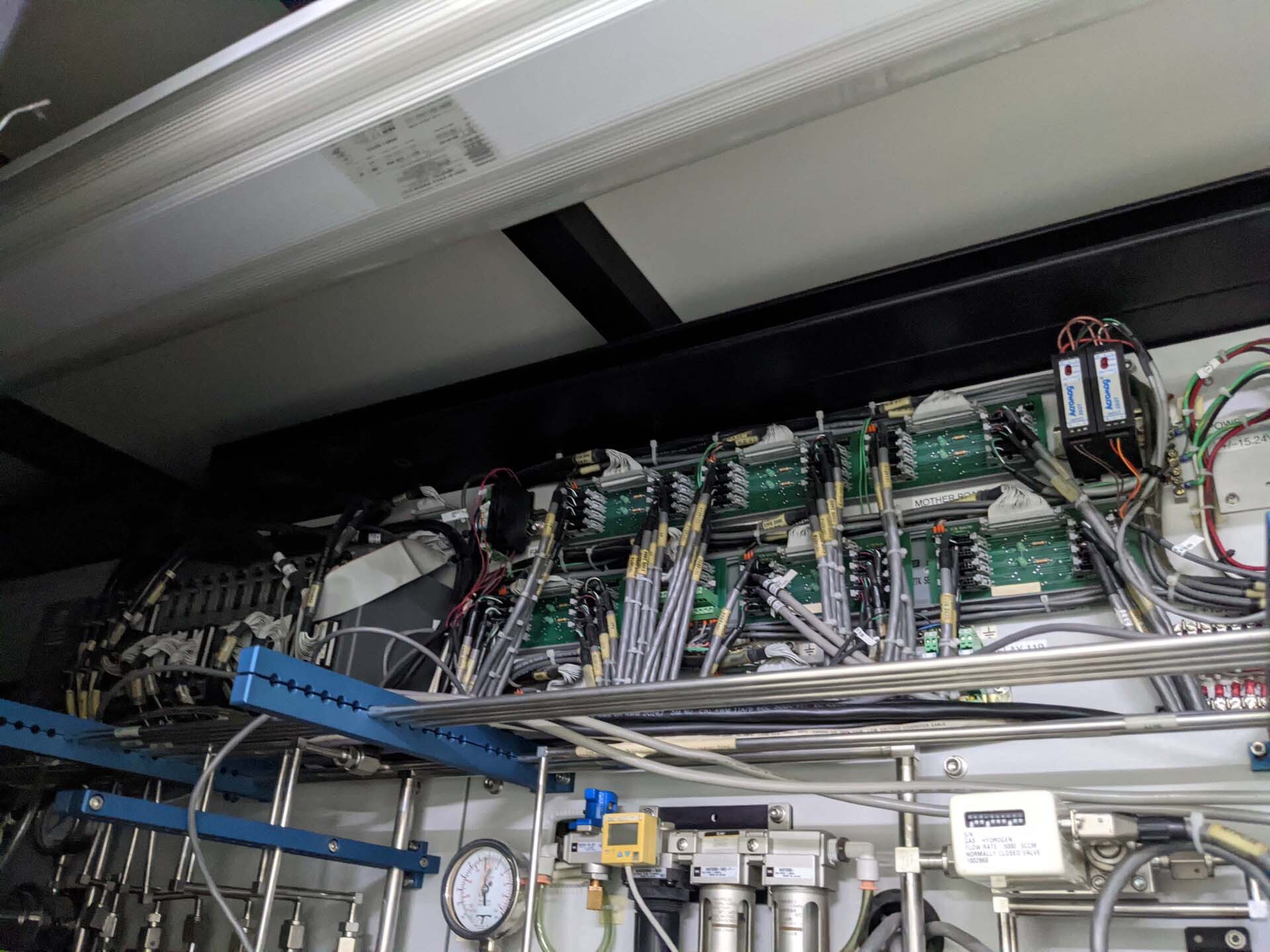

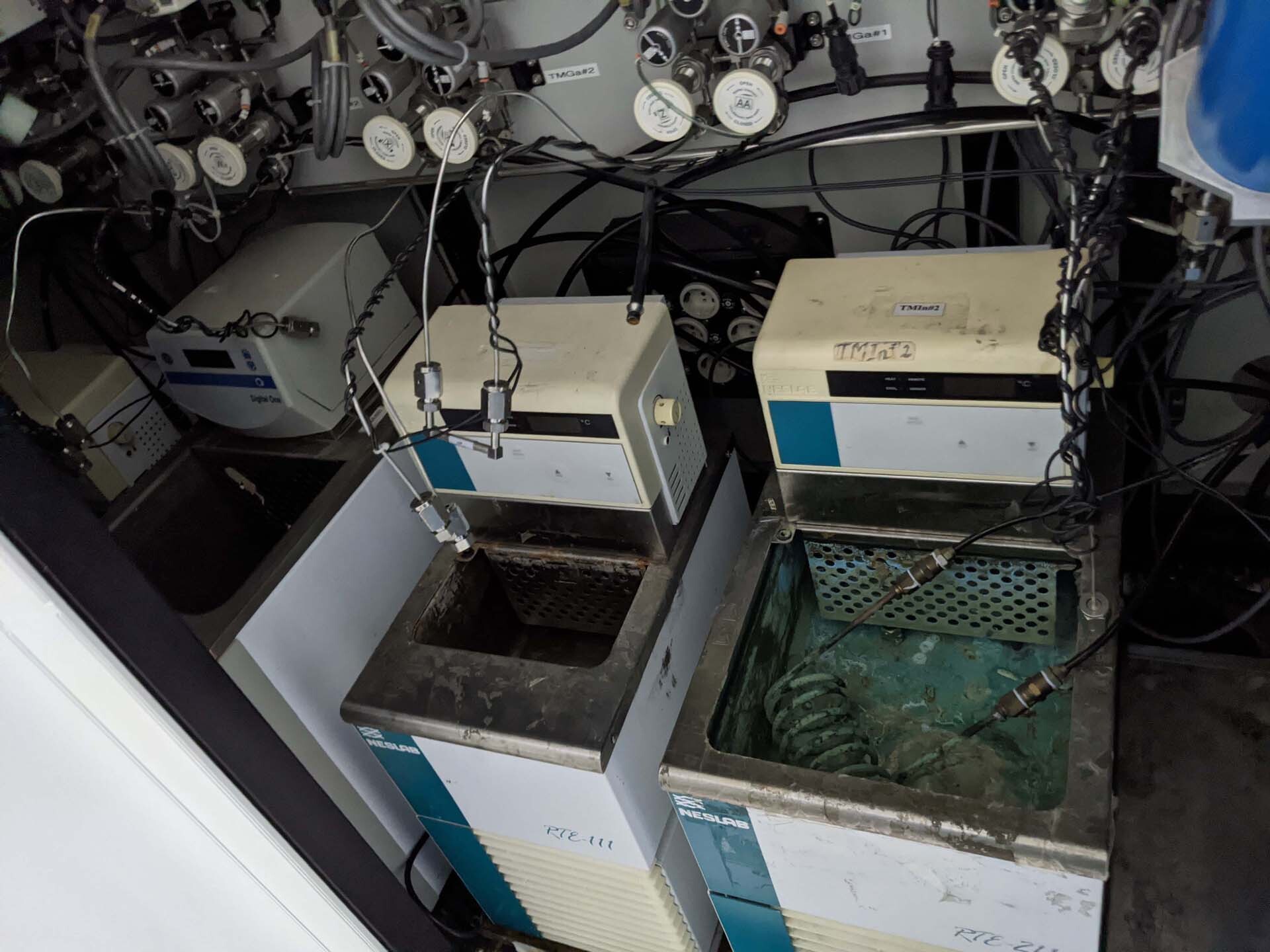

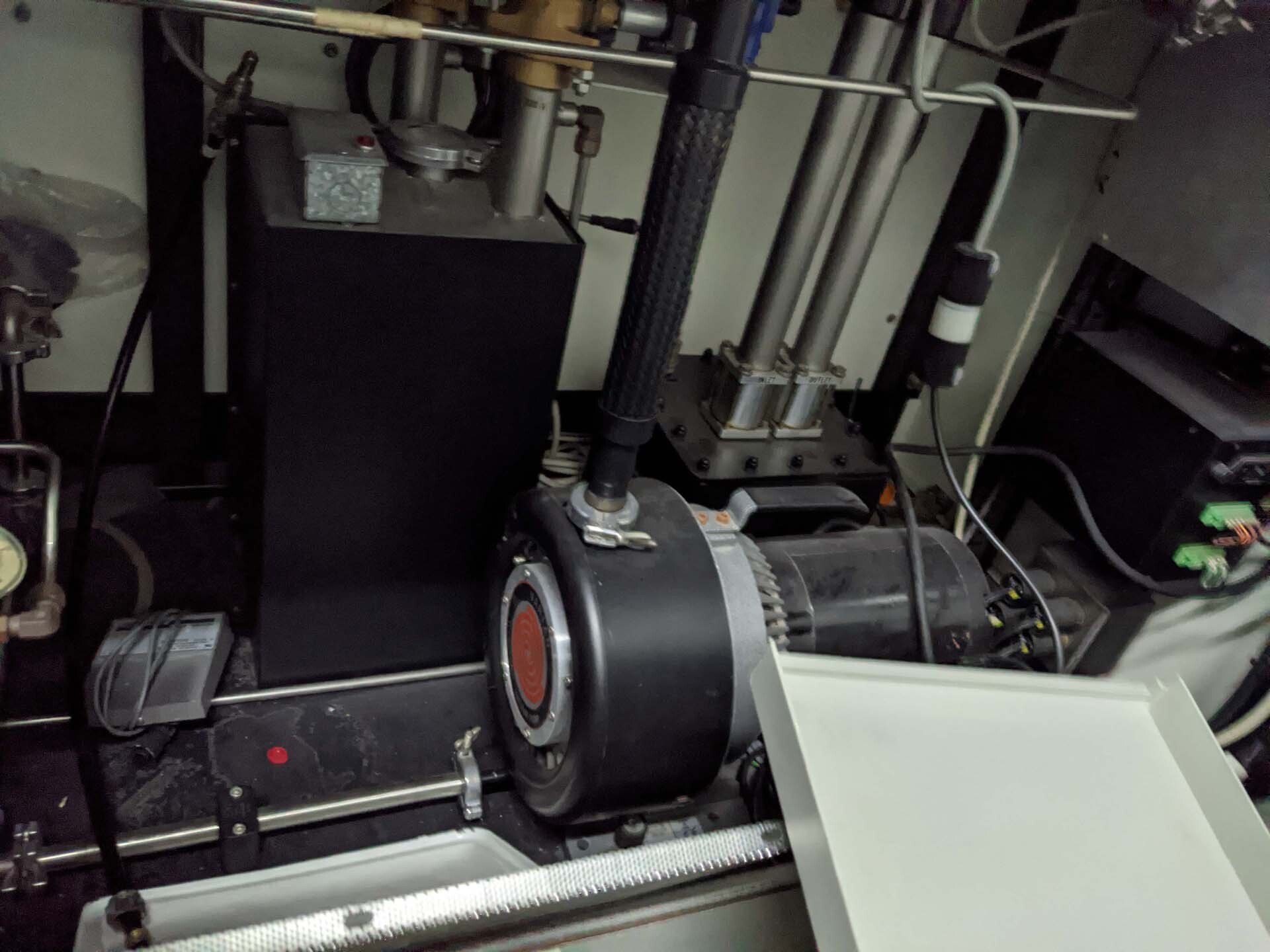

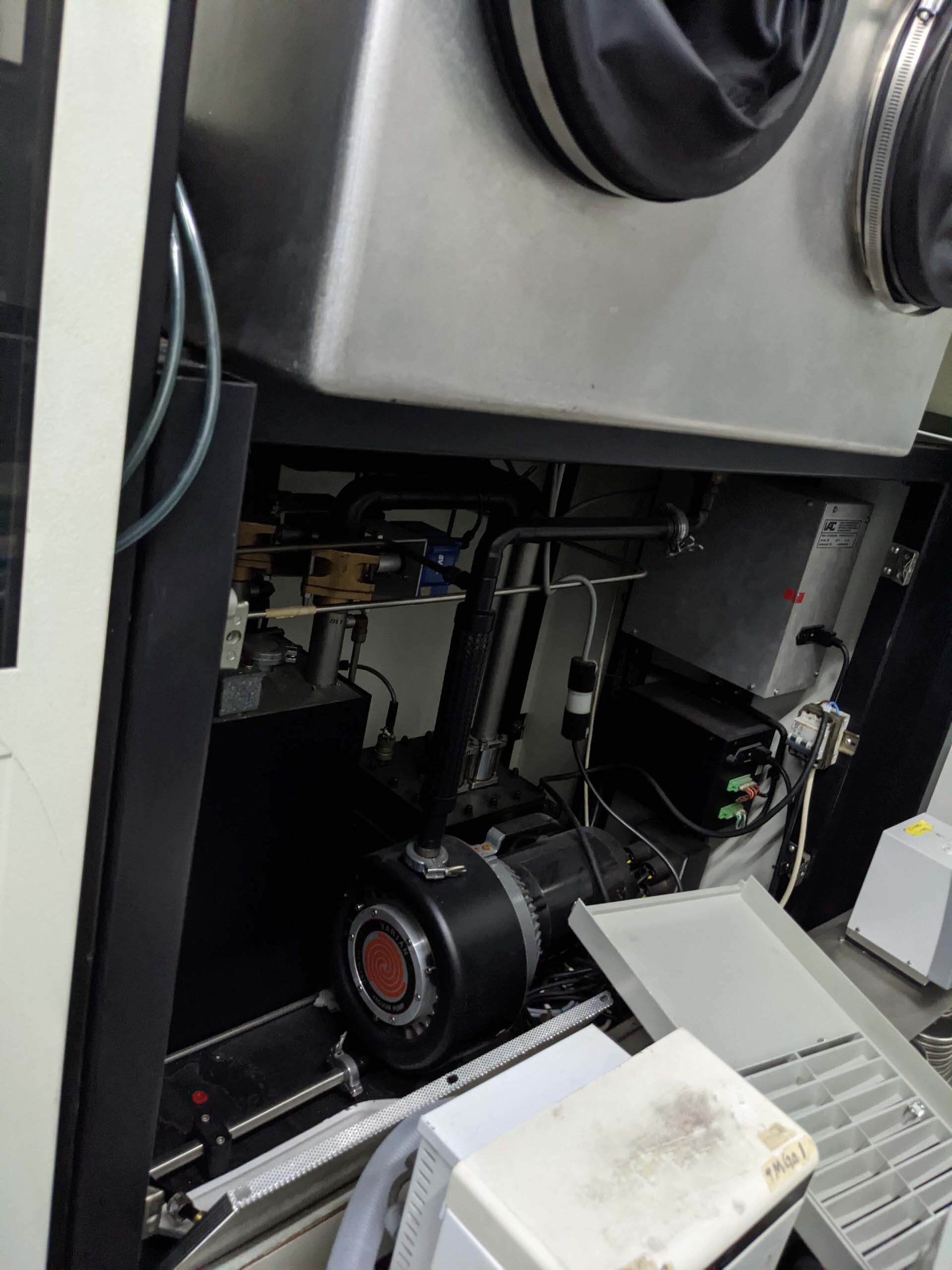

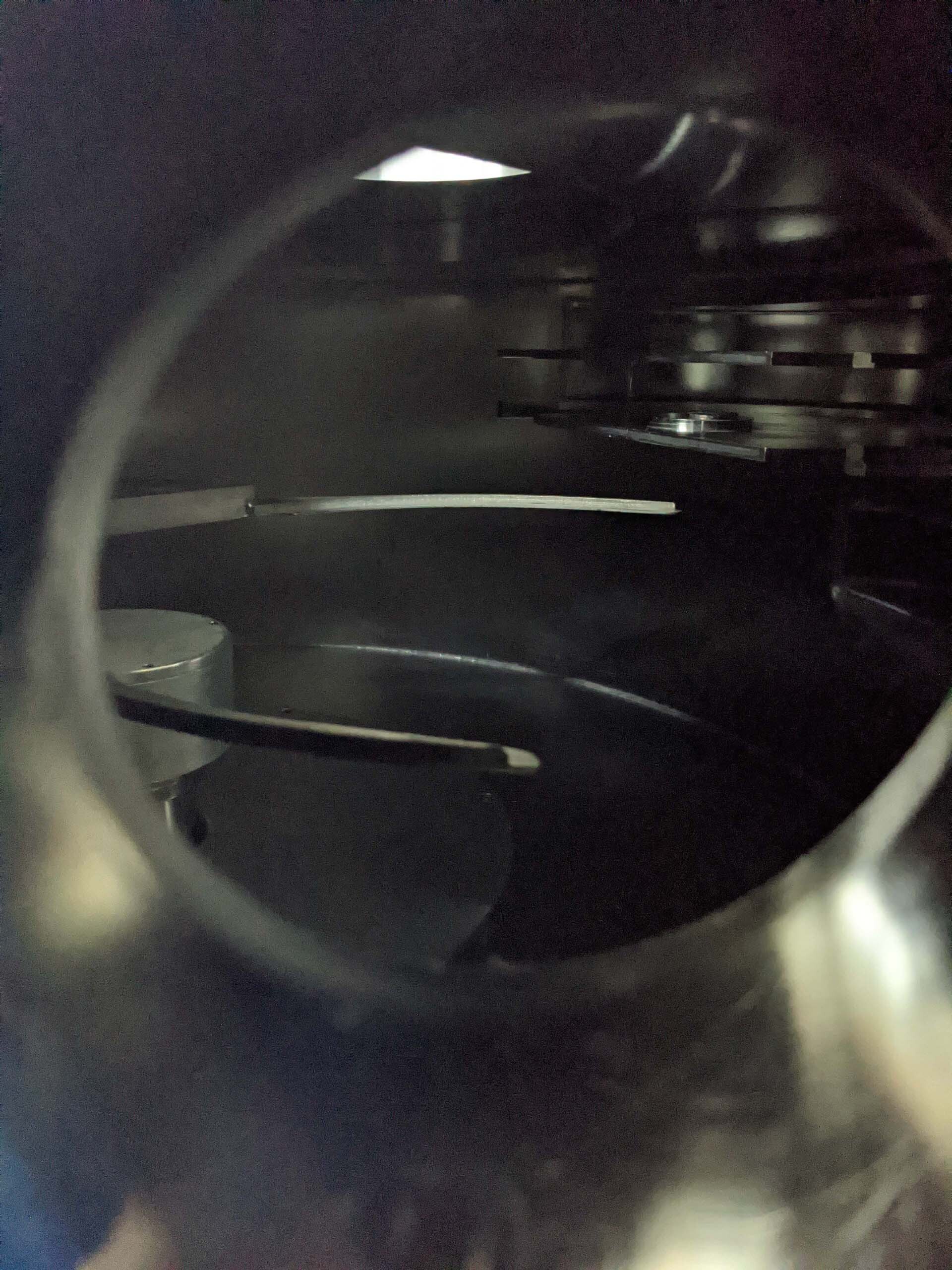

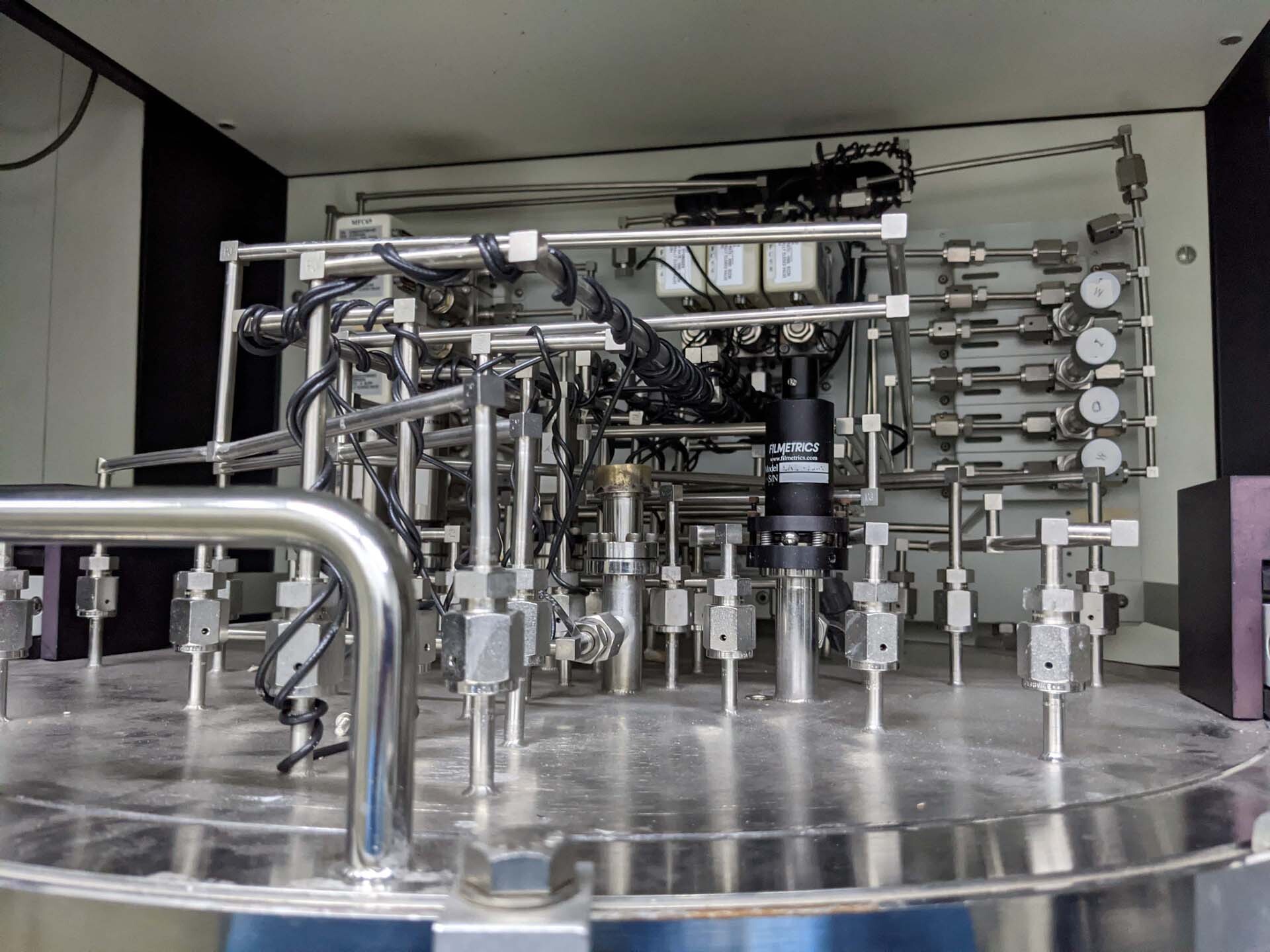

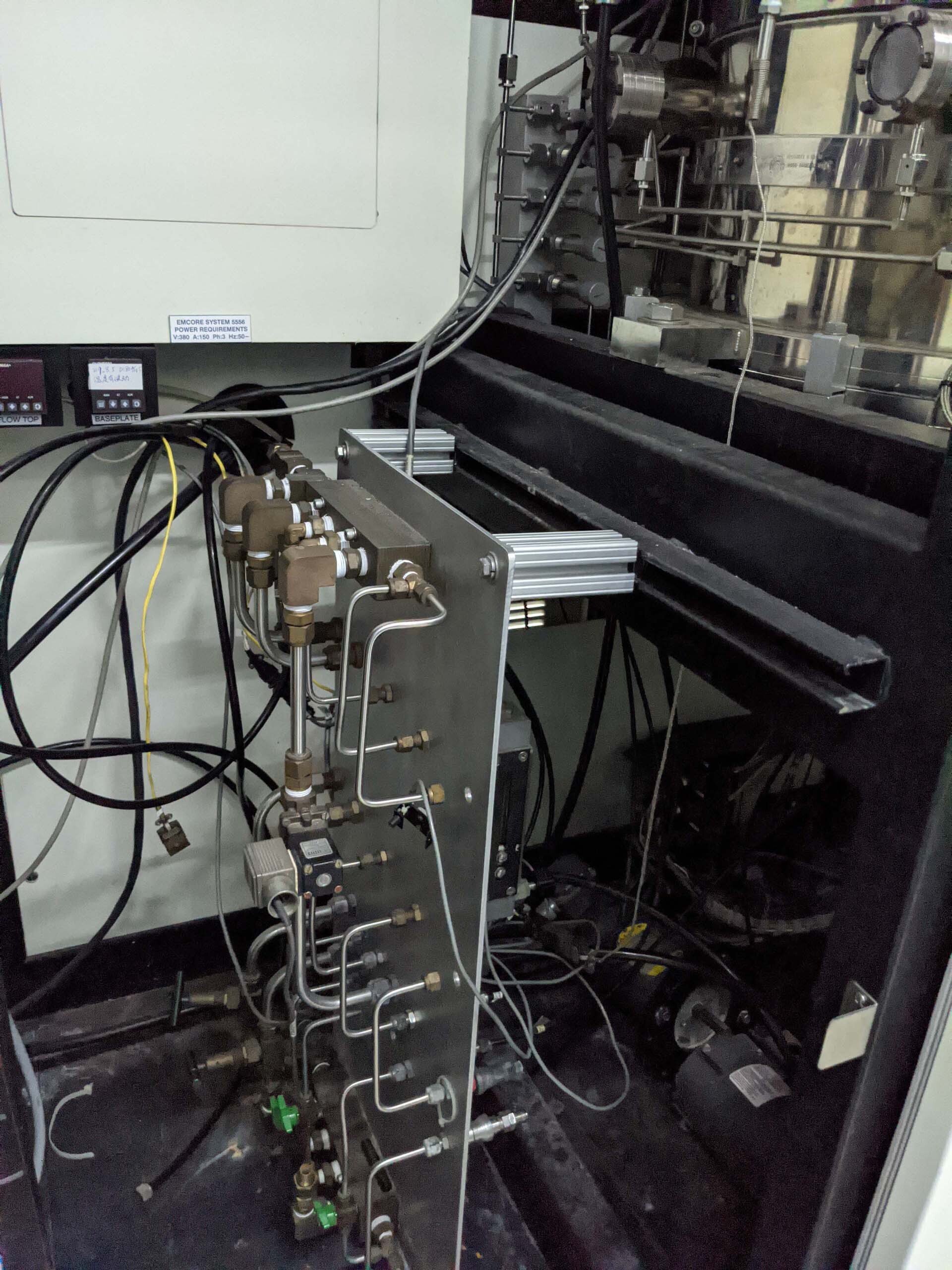

VEECO / EMCORE E400 Reactor is an advanced semiconductor fabrication tool used to create a variety of different photonic integrated circuits. It is typically used in the design and production of complex photonic integrated circuits such as Semiconductor optical amplifiers, Mach-Zehnder Interferometers, and DFB lasers. VEECO E400 Reactor is capable of producing up to 300 mm wafers, allowing it to be used in the production of small-scale photonic devices such as VCSELs and HD-LEDs. EMCORE E400 Reactor utilizes a multi-zone multi-stage process that involves an ultra-high vacuum, photolithography, embedded deposition, and a reactive ion etch system. This allows for precise control of the deposition of the film layers and etching of the structures. E400 Reactor is capable of producing fine features down to 0.25 μm and feature aspect ratios of up to 10:1. VEECO / EMCORE E400 Reactor utilizes a variety of sources and detectors to ensure the most accurate deposition of all materials used in the production, from metals to dielectrics. The system contains four column-mounted quartz lamps that produce broadband UV exposure, while 19 ultra-violet laser diodes are used to provide line-scan imaging for high precision patterning. The laser diodes also allow for the exposure of multiple layers simultaneously, allowing for high rate industrial production of multiple photonic devices. VEECO E400 Reactor also contains a gas injection system for the CVD-type deposition of thin film materials. This allows for precise control of the deposition process and ensures that consistent film properties are achieved. EMCORE E400 Reactor also contains a high-speed turbine for rapid etching of substrate surfaces to create high-aspect-ratio features. Overall, E400 Reactor is an advanced tool capable of precision production of a variety of photonic integrated circuits. It is highly accurate, with proprietary sources and detectors allowing for precise deposition of thin films while a high-speed turbine provides rapid etching of materials. This state-of-the-art tool is capable of producing a variety of photonic integrated circuits in an industrial scale with high accuracy and speed.

There are no reviews yet