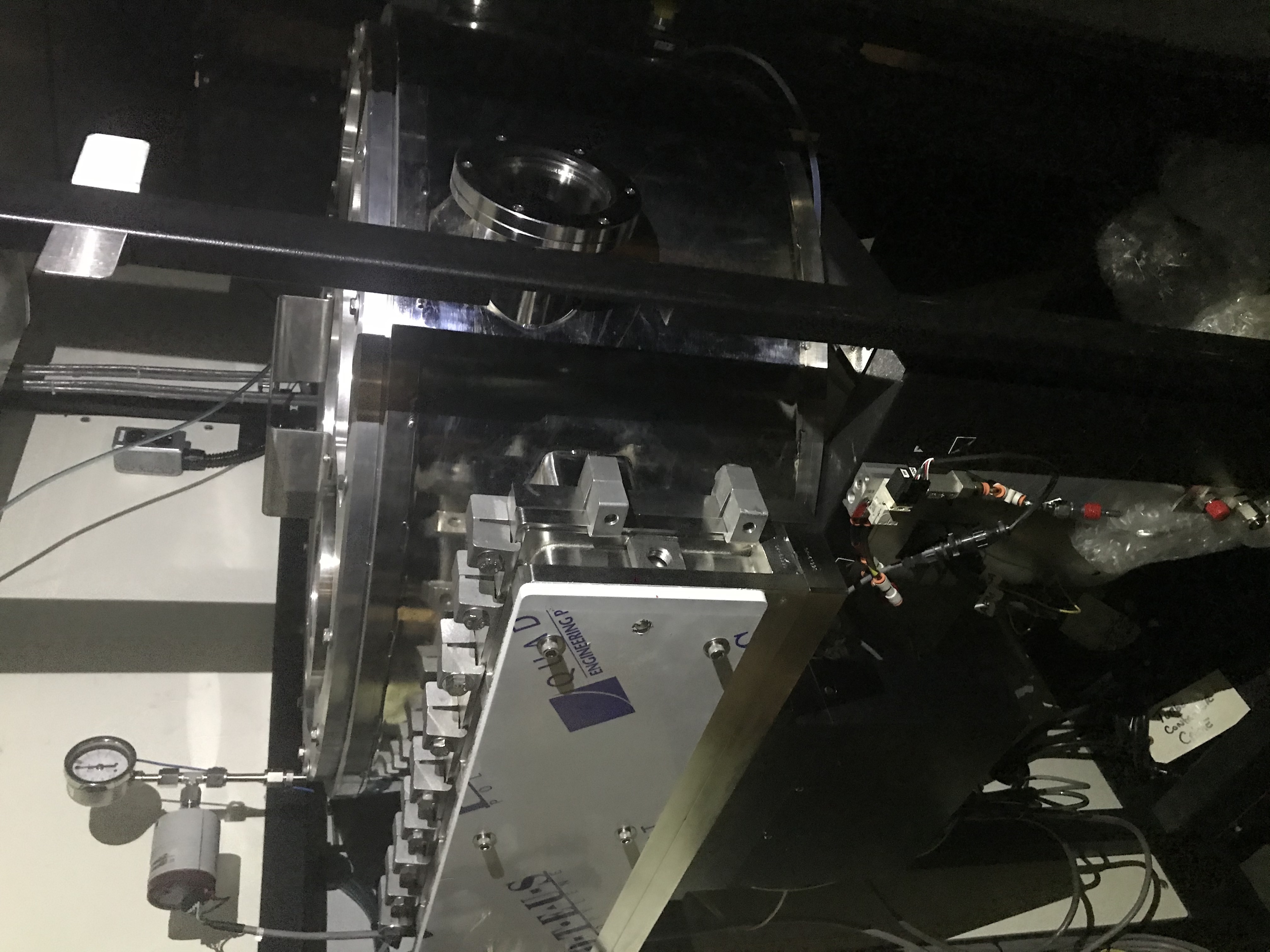

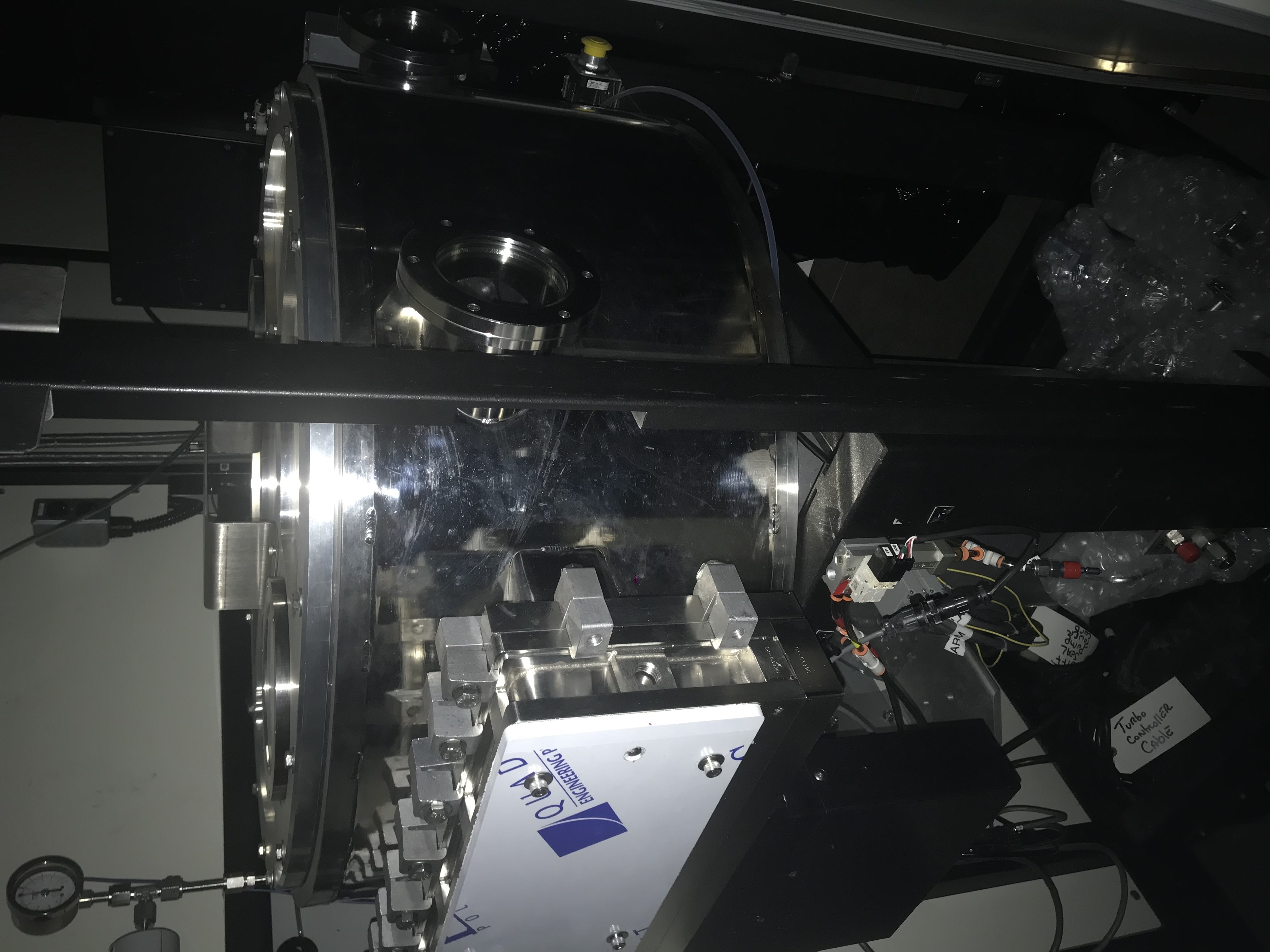

Used VEECO / EMCORE E450 #9283634 for sale

URL successfully copied!

Tap to zoom

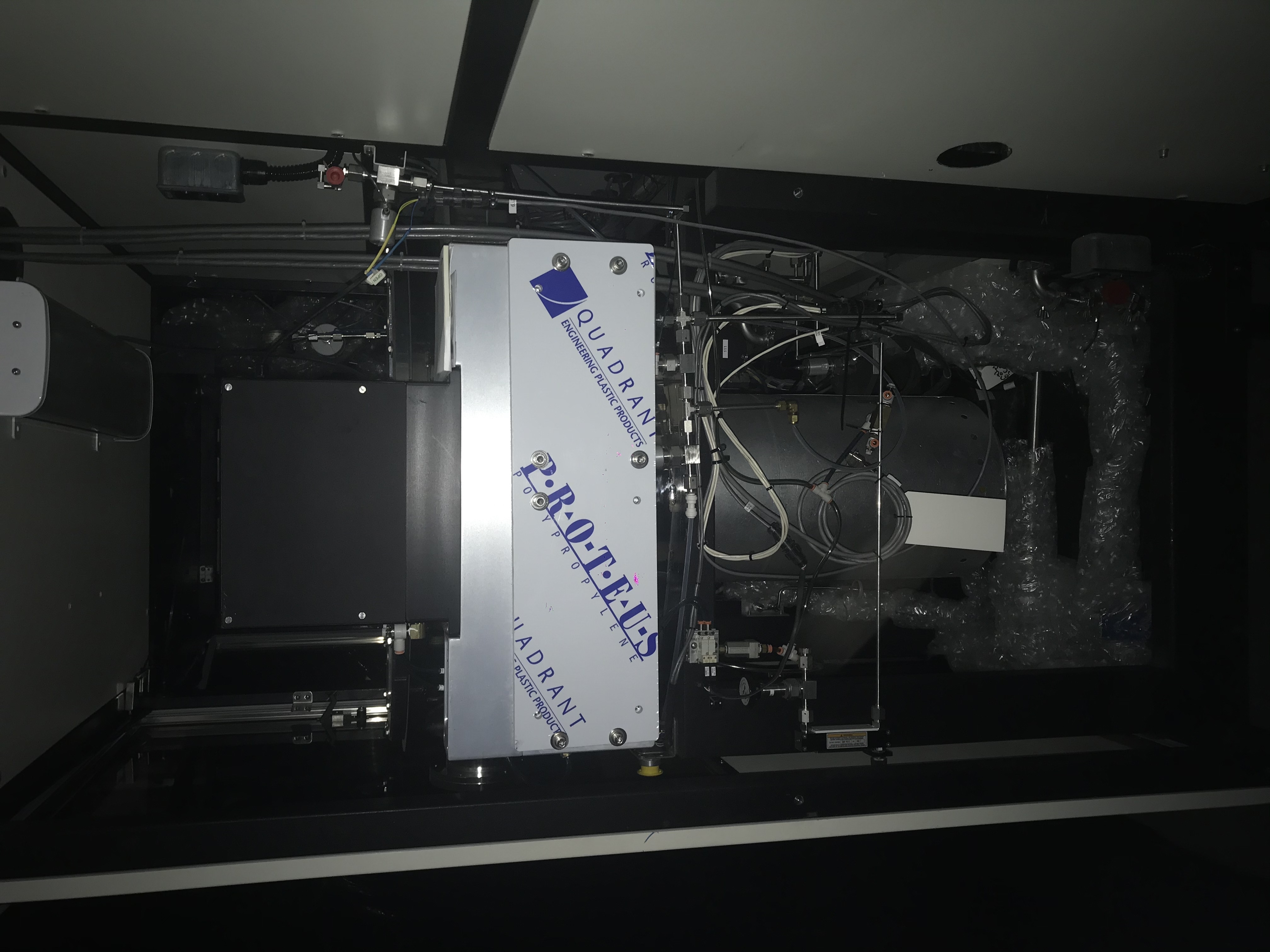

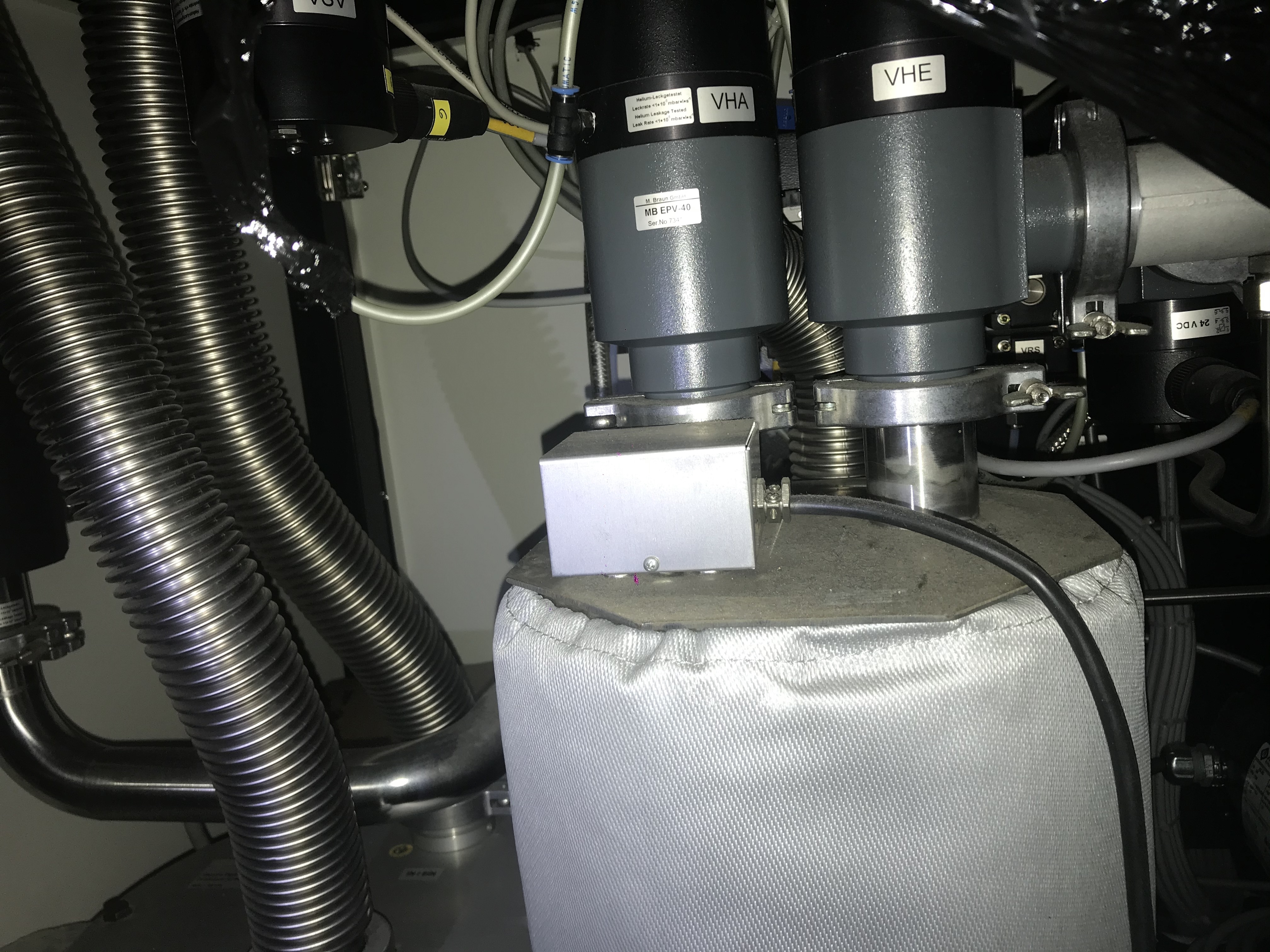

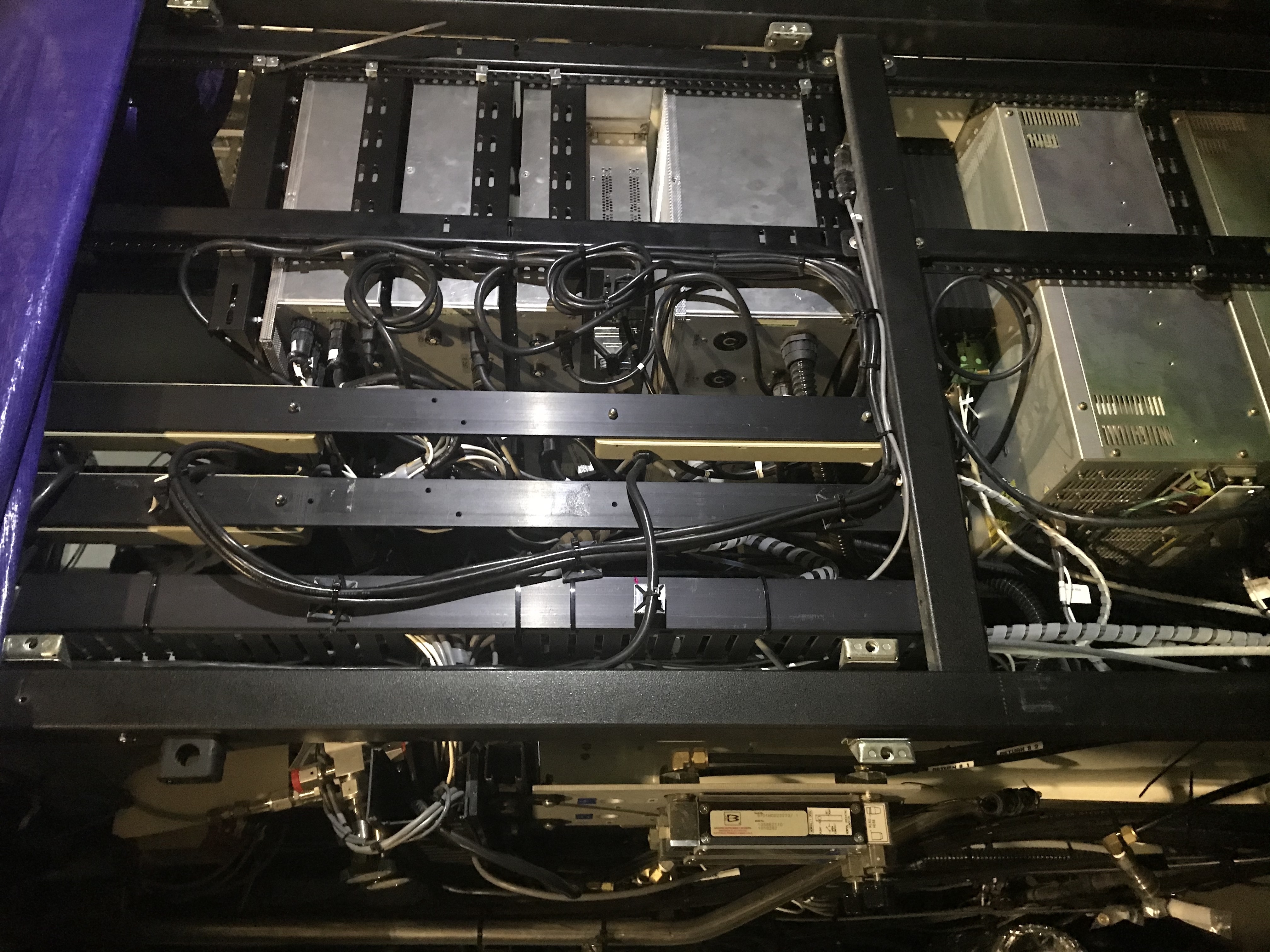

VEECO / EMCORE E450 reactor is a specialized tool used to deposit single and multi-layer thin films on substrates for a variety of applications in the electronics and optoelectronics industries. It represents the most advanced commercially available low-pressure chemical vapor deposition (LPCVD) equipment available today, making it a powerful tool for advanced thin film processing and materials engineering. VEECO E450 reactor is equipped with an automated Quartz boat assembly that can be loaded with up to 12 individual substrates measuring up to 4" x 6" in size, or one 4"x12" substrate, with each substrate position adjusted for optimal thickness and deposition uniformity. Electrical heating elements enable accurate temperature control, and there are four additional heating zones available for advanced application-specific processing. The reactor is capable of either batch or continuous operation with a changeover time of less than 40 seconds, and also allows users to customize their process as needed without the need to change process parameters. The reactor is controlled by a specialized software program with the ability to store up to five different profiles at one time. The exact deposition rate, temperature, and pressure range can all be adjusted in order to achieve the desired results, with up to four deposition sources available for ultimate manipulation of the properties of the thin film being deposited. The software also allows for real-time monitoring of the deposition process, and for the collection of a variety of process data for review. EMCORE E450 reactor is also designed with a number of safety features, including an over-temperature and over-pressure detections system, as well as an auto-purge function to ensure proper handling of reactive gases during operation. The vacuum unit also includes an oil-mist filter for extra protection from contamination, and the machine is designed for minimal maintenance through a simple cleaning procedure. The reactor is also RoHS compliant and is qualified to the latest international safety standards. In short, E450 reactor is a powerful and advanced thin film deposition tool offering superior temperature and pressure control, as well as a variety of application-specific processing options, to allow users to achieve their desired results. The reactor's software-driven control tool and safety features make it an attractive option for any electronics or optics manufacturer looking for reliable and precise thin film deposition.

There are no reviews yet