Used VEECO / EMCORE K465i #9045105 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9045105

Vintage: 2010

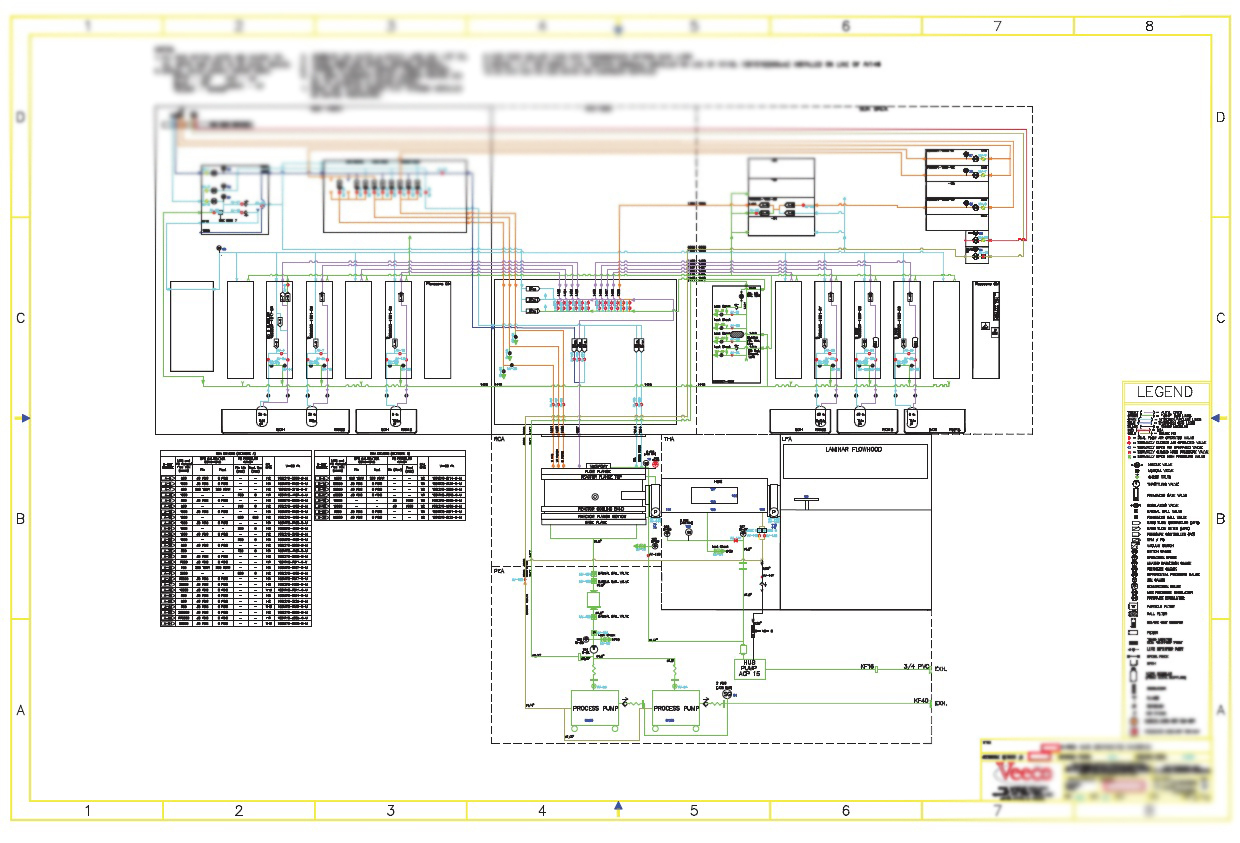

GaN MOCVD system

Includes:

Insitu: (1) DRT + (2) RT

(6) Bubbler slice (TMAI, TEGa, TMGa Cp2Mg, TMIn#1,TMIn#2)

(5) Source bath (Model E212)

(2) Piezocon control (TMIn#1,TMIn#2)

In-line purifier: N2, NH3

Gas purification: H2

Software: Nexus v3.05.02

Flowflange maintenance jig: Excluded fork lift

2010 vintage.

VEECO / EMCORE K465i epitomizes the modern advancement made in high-efficiency plasma processing equipment. This sophisticated industrial reactor combines exceptional performance and features from two market leaders, VEECO and EMCORE, to create a comprehensive and fully-integrated equipment to dramatically increase process throughput for a variety of electronics and materials applications. VEECO K465i is designed to provide robust and reliable processing power, with its ability to run an exhaustive range of etch (without, dielectric, passivated metal) and deposition (CVD) processes at high throughput rates. Its robust, open-ended design allows for maximum flexibility for any custom process development and control, ensuring a steep learning curve and minimizing time-to-market. EMCORE K465i features a revolutionary patented design, with two unique processing chambers. These chambers house multiple electromagnetic source coils that can provide up to 512 amps and an RF waveguide offering up to 500W of power. The versatile processing flexibility afforded by this powerful source configuration makes this reactor capable of processing substrate sizes up to 300mm with excellent uniformity at rates far beyond conventional tube reactors. The thermoelectric cooled chamber prevents adverse reaction between substrate wafers during etching, enabling higher substrate yields and throughput rates. In addition, the closed-loop process control system provides comprehensive real-time process control and monitoring, ensuring full end-product customization. This closed-loop monitoring unit prevents accidental process drifts due to human mistakes or unexpected material characteristics. K465i also features advanced diagnostics and machine protection. The advanced diagnostic sensing techniques enable users to see, within specification, what the process is actually doing. This is particularly helpful in reducing downtime and supporting production cost containment and yield optimization. In addition, the tool's innovative safety systems ensure safe, reliable operation even when running at high power densities. VEECO / EMCORE K465i is an excellent example of advanced reactor technology, as it provides the ultimate in cost-efficiency for a wide range of industrial processing applications. The compact footprint, high degree of flexibility and asset safety make it one of the top choices for plasma processing needs.

There are no reviews yet