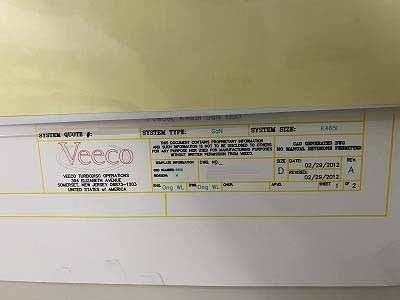

Used VEECO / EMCORE K465i #9273446 for sale

URL successfully copied!

Tap to zoom

VEECO / EMCORE K465i is a highly advanced E-beam reactor, designed for high-precision processing in the manufacture of semiconductor, optical, and other advanced microfabrication applications. It features a variety of powerful enhancements, including a 4-axis motion control equipment, allowing for controlled and precisely aligned scan patterns. The resulting high-speed deposition and etching processes allow for very accurate and reliable fabrication results. At its core, VEECO K465i leverages advanced E-beam technology to generate an intense, highly focused beam of high-energy electrons. This beam is subsequently accelerated through a series of drift tubes, where it is forced to interact with a gaseous source material. The source material is then excited and accelerated by the electron beam, producing reaction products which are subsequently deposited on the substrate material. This process enables very fine deposition control, ultimately leading to higher yields, superior uniformity, and lower defect rates. EMCORE K465i can be operated in the range of high currents up to 500 mA, with a minimum beam diameter of 1 μm, and can achieve a throughput of up to 10 wafers per hour. The advanced 4-axis motion system is capable of accommodating wafers up to 6 inches in diameter, up to 0.015 mm in thickness, with a minimum beam alignment tolerance of 0.5 μm. The unit can also be configured to enable plasma-enhanced or polymer coating processes. In terms of safety, K465i reactor employs a variety of measures to protect personnel from exposure to radiation. These include an advanced safety interlock machine, a power failure shutdown tool, and an automated asset for monitoring water temperatures and pressure. In summary, VEECO / EMCORE K465i is a reliable and precise E-beam reactor, designed for high-precision processing in a variety of advanced fabrication applications. Its powerful 4-axis motion model, high throughputs, and maximum currents of 500 mA make it an ideal tool for the production of precision devices. In addition, its advanced safety measures and automated monitoring equipment ensure reliable and safe operation.

There are no reviews yet