Used VEECO / EMCORE K465i #9274047 for sale

URL successfully copied!

Tap to zoom

ID: 9274047

Wafer Size: 6"

Vintage: 2010

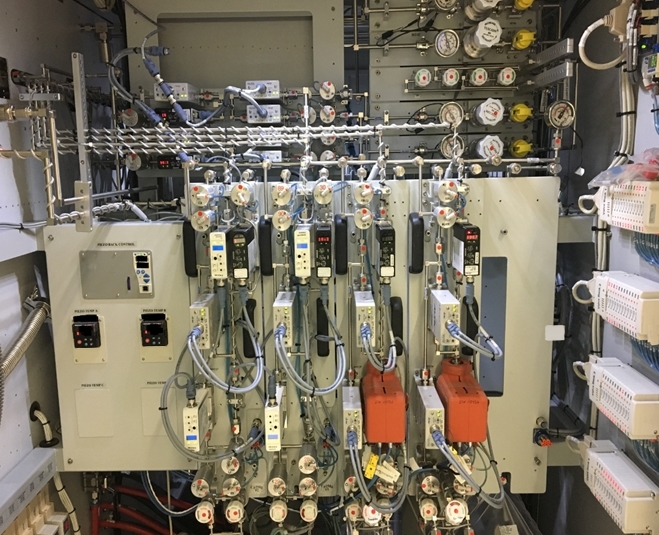

MOCVD Reactor, 6"

Upgraded from K465

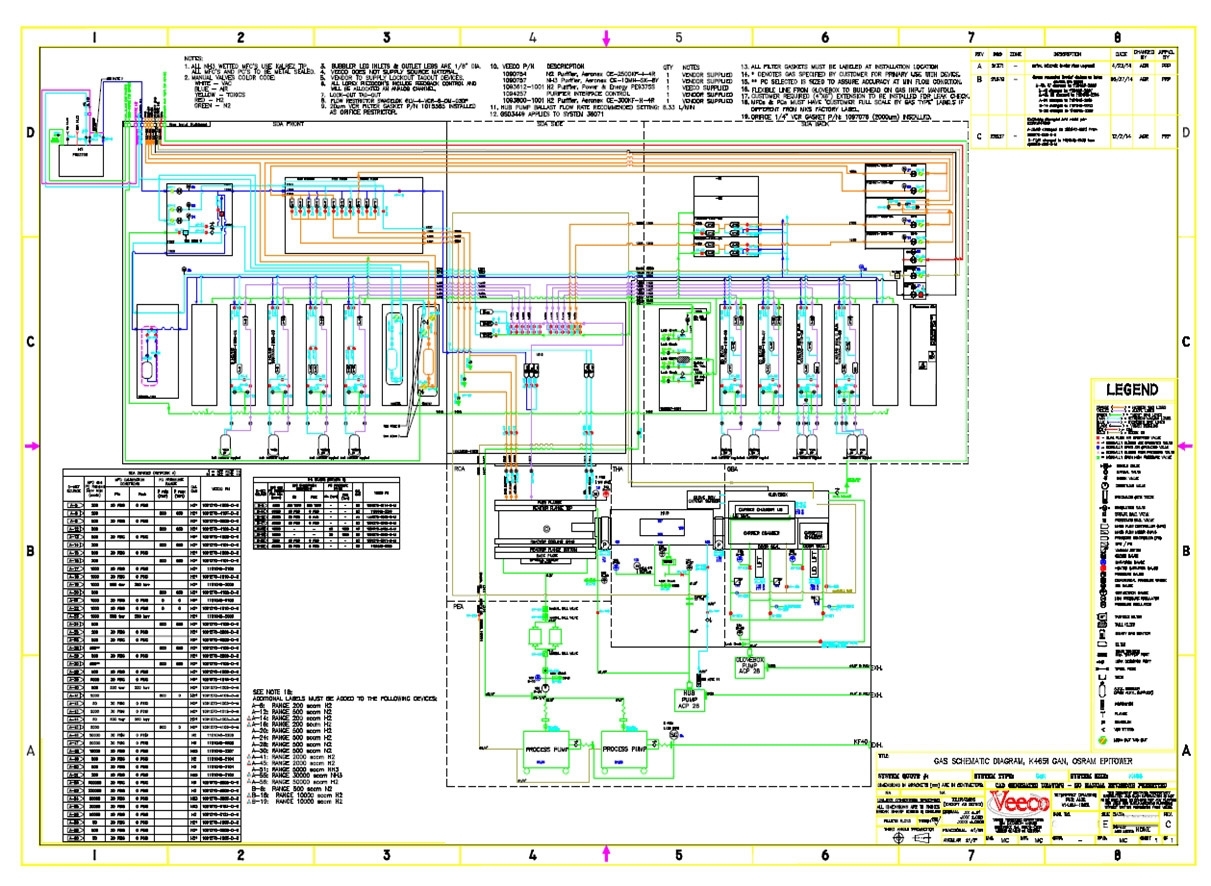

Process: GaN

LED Application

(2) SiH4 Gases

NH3, H2, N2, TMGa, TEGa, Cp2Mg, TMAl, SiH4, TMIn

Control PC:

No hard drive

No operating system

In situ monitoring:

RealTemp200

No harddrive

No operating system

Wafercarrier robot handling

Standard integrated VEECO VAC-Glovebo

ESA25D Vacuum Pump

ACP28 DOR Pump

ACP28 Glovebox pump

Water cooled up to 6 pcs

Up to 2 pcs for TMI

Standard veeco reactor

Flow flange generation

MO Dopant lines

No HDD

No scrubber

No exhaust heater

2010 vintage.

VEECO / EMCORE K465i is a reactor that is used to create thin-film semiconductors. It was developed by VEECO Instruments and EMCORE Corporation as a next-generation tool for microelectronics and optoelectronics manufacturing. VEECO K465i is a single-chamber, hybrid-version reactor that uses inductively-coupled plasma (ICP) and radio-frequency (RF) power to deposit thin films on various substrates. It is a very versatile tool, capable of depositing a wide variety of material types, from silicon-based compounds to exotic metal-insulator compounds. EMCORE K465i is a fully automated system that can be easily programmed to accommodate different combinations of substrate sizes, process temperatures, pressure regimes, gas mixtures, and RF and ICP power. The system also allows for in-situ monitoring of process parameters such as pressure, temperature, RF, ICP power, and gas flow. K465i reactor combines a number of different components, including a process chamber and a gas box. The process chamber contains a susceptor, which is used to support the substrate during the deposition process, as well as an RF coil and the process gases. The gas box contains a gas supply unit and various valves and valves controllers. VEECO / EMCORE K465i's modular configuration allows it to be tailored to various production processes, from high-value, low-volume products like optoelectronic devices to high-volume, low-cost electronics. Other benefits of VEECO K465i include its wide range of process integration options, quick and easy tool changeover, increased process control and stability, and improved production yields. Overall, EMCORE K465i is an innovative and powerful tool for thin-film semiconductor production. It is robust, reliable, and easy to use, and its versatile configuration and advanced process control capabilities make it a great choice for a wide variety of production needs.

There are no reviews yet