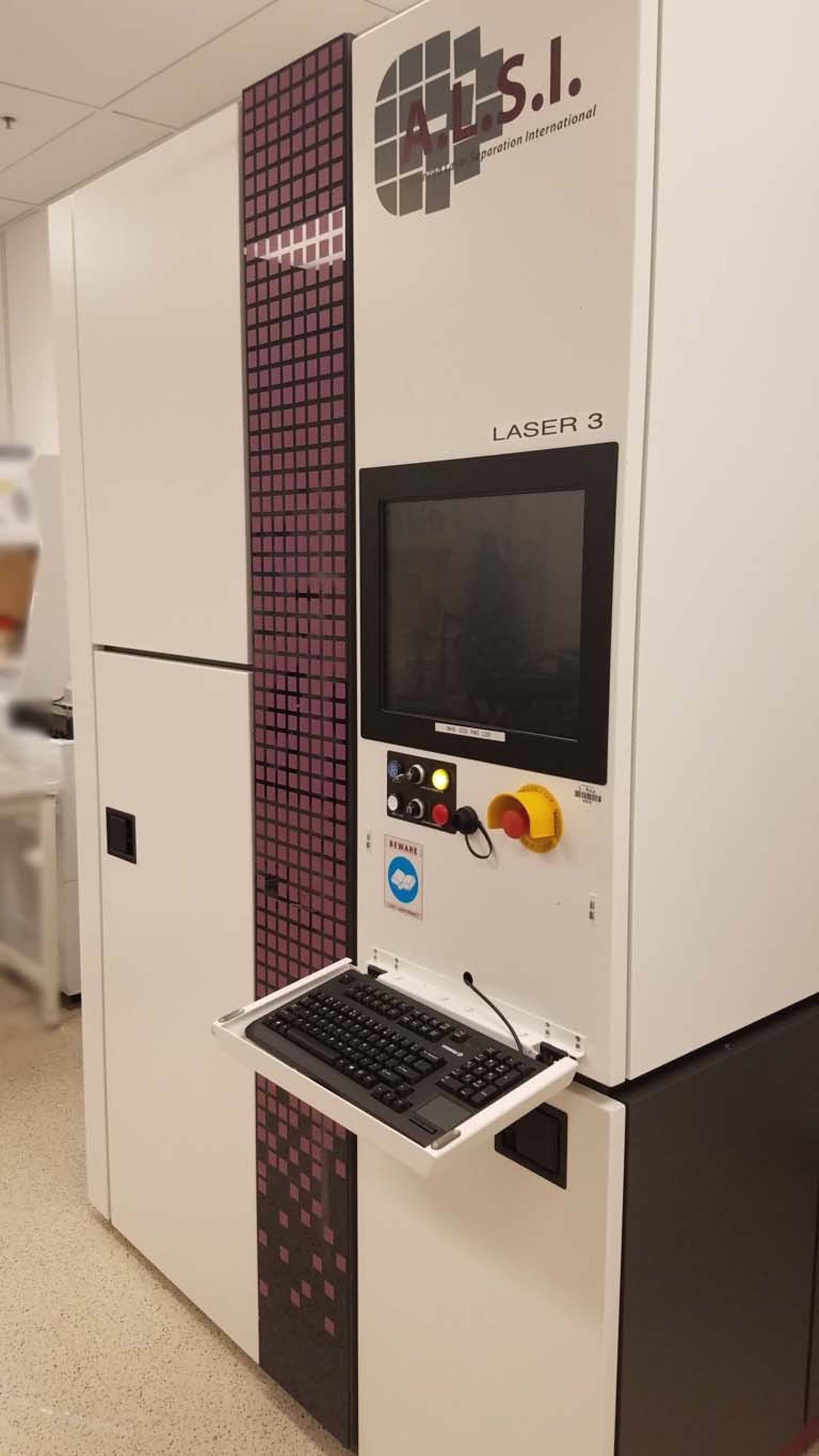

Used ASM ALSI ICA1204 #9254251 for sale

URL successfully copied!

Tap to zoom

ID: 9254251

Vintage: 2012

Laser dicing system

JDSU Q-Series UV Laser, 355 nm

Module: Coater / Cleaner

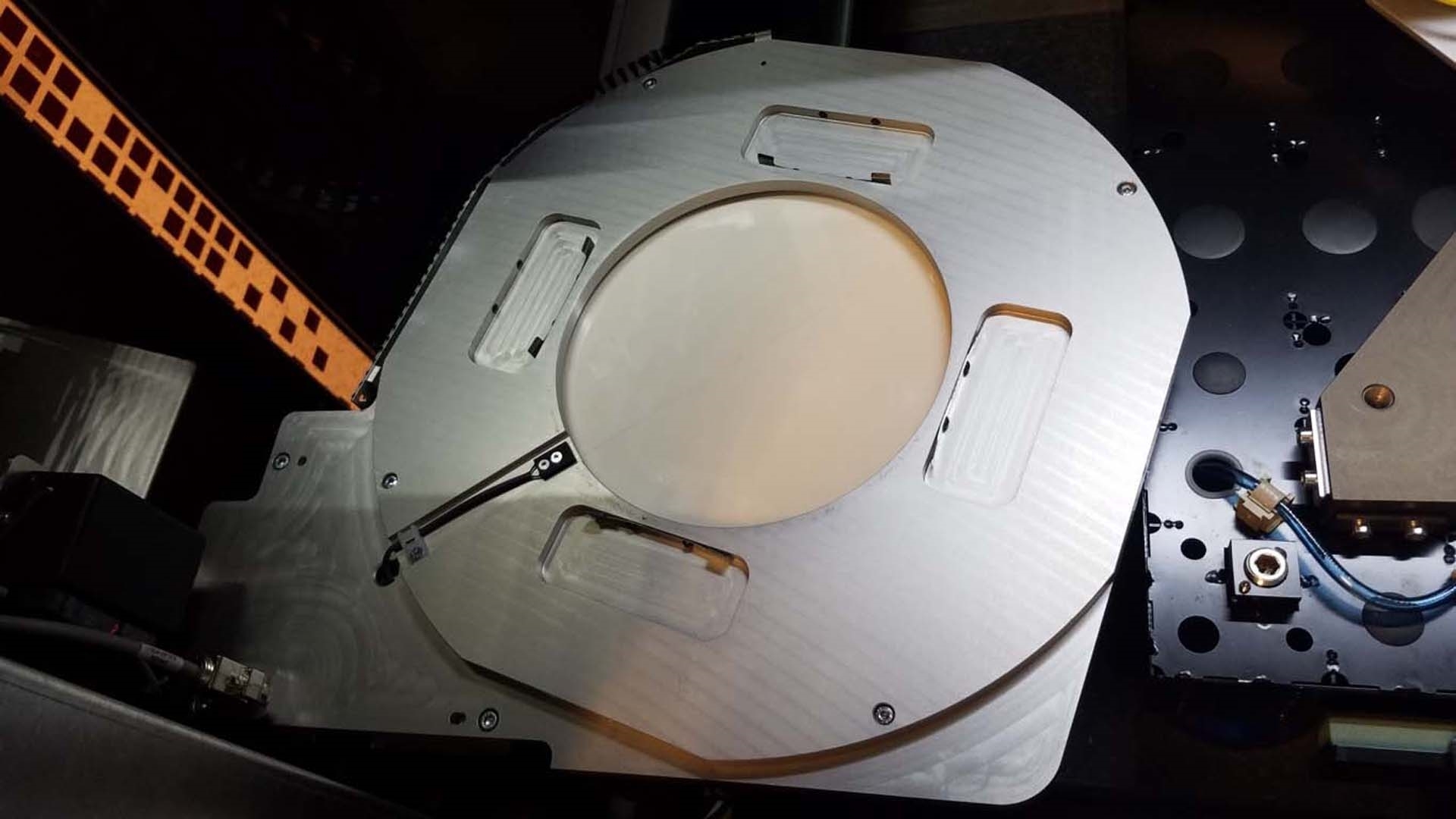

Tape frame size: DISCO Frame 261 (8.9" OD x 7.6" ID)

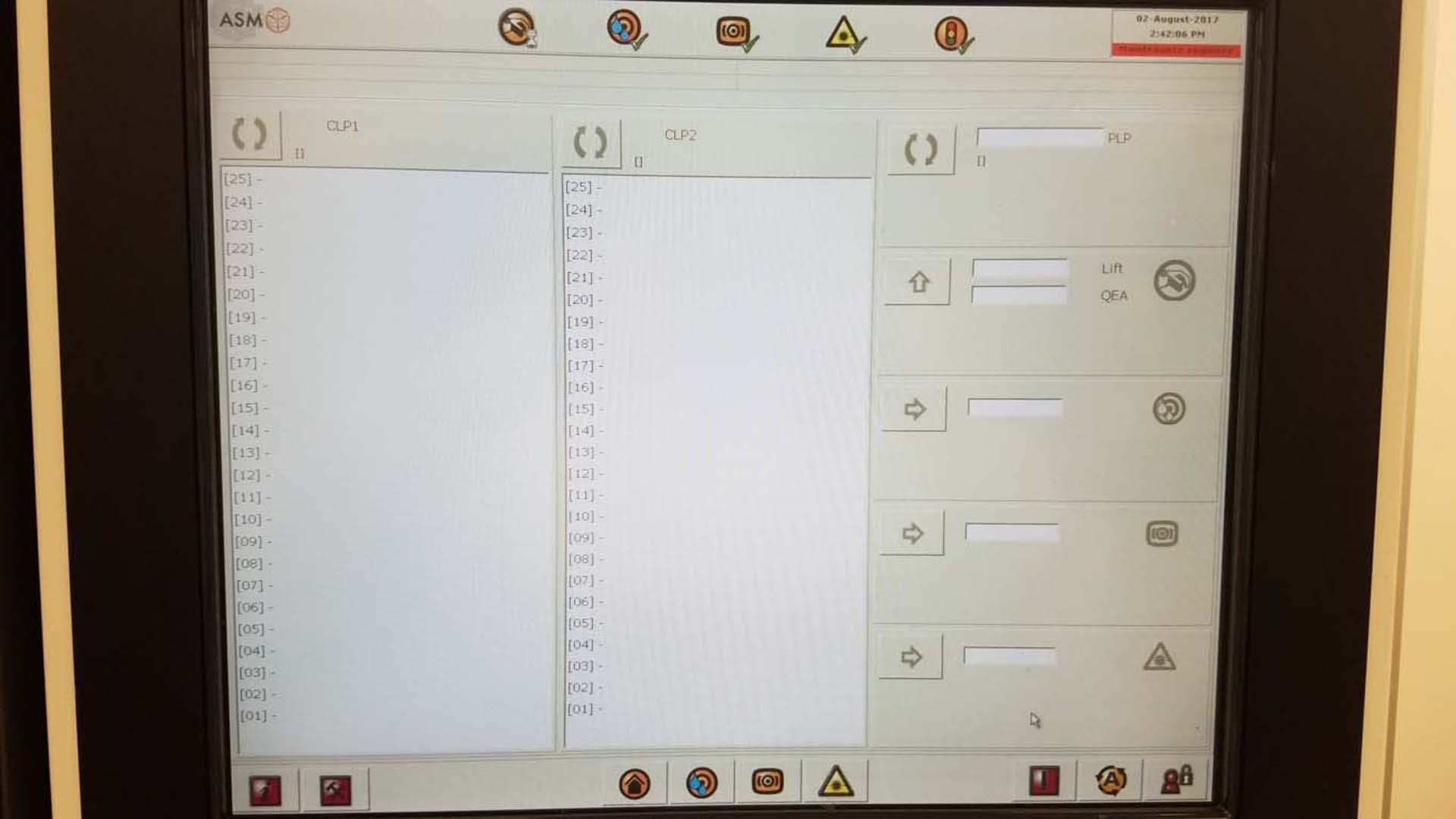

(2) Cassette stations and priority load port

Single wafer load port priority port

(2) Independent cassette stations:

12 Slots cassettes, 300 mm

24 Slots cassettes, 200 mm

Stroke x-axis: 380 mm

Stroke y-axis: 380 mm

Stroke z-axis: 3 mm

Max speed (X,Y): 500 mm/s

Accuracy:

Dynamic: 0,5 μm

Static: 0,1 μm

Laser cabinet size (W, D, H):

1500 x 2000 x 2200 mm

600 x 800 x 800 mm

Vacuum: - 0,85 bar, max 20 l/min

DI Water: 1 Bar, 2,5-10 l/hr, max 0,5 l/min

Water: 5 Bar, max 16-20°C, 20 l/min

Process exhaust: 0,85 ± 0,02 Bar filtering required (est 40 m³/hr)

Machine exhaust: 100-150 m³/hr

Ambient temp: 20°C - 25°C

Clean room: < 10.000

Power:

Nominal: 8 kVA to 12 kVA

Peak: 14 kVA to 18 kVA

Input voltage: 400/VAC

Connection type: 3 Phase delta + N + PE

Frequency: 48 - 60 Hz

Compressed air: 5 Bar, max 700 ln/min

2012 vintage.

ASM ALSI ICA1204 is a fully automated scribing, dicing and lapping equipment designed for high throughput production of ICs. With an integrated vision algorithm and an integrated CAD database, the system provides the highest scribing resolution on the market with a superior ability for detecting defects on the dice. ALSI ICA1204 is a fully automated unit, providing the latest advancements in patterning and edge detection for accurate scribing of ICs. The high speed scribing machine features an integrated vision algorithm for precisely detecting defects on the die prior to scribing or dicing. The tool is equipped with a vision camera to take multiple microscopic images of the wafer and verify the pattern accuracy. It also includes an integrated CAD database which stores the patterns and data of individual ICs in order to accurately scribe and dice them. Additionally, ASM ALSI ICA1204 employs high-precision laser scribing, allowing it to achieve the highest resolution and patterning accuracy on the market. The asset also features a fully automated lapping operation for quickly and accurately processing the ICs after scribe and dice. The integrated lapping operation incorporates a grooving and polishing process, providing excellent edge and surface finishing of the IC's. This process is essential for ensuring high yields of the finished ICs. Furthermore, the lapping operation can be adjusted to meet the requirements of different production job sizes. ALSI ICA1204 is a reliable and efficient model designed to provide high-throughput production of ICs. Its fully automated operation, seamless integration of vision algorithms and CAD databases, and advanced laser scribing and lapping processes allow it to achieve the highest level of accuracy and quality in the processing of ICs. The equipment is a cost-effective and reliable solution for all your scribing, dicing and lapping needs.

There are no reviews yet