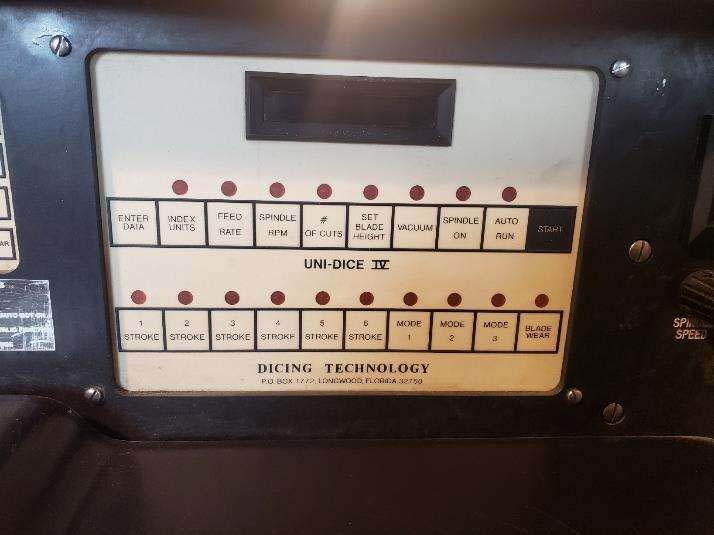

Used DICING TECHNOLOGY Uni-Dice IV #293597023 for sale

URL successfully copied!

Tap to zoom

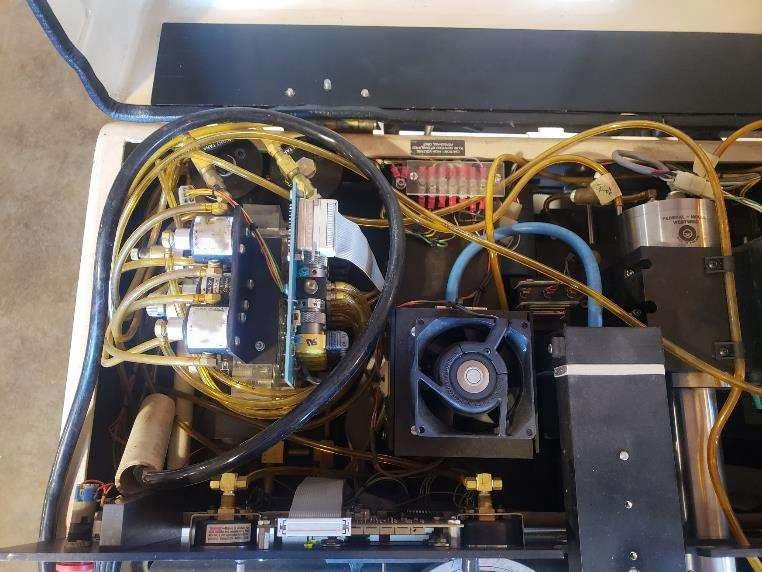

DICING TECHNOLOGY Uni-Dice IV is a state-of-the-art scribing/dicing equipment for semiconductor circuit fabrication. It utilizes plasma jet technology to precisely cut microscopic features on individual circuit boards. By utilizing smaller features than traditional scribing methods, Uni-Dice IV provides precise control of each cut and reduces the need for post-processing. DICING TECHNOLOGY Uni-Dice IV system consists of a plasma jet generator and a cutting unit. The plasma jet generator produces a pulse of plasma that is capable of cutting a wide range of semiconductor materials. It is capable of producing a precise plasma jet with a diameter of 0.4mm. The cutting unit uses two-axis control for precise cutting of features on the board. Its cutting speed is up to 10,000 RPM, making it capable of producing complex patterns on the board. Uni-Dice IV is designed to offer maximum flexibility and user-friendliness. It has a user-friendly graphical user interface (GUI) that makes the unit easy to operate and control. It also offers a library of pre-defined cutting parameters that make it easy to use. The GUI also allows for programming of customized cutting operations. DICING TECHNOLOGY Uni-Dice IV machine is capable of cutting a variety of materials, including copper, aluminum, polyimide, polyethylene terephthalate (PET), polymethylmethacrylate (PMMA), polyvinyl chloride (PVC), polyamide, polycarbonate, polyethersulpone (PES), polyetherketone (PEK), polyurethanes (PU) and polytetrafluoroethylene (PTFE). It can also handle twisted metal chains, tinsel coil, and strips of wire. The tool is designed to minimize contamination and risk of scratching, by reducing static and dust buildup during the cutting process. Additionally, it is equipped with a nozzle with patented air flow technology that further reduces the risk of damage to the board. Furthermore, its air flow technology minimizes power consumption, which makes it much more environmentally friendly. Uni-Dice IV also offers a choice of two different cutting strategies. One is used for fine pitch cuts, while the other is used for larger cuts. This allows for higher levels of flexibility, reduced cutting times and more precise cuts. Overall, DICING TECHNOLOGY Uni-Dice IV is an advanced scribing/dicing asset for semiconductor circuit fabrication. It is capable of cutting a variety of materials with a high degree of precision and minimal damage to the board. It is also user-friendly, energy-efficient and environmentally friendly.

There are no reviews yet