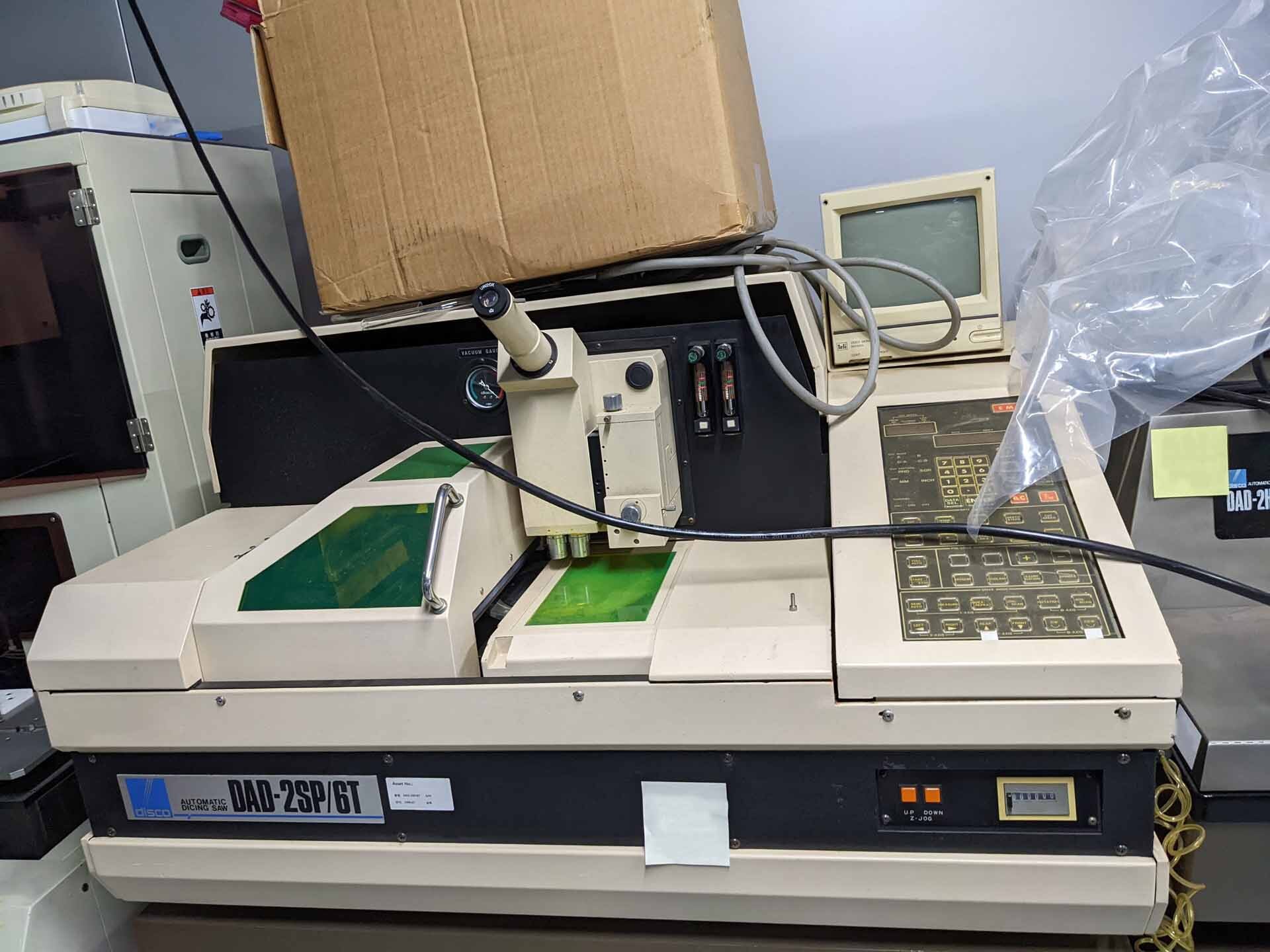

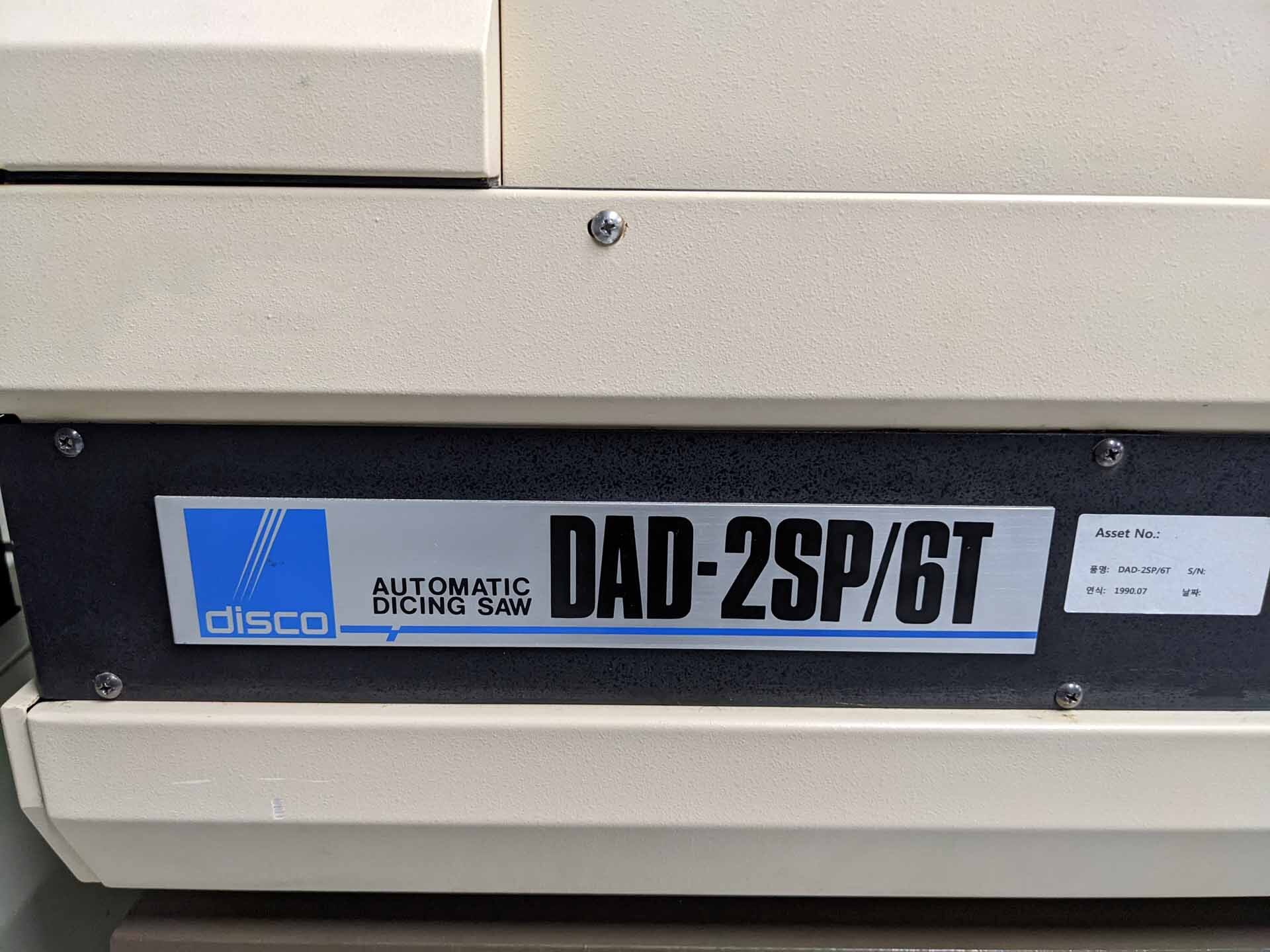

Used DISCO DAD 2SP/6T #293643411 for sale

URL successfully copied!

Tap to zoom

DISCO DAD 2SP/6T is a complex scribing and dicing equipment which is used to aid the production of printed circuit boards. This system consist of two scribing lasers, two cutting lasers, a scribing unit and a press roller feeder. The two scribing lasers are used to cut trace paths into the substrate material, with the two cutting lasers used to cut through the substrate material into predetermined shapes. The scribing machine is used to create the trace paths that the two scribing lasers will cut, while the press roller feeder is used to transport material to the cutting/scoring area. The two scribing lasers are designed to cut into the substrate material at a rate of up to 6 metres per minute, at an accuracy of around 0.008mm. The beam diameter of the lasers is 0.3mm with a maximum line width of 0.2mm. The cutting lasers are designed to have a higher power output than the scribing lasers. The cutting lasers have a power output of 500W with a maximum cutting depth of up to 4mm. The beam diameter of the lasers is 0.4mm with a maximum kerf of 0.4mm. The scribing tool is used to apply the trace paths which will be cut by the scribing lasers. It is an adjustable asset that allows the flexible application of trace paths accordingly to the user's needs. The model is composed of two components, the main control unit and the laser head. The main control unit provides the user interface for the application of the trace paths and the laser head is mounted onto the substrate material to apply the trace paths. The press roller feeder is used to move the material through the equipment. It is designed to have an adjustable feed rate, up to 16 metres per minute. This allows for quick, consistent and accurate movement of the material through the system, ensuring that all trace paths and cuts are consistent with each other. Overall, DISCO DAD 2SP/6T is an advanced scribing and dicing unit that is designed to aid the production of printed circuit boards. It has two scribing lasers, two cutting lasers, a scribing machine and a press roller feeder. The lasers are designed to cut with an accuracy of up to 0.008mm, while the press roller feeder allows for quick and consistent movement of material through the tool. This asset ensures that all trace paths and cuts are accurate and consistent.

There are no reviews yet