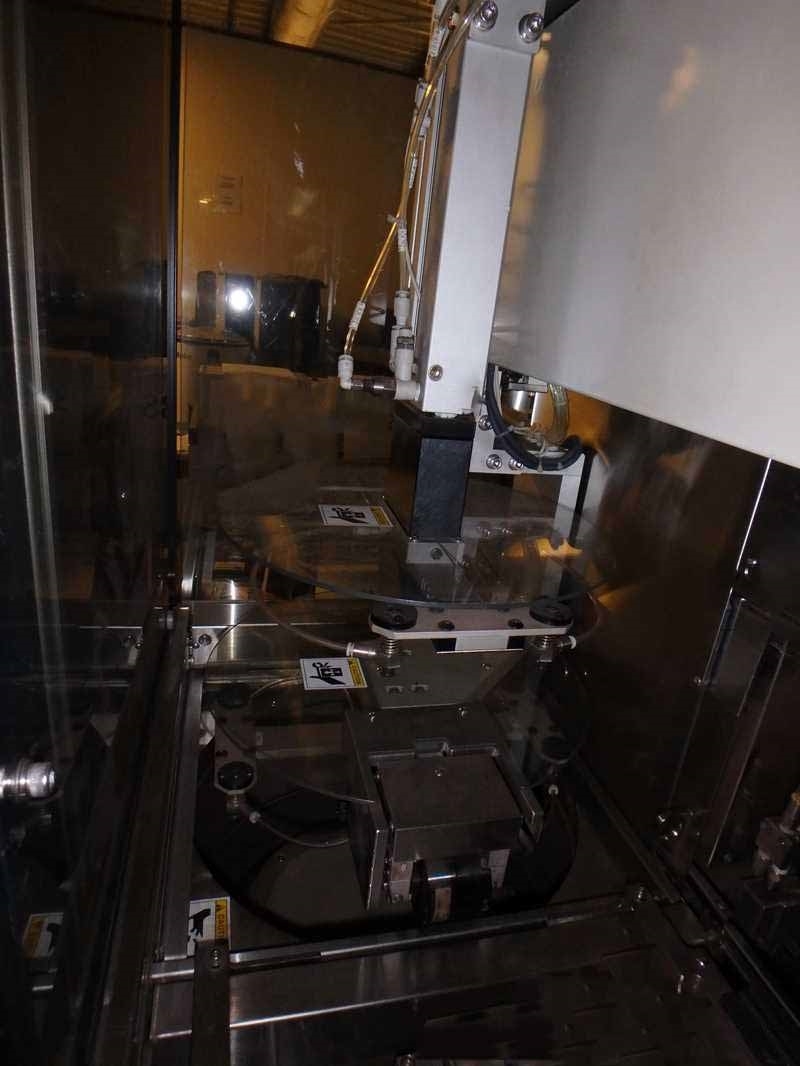

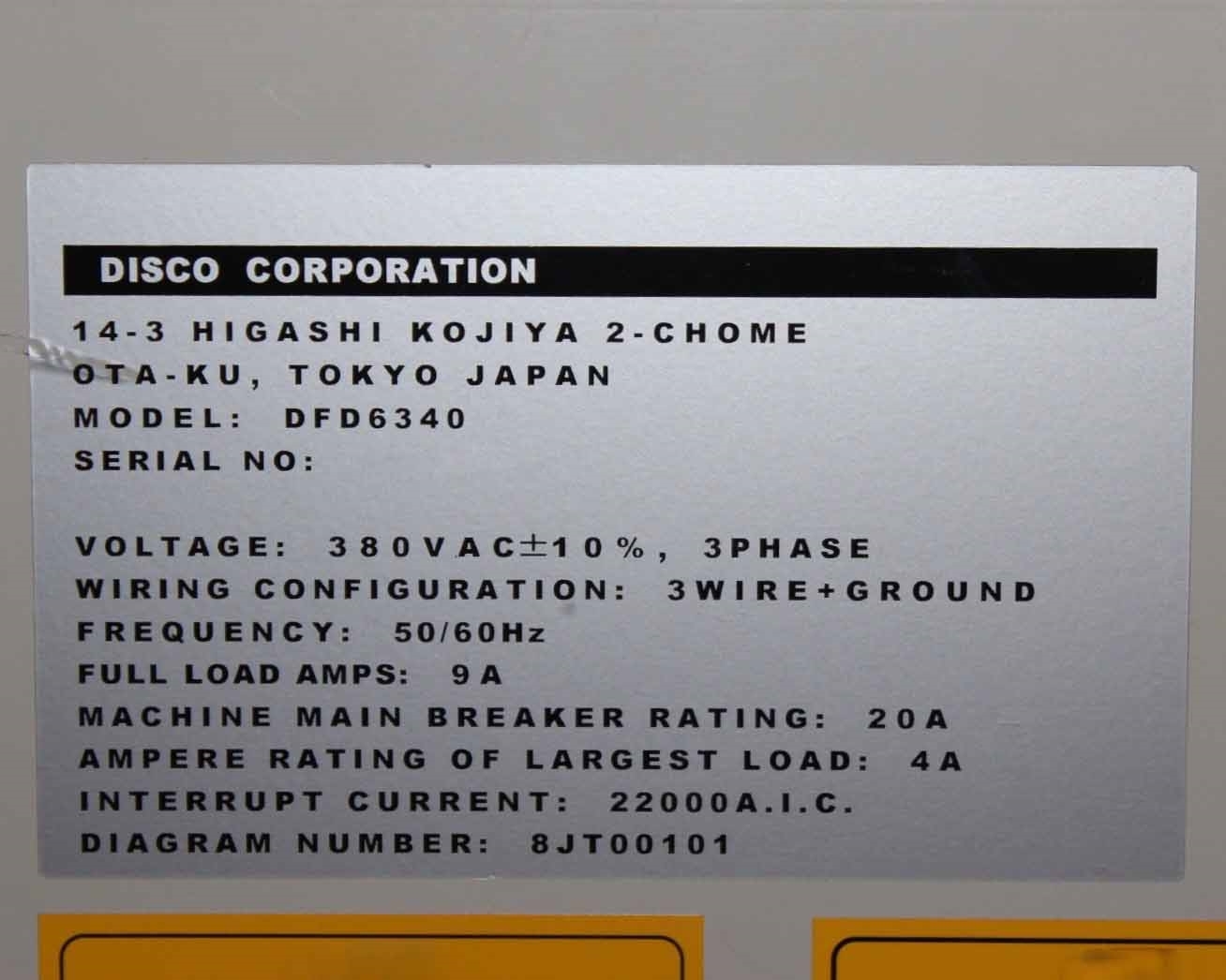

Used DISCO DFD 6340 #9222957 for sale

URL successfully copied!

Tap to zoom

ID: 9222957

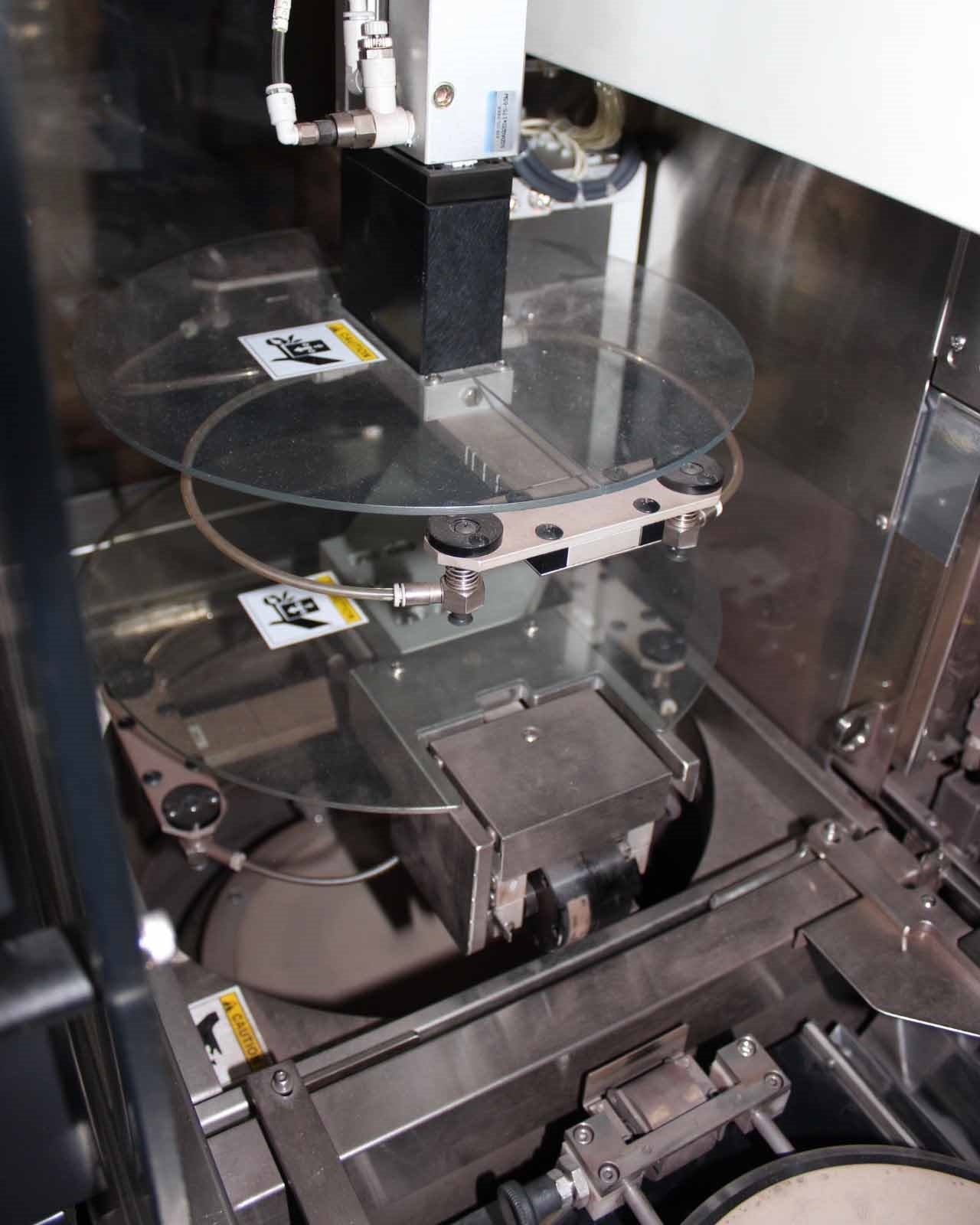

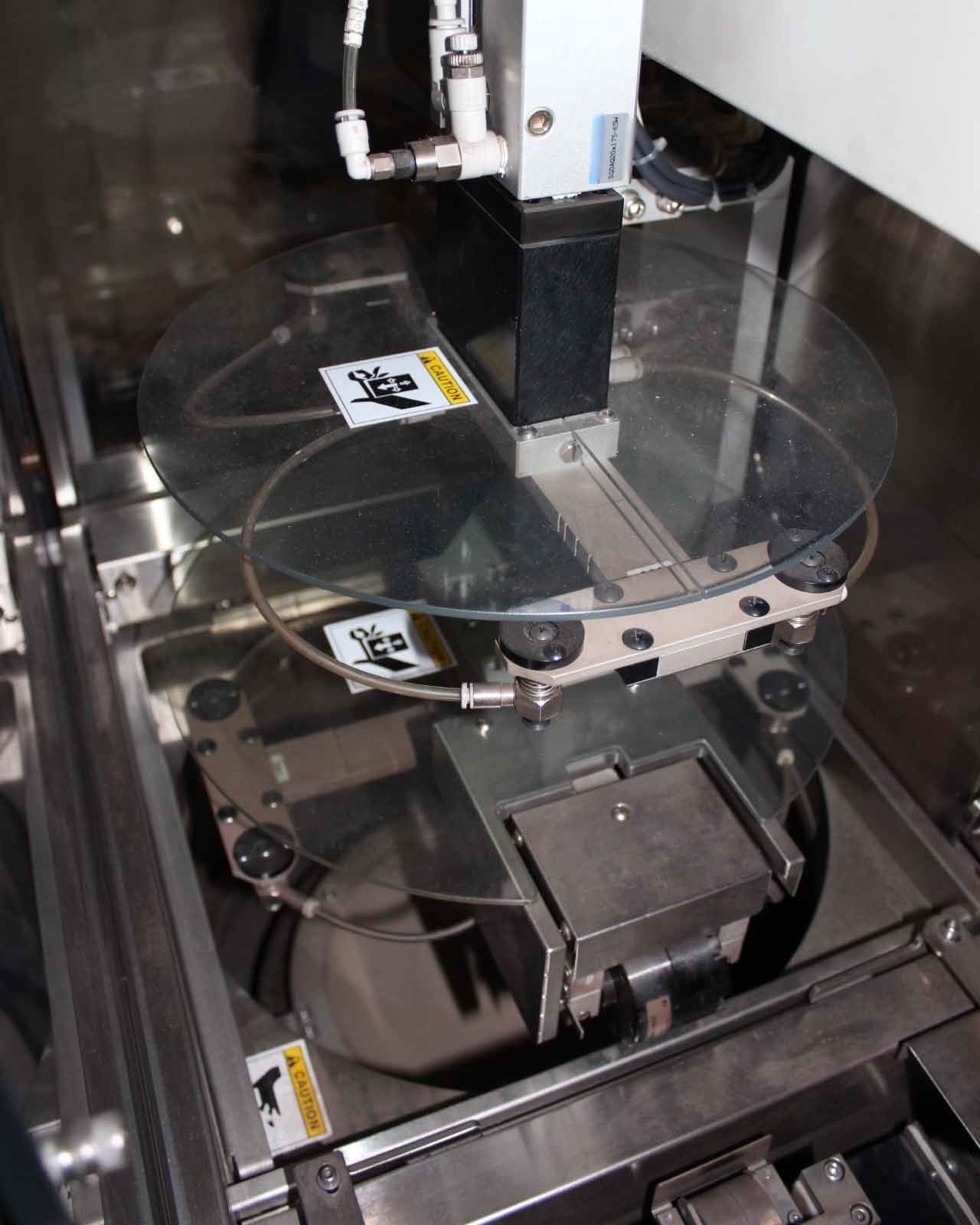

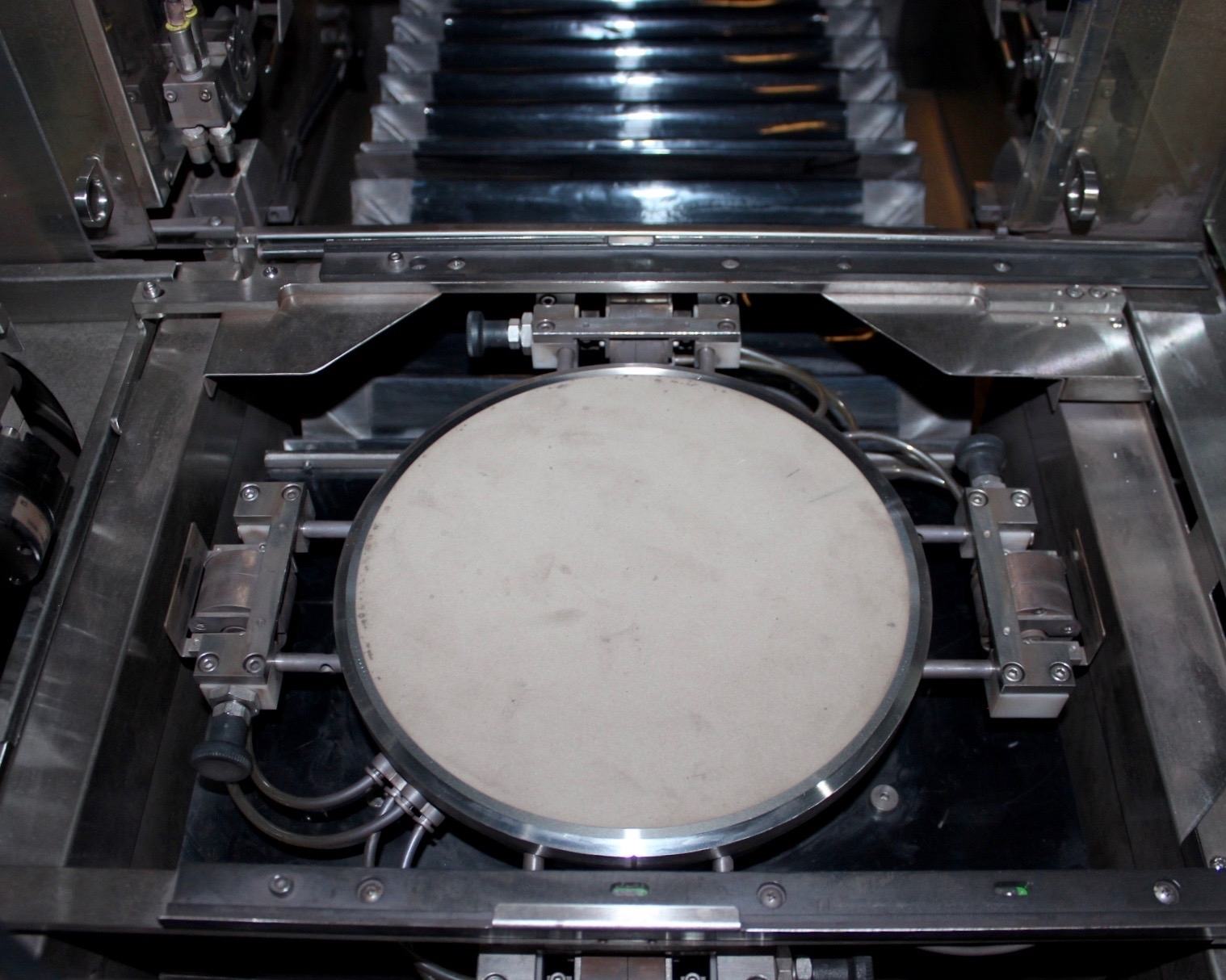

Wafer Size: 8"

Vintage: 2003

Automated dicing saw, 8"

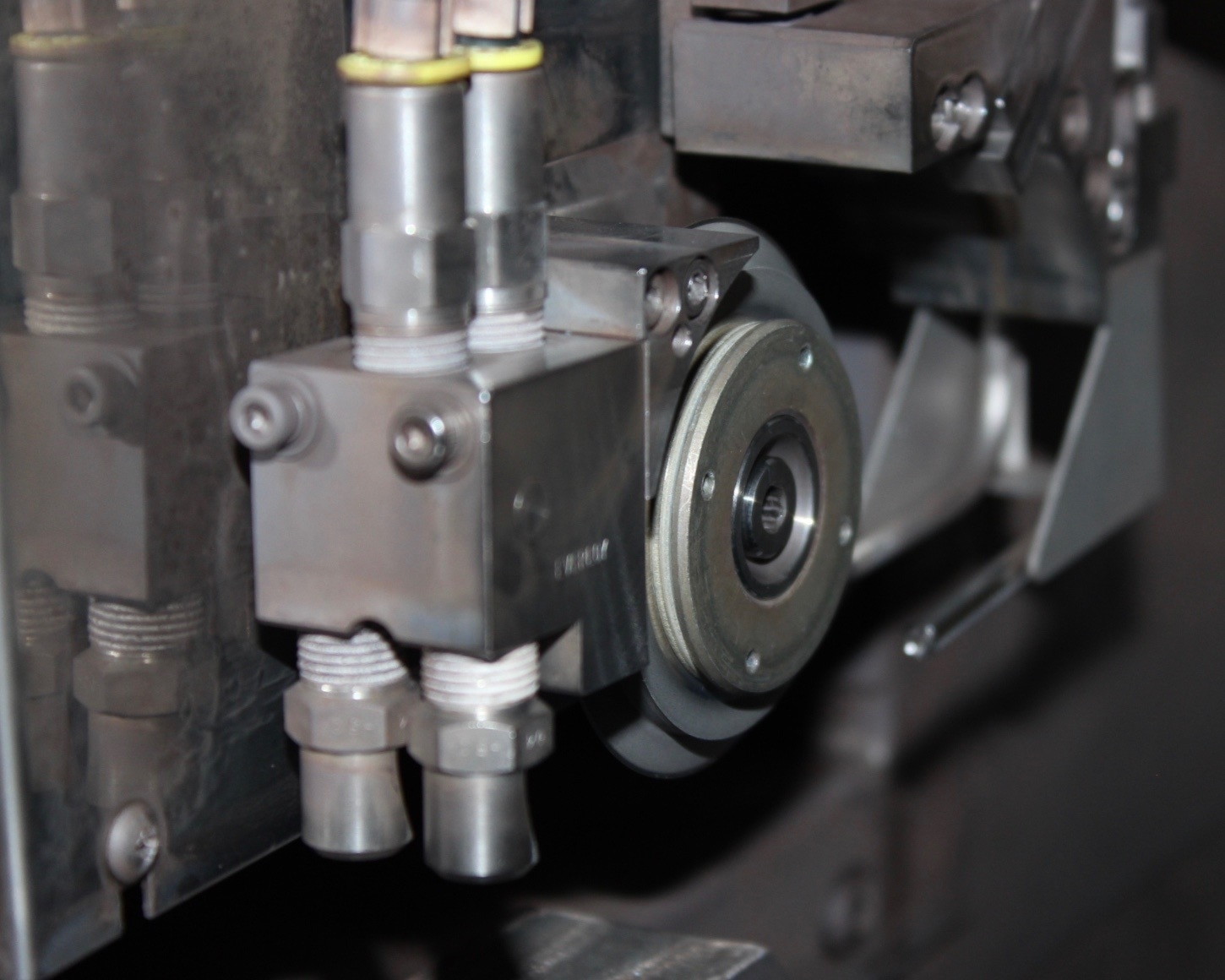

Process stability: Cutting water flow control

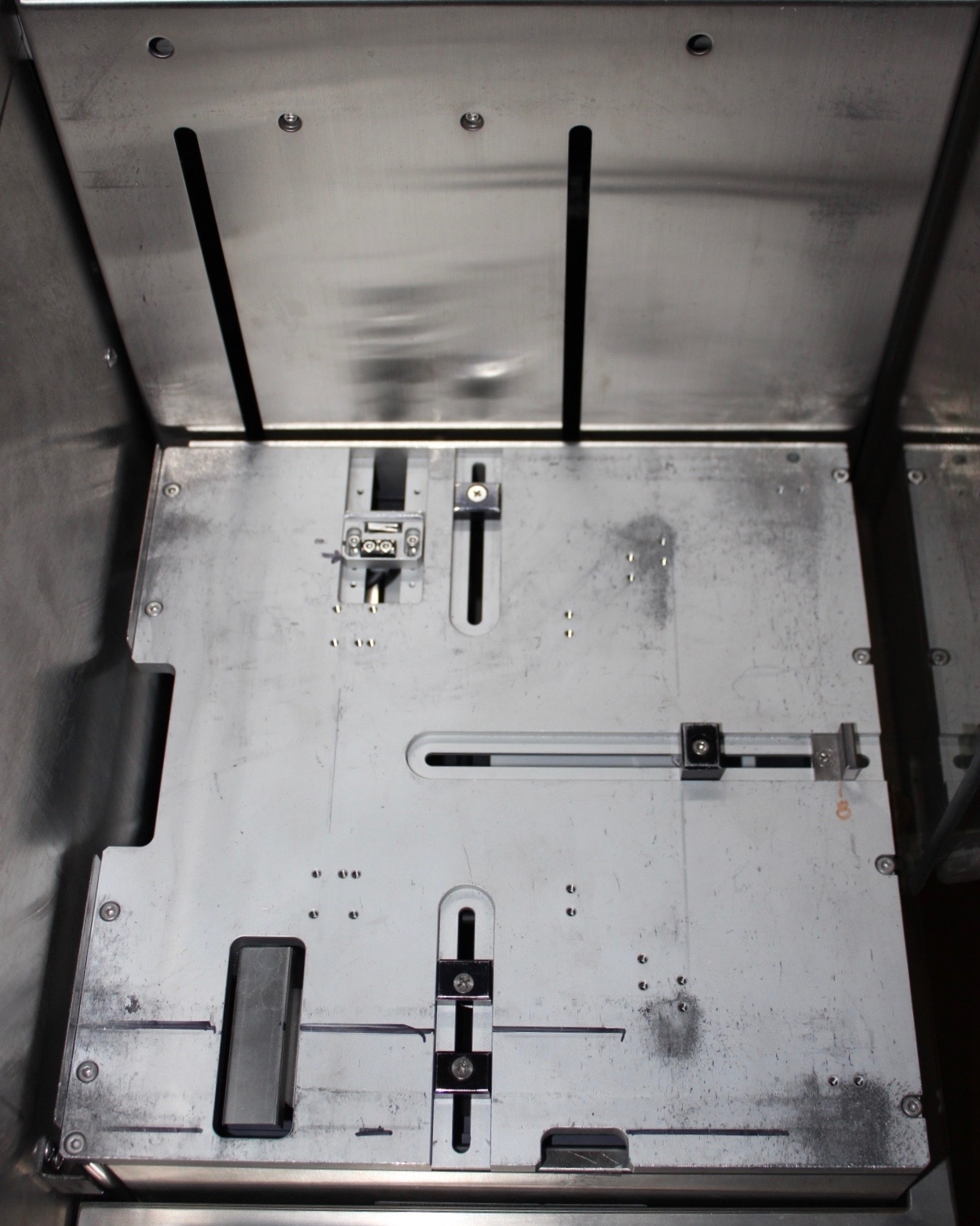

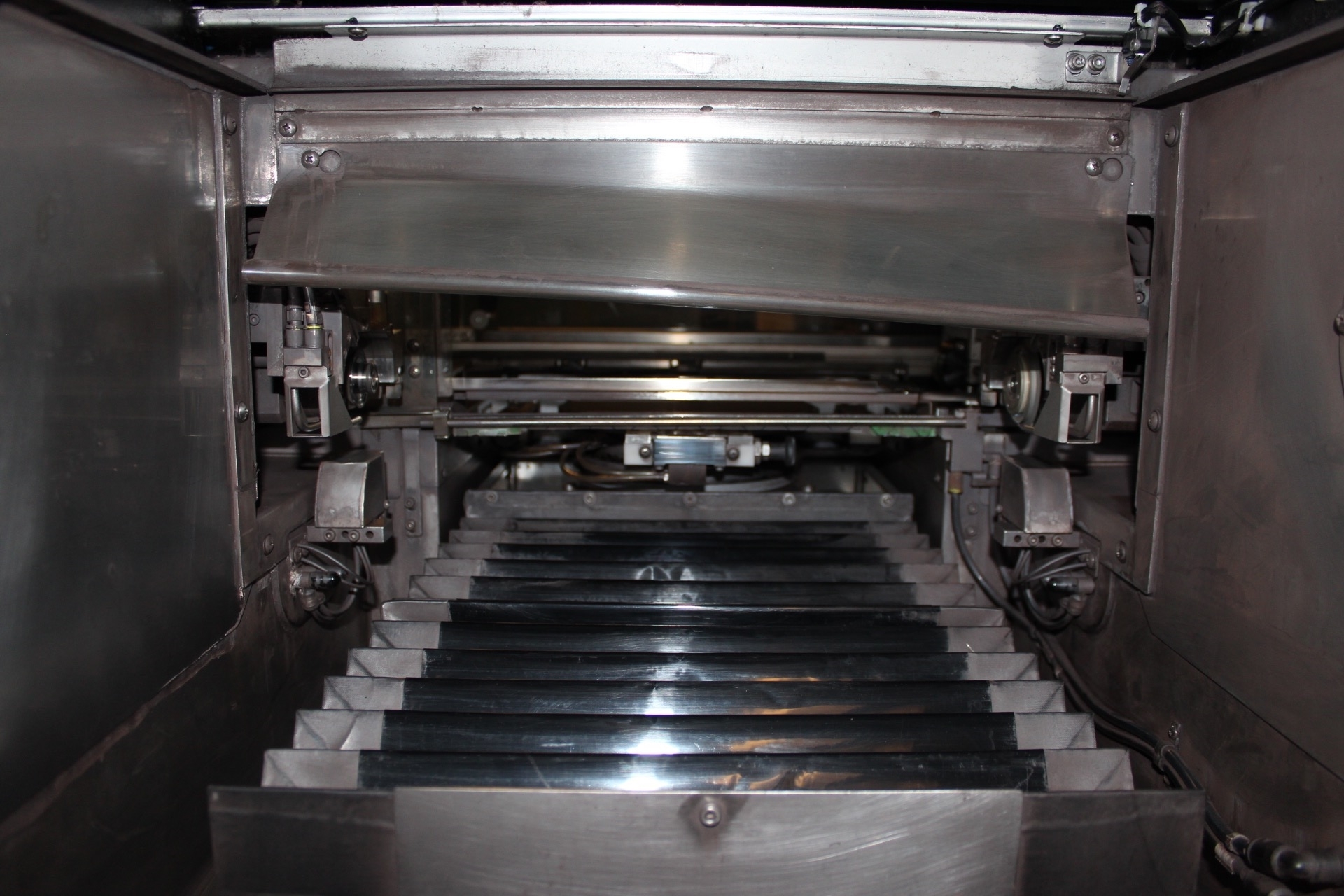

X-Axis:

Cutting range: 210 mm

Maximum cutting speed: 600 mm/s

Y1 & Y2 Axis:

Cutting range: 210 mm

Index step: 0.0001 mm

Index positioning accuracy: 0.002/210 mm

Zl & Z2 Axis:

Maximum stroke:

19.22 mm (For Φ2" blade)

19.9 mm (For Φ3" blade)

Moving resolution: 0.00005 mm

Repeatability accuracy: 0.001 mm

Maximum blade size: Φ58 mm

θ-Axis: Maximum rotating angle: 380°

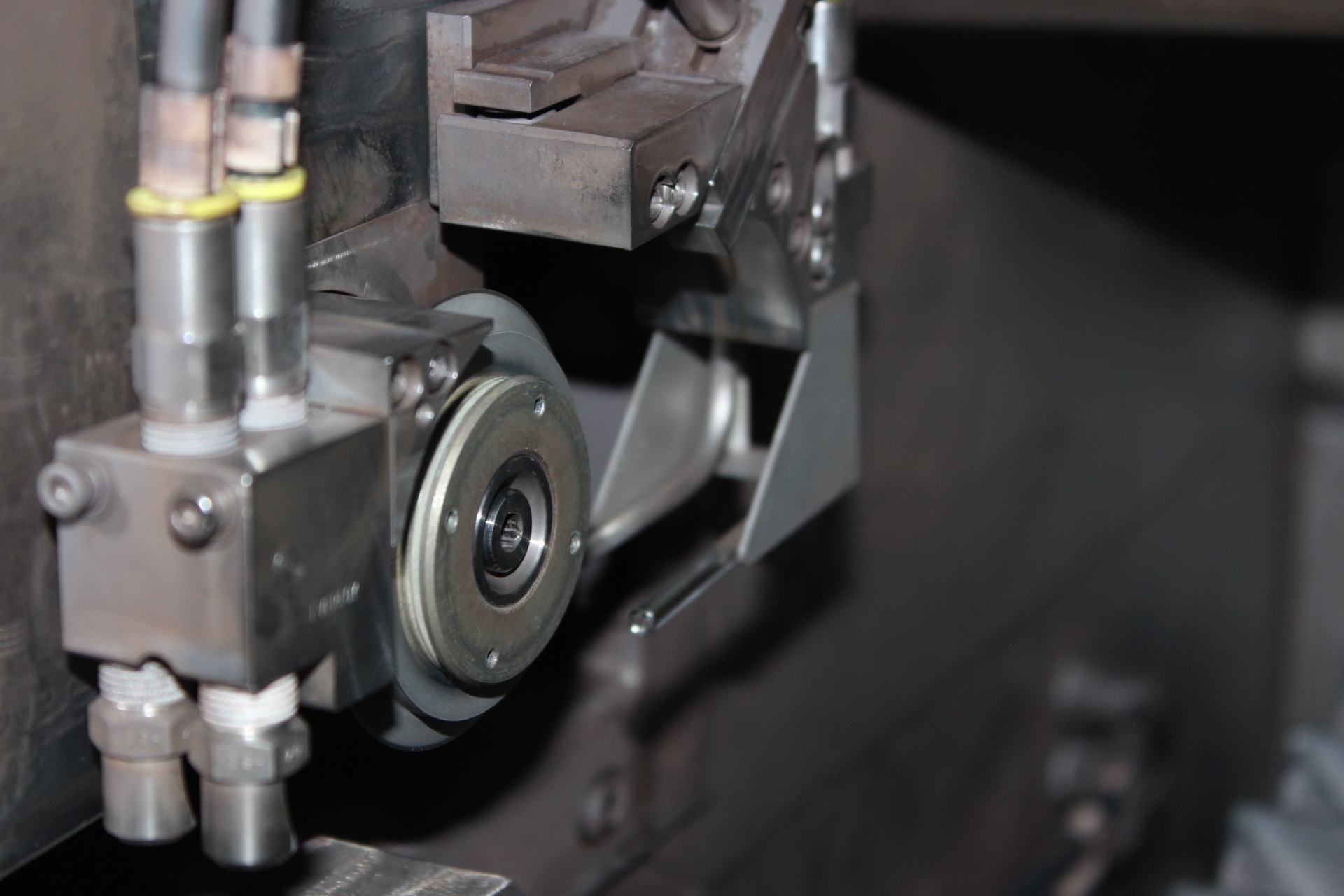

Spindle:

Output: 1.2 kW at 60,000 min^-1

Rated torque: 0.19 nm

Revolution speed range: 6,000-60,000 min^-1

Applicable tape frame: 2-8-1

Utilities requirement:

Air pressure: 0.5 ~ 0.8 MPa

Air maximum consumption: 378.0 L/min (ANR)

N2 Pressure: 5 ~ 0.8 MPa

N2 Maximum consumption: 216.0 L/min (ANR)

Pressure: 0.2 ~ 0.4 MPa

Maximum flow rate (L/min):

Cutting water: 12

Water curtain: 1

Cooling water:

Pressure: 0.2-0.4 MPa

Flow rate: 3.0 at 0.3 MPa

Exhaust duct capacity: 5.0 m³/min

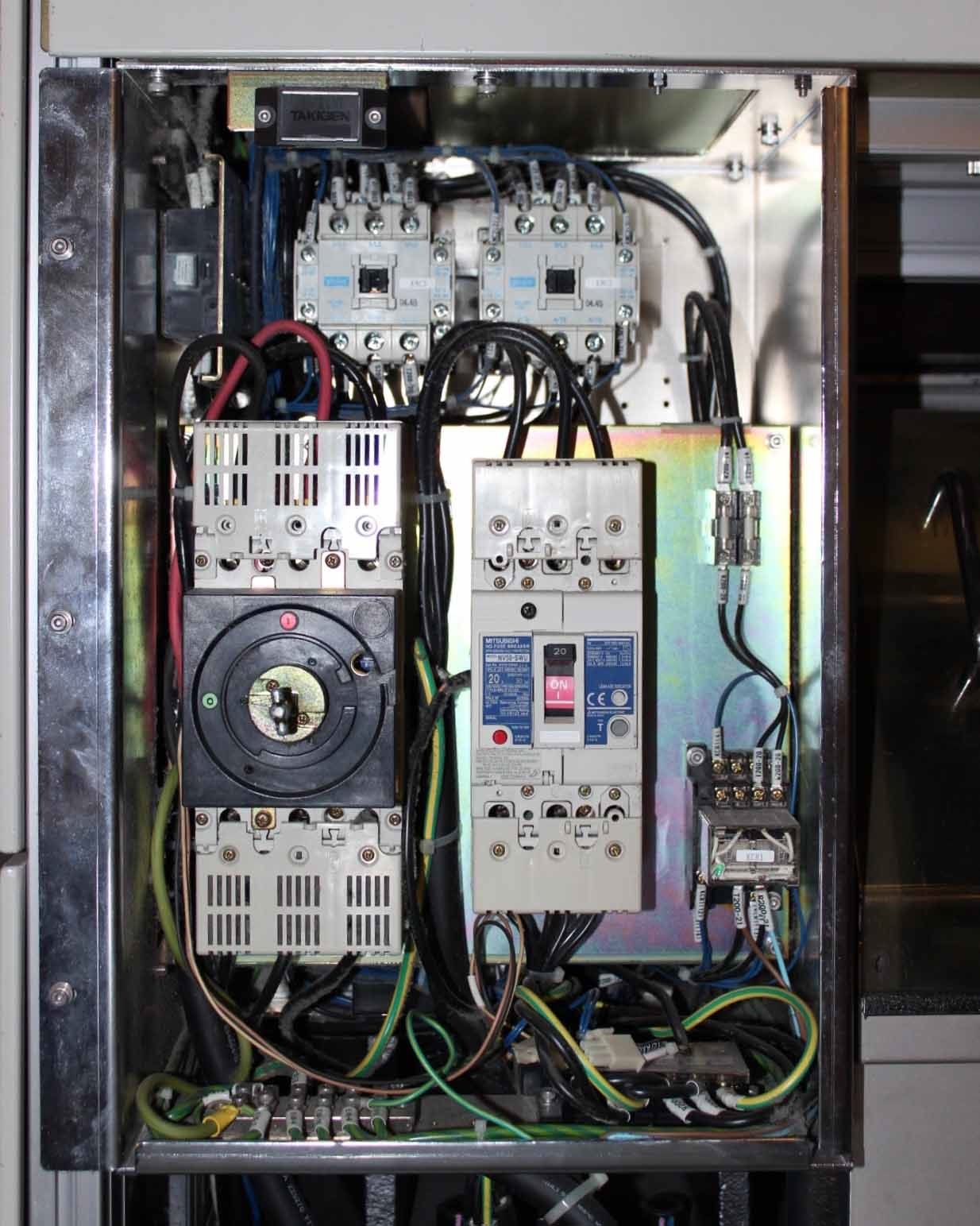

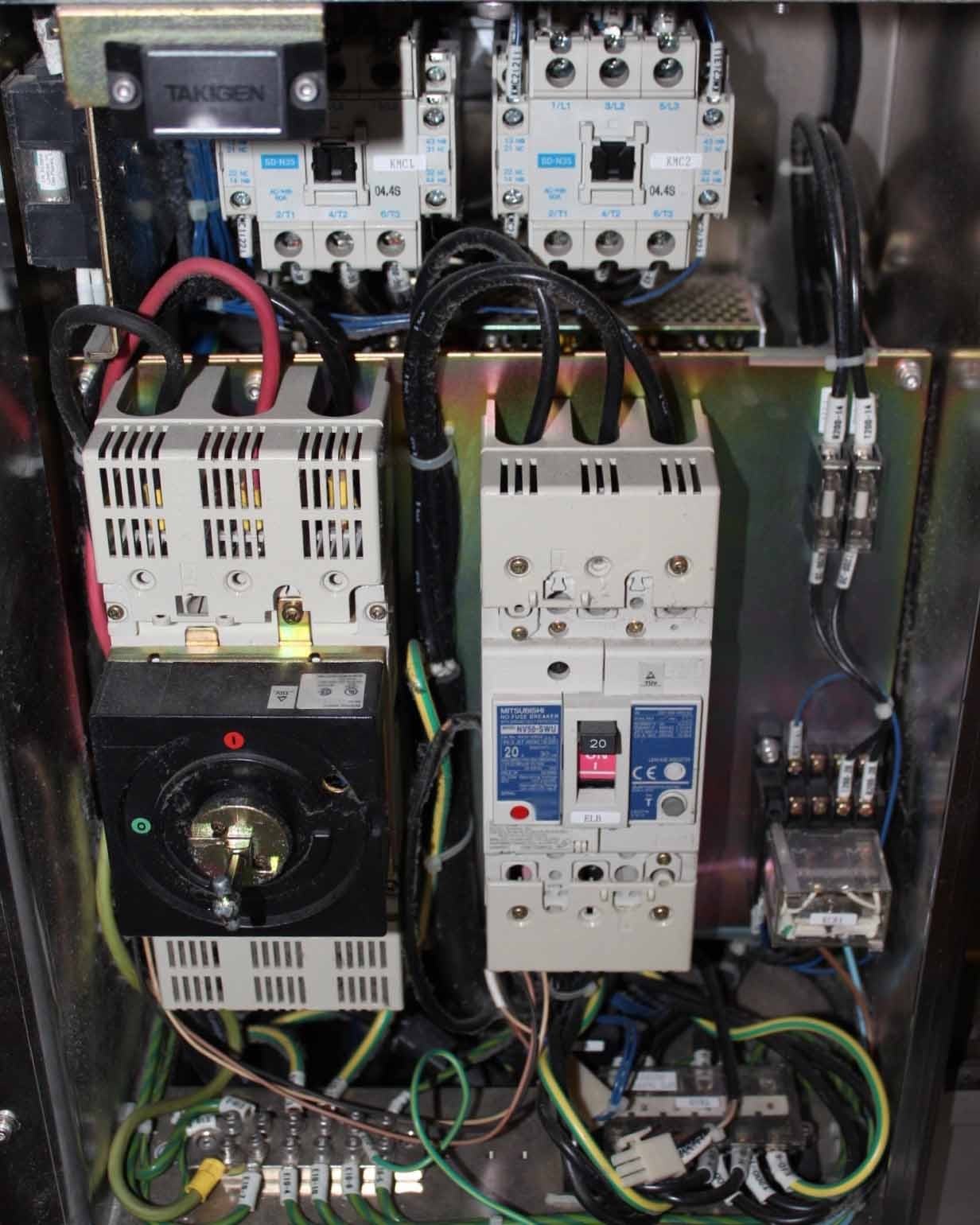

Power consumption:

Maximum power: 6.9 kVA

Power supply: 200-240 V AC±10 %, 3 Phase, 50/60 Hz

2003 vintage.

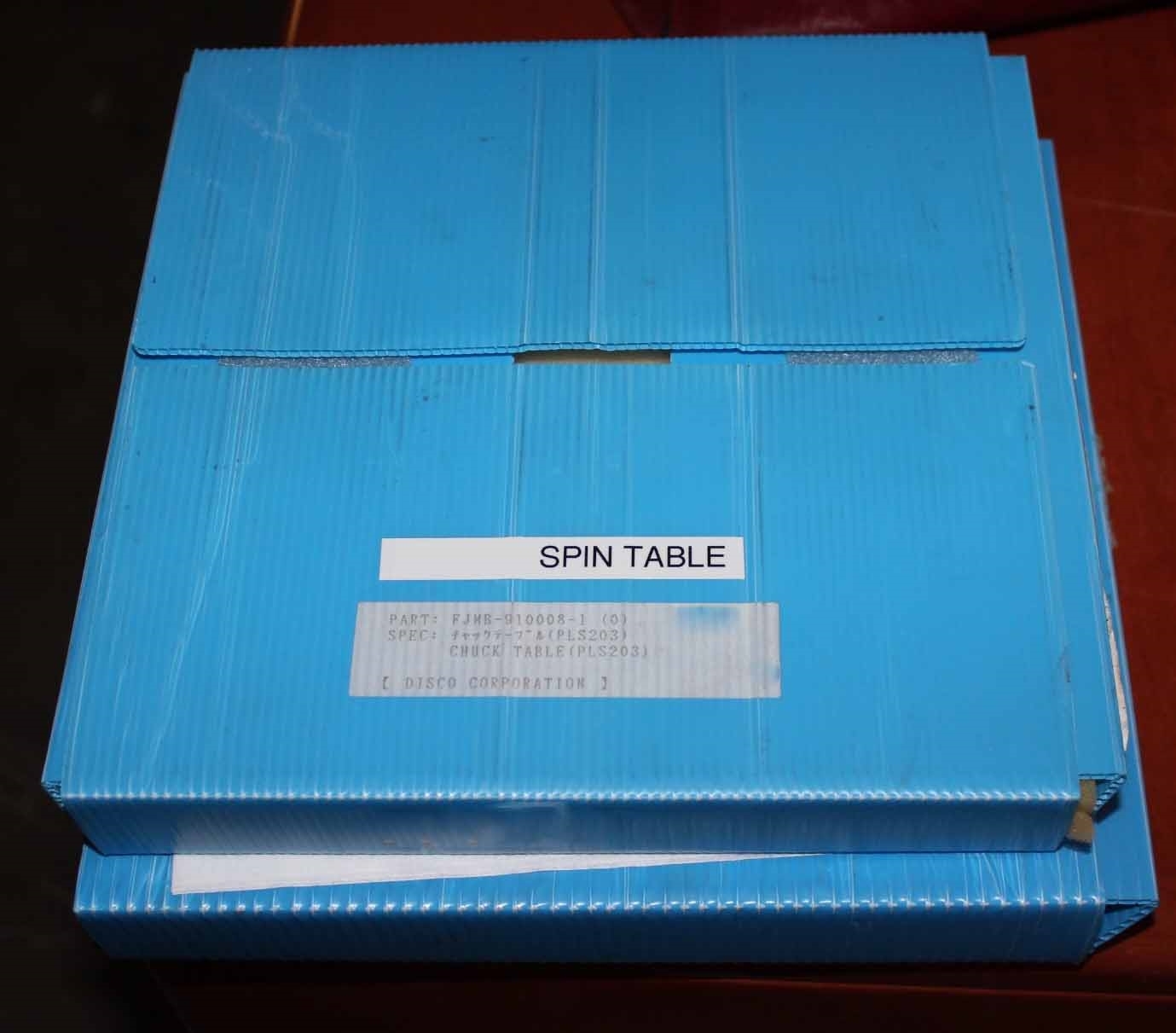

DISCO DFD 6340 is a scribing and dicing equipment specifically built for ultra precision machining of ferrous and non-ferrous materials. It combines a high-precision, servo-driven roller feeder with a high-speed linear axis mechanism, allowing for precise and fast automated scribing and dicing operations. The roller feeder has an adjustable feed direction and rate, adjustable cutting force and pressure, and a contoured ball bearing press-roll guide system. This allows for the consistent pressure feed, while the contoured balls ensure an exact and repeatable cut. The feeder also has an integrated forward/reverse capability and adjustable limit switches for easy operation. The linear axis mechanism is capable of a maximum speed of 7,200 mm/min and a maximum travel length of 2,400 mm. It is designed with a direct drive motor unit and 24 part-programmable work zones, allowing for complex and sophisticated cuts. The motor machine also allows for extremely smooth lateral cutting acceleration, deceleration and travel, resulting in accurate and repeatable cuts without the need for machine calibration. DISCO DFD6340 also boasts a sturdy frame and environmental protection, with a dust-collecting tool that is equipped with contact and noncontact safety switches. This helps ensure a safe and healthy working environment. The asset is also equipped with a range of coolant systems to protect the material and provide a sterile work environment. The use of a high-pressure coolant model is highly recommended for optimum results and longevity of the equipment. Overall, DFD 6340 is an extremely precise and efficient scribing and dicing system, designed for high-volume industrial applications. It offers unparalleled accuracy, consistency and speed, making it ideal for precision manufacturing tasks in a wide range of industries.

There are no reviews yet