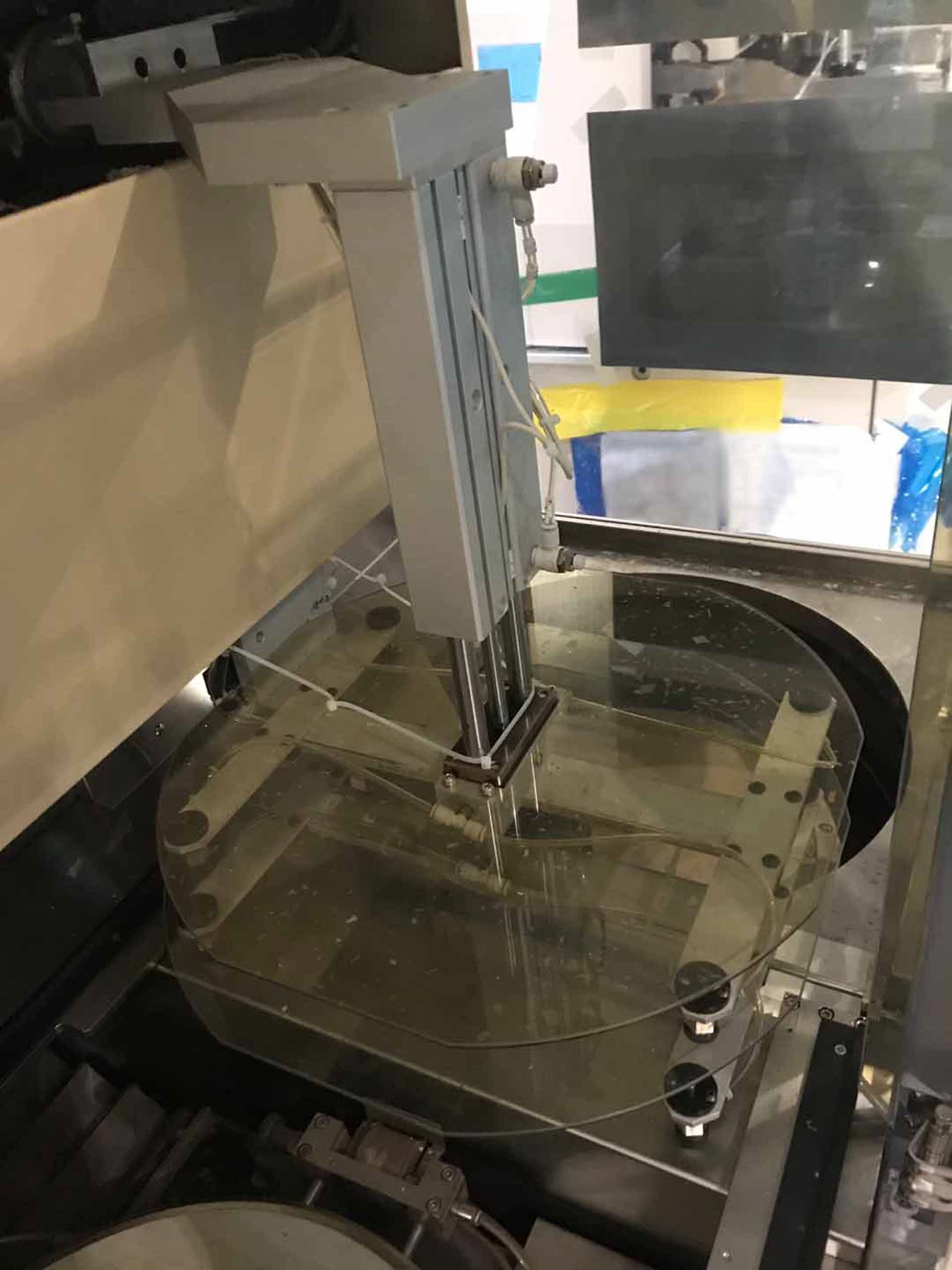

Used DISCO DFD 6340 #9229956 for sale

URL successfully copied!

Tap to zoom

ID: 9229956

Wafer Size: 12"

Wafer dicing saw, 12"

Workpiece size: 12"

Maximum blade size: 61 mm

Air bearing spindle: 1.0 kW Synchro spindle

Facing dual-spindles

Graphical user interface: Intuitive operation

Process method:

Dual cut

Step and bevel cut

X-Axis:

Useable stroke: 310 mm

Cut speed: 0.1~600 mm/s

Y-Axis:

Useable stroke: 310 mm

Indexing step: 0.0001 mm

Position accuracy (cumulative pitch): Less then 0.003/310 mm

Position accuracy (single pitch): Less then 0.002/5 mm

Scale resolution: 0.0002 mm

Z-Axis:

Maximum cutting stroke: 14.7 mm (for φ2" Blade)

Minimum step: 0.00005 mm

Repeating accuracy: 0.001 mm

Maximum blade size: 60 mm

Θ-Axis:

Rotation angle (max.): 380°

Spindle:

Output: 1.0 kW

Maximum revolution: 60,000 min^-1(rpm)

Applicable tape frame: 2-8-1 2-12

Utilities:

Power supply: 3 Phase, 200V, 50-60Hz

Power consumption:

When processing: 2.2 kW

During warm-up: 1.8 kW

Maximum power: 6.9 kVA

Air pressure: .05~0.8 (5.0~8.0) (Mpa(kgf/cm²))

Air flow rate: 378 L/min(ANR)

N2 Pressure range: 0.5~0.8 (5.0~8.0) Mpa (kgf/cm²)

N2 Maximum consumption: 216 (L/min(ANR))

Water pressure:

Cutting water (Cleaning water): 0.2~0.4 (2.0~4.0) Mpa (kgf/cm²)

Cooling water: 0.2~0.4 (2.0~4.0) Mpa (kgf/cm²)

Water flow rate:

Cutting water: 12.0 (L/min)

Spinner cleaning water: 1.0 (L/min)

Water curtain: 1.0 (L/min)

Cooling water: 3.0 (L/min)

Duct required suction: 5 (m³/min).

DISCO DFD 6340 is a scribing and dicing equipment used to process a variety of materials quickly and accurately. This process involves using lasers to cut precise shapes out of sheets of material. DISCO DFD6340 system is highly versatile and can be used for different applications, including cutting and etching, surface trimming, drilling, and machining. The heart of the scribing and dicing unit is the laser, which can be configured to emit light in specific wavelengths and intensities, enabling precise speed and cutting accuracy. The laser can be used to cut material at a variety of scales, ranging from millimeters to centimeters. The laser operates by heating up and vaporizing the material, allowing an exact shape to be cut. The cutting speed depends on the type of material being processed and the thickness of the material. The machine is equipped with a variety of safety features to ensure the safety of the operator and the materials being processed. The most important of these features is an enclosed self-contained work area, preventing any dust or other particles from escaping into the atmosphere and causing health problems. In addition, the laser has emergency power shut off buttons in case of an emergency. DFD 6340 tool is highly precise and efficient, reducing the time and cost of producing parts, and is ideal for high volume production. The software that it uses is designed for flexibility and scalability, so that it can easily be customized to meet job-specific needs. Once the job is complete, DFD6340 provides high-quality products in a timely fashion. In addition, the asset is compatible with a variety of other components, such as post-processing equipment and optical devices, making it an ideal choice for many industrial applications.

There are no reviews yet