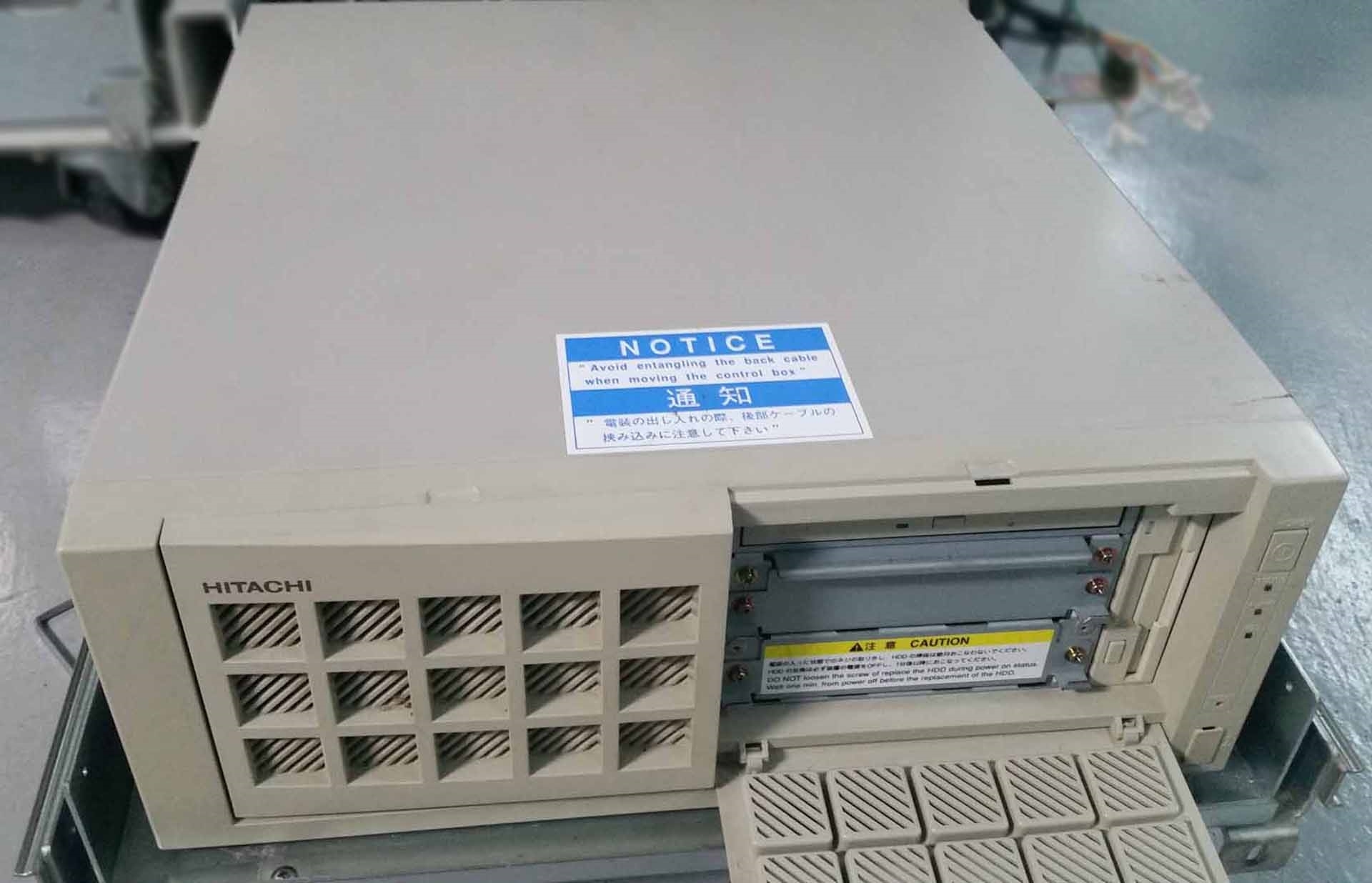

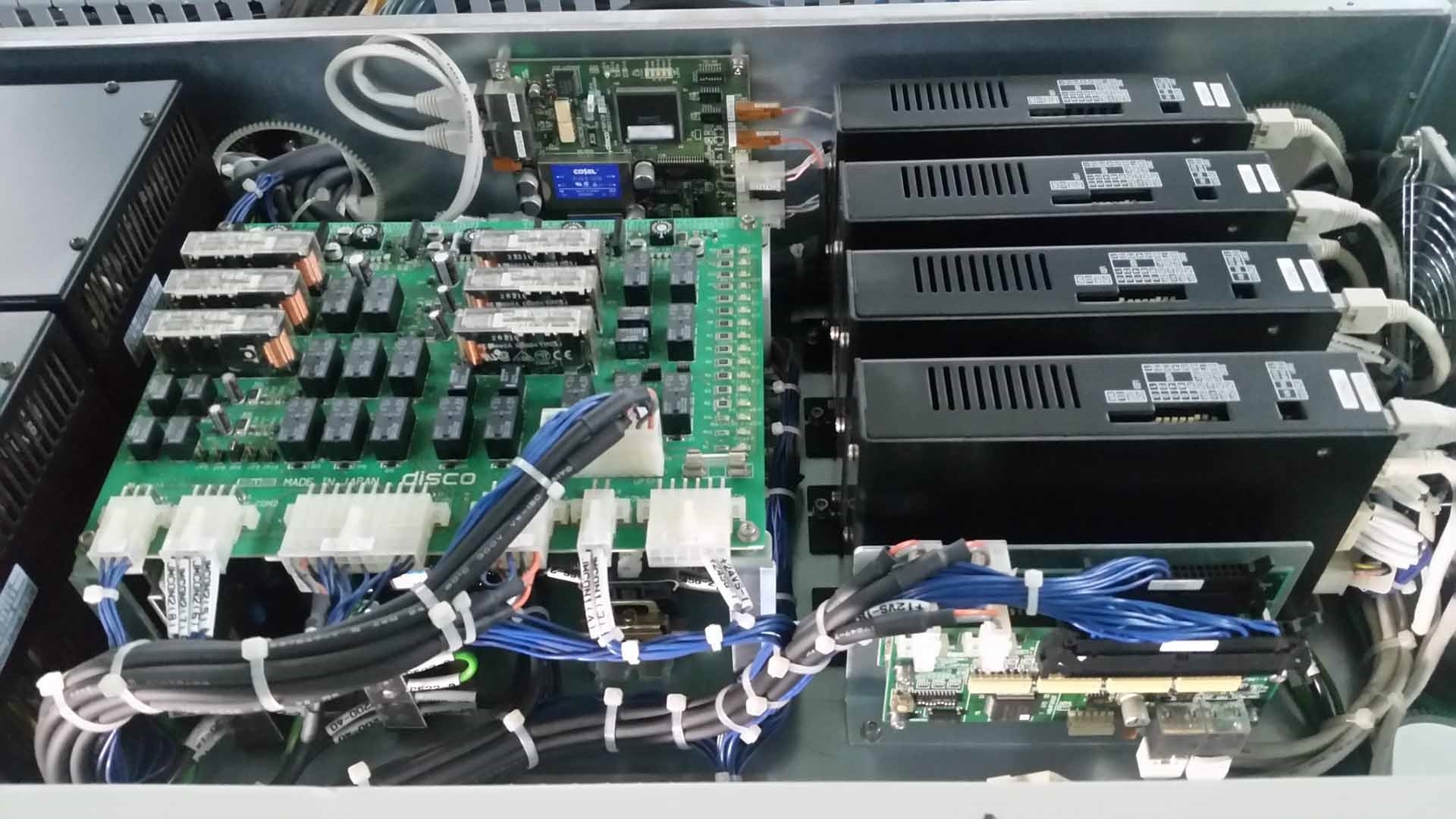

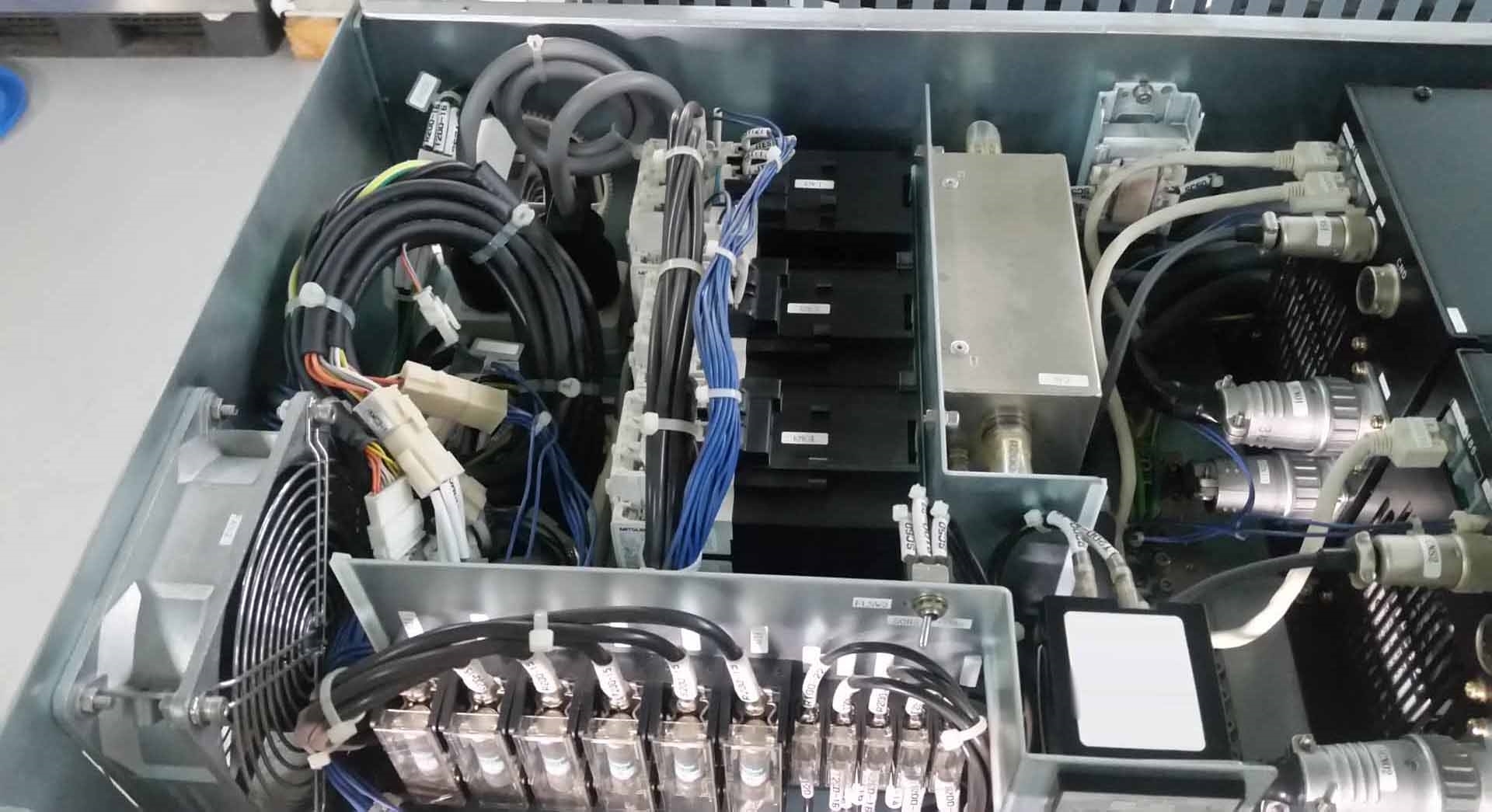

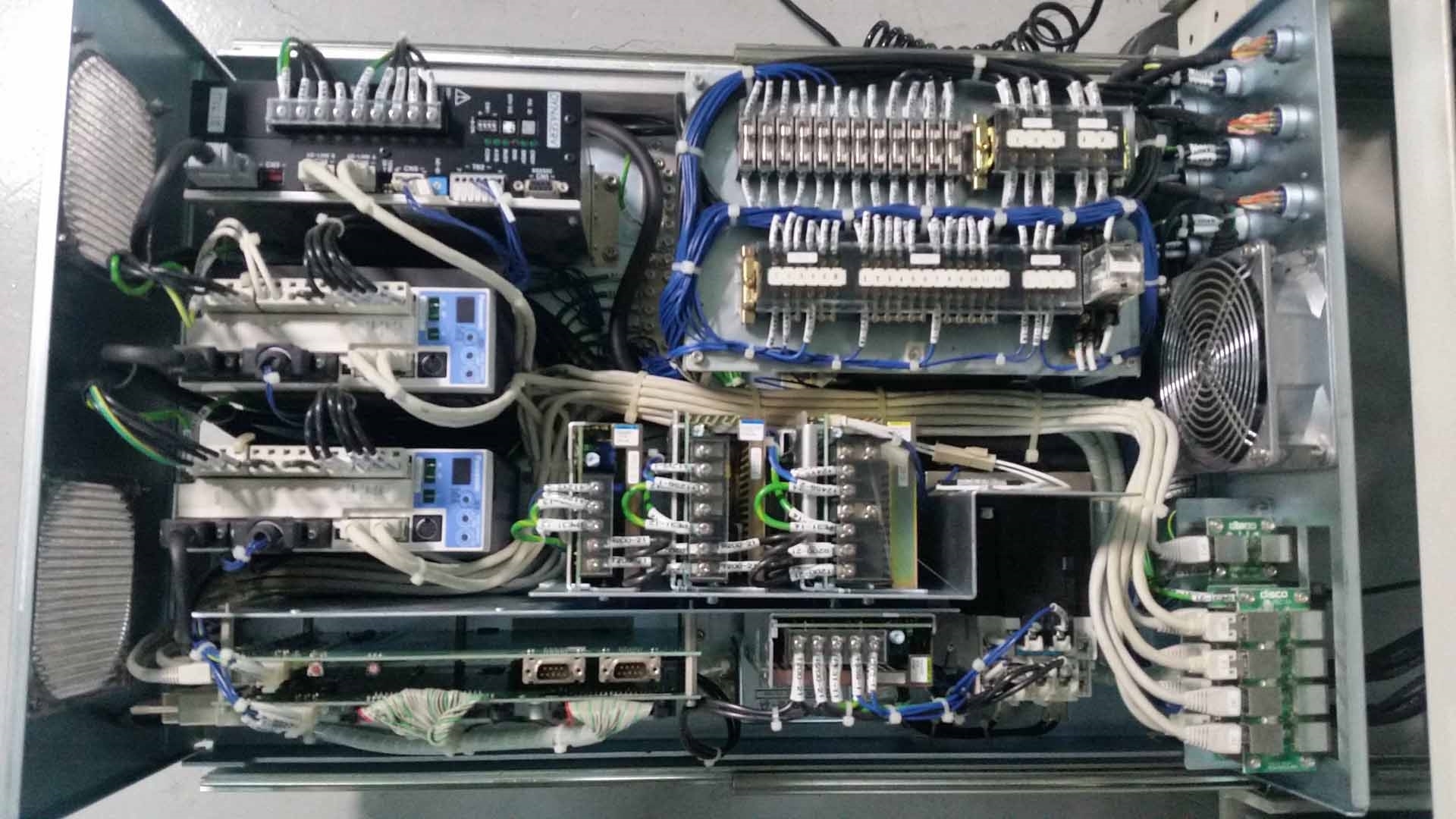

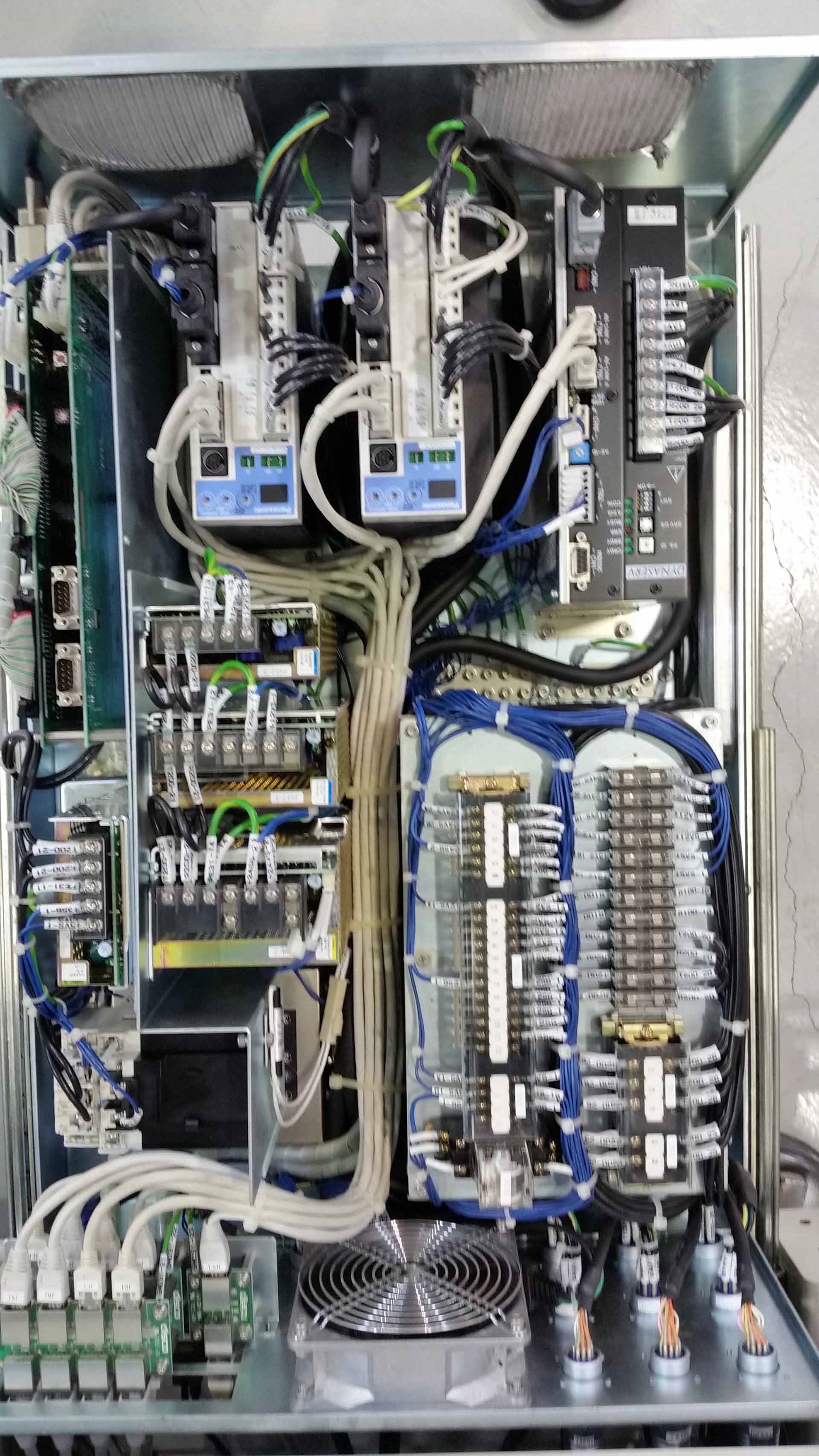

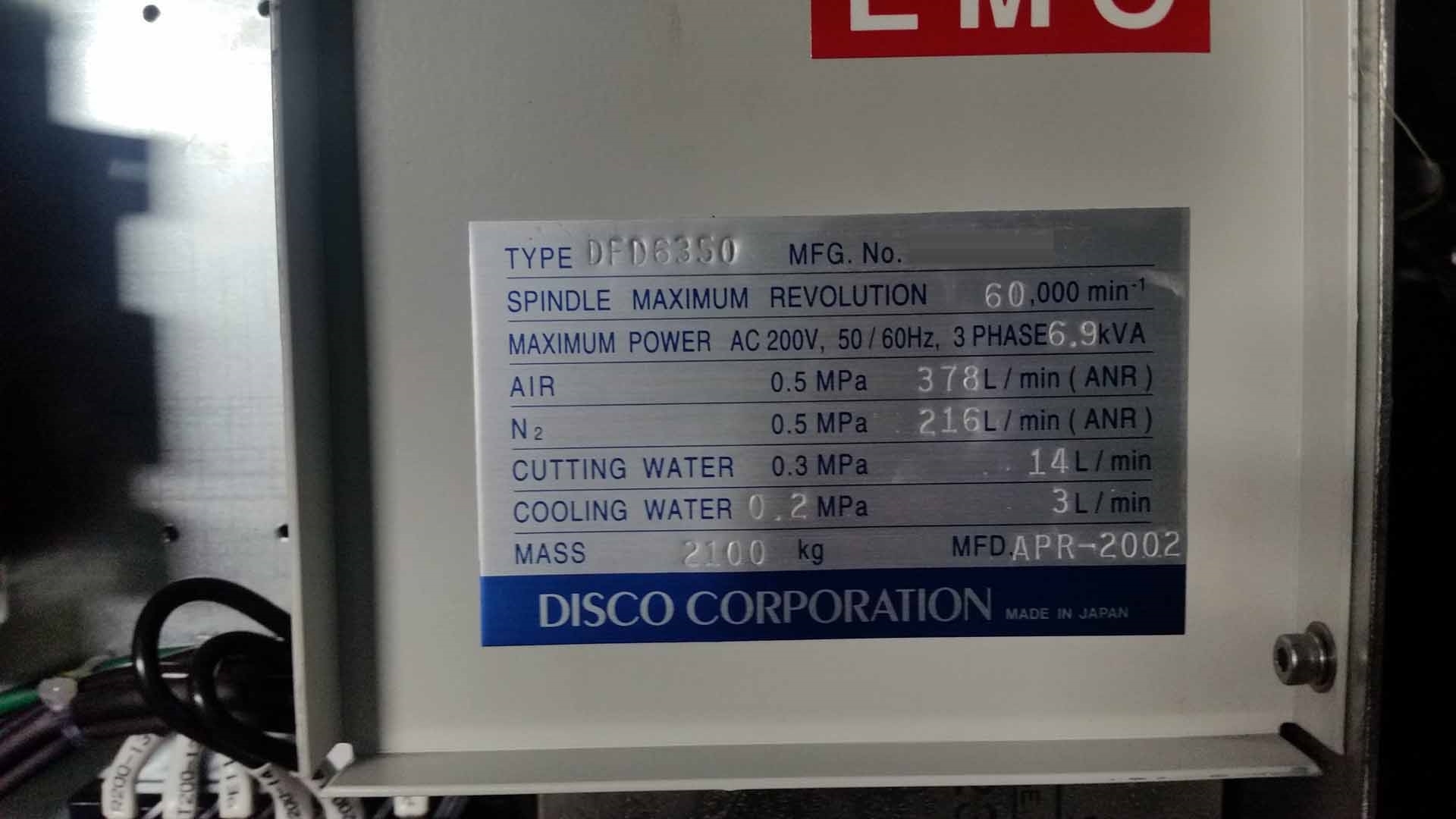

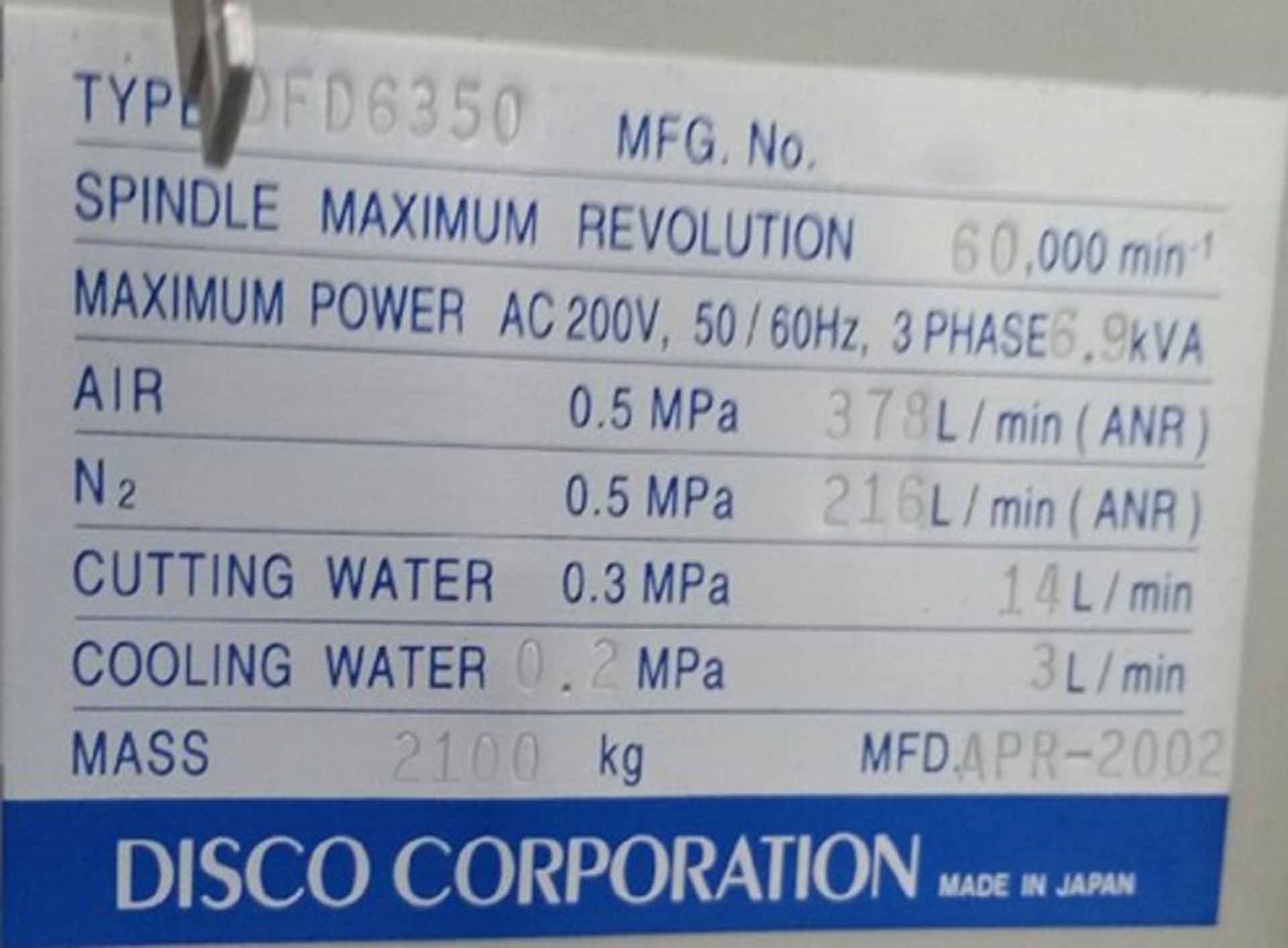

Used DISCO DFD 6350 #9218722 for sale

URL successfully copied!

Tap to zoom

ID: 9218722

Vintage: 2002

Dicing saw

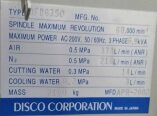

SYNCHRD NCPA0055 Spindle

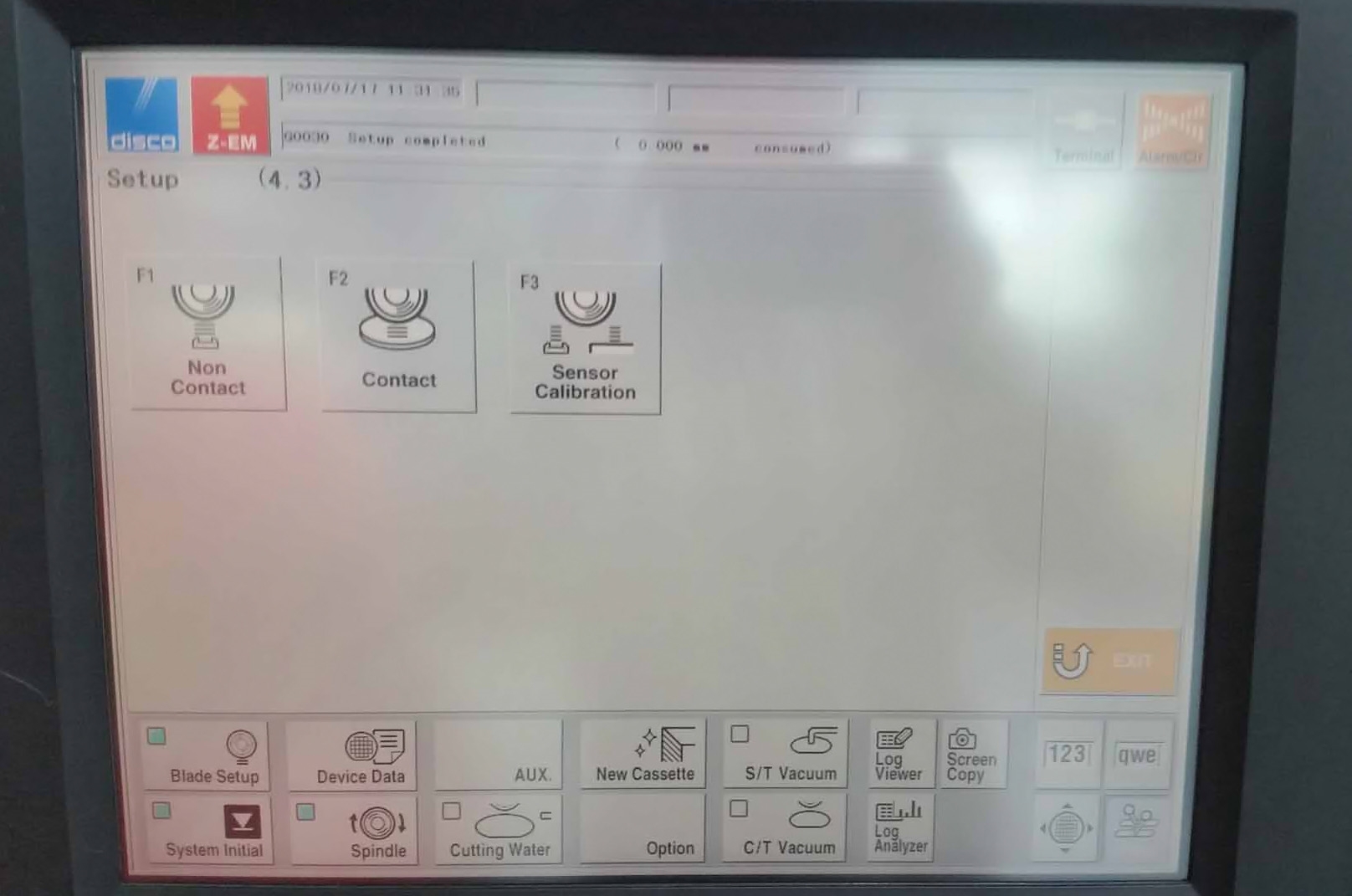

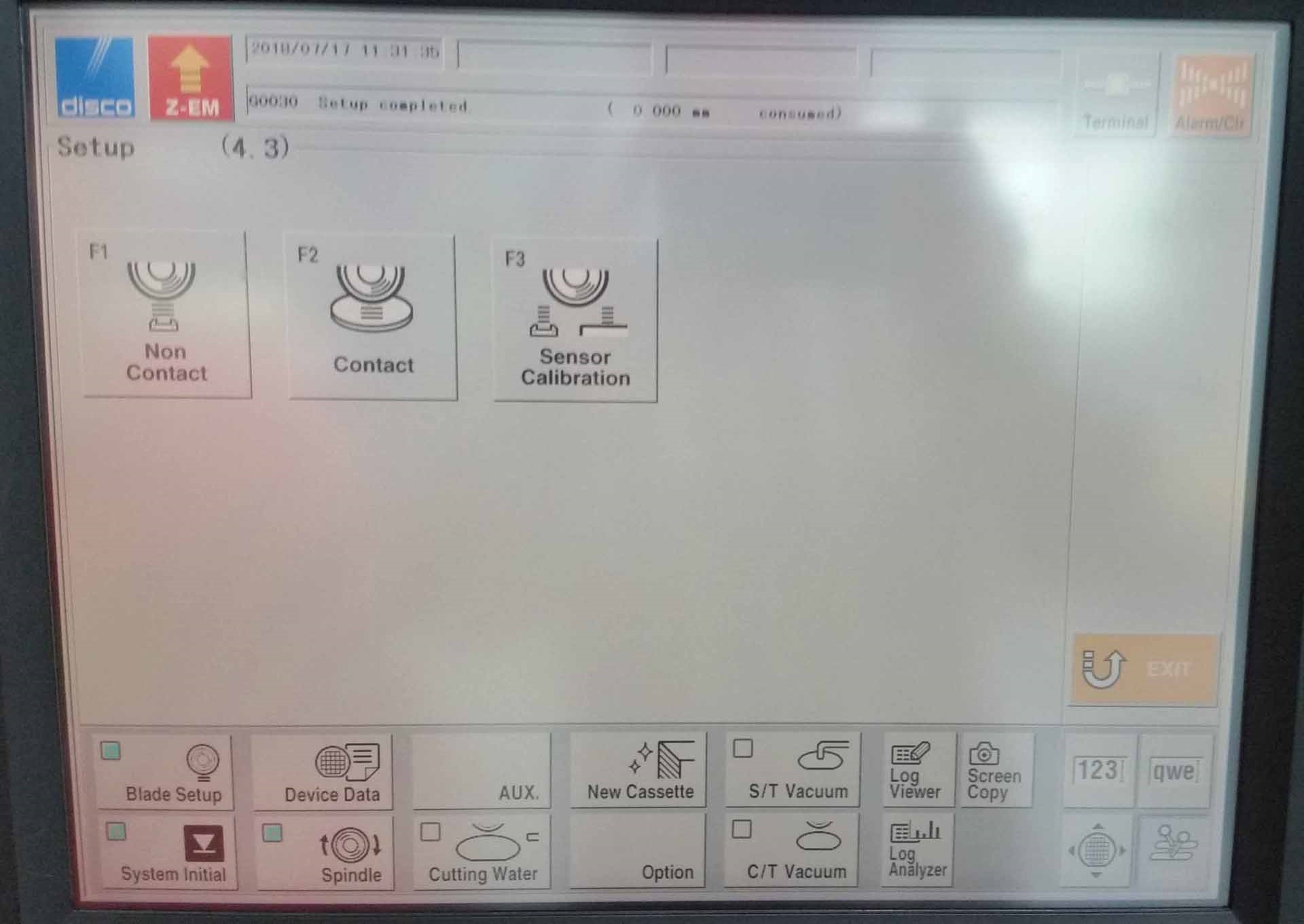

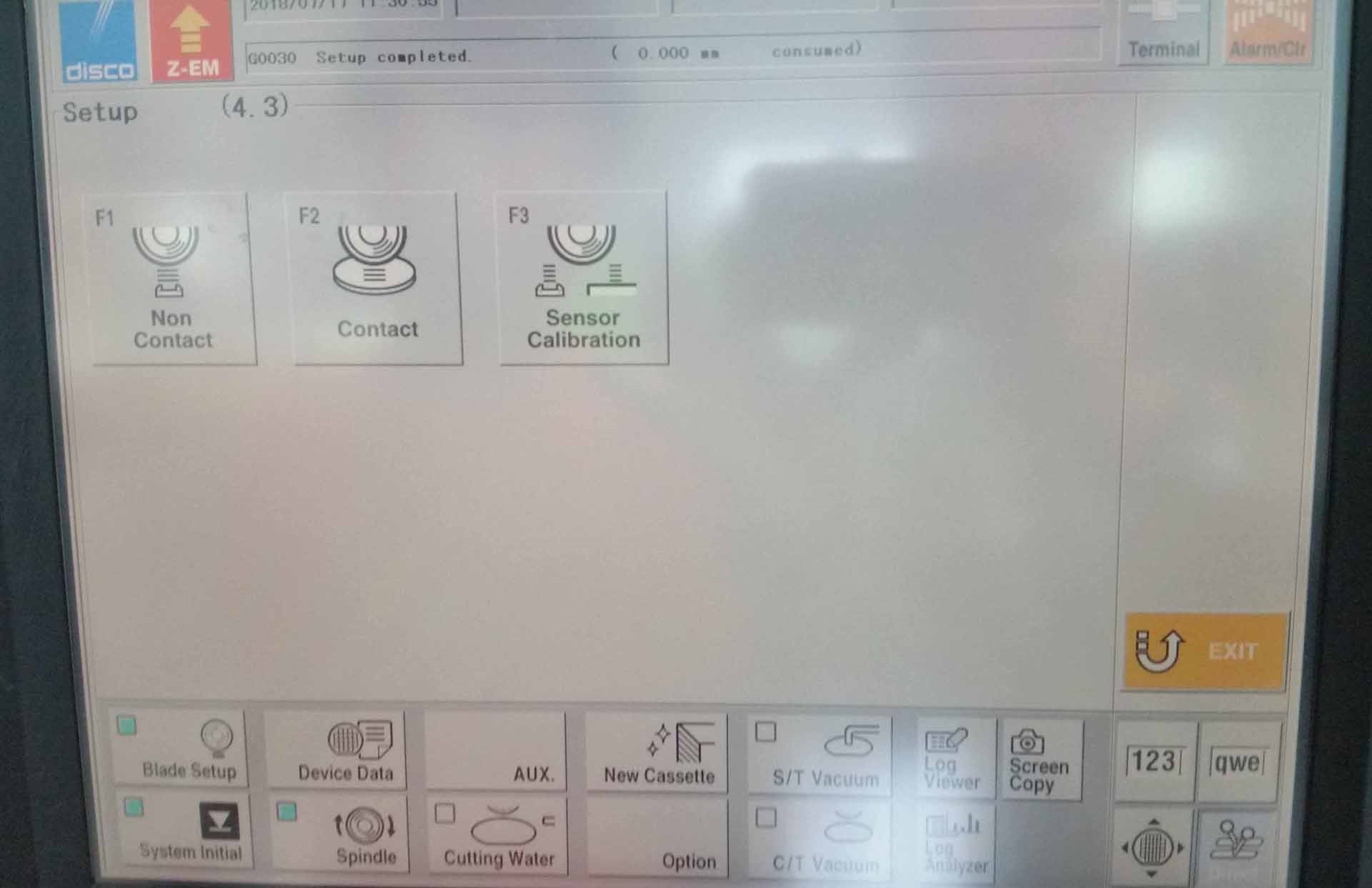

About each axis check:

Contents Allowance Measure

Camera XY perpendicularity 3 µm / 100 mm or less Maximum 3 µm

Wave X-axis - Clear

Straight Y axis 3 µm / 310 mm or less Maximum 2 µm

Y Axis squareness 5 µm / 310 mm or less Maximum 4 µm

Y Axis deviation index 2 µm / 155 mm or less Maximum 2 µm

Set up repeatability 5 µm / Below 10 Maximum 3 µm

Z Axis repeatability 1 µm / Below 10 Maximum 1 µm

Spindle shake 3 µm Below Maximum 2 µm

Flange cross section Less than 2 µm Maximum 2 µm

Spindle rotation Rotational speed within ± 3% 100 RPM

X Axis flatness (Base) 4 µm and under Max 4 µm

X-Axis flatness (Table) 8 µm / 300mm and underMax 8 µm

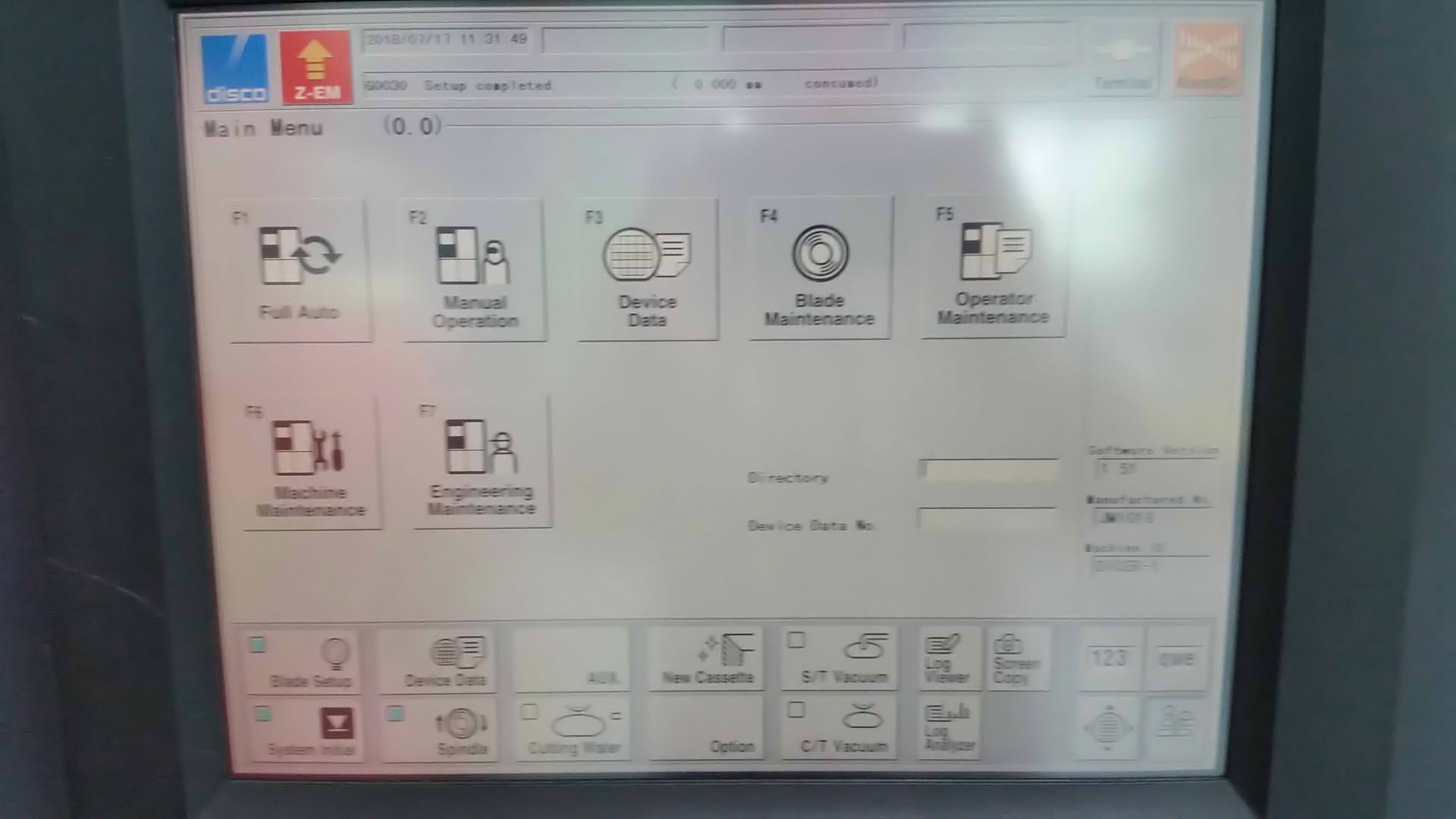

Check each part functions:

Item Standard Measure

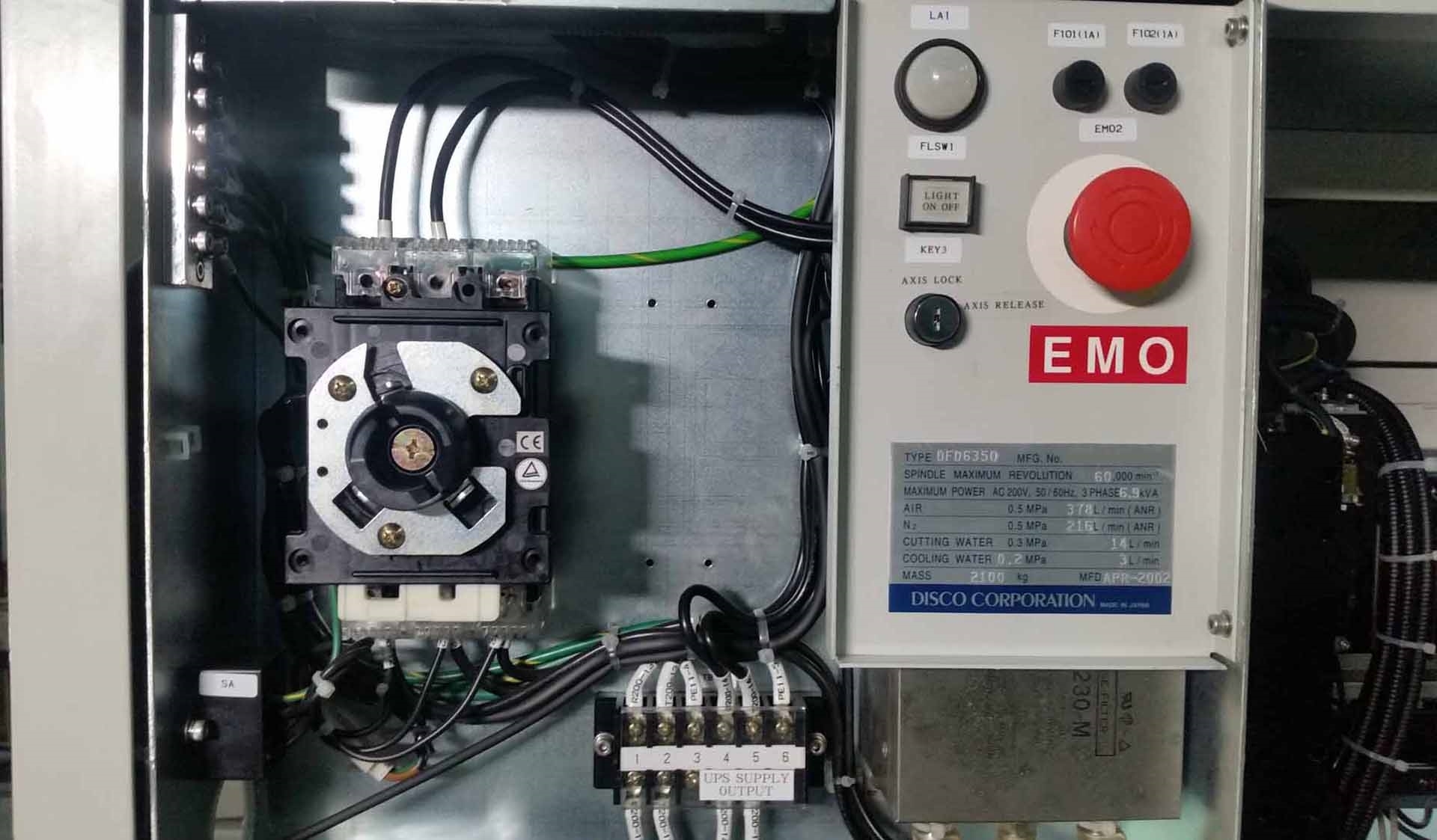

EM Operating status Stop power off Clear

Sensor shaft operating state Axis stop alarm Clear

Monitor status No screen cracks Clear

Table vacuum pressure Over - 60kpa 72

Flow meter operation V Position Clear

Spindle cooling unit 1 ℓ / min or more Clear

Carbon brush status 30 Ω or less 17.5

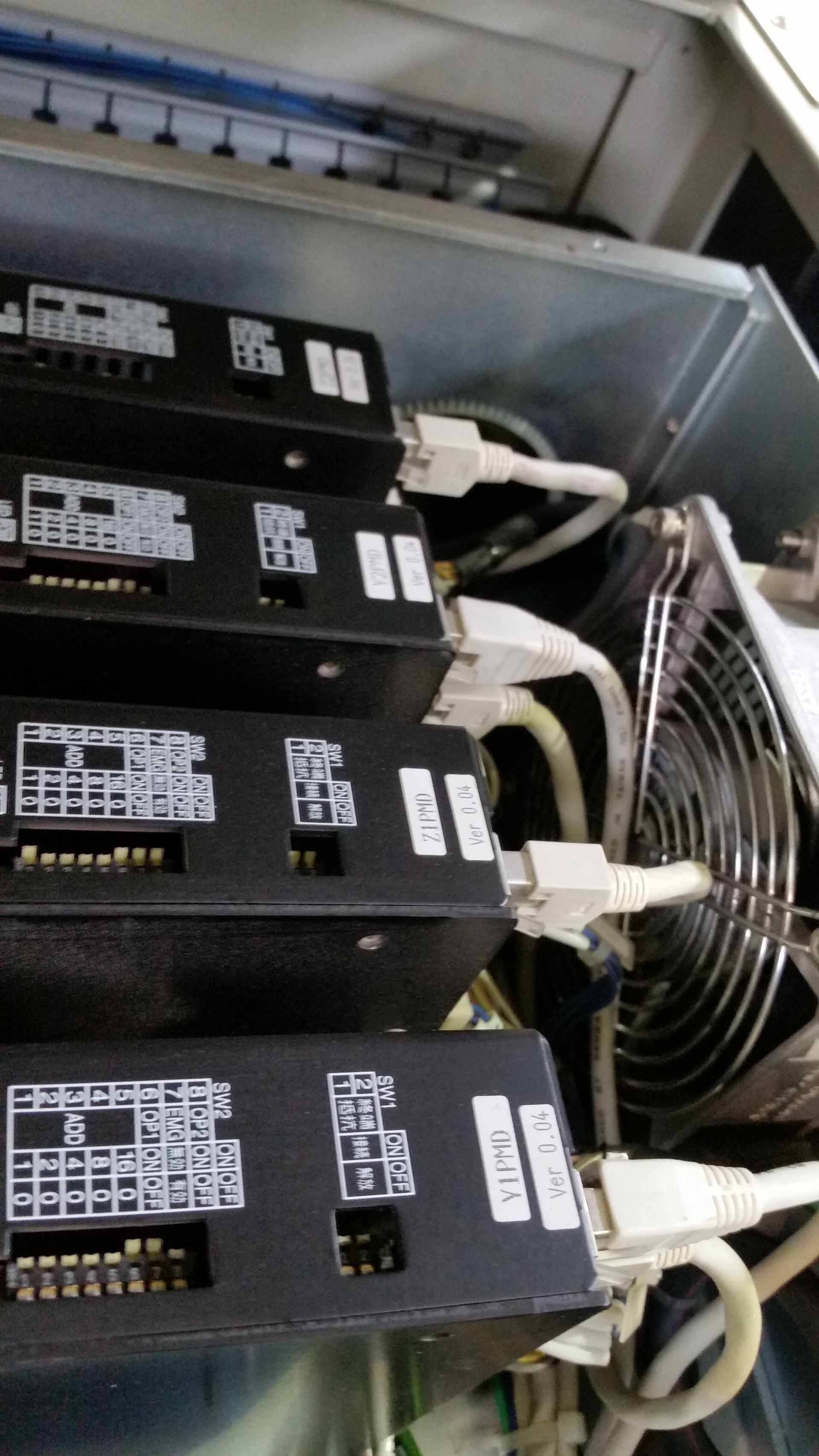

Item Standard Measure

PS5-1 DC 5 V ± 5% Clear

PS12-1 DC 12 V ± 5% Clear

PS12-2 DC 12 V ± 5% Clear

PS24-1 DC 24 V ± 5% Clear

PS24-2 DC 24 V ± 5% Clear

Item Standard Measure

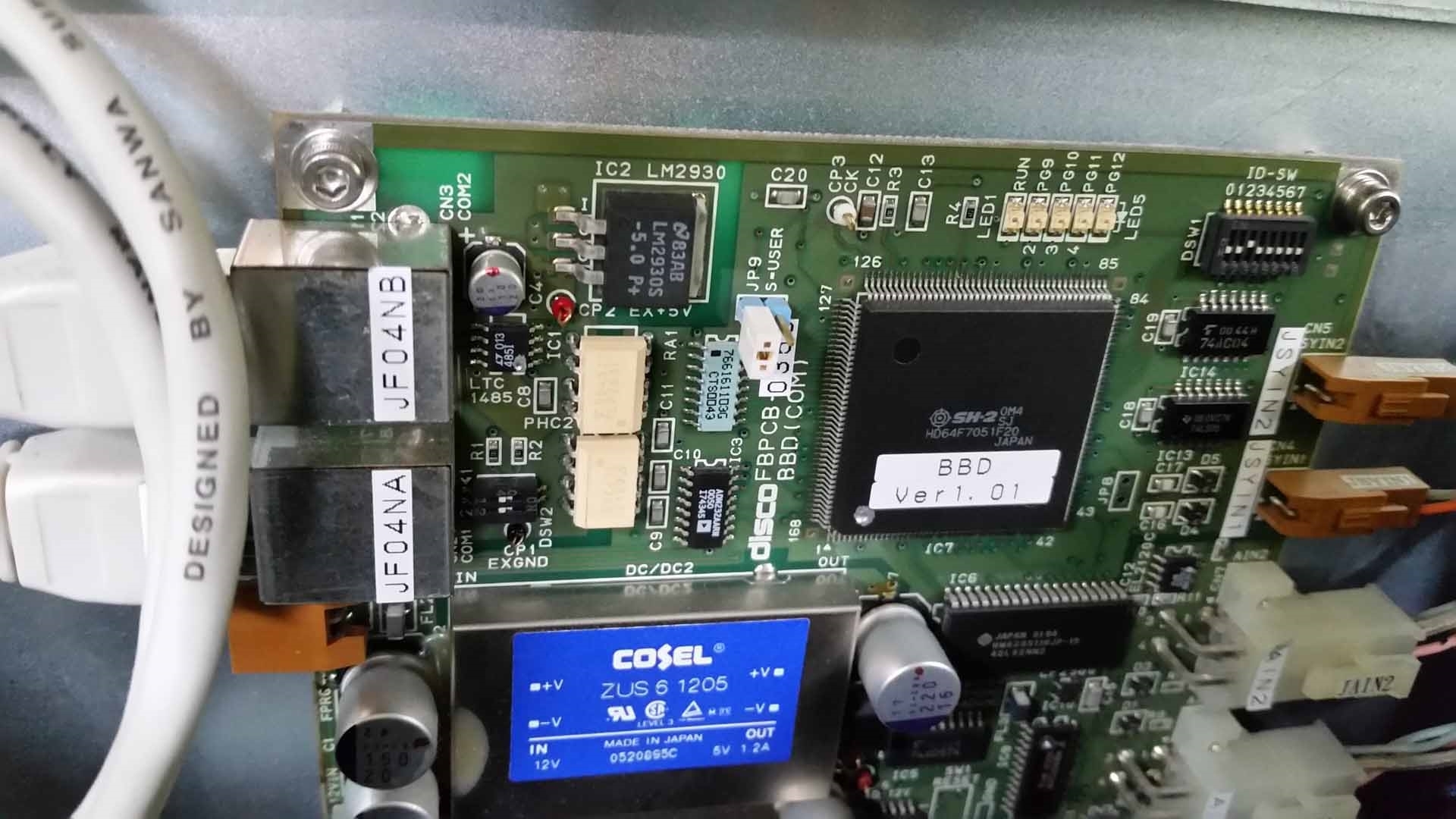

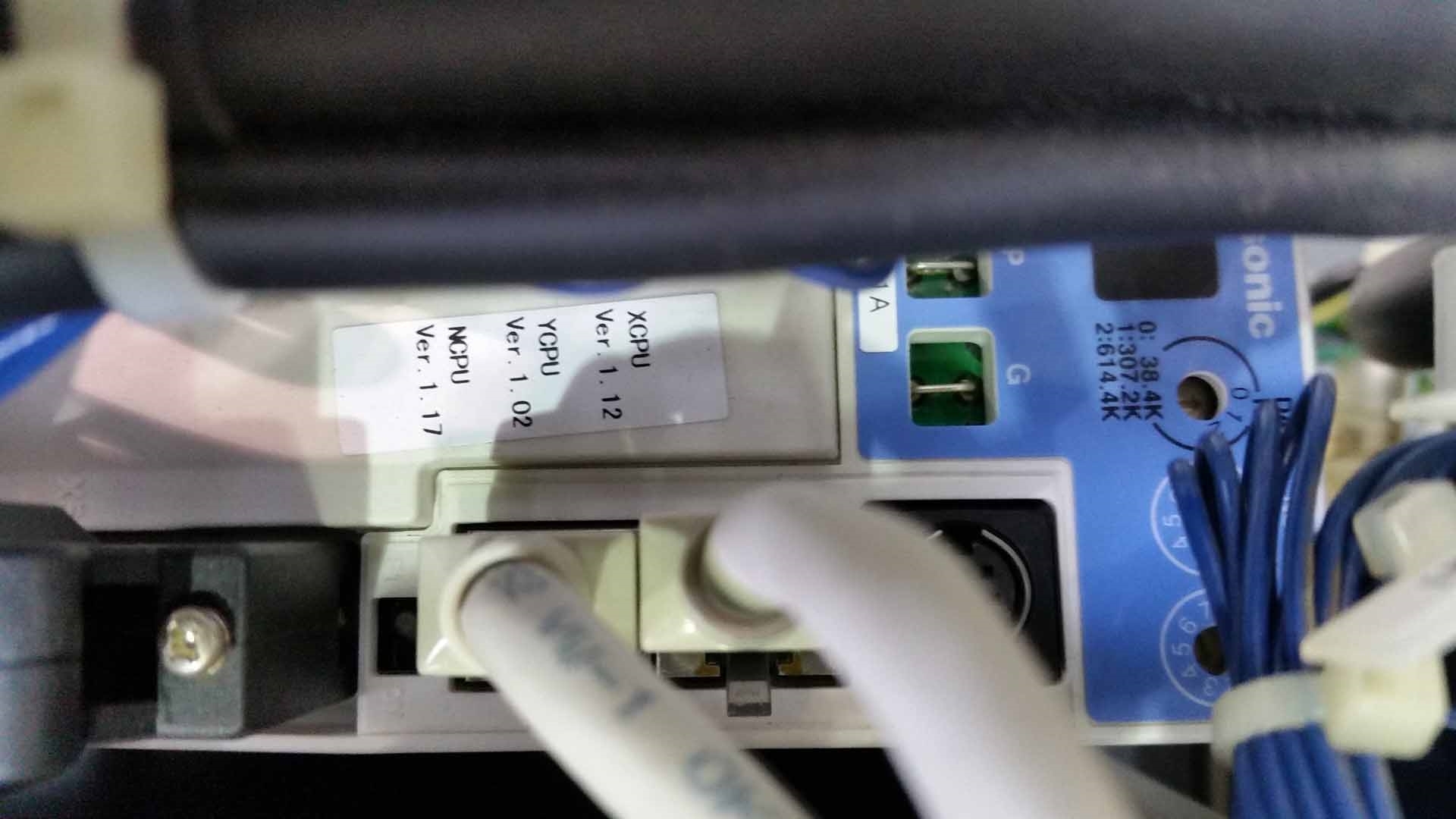

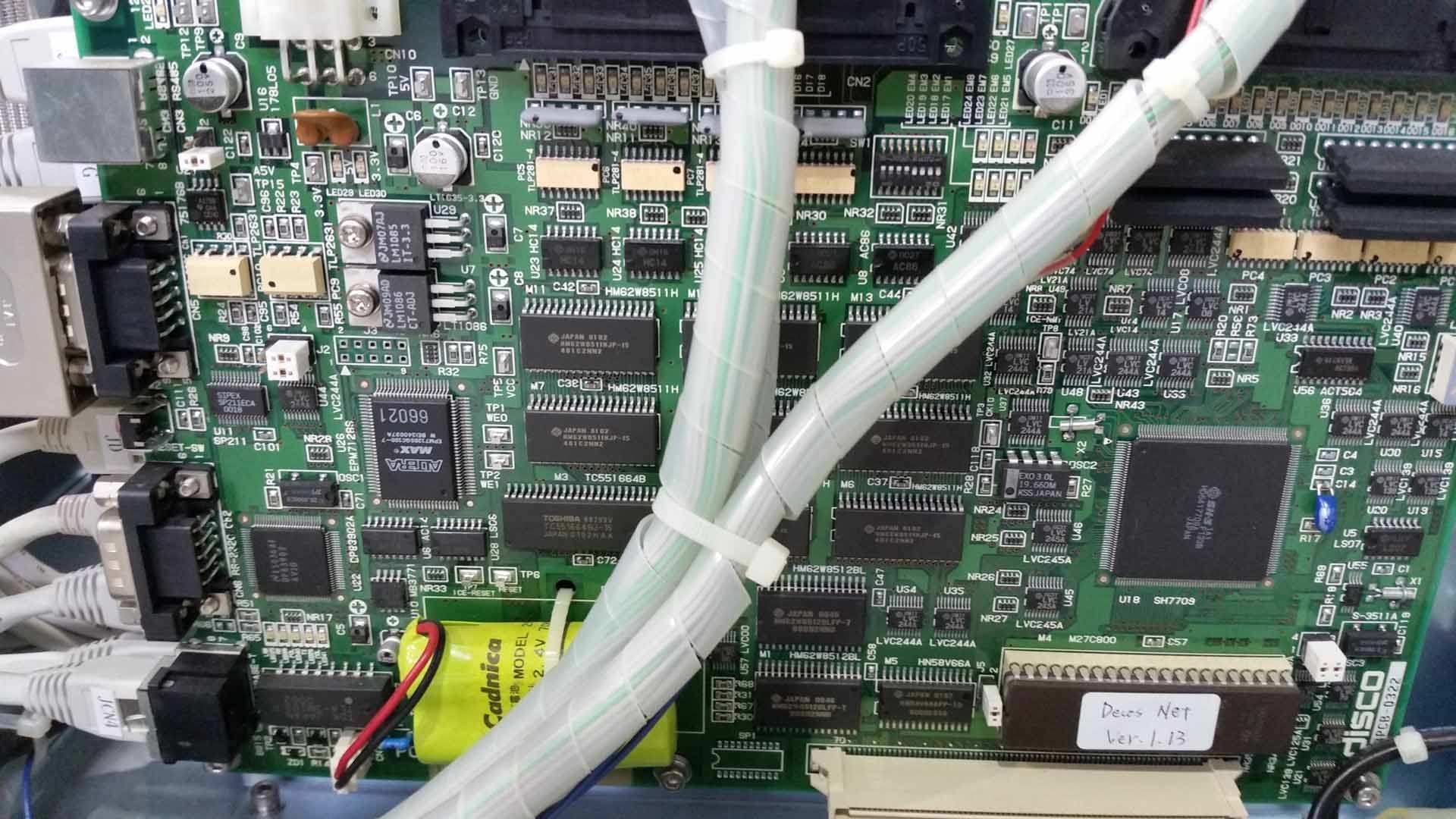

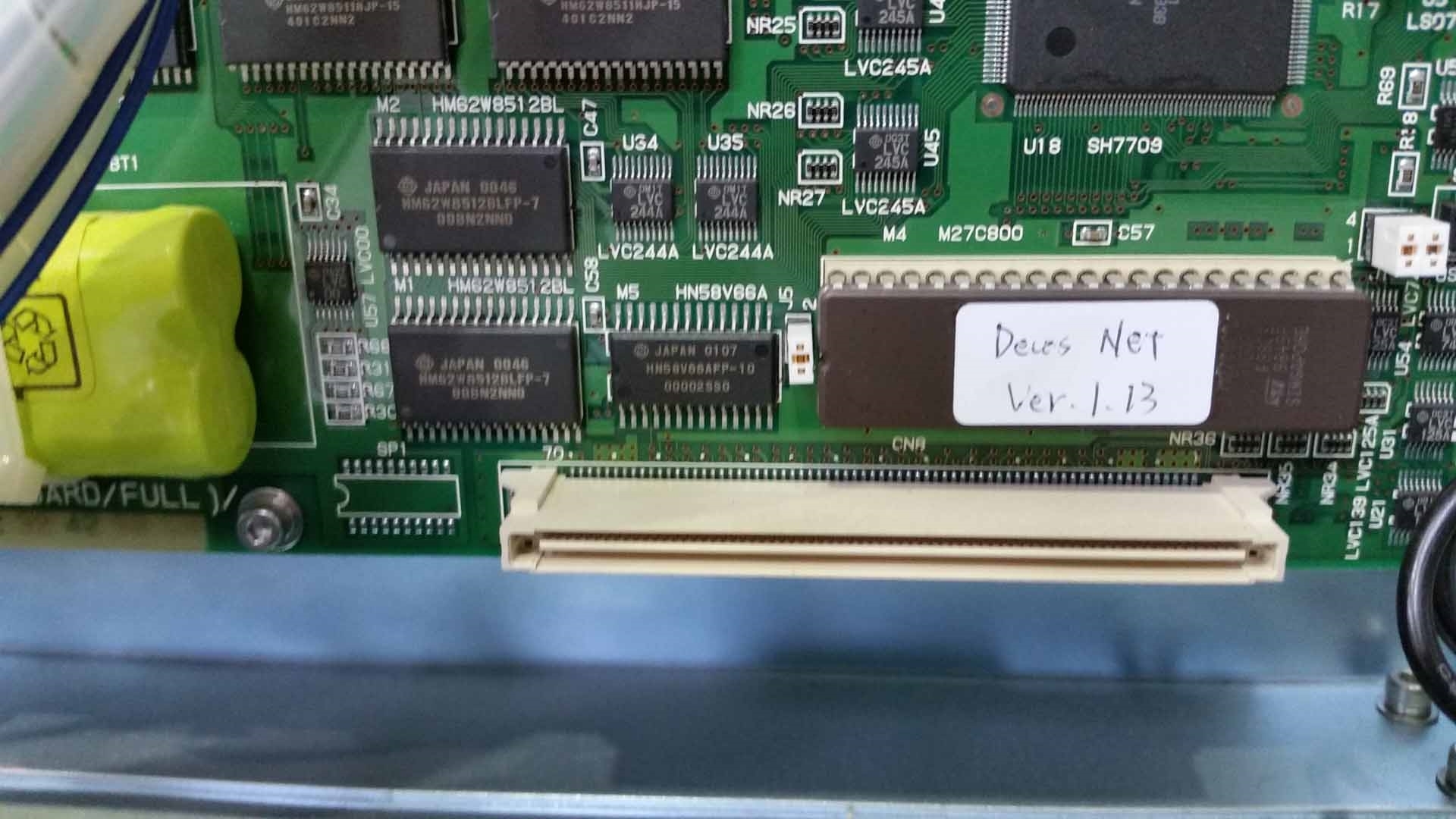

CPU BAT1 DC 3.6V 3.56

VGA Screen status Clear

EM / SETUP BAT1 DC 3.6V 3.45

COMM I / F Operating condition Clear

2002 vintage.

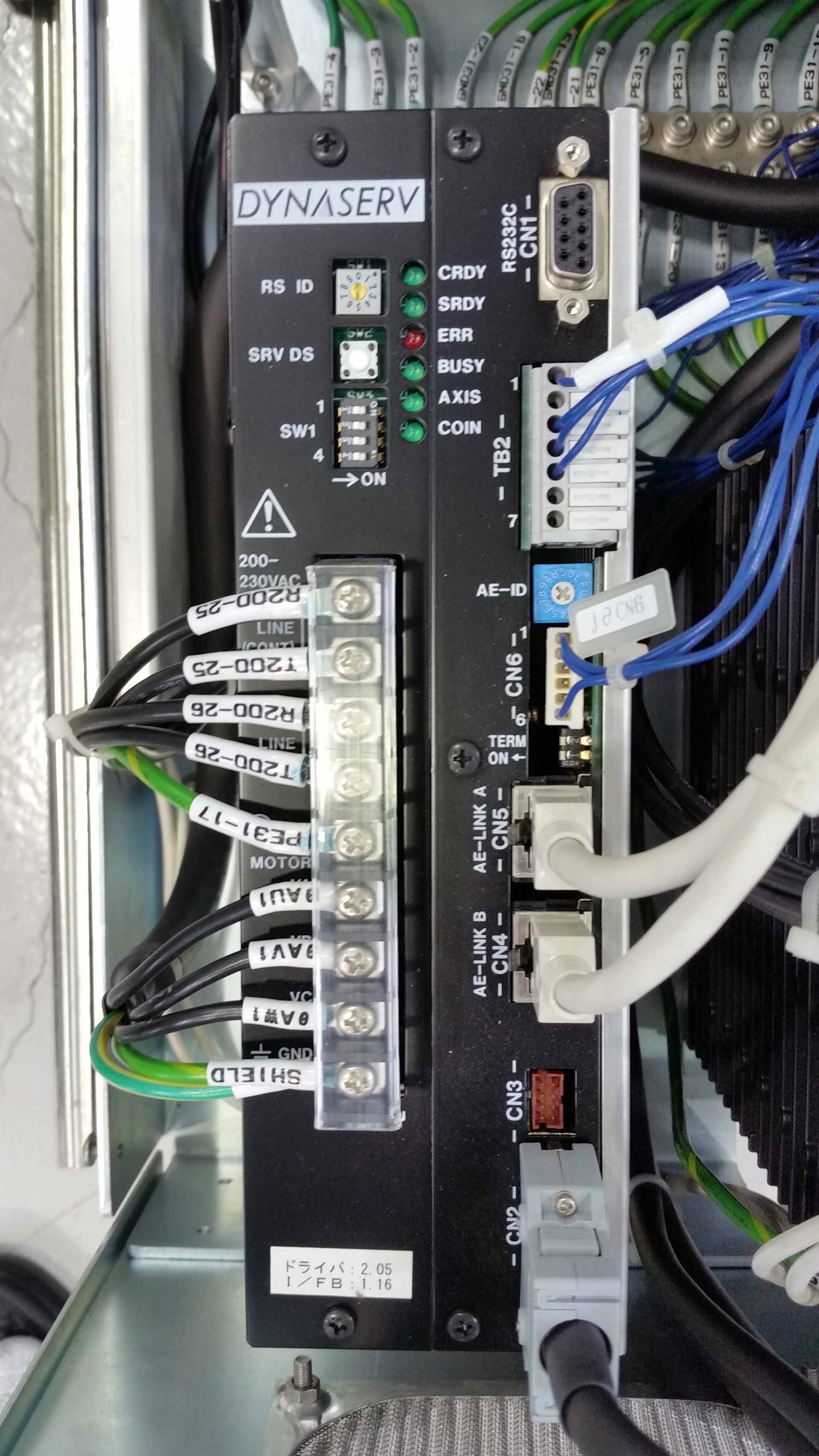

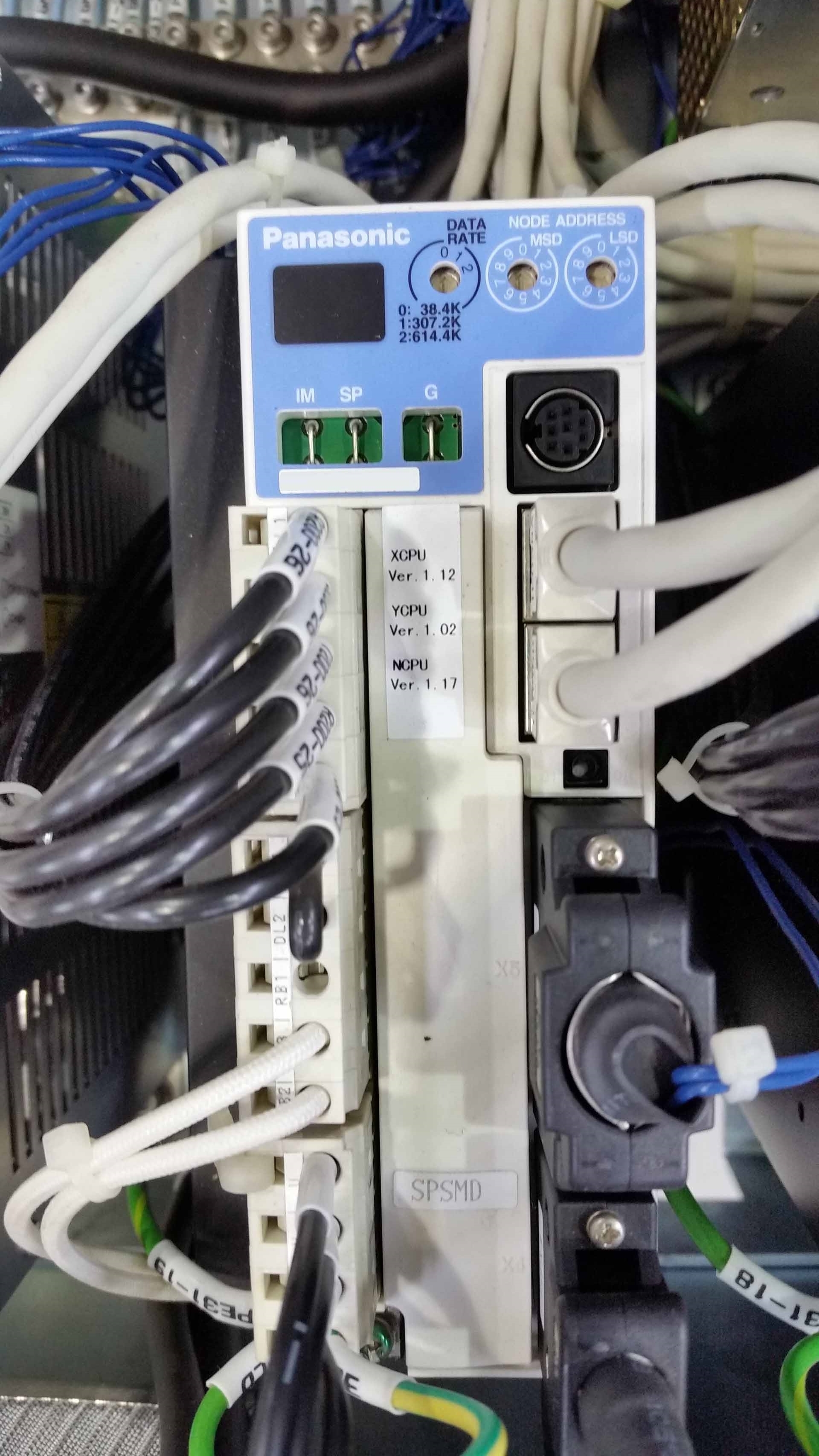

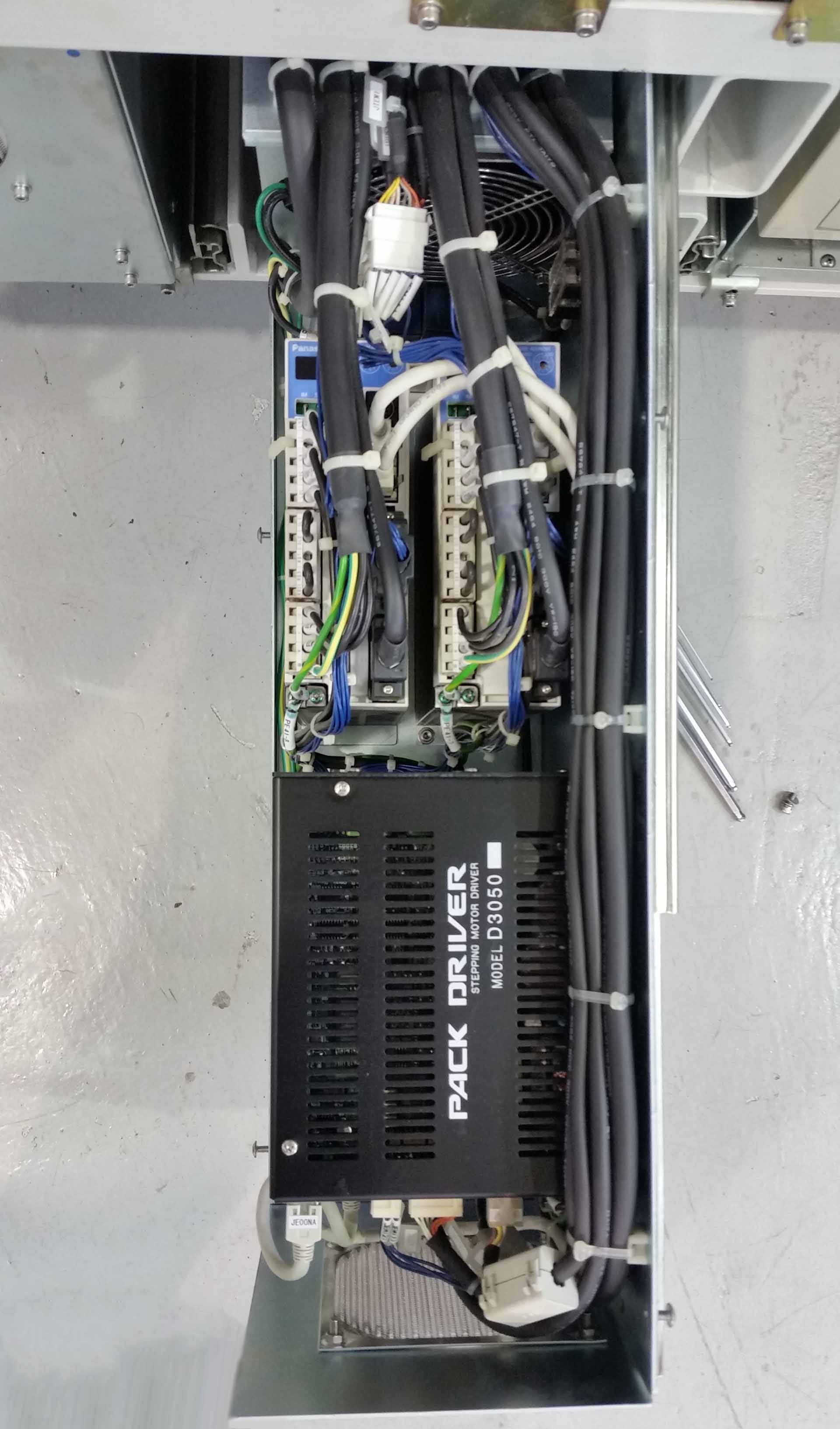

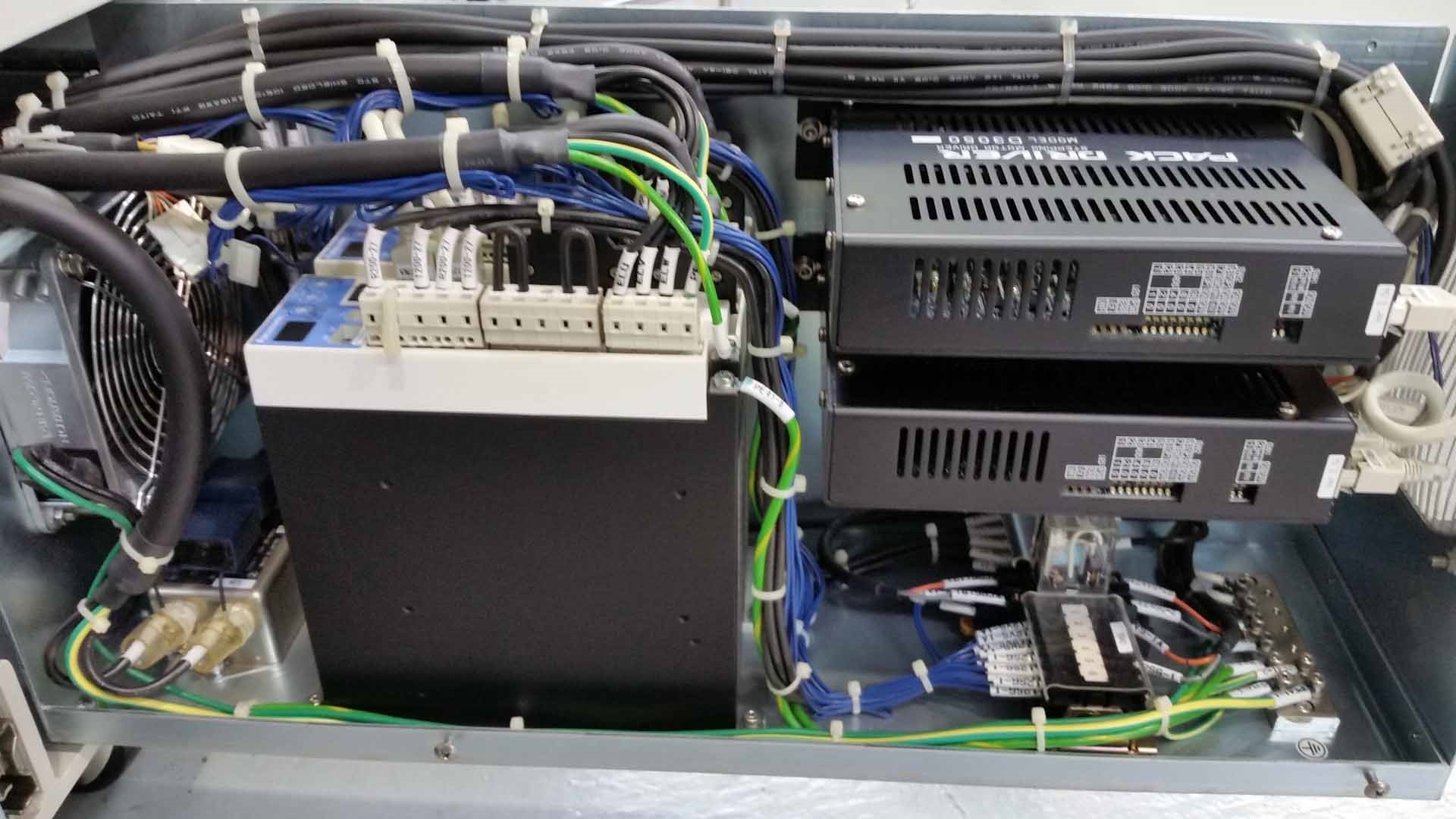

DISCO DFD 6350 is a high-precision scribing / dicing equipment used in a variety of precision manufacturing applications. The machine, designed by DISCO Corporation, is built to process thin, hard substrates such as silicon, sapphire, and quartz with great precision. DFD 6350 is a high-grade machine, featuring three precision linear axes, and one controllable rotary axis. These axes are all driven by a direct drive linear motor system, which is capable of maintaining extremely consistent accuracy. The machine also has a position control unit for precise control of the process. DISCO DFD 6350's scribing function utilizes a high precision diamond tipped blade that is accurate to within 1 micron accuracy. The blade is driven at high speed while the positioning of the blade is precisely controlled. This ensures that very accurate designs can be implemented into the material. DFD 6350 also has an integrated machine for dicing small substrates using a high speed laser dicing technique. The tool utilizes a high power laser to scribe the material, creating very precise cuts with minimal debris production. The laser is capable of cutting substrates up to 5mm thick and is accurate to within 0.1 micron precision. DISCO DFD 6350 also has an integrated vision asset for the detection and counting of substrate chips. This model is able to detect chips as small as 0.5mm^2, and can also measure chip size to great accuracy. This ensures that the process is running optimally and prevents excessive debris buildup. To complete the equipment, DFD 6350 has an auto loader/unloader for loading and unlading substrates. This system allows for automated substrate loading and unloading, greatly increasing efficiency. Overall, DISCO DFD 6350 is a high-precision machine performing two key functions in the manufacture of precision components: scribing and dicing. The unit is capable of very precise implementation of designs on thin, hard substrates, as well as fast and precise dicing of small substrates. Furthermore, an integrated vision machine for chip detection and counting, as well as an auto loader/unloader, ensure that the process is running at optimal pace and efficiency. DFD 6350 is an ideal choice for precision manufacturing.

There are no reviews yet