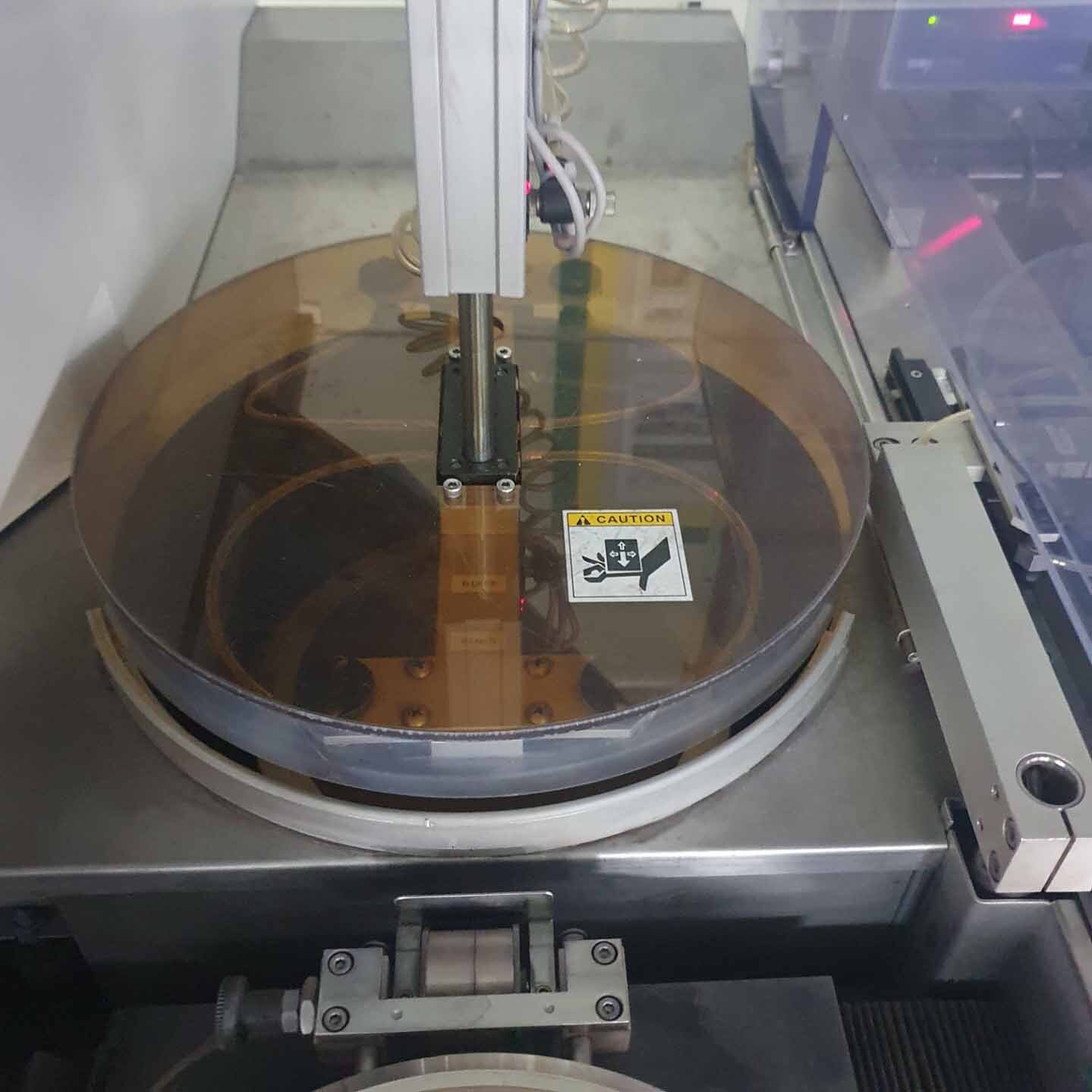

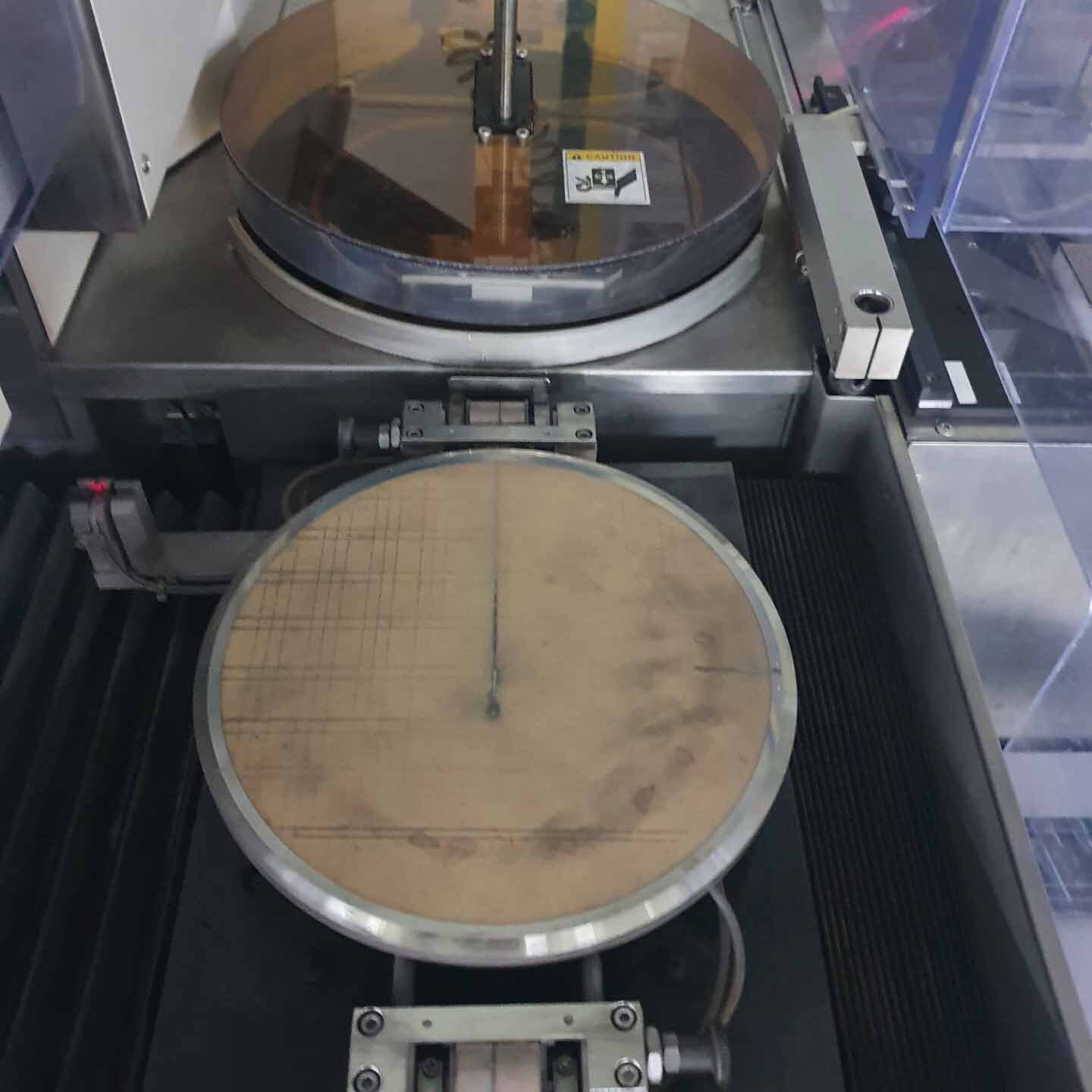

Used DISCO DFD 640 #293602401 for sale

URL successfully copied!

Tap to zoom

DISCO DFD 640 is a scribing / dicing equipment designed to be used in semiconductor fabrication. It is a fully automated system capable of producing precision cutting of through-silicon via (TSV) faces and dicing of wafers into small chips. It's automated operation is driven by an advanced PC based controller and software, allowing it to perform a variety of functions with high accuracy. The unit has an accuracy of up to ±3μm and performs actions such as die (dicing) and thru-silicon via face scribing, with speeds up to approximately 6300 lines per minute. This machine also provides fully automated inspection of the cut lines with a built-in optical tool. DISCO DFD640 offers a variety of benefits, such as low downtime, fully automated operation, and the high-degree of accuracy and speed. Additionally, the asset is capable of monitoring the process to make sure each step is done properly. For example, its built-in optical model is designed to reduce the chance of failure in the cutting process, by inspecting each cut line. Furthermore, the equipment offers a high repeatable accuracy and guarantees the desired dimensions and shapes of the scribed wafer or dicing plane. The system offers many different types of cutting operations, including single cuts, repeated cuts, multiple layer cutting, and curved or angled cuts for increased flexibility. Finally, DFD 640 is equipped with a self-monitored unit that keeps track of machine conditions and detects any change, helping to maximize its performance. The machine is programmed to detect any discrepancy that may occur in the machine, alerting the operator and creating an audit trail for traceability. All in all, DFD640 is a powerful and accurate tool designed to provide precise cutting of through-silicon via faces and dicing of wafers into small chips. Its high speed, accuracy, and automated processes make it ideal for semiconductor fabrication.

There are no reviews yet