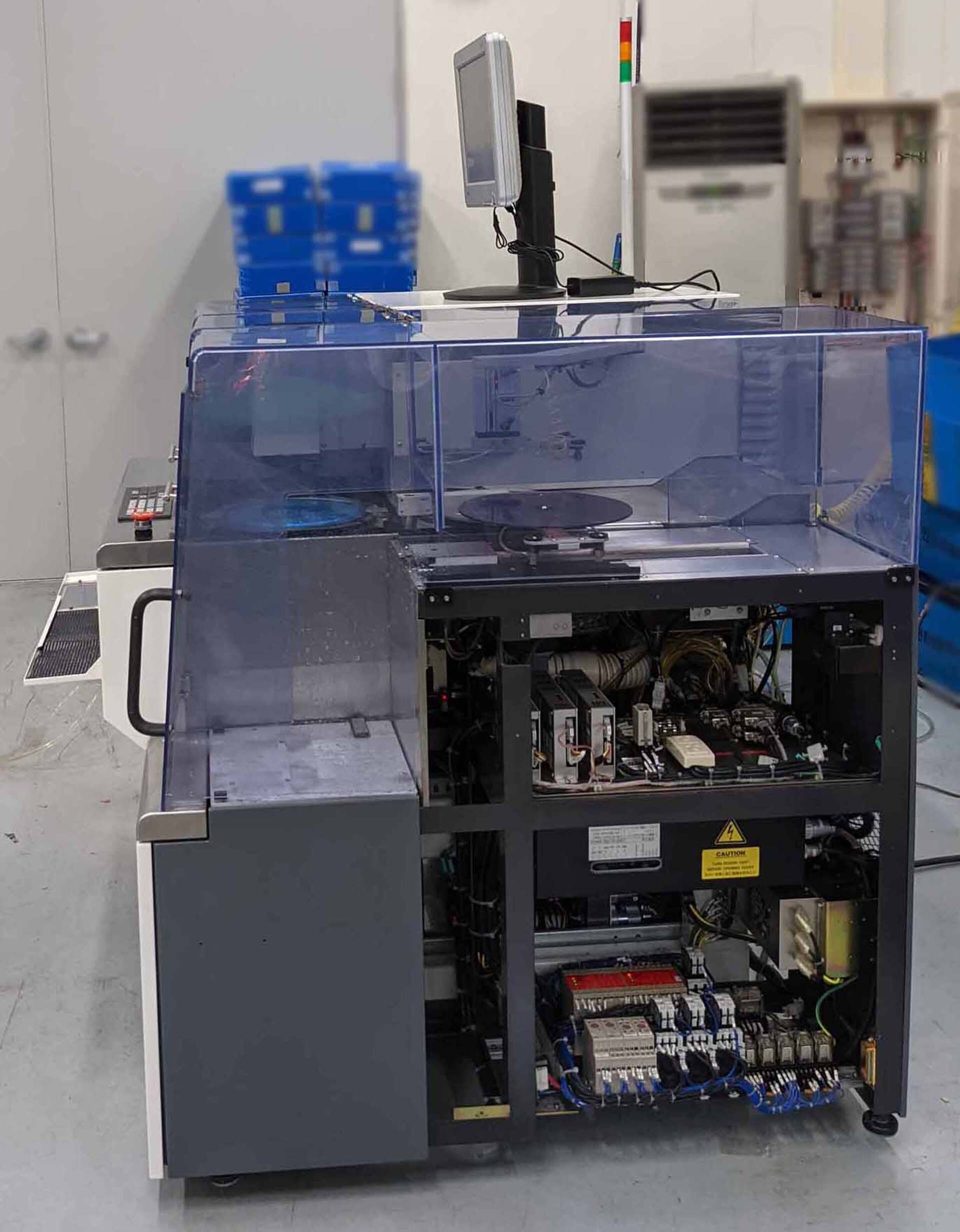

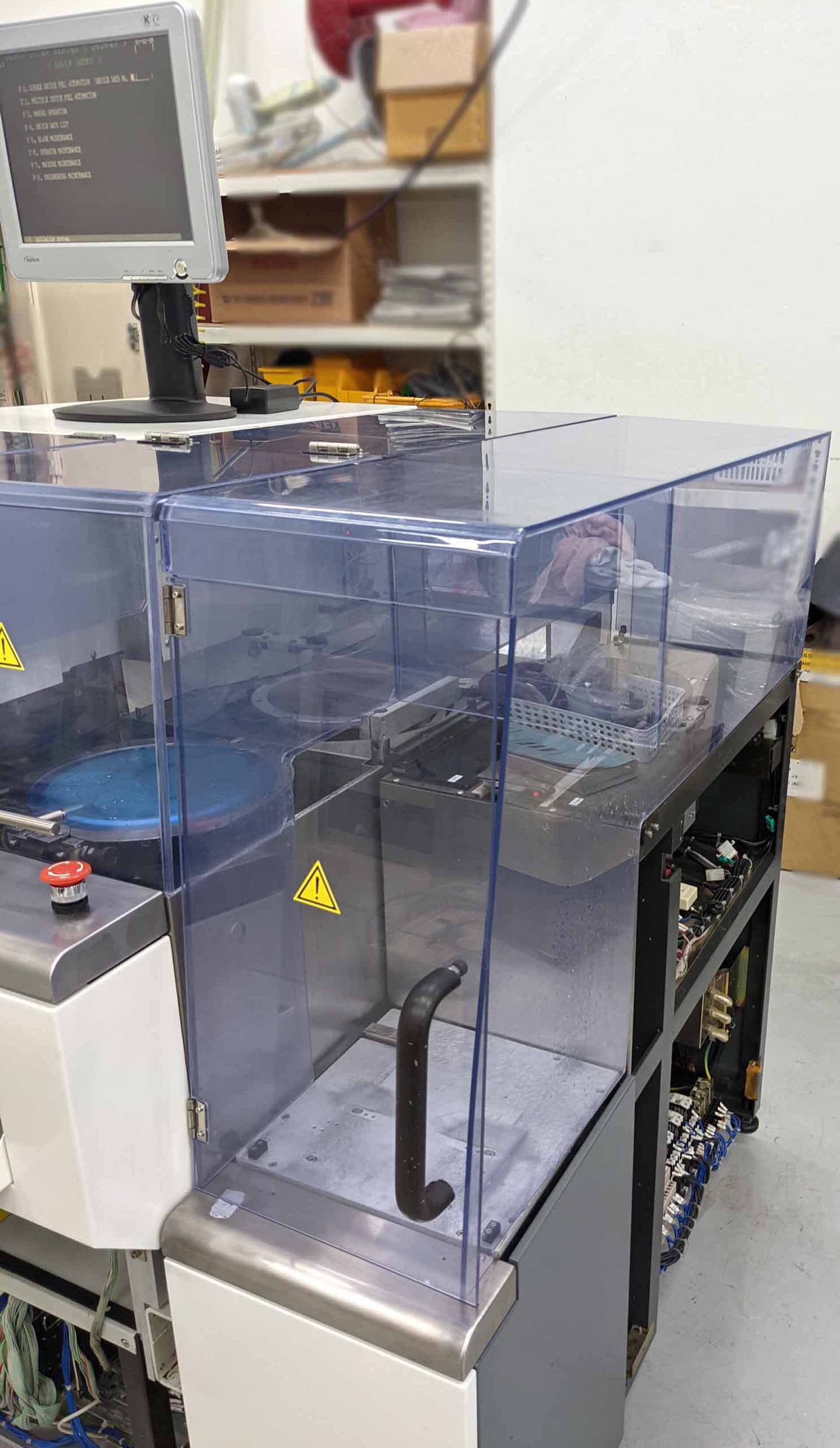

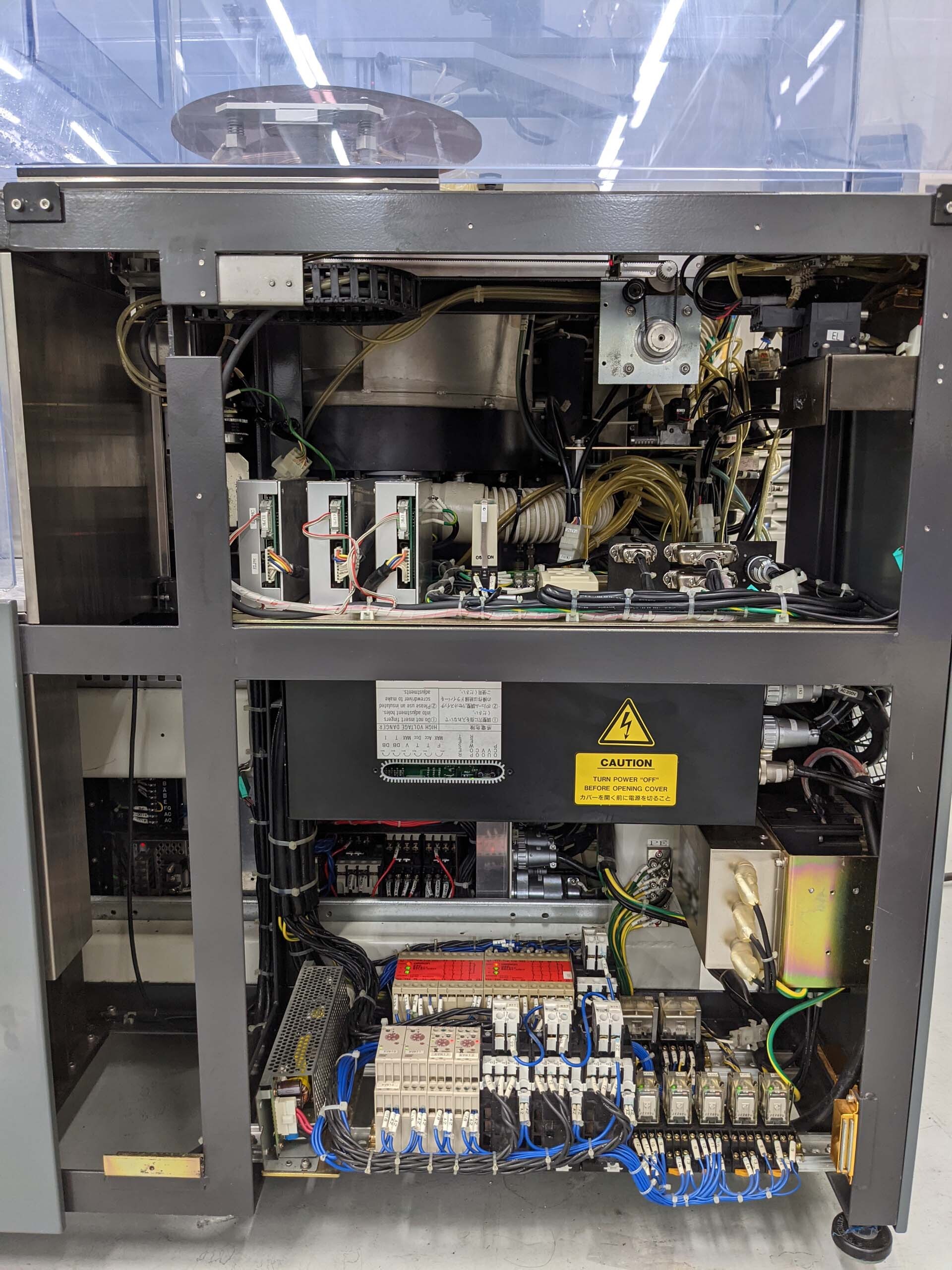

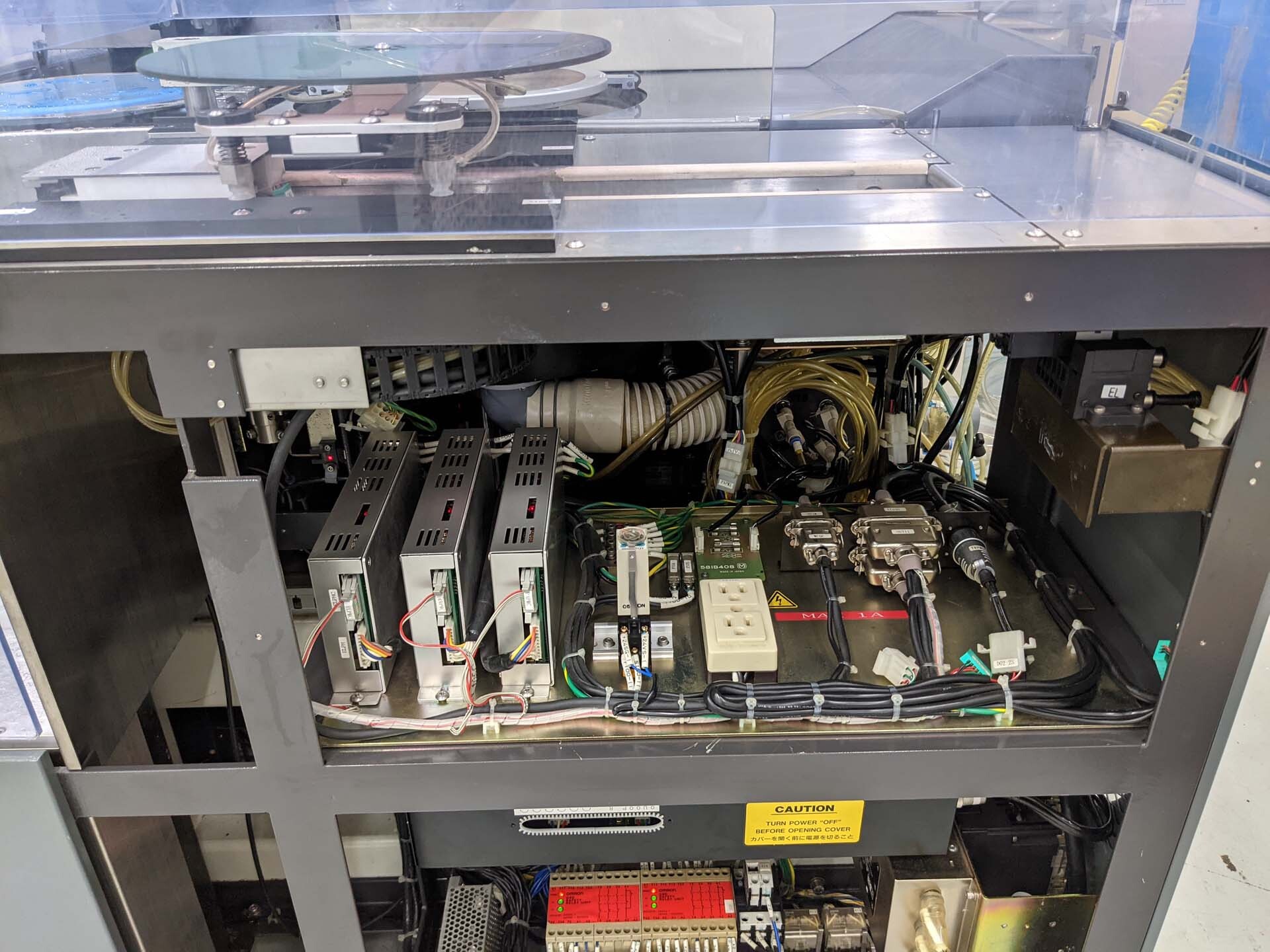

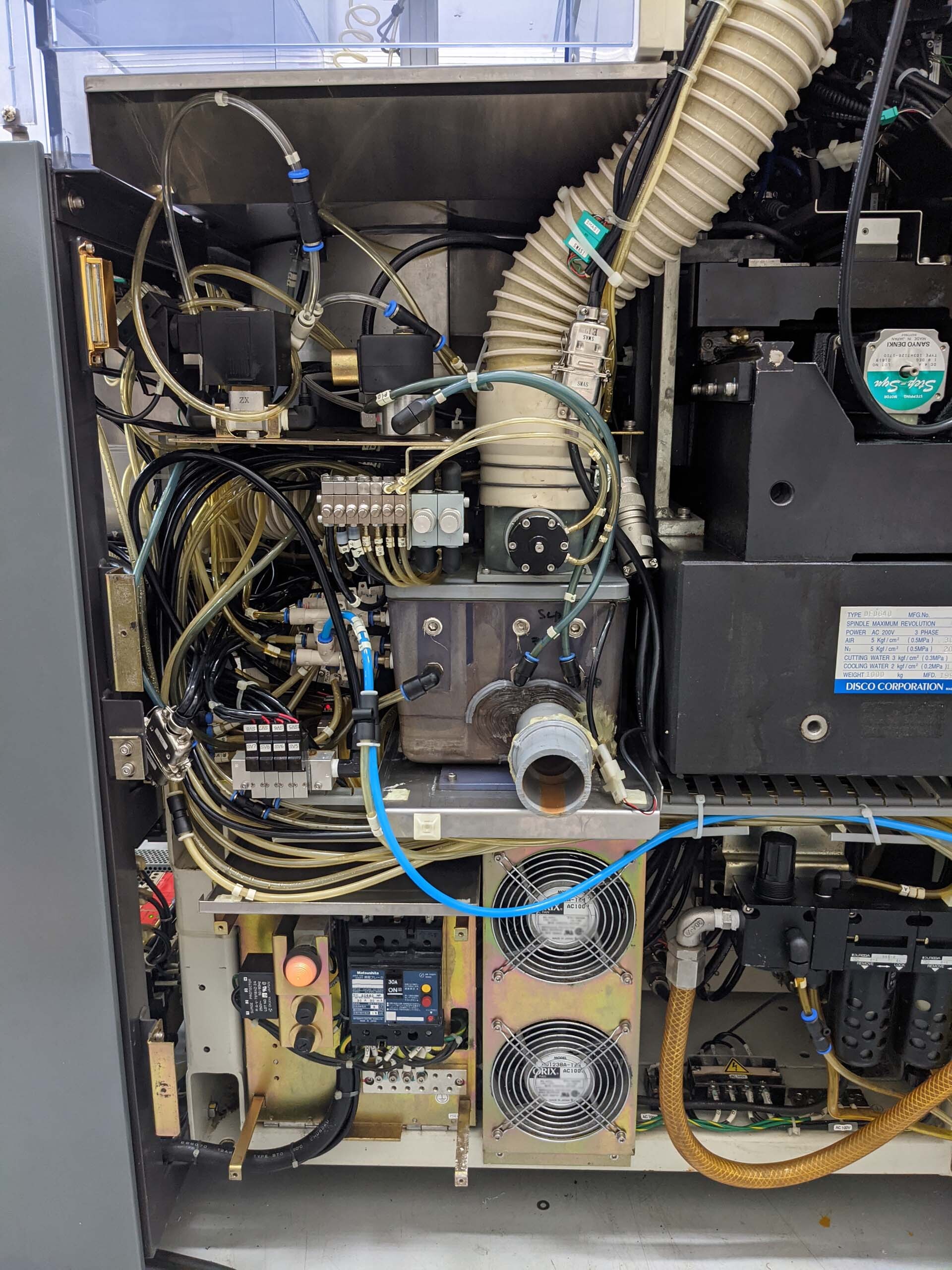

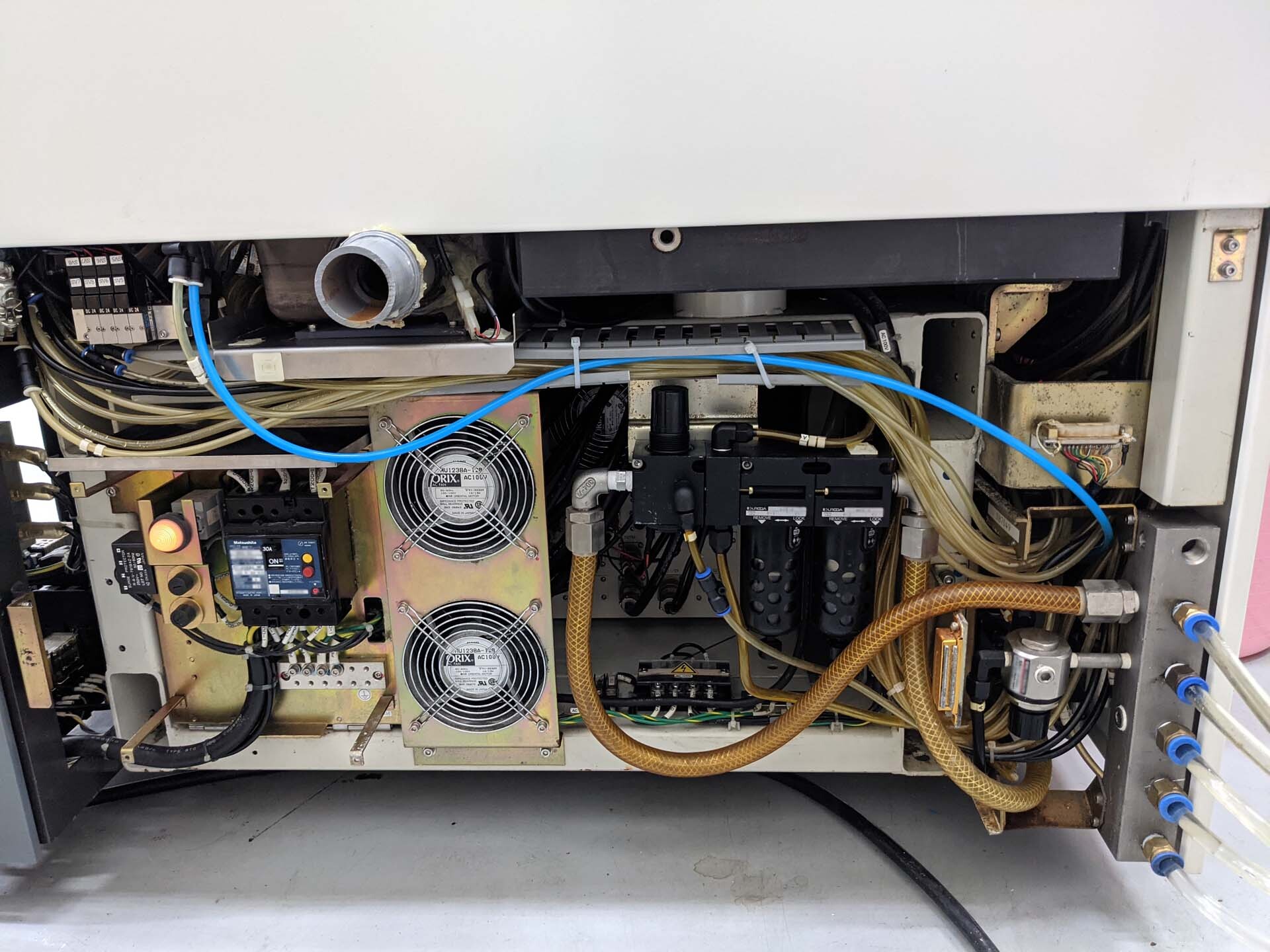

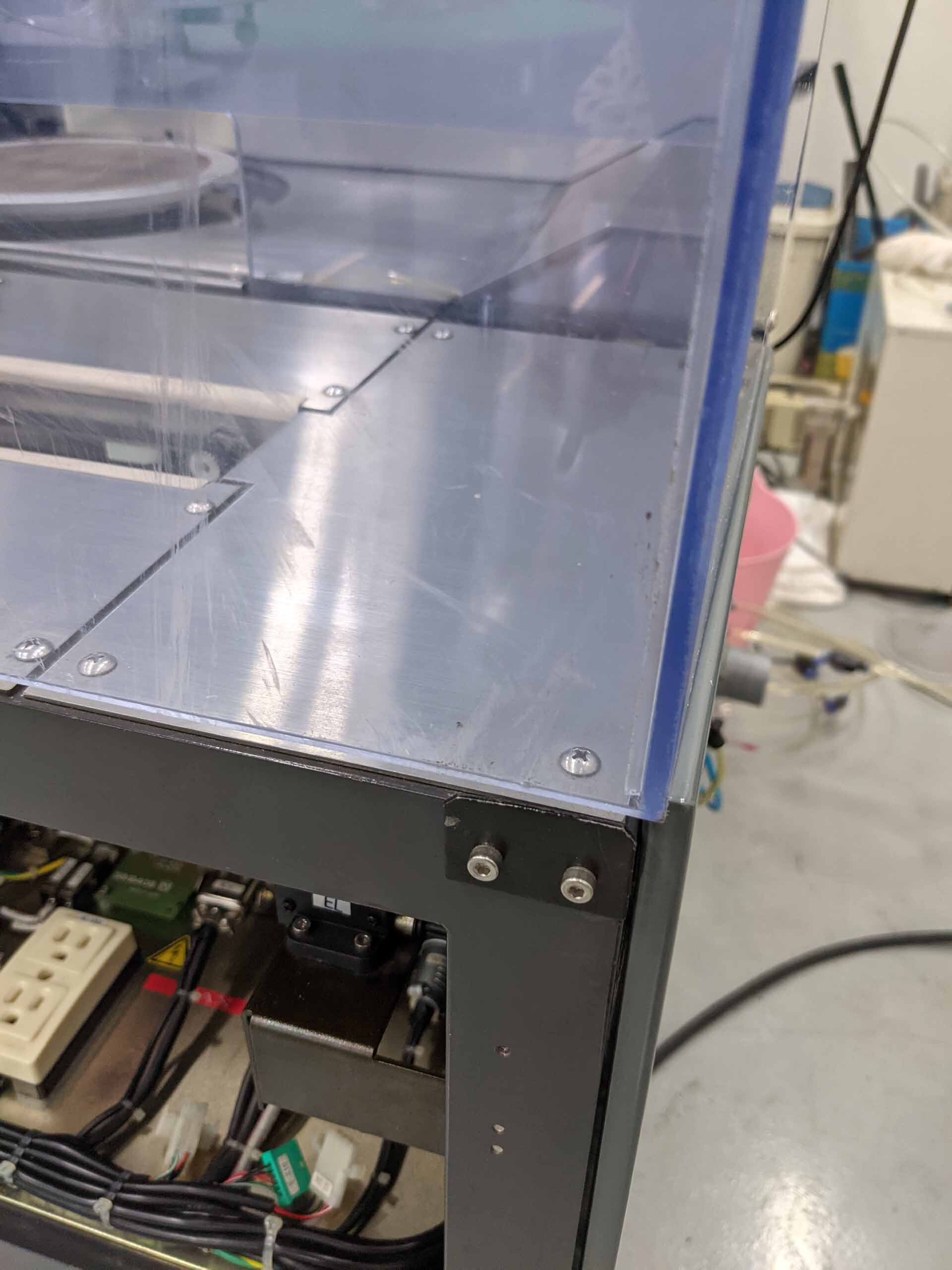

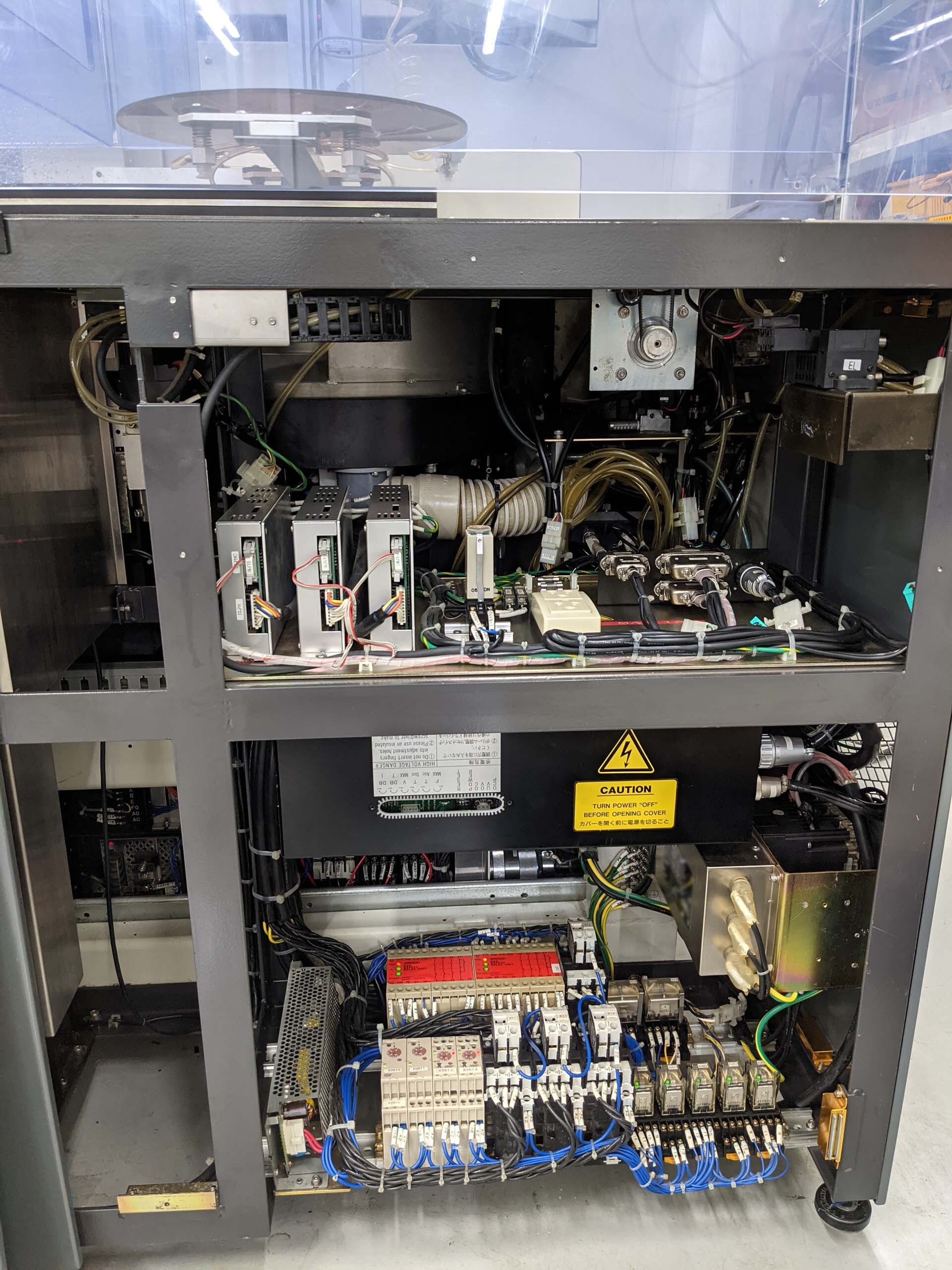

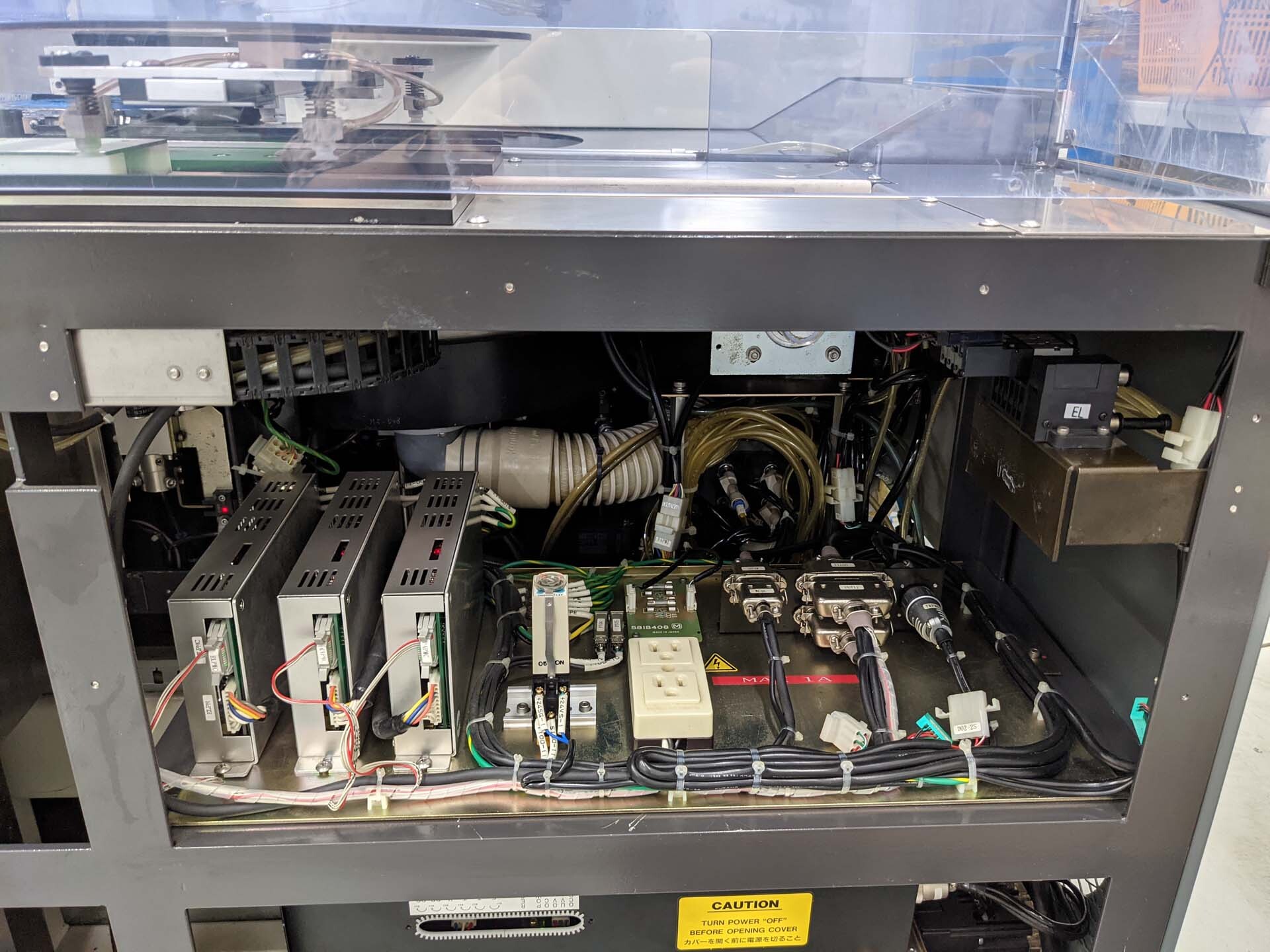

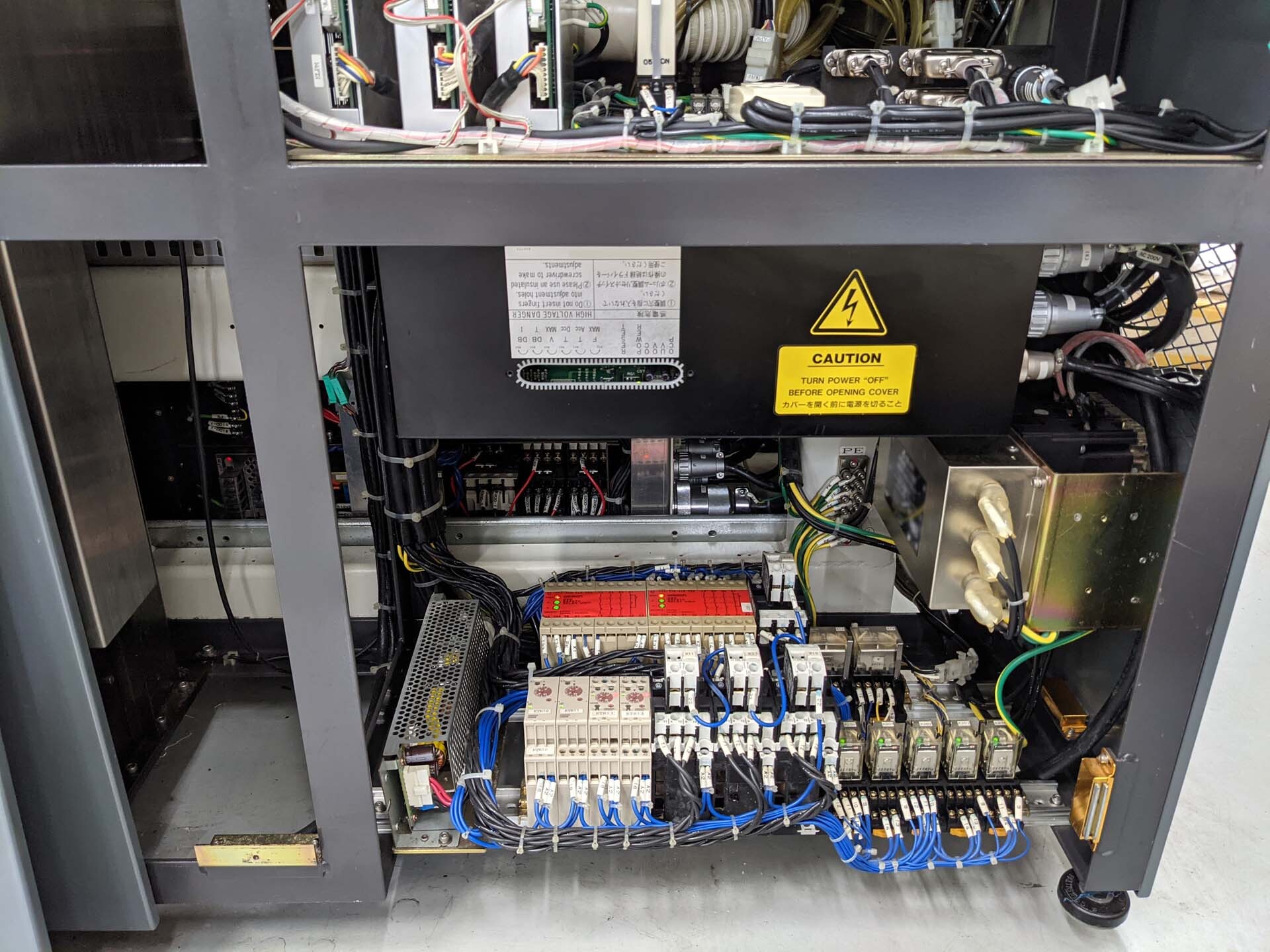

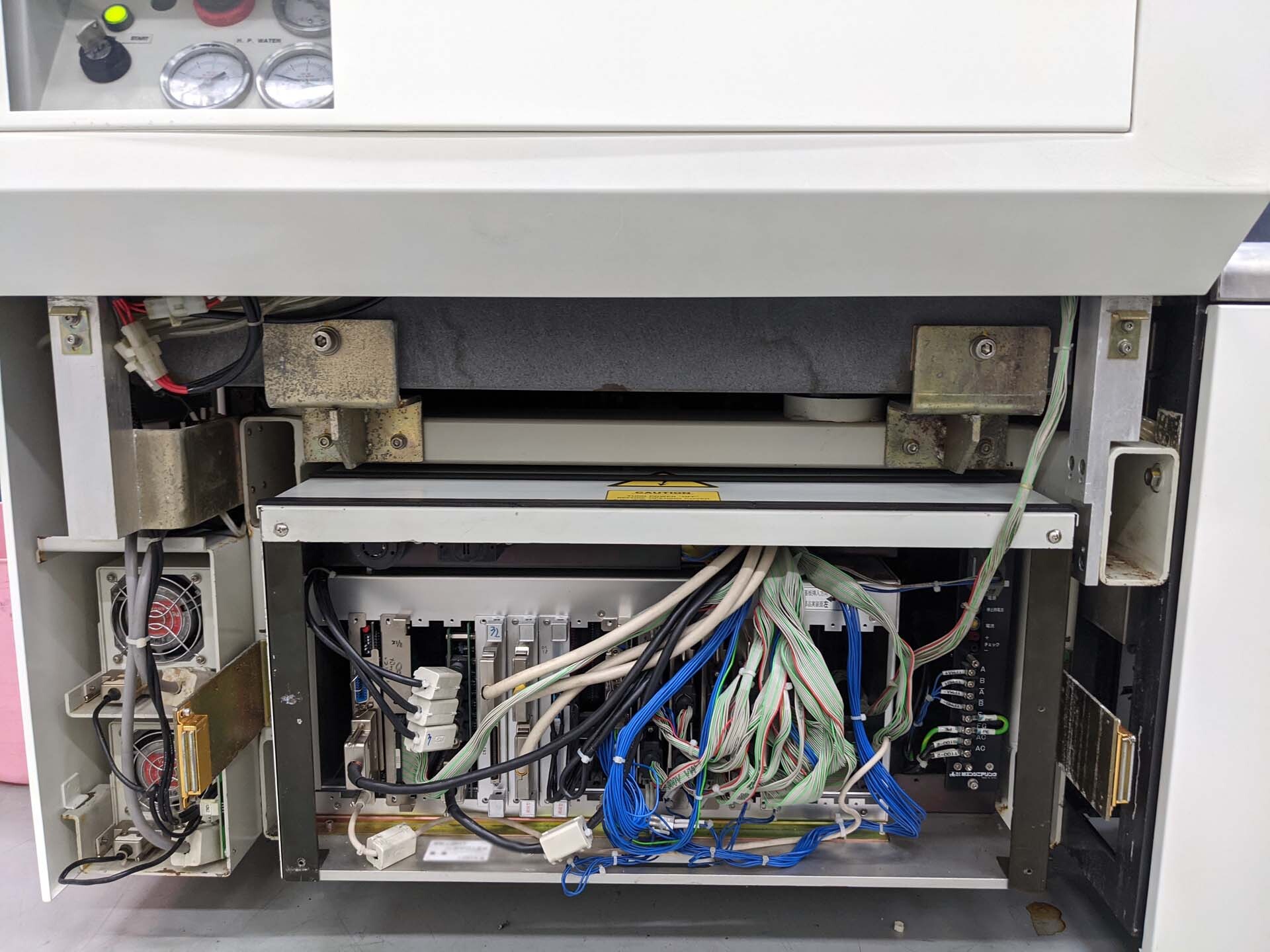

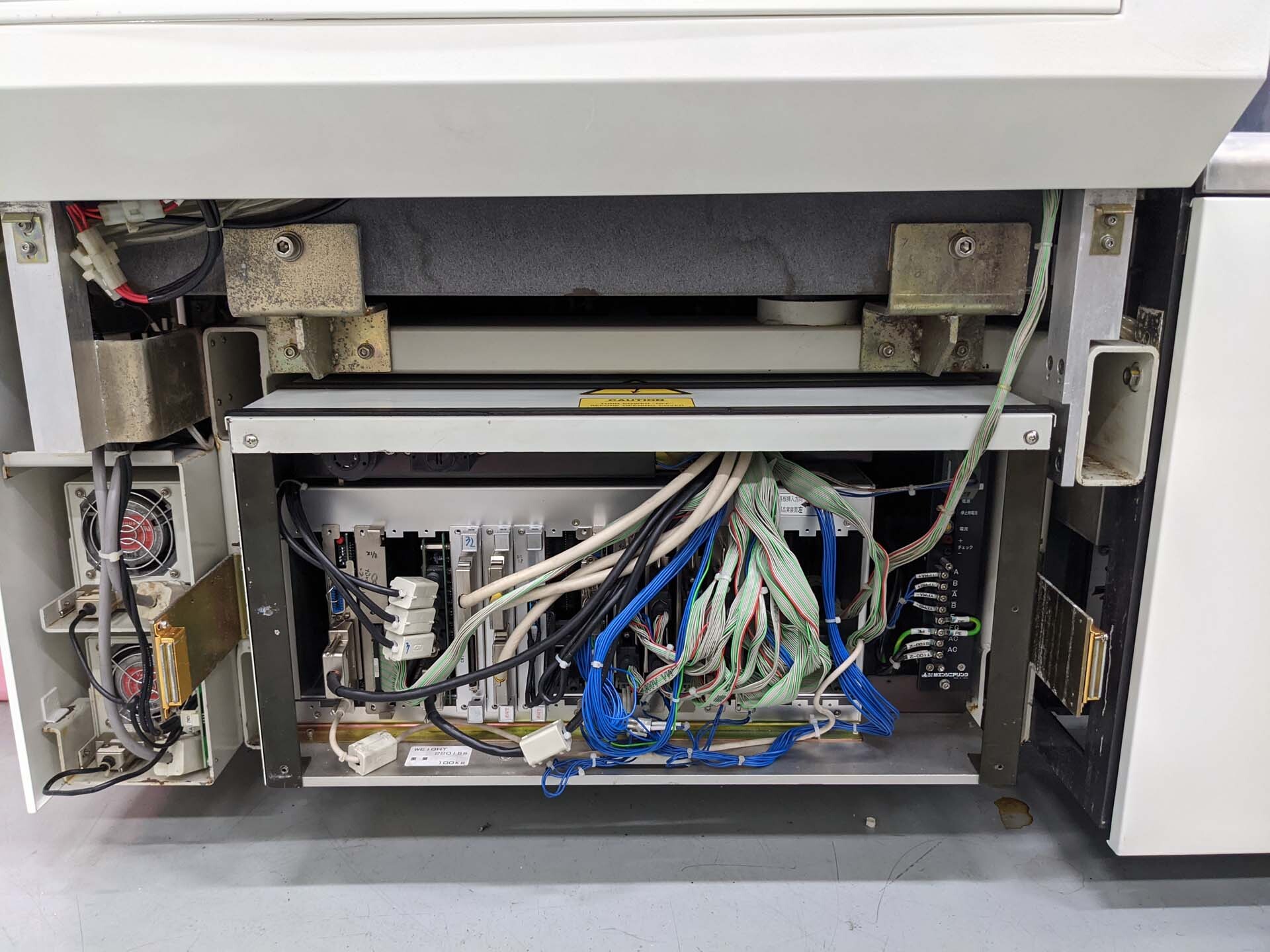

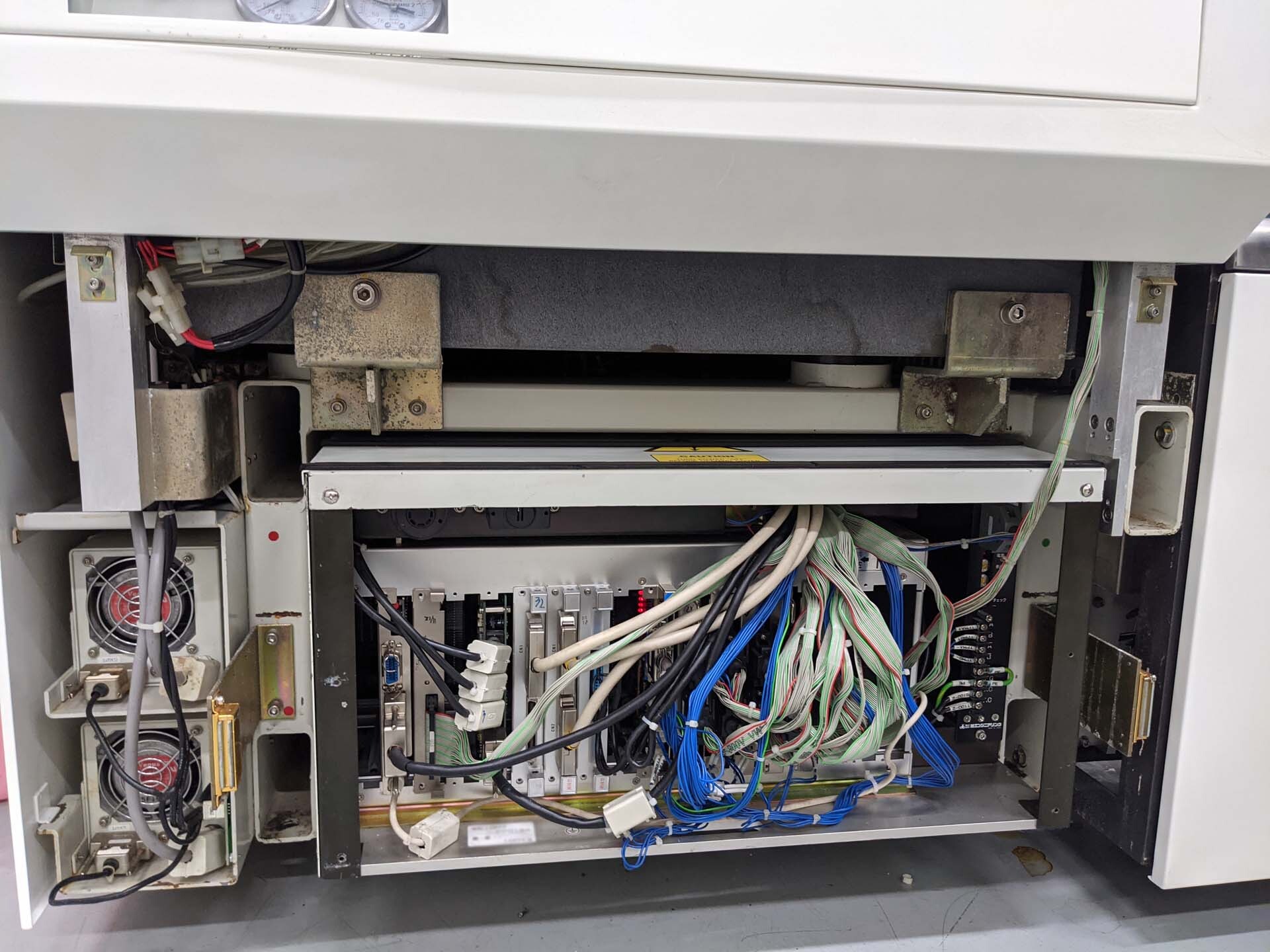

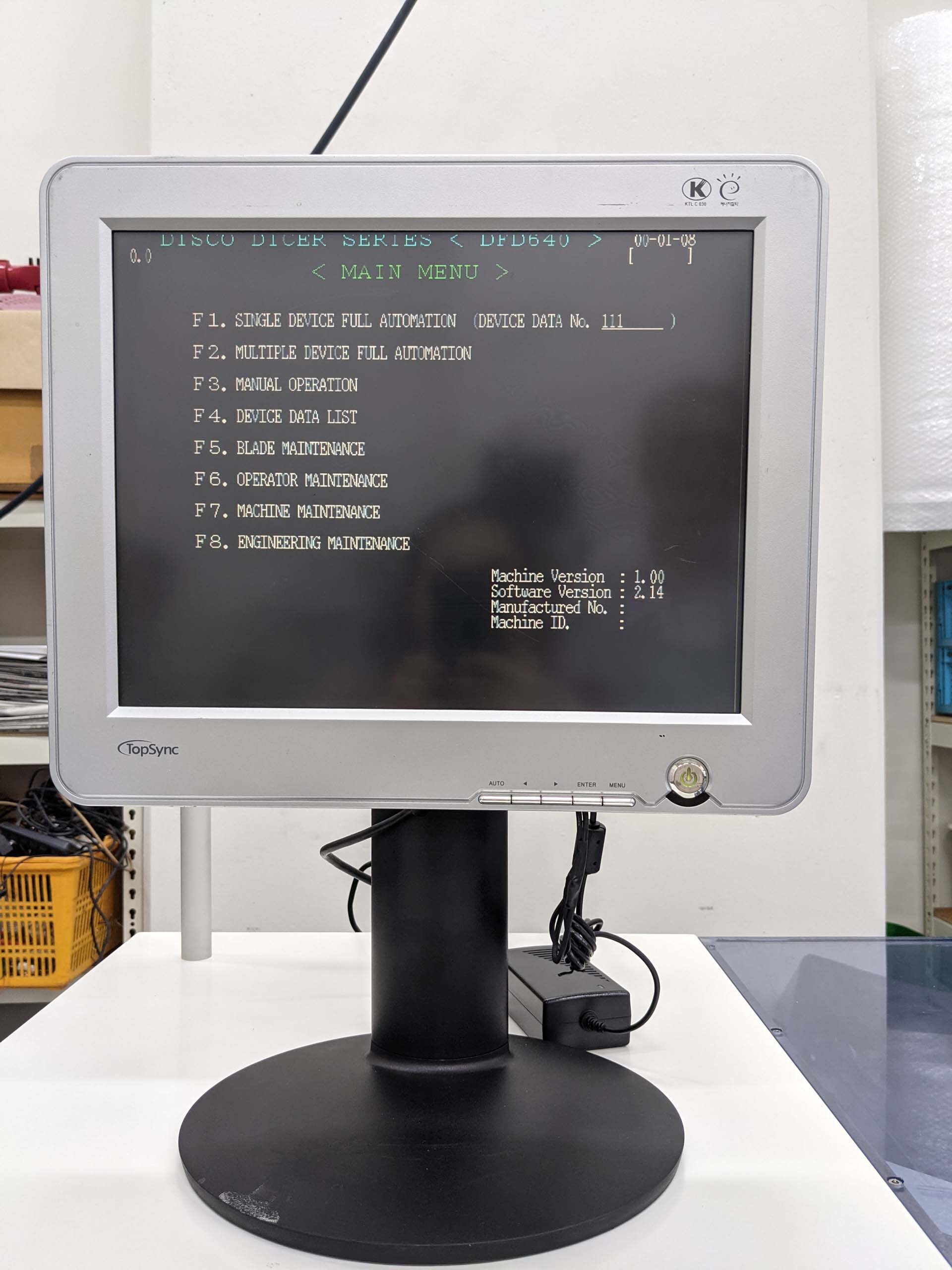

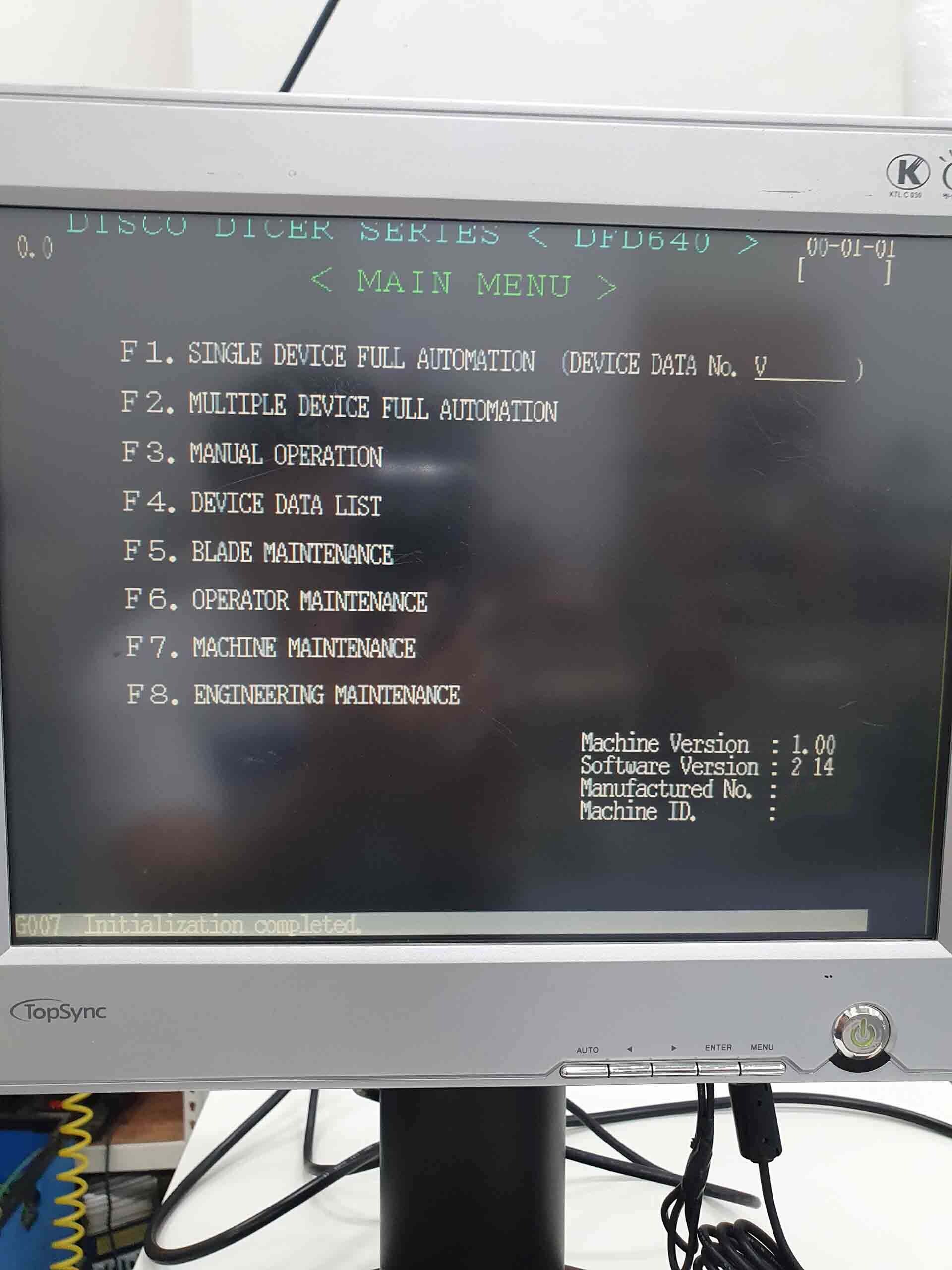

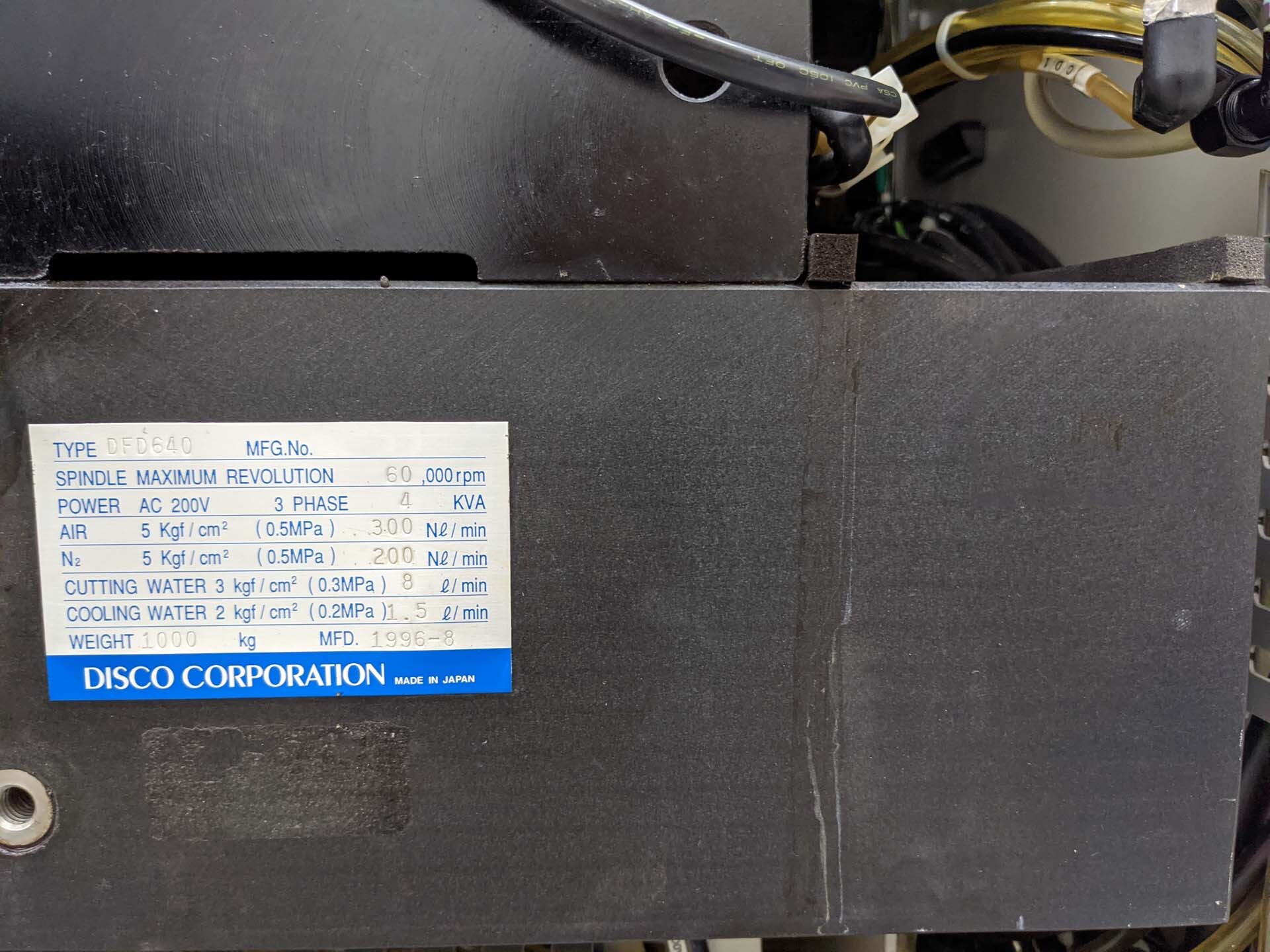

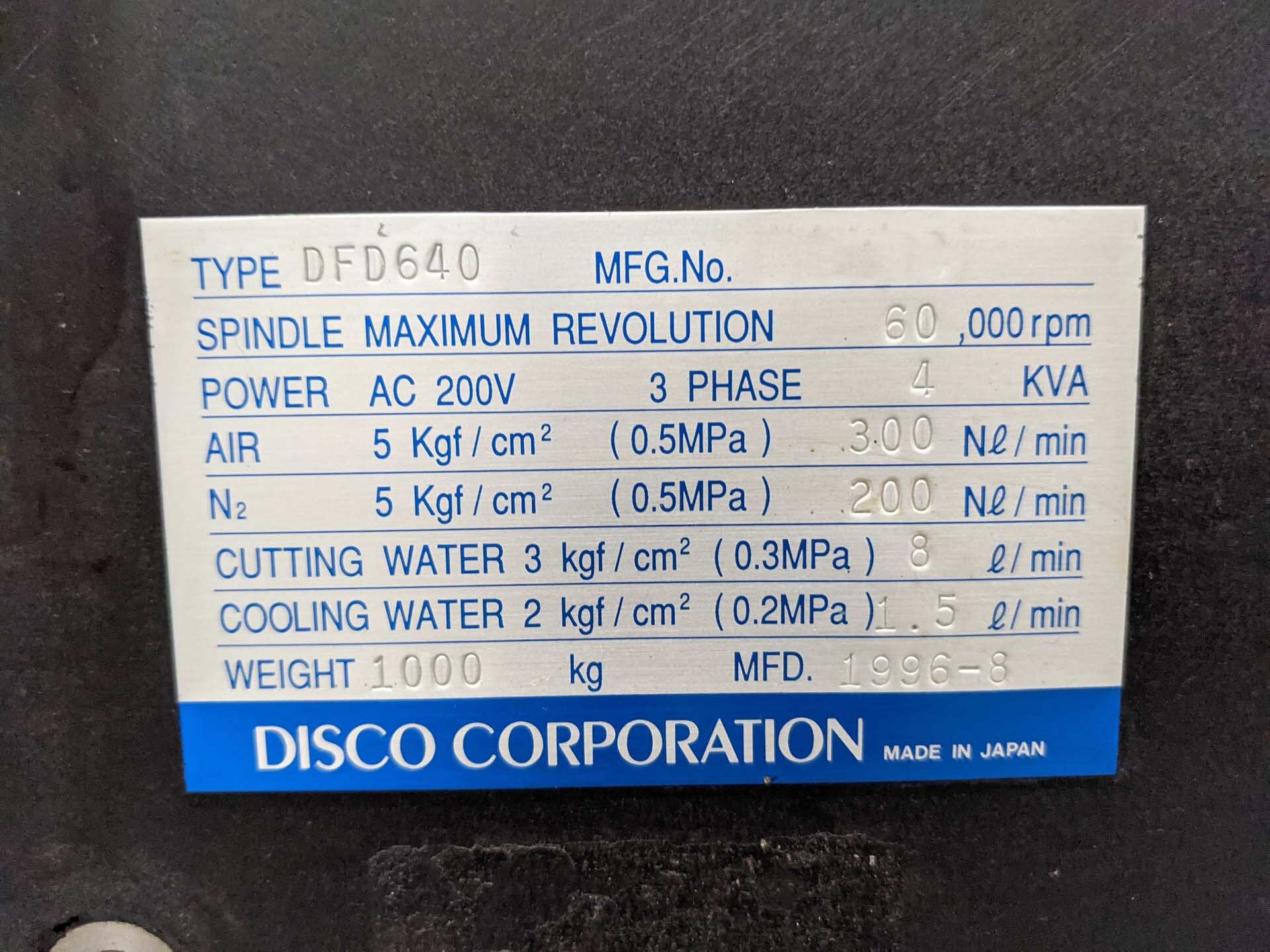

Used DISCO DFD 640 #9390766 for sale

URL successfully copied!

Tap to zoom

ID: 9390766

Vintage: 1996

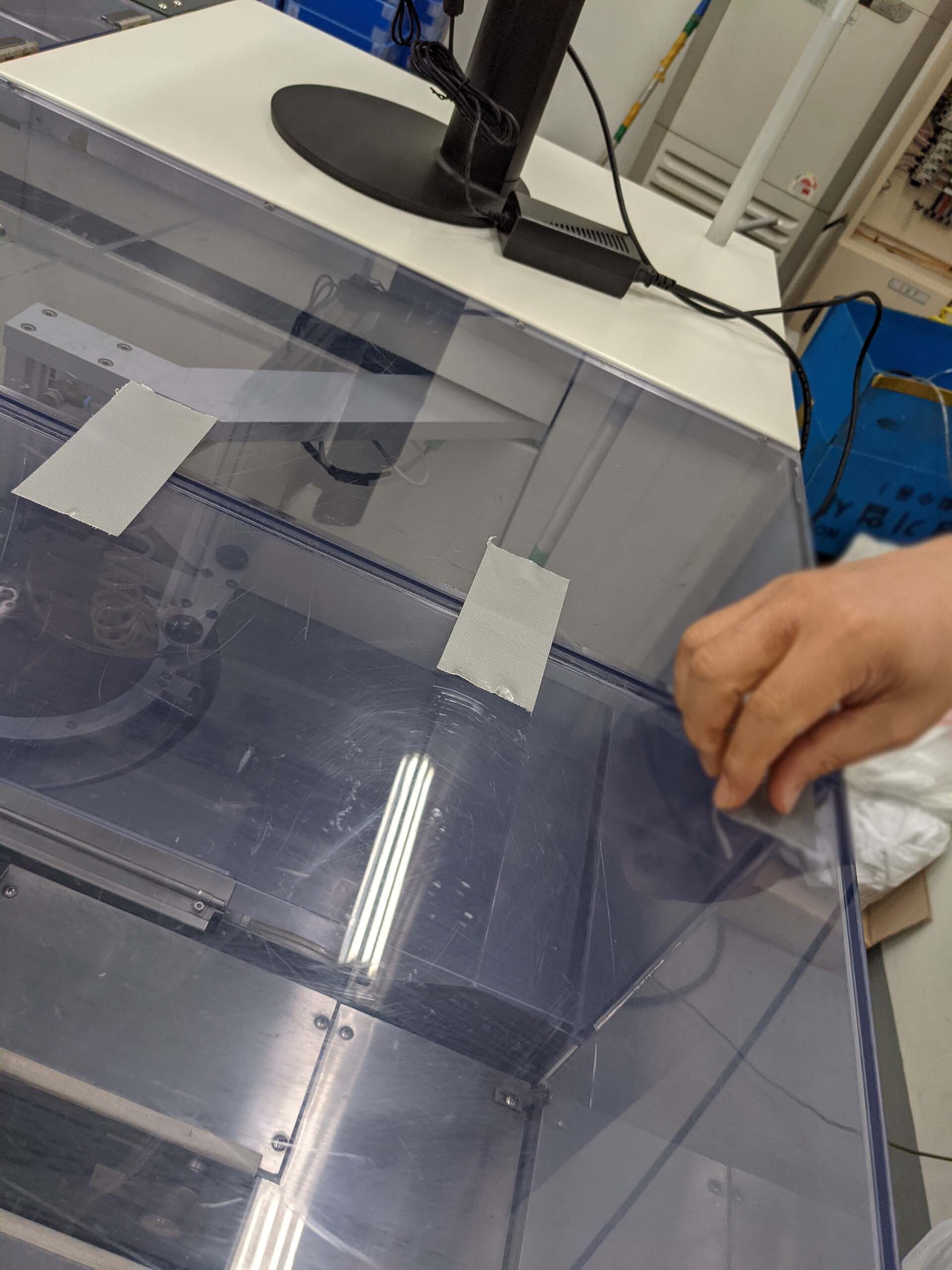

Dicing saw

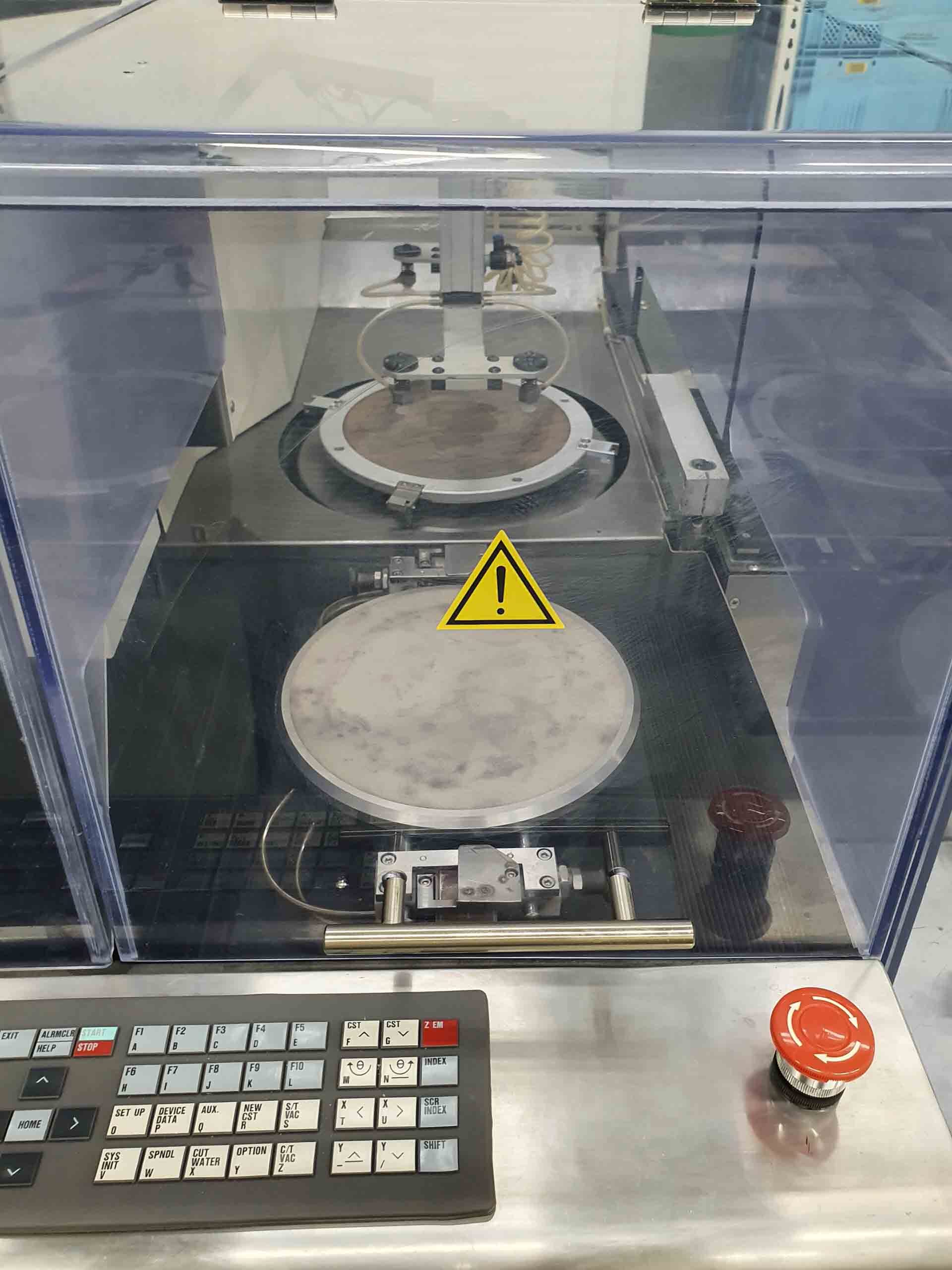

Work piece size: φ203.2 mm

X-Axis:

Useable stroke: 210 mm

Cut speed: 0.1-450 mm/s

Y-Axis:

Useable stroke: 210 mm

Indexing step: 0.0001 mm

Index accuracy single pitch: 0.002 mm

Index accuracy cumulative pitch: 0.003/210 mm

Scale resolution: 0.0002mm

Z-Axis:

Maximum cutting stroke: 7.2 mm (when installing φ2: flange)

Minimum step: 0.00025 mm

Repeating accuracy: 0.001 mm

Maximum blade size: 55.56 mm

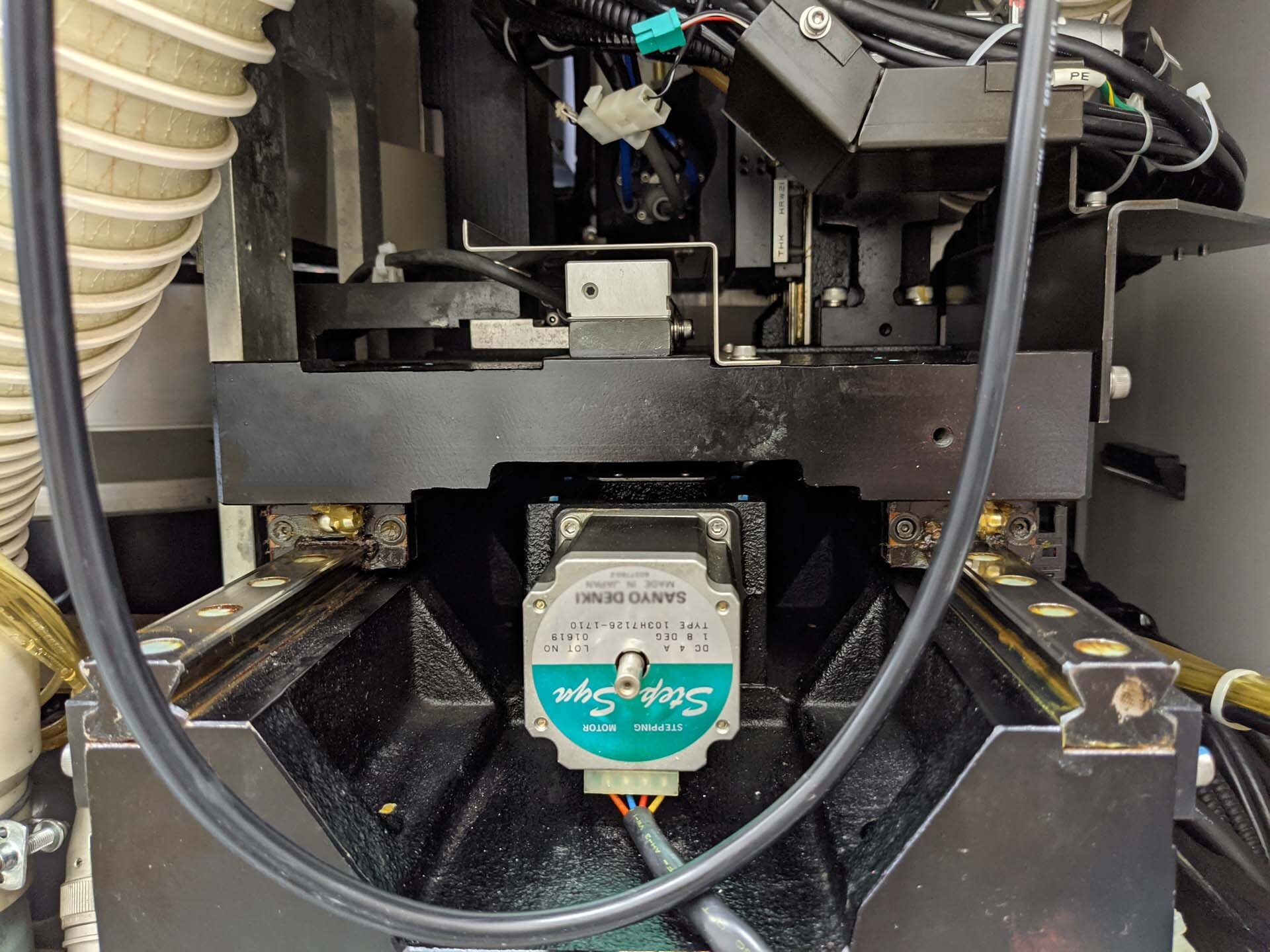

θ-Axis:

Maximum rotating angle: 380°

Spindle output: 1 kW

Maximum revolution: 60,000 min-1 rpm

Applicable tape frame: 2-6, 2-6-1, 2-8-1

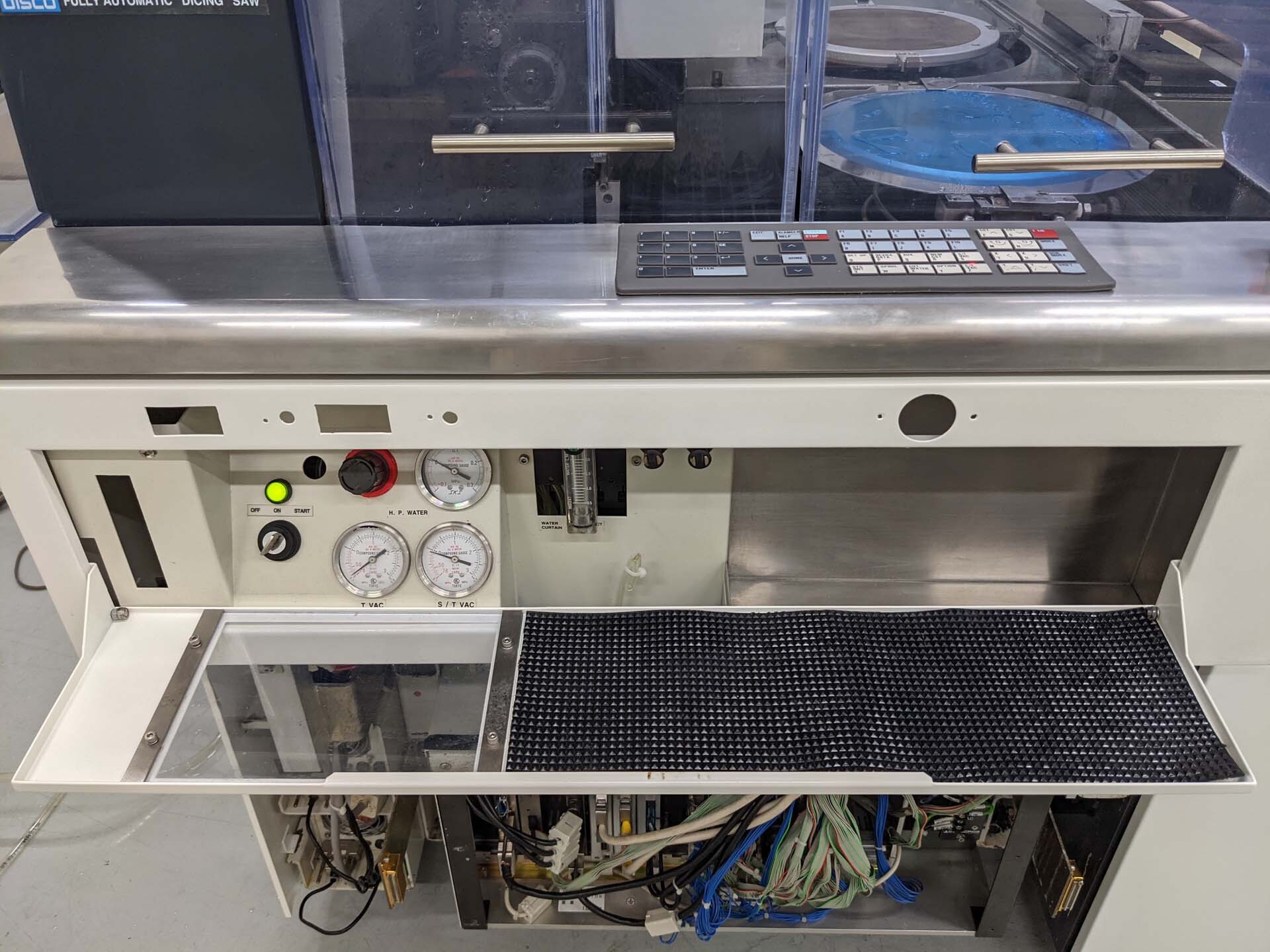

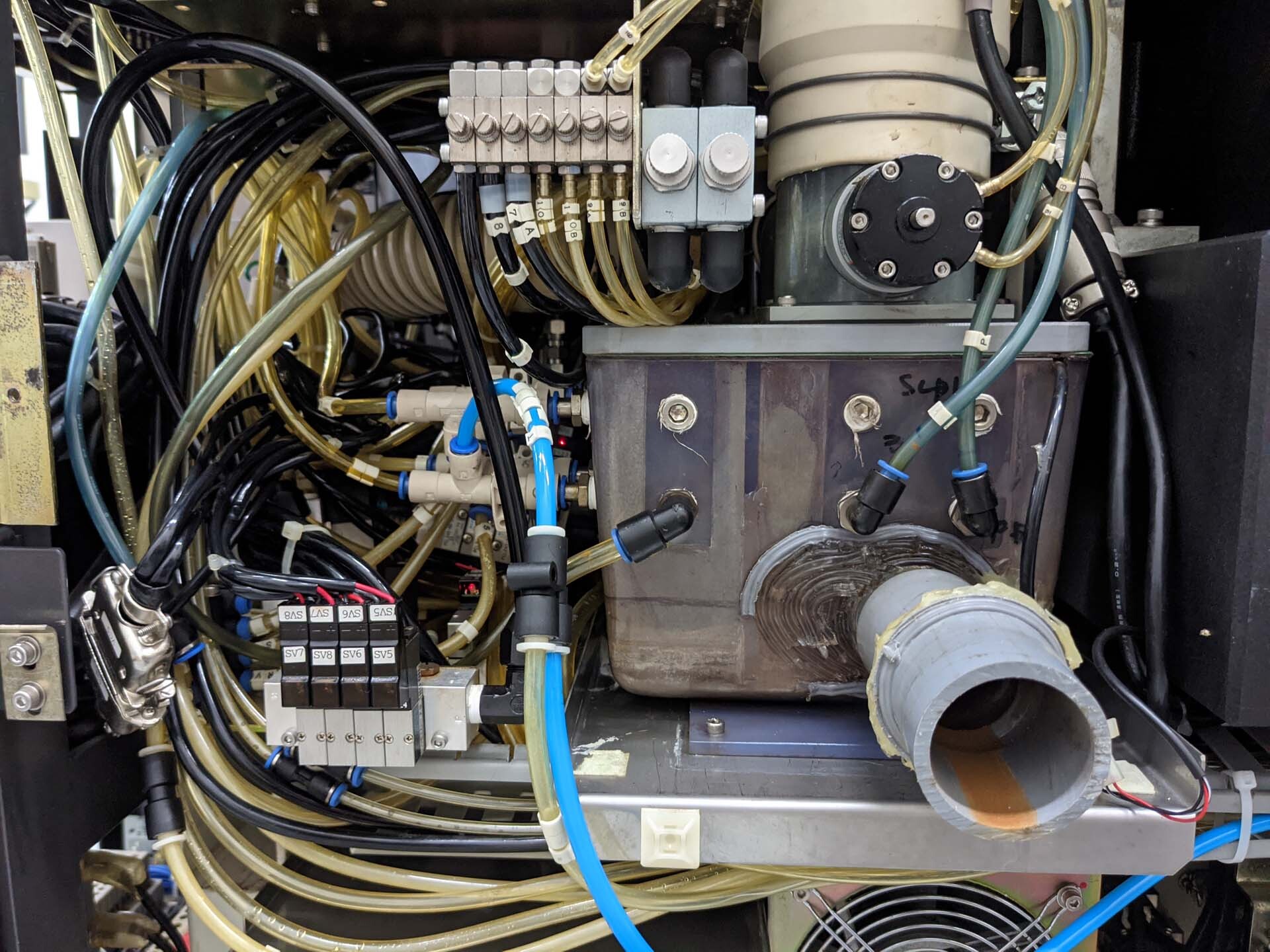

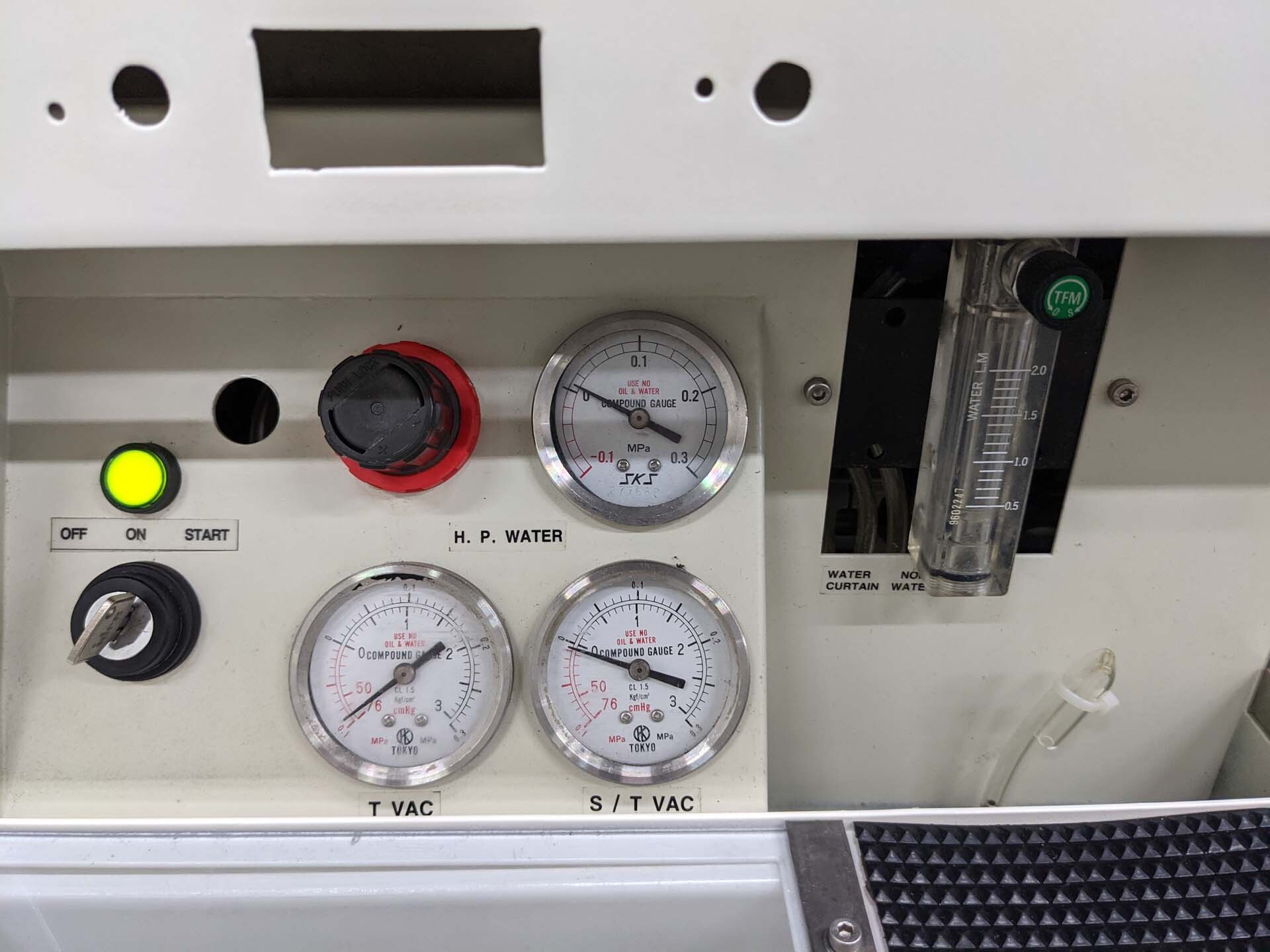

Utilities:

Power consumption:

When processing: 1.7 kW

During warm-up: 1.3 kW

Maximum power: 3.2 kVA

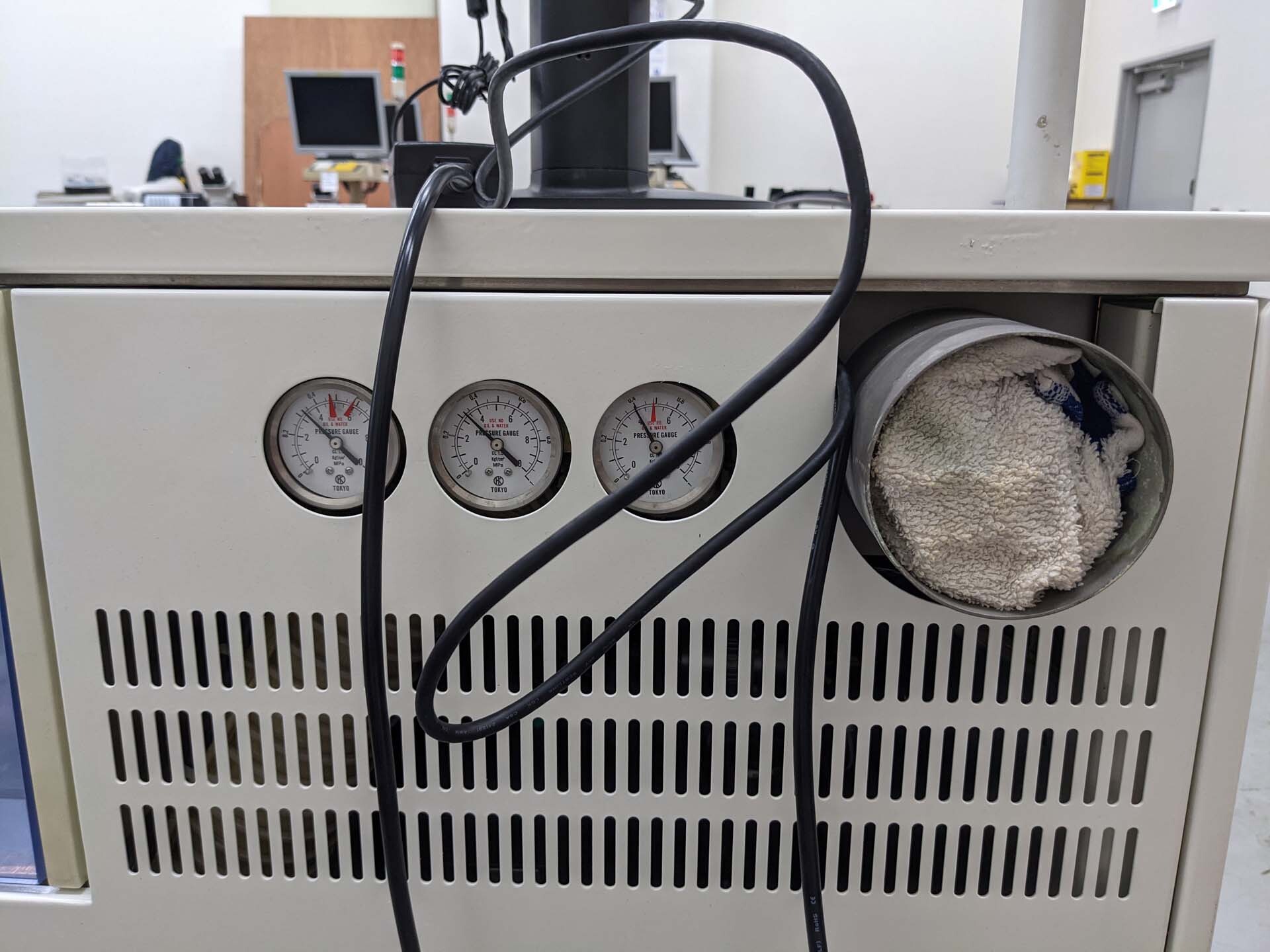

Air pressure: 0.5 [5.0] - 0.6 [6.0 ] MPa・G [kgf /cm²・G]

Air flow rate: 300 N l/min

Water pressure:

Cutting water: 0.29 [3.0] MPa [kgf /cm²]

Cooling water: 0.2 [2.0] MPa [kgf /cm²]

Water flow rate:

Cutting water: 1.0-6.0 L/min

Cooling water: 1.5 or more L/min

Connection port: Duct hose

Nominal size: 100 mm

Duct required suction: 5 m³/min

Power supply: 200 V AC, 50-60 Hz, 3 Phase

1996 vintage.

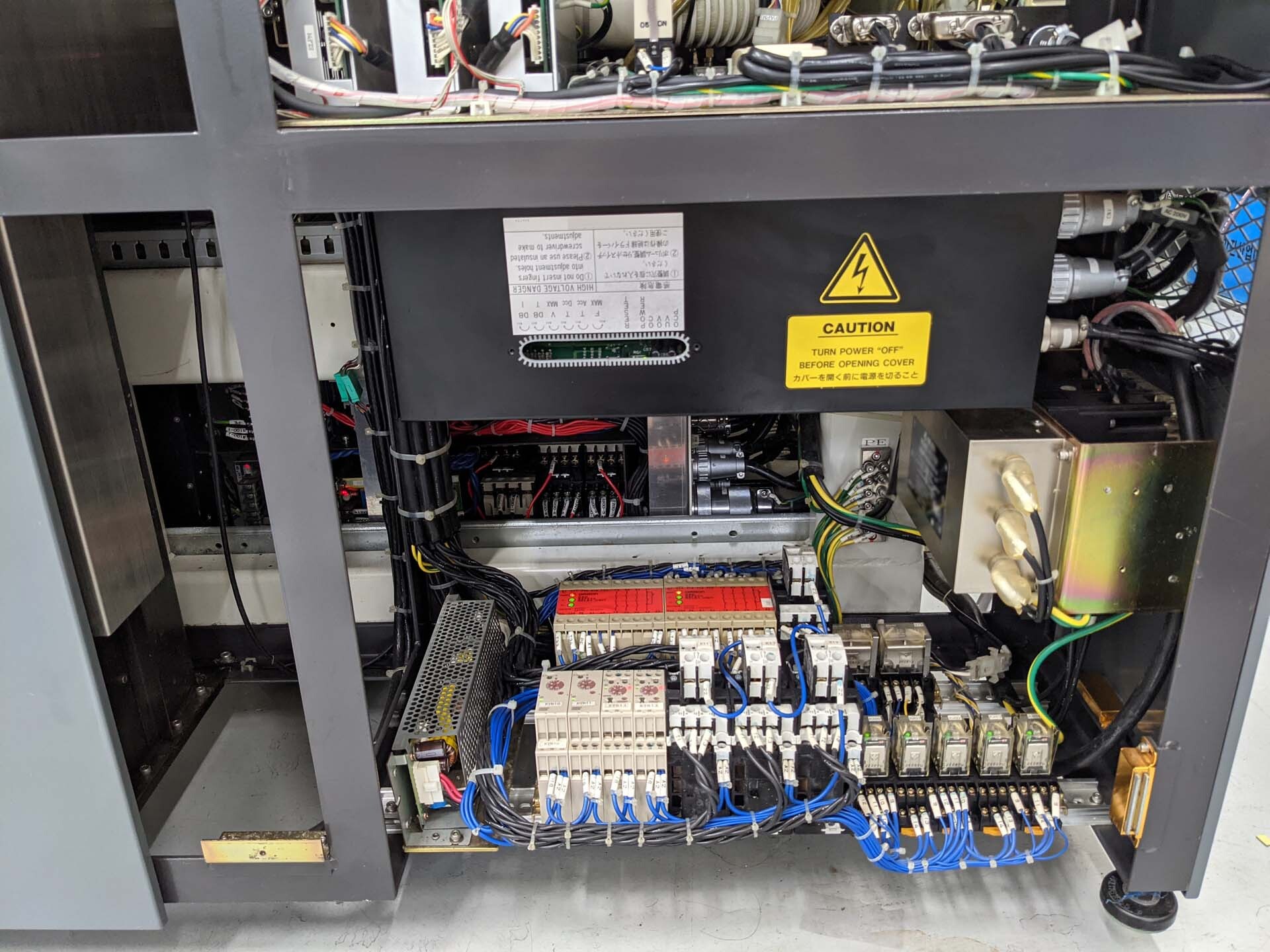

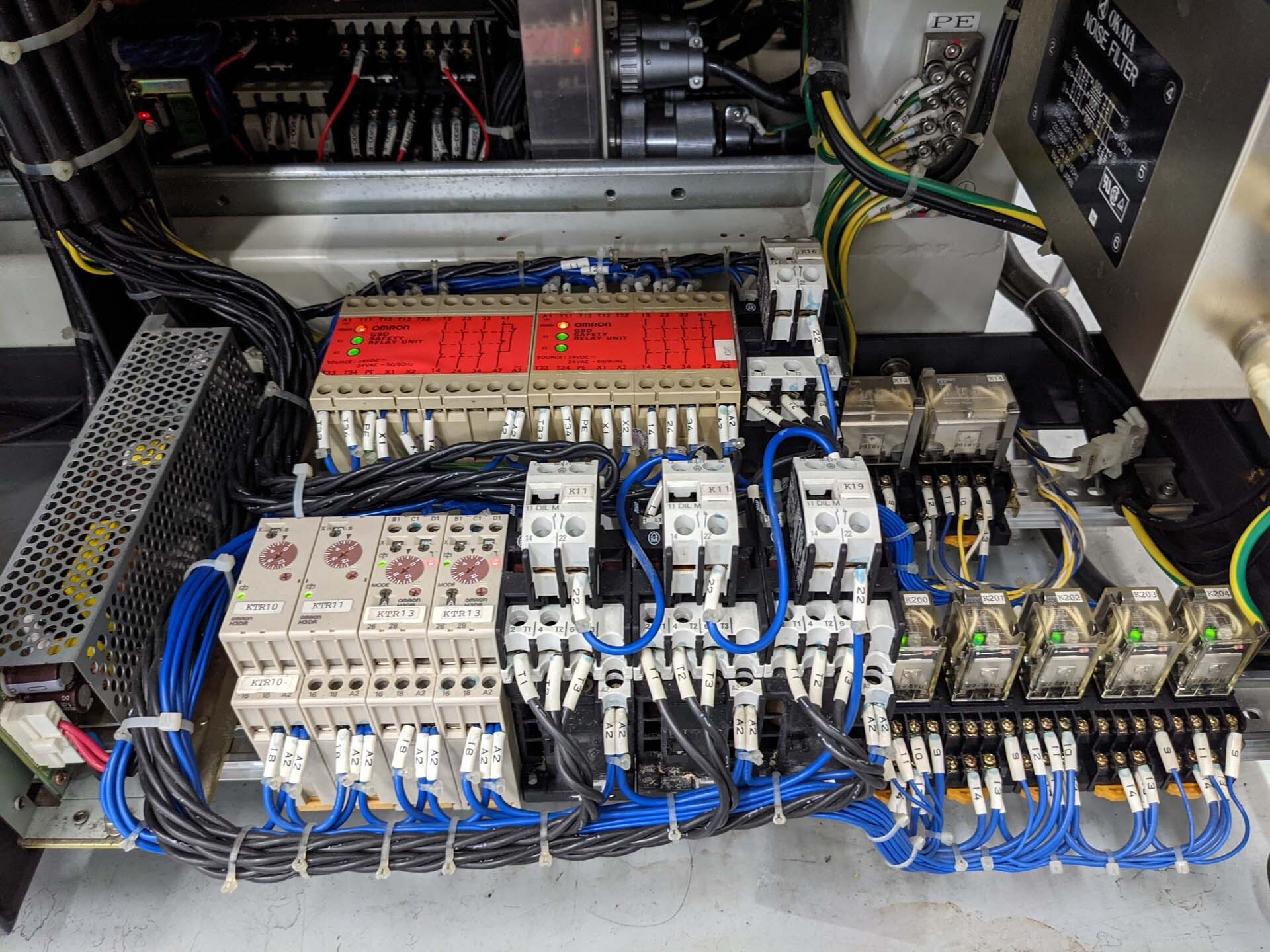

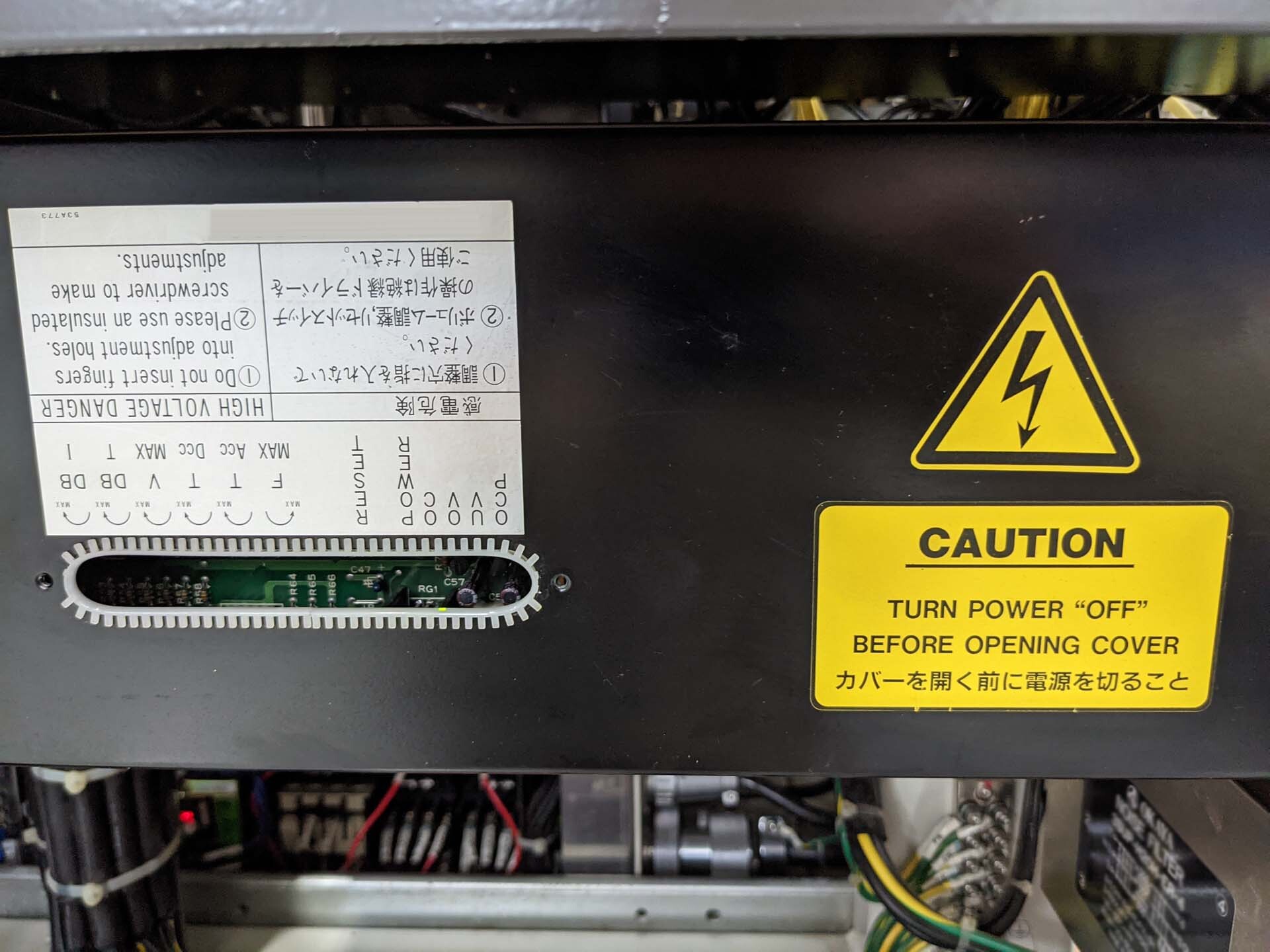

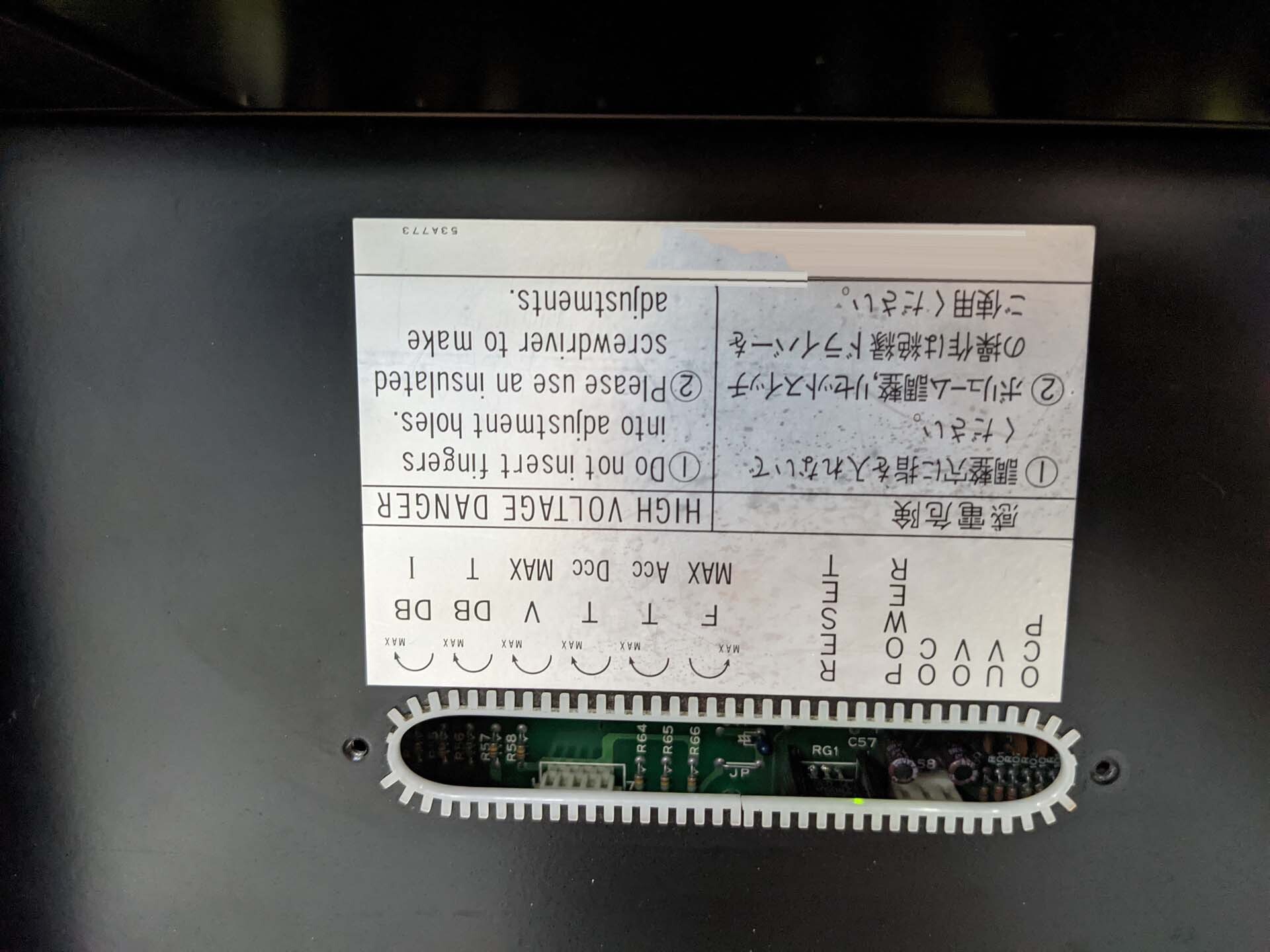

DISCO DFD 640 is a versatile scribing / dicing equipment for processing a wide variety of materials, featuring high precision, flexibility, and a robust design. The system is capable of quickly and accurately producing dices with up to 0.1 mm accuracy, making it an ideal choice for highly accurate production, no matter the complexity. The unit also offers a variety of cutting/scribing options, including flat cut and diamond cut, which can be applied to various materials with thicknesses ranging from 125 microns to 8.5 mm. A DI110 electrode, which is operated with electrodes at a voltage of 0 to 110V, is equipped, providing the option of fine adjustment of the cutting speed for optimum results. DISCO DFD640 also includes a mobile workstation consisting of a stand, a controller, and a touch panel, allowing simple and convenient operation of the machine. The control panel contains a 10-inch touchscreen, sixteen function keys and a control lever knob, allowing operators to control the processing conditions with ease. A corrosion-resistant stainless steel body ensures longevity and durability, while the design also reduces vibration and dust formation while scribing, allowing maximum productivity with minimum noise and cleanliness levels. The tool is pre-programmed with patterns, and a made-to-ordersystem can also be constructed to meet the specific needs of an industrial application. With the addition of an automated loader, the asset can also complete a wide range of processes and enable mass-production of dices with greater efficiency than manual labor. For added safety and convenience, the model is equipped with multiple safety features, such as an oil mist sealant, a metal mesh chain guarding, and a scriber blade protector, and is CE-certified. In summary, DFD 640 is a reliable and accurate scribing / dicing equipment that can be used to quickly produce dices with high precision, making it well suited for precision manufacturing and industrial applications.

There are no reviews yet