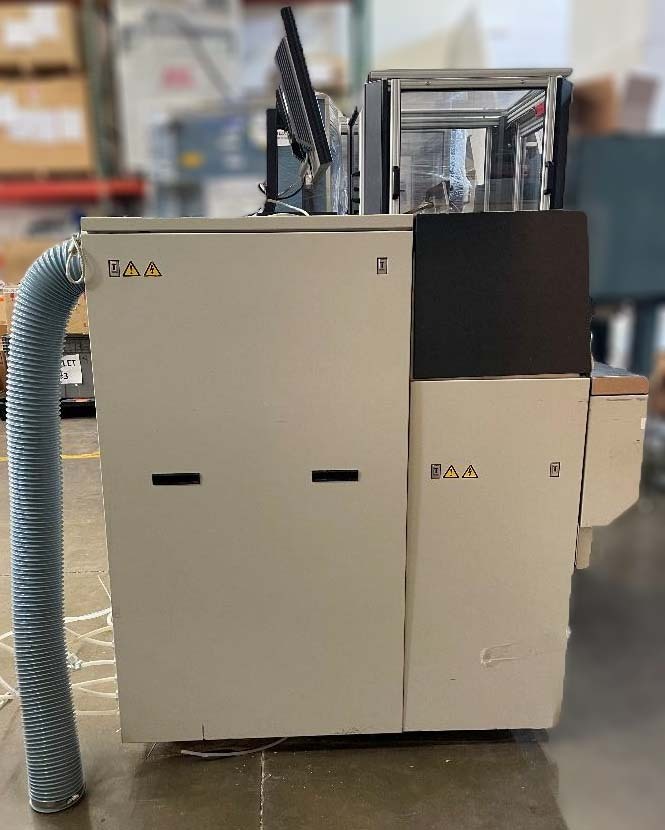

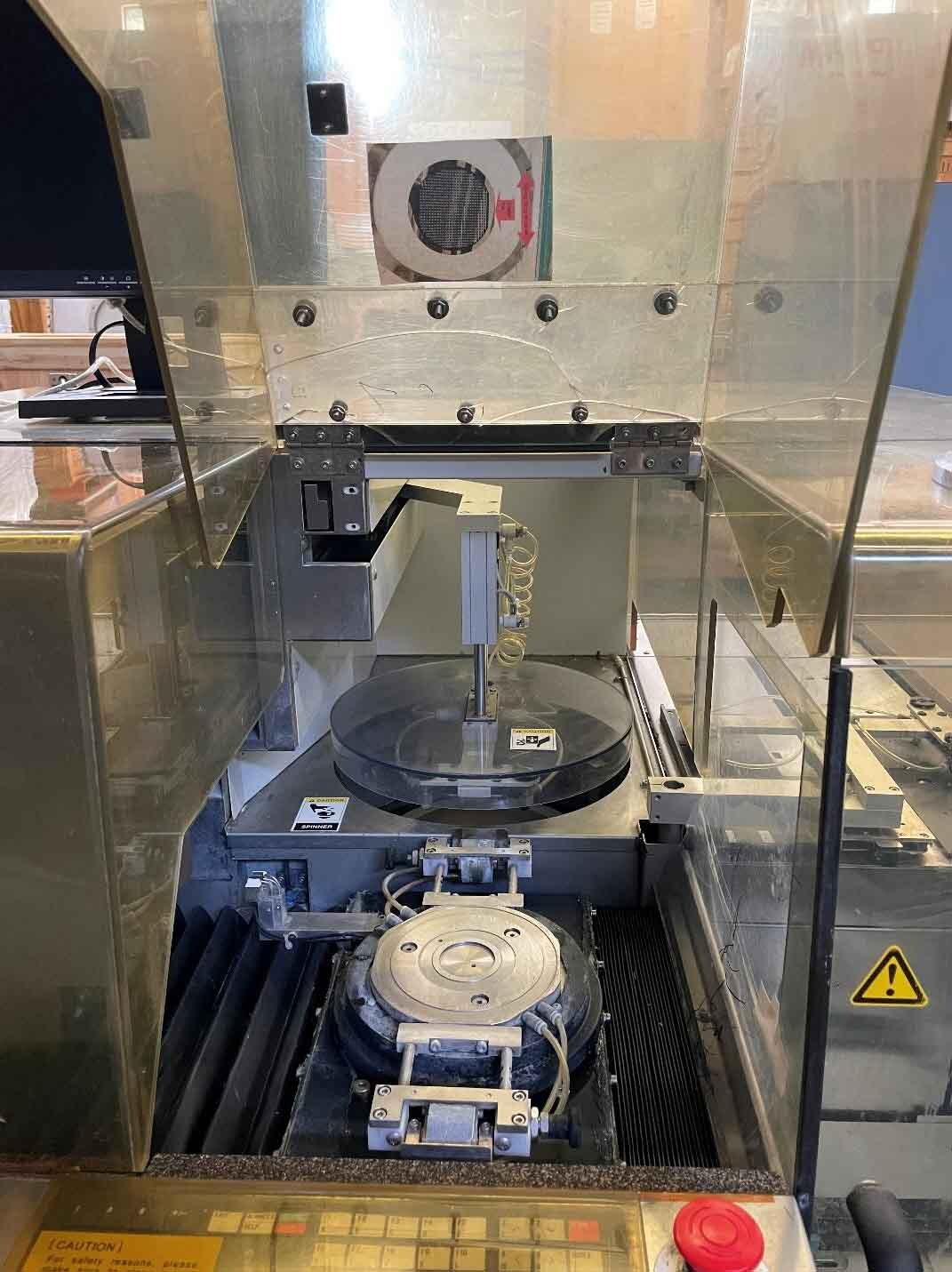

Used DISCO DFD 641 #293603501 for sale

URL successfully copied!

Tap to zoom

ID: 293603501

Vintage: 2008

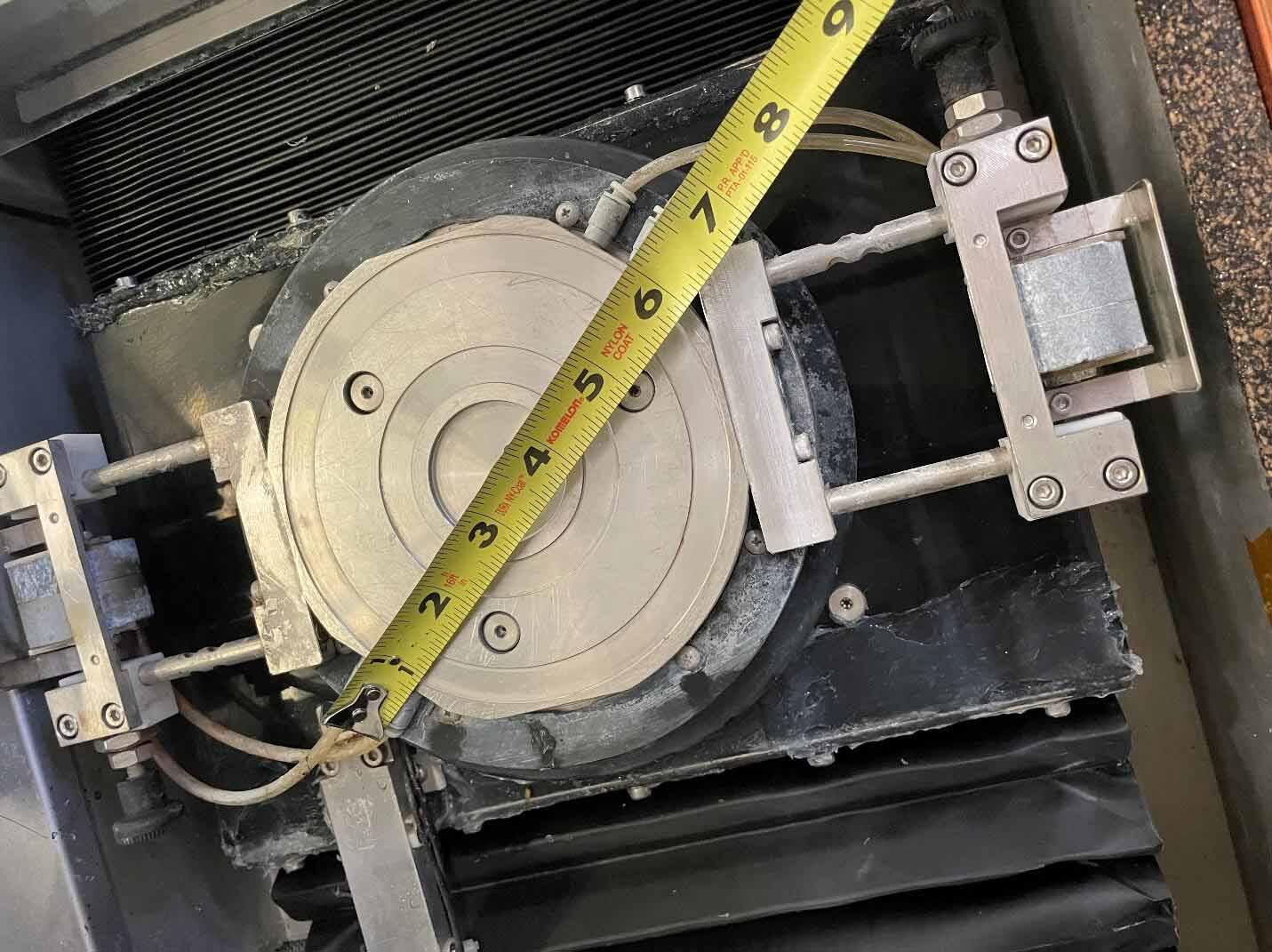

Dicing saw, 8"

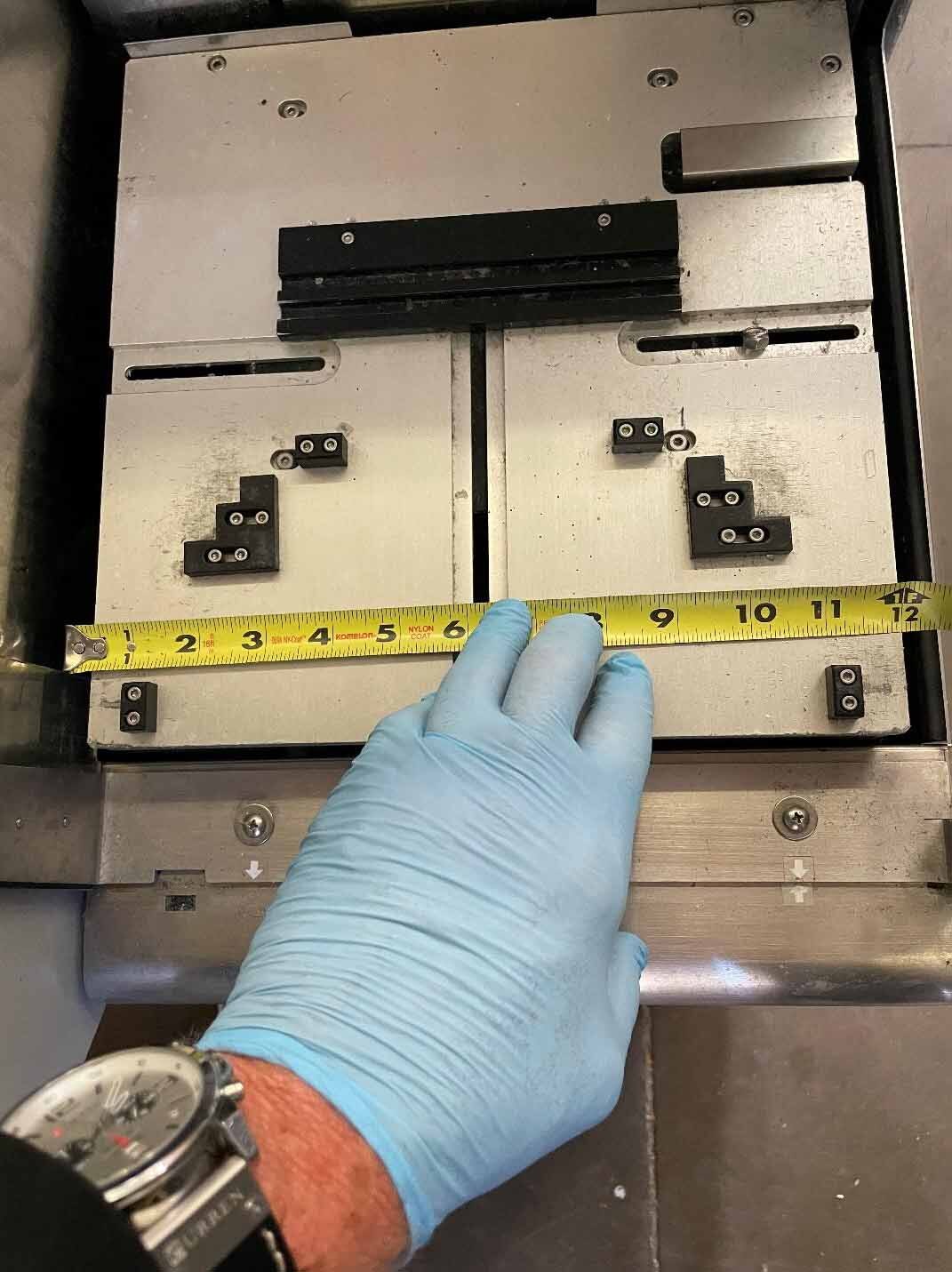

Maximum work piece size: ø 203.2

Tape frame: 2-6, 2-8

X-Axis:

Cutting range: 210 mm

Maximum cutting speed: 0.1 - 450 mm/s

Y-Axis:

Cutting range: 210 mm

Index step: 0.0001 mm

Single error: 0.002 or less / 5 mm

Positioning accuracy: 0.003 or less / 210 mm

Scale resolution: 0.0002 mm

Z-Axis:

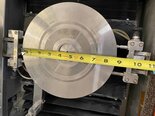

Maximum stroke: 7.2 (for ø 2" blade)

Moving resolution: 0.00025 mm

Repeating accuracy: 0.001

Maximum blade size: Φ 55.56

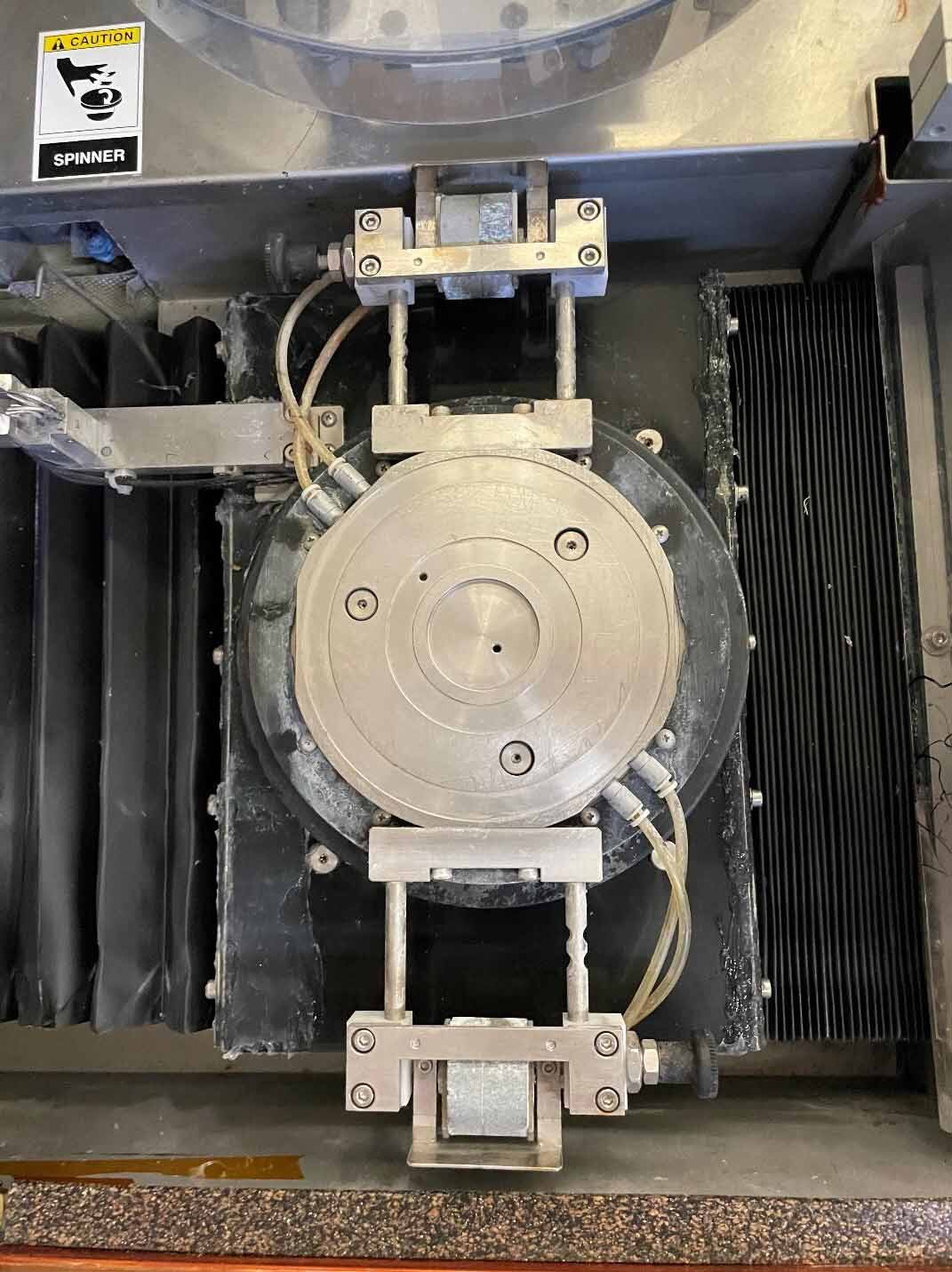

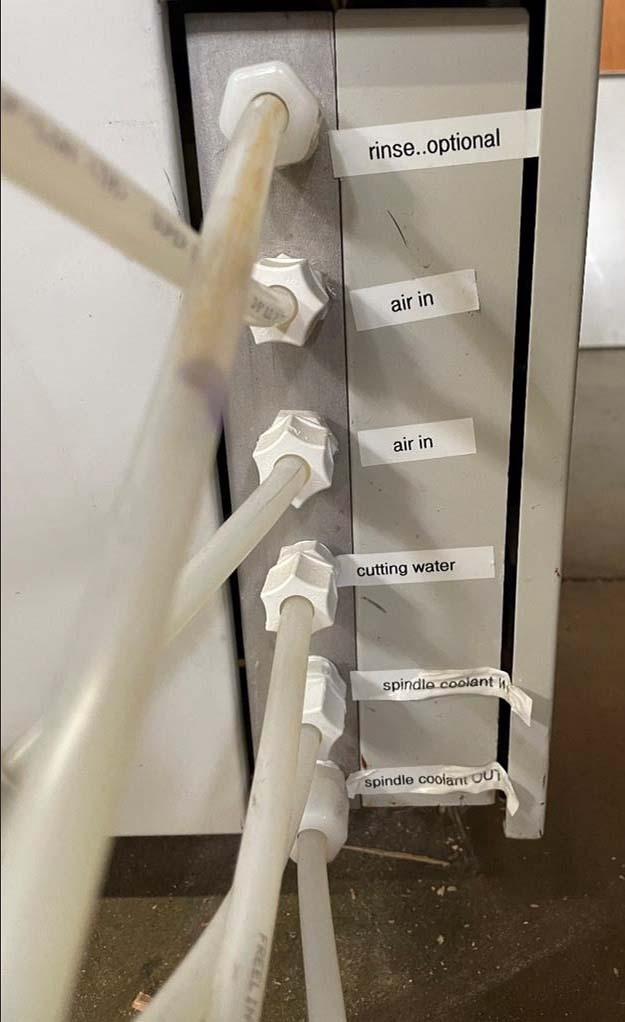

Spindle:

Output: 1.0 at 60,000 min^-1 kW

Torque: 0.16 N-m

Revolution speed range: 6,000 - 60,000 min^-1

2008 vintage.

DISCO DFD 641 is a high-performance scribing/dicing equipment that is designed to deliver superior performance in both production and research applications. The system is capable of scribing and dicing wafers up to 8 inches in diameter in both prototype and production runs. It is an ideal solution for applications such as patterning and die down to nanoscale precision, or for creating intricate, complex geometries. The unit consists of two independent stations for applying either liquid epoxy scribing or dry laser dicing. The entire machine is designed around a cutting-edge Design for Manufacturing (DFM) concept and features a number of identical mechanical modules configured in a linear-arrayed fashion. This allows for maximum scalability and functionality of the overall tool. The scribing station has a number of features designed to ensure precision accuracy. These features include the use of a retractable laser beam that is capable of accurately scribing the wafer surface in a variety of directions. It also features a high-precision epoxy fountain that is designed to accurately dispense the liquid epoxy along the prescribed scribe line. Last, a vacuum nozzle with an adjustable pressure setting has been included to allow for quick and efficient removal of excess epoxy dispensed. The dry laser dicing station is equipped with a high-power laser diode and an accompanying scanner head. The laser diode is capable of producing laser pulses with a variety of pulse lengths, duty cycles and energy outputs, thus making it suitable for a wide range of nanoscale applications. The scanner head enables precise, dynamic movement, thereby allowing for a controlled and precise removal of material from the wafer surface. Additionally, DISCO DFD641 asset has sophisticated software that provides advanced control over the scribing and dicing processes. This includes tools for determining the optimal cut path and closed-loop feedback control algorithms. It also includes a user-friendly, graphical interface that allows operators to quickly select specific cutting parameters and visualize the process within a fraction of a second. DFD 641 is an advanced scribing and dicing model that offers an unparalleled level of precision and control. Its cutting-edge design and advanced software makes it an ideal solution for applications requiring nanoscale production or prototyping. This equipment is highly scalable and allows for a wide variety of cutting parameters, thus making it a great choice for those seeking high-performance cutting solutions.

There are no reviews yet