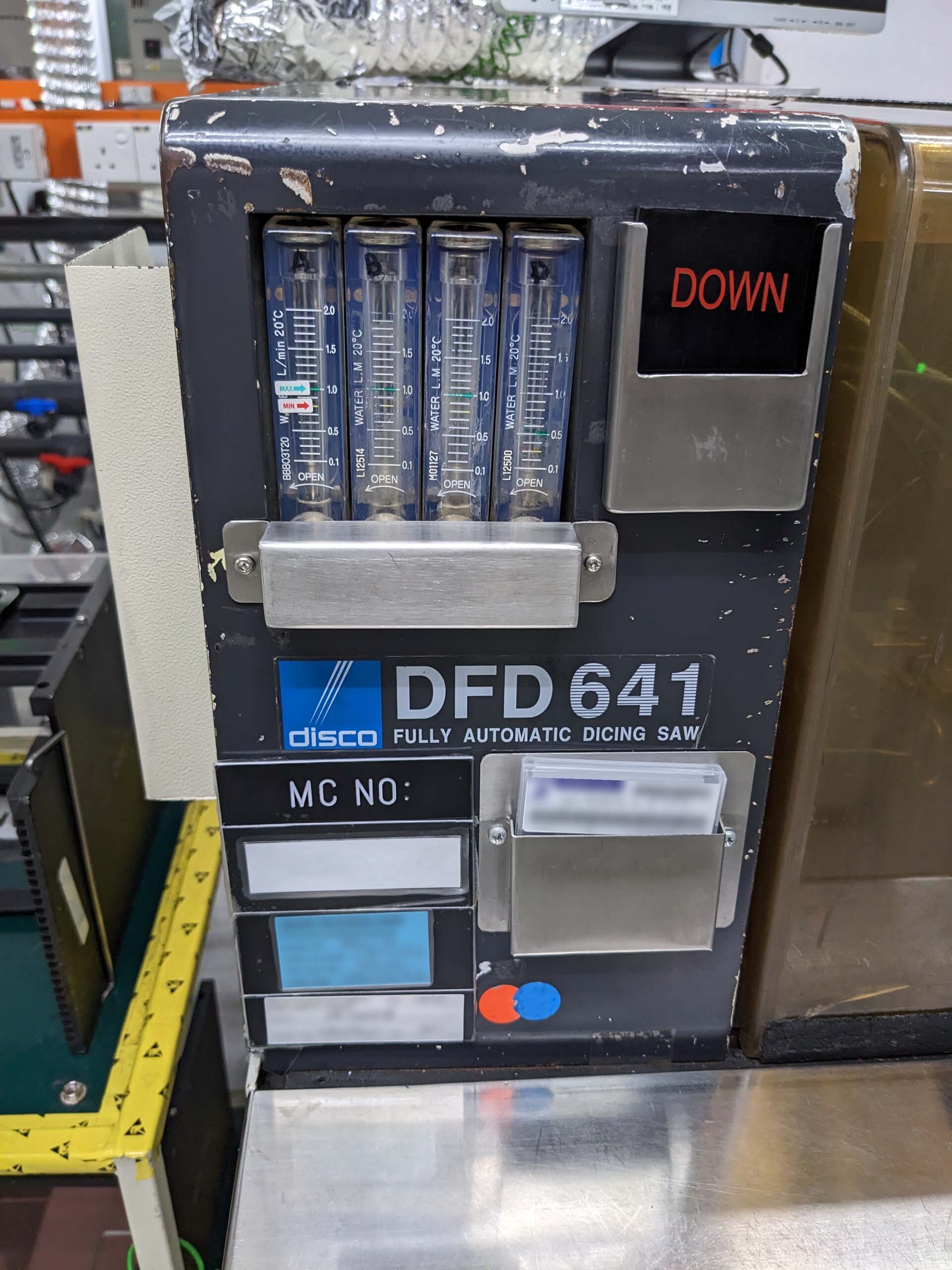

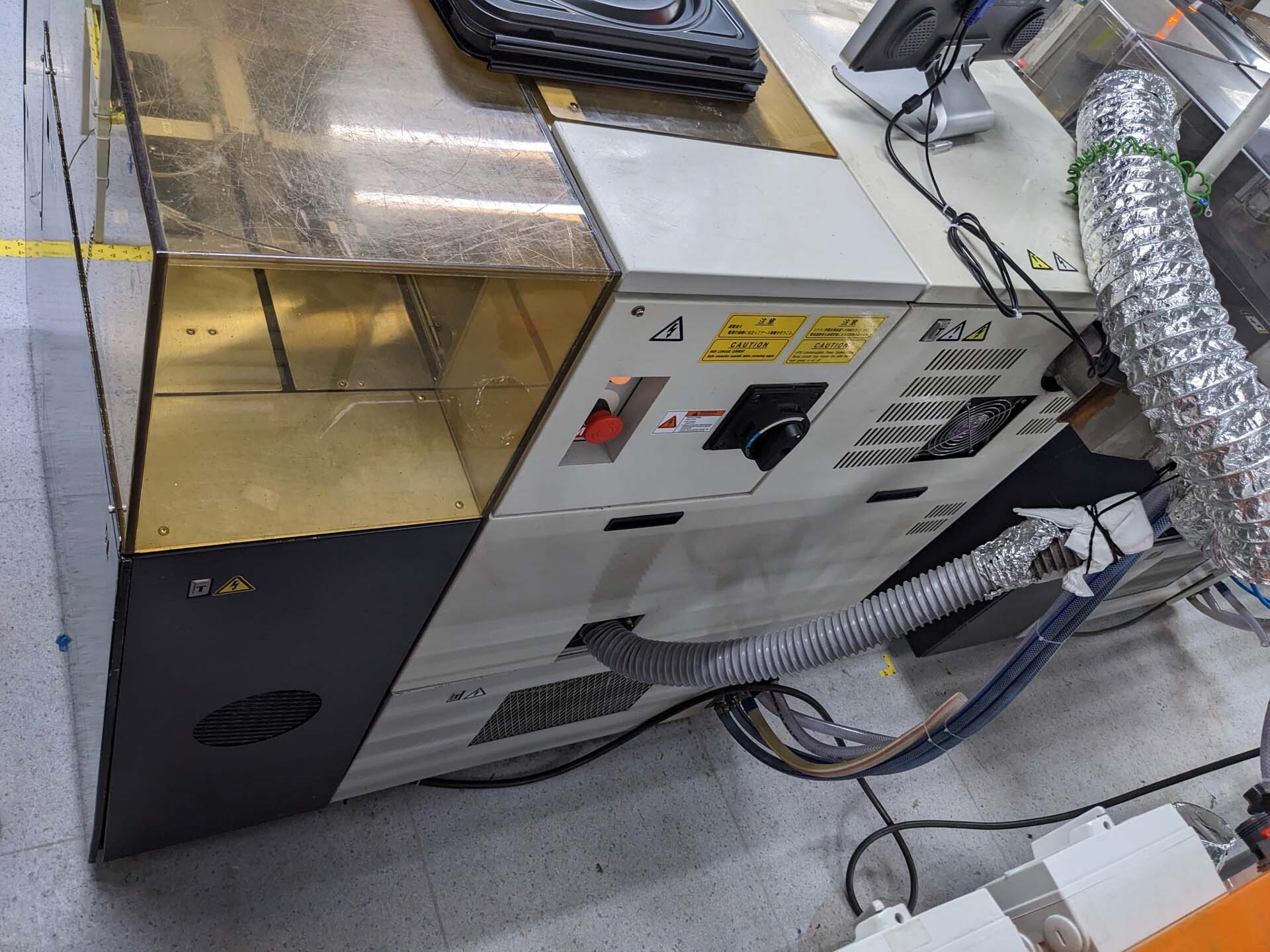

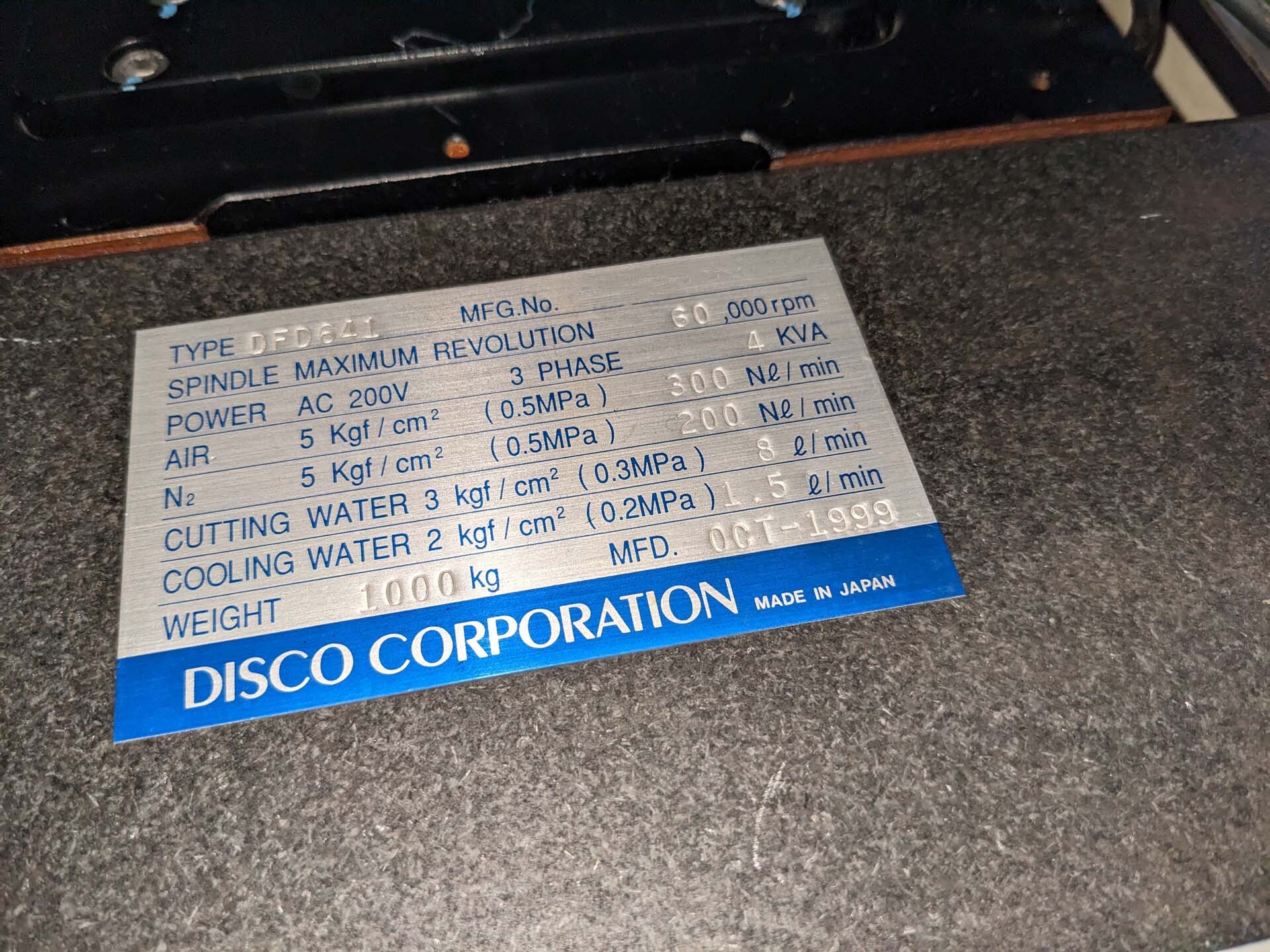

Used DISCO DFD 641 #293642246 for sale

URL successfully copied!

Tap to zoom

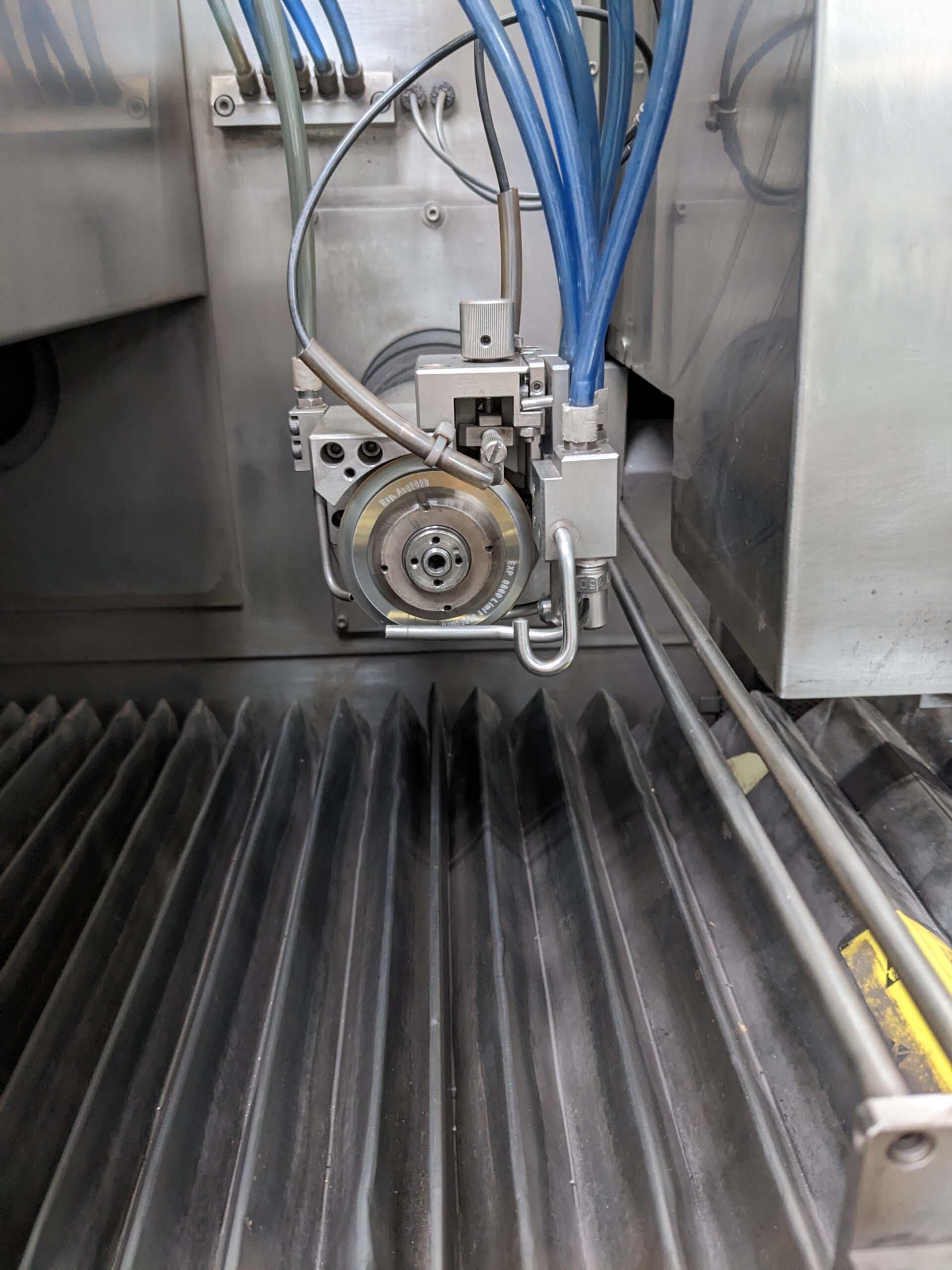

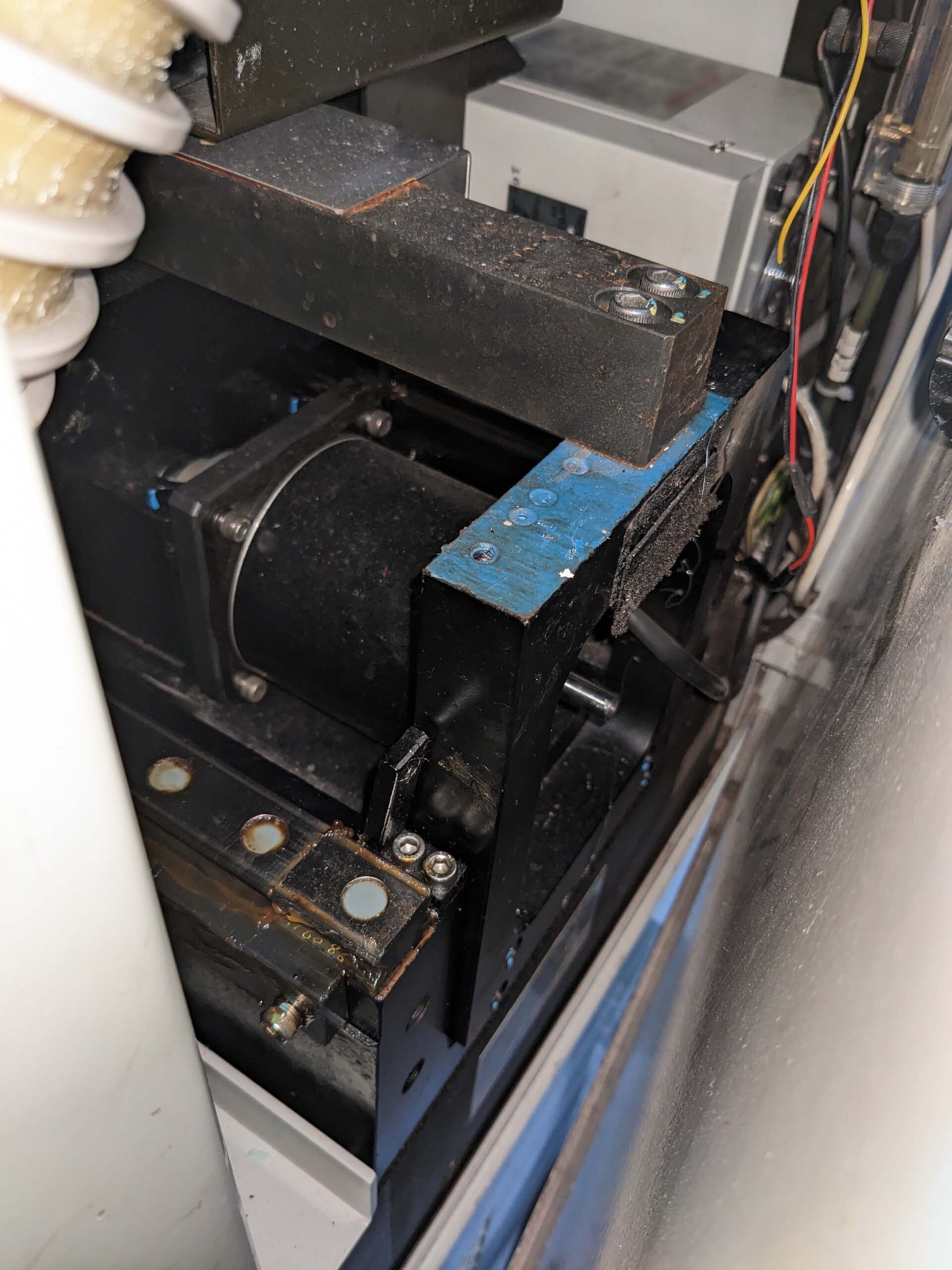

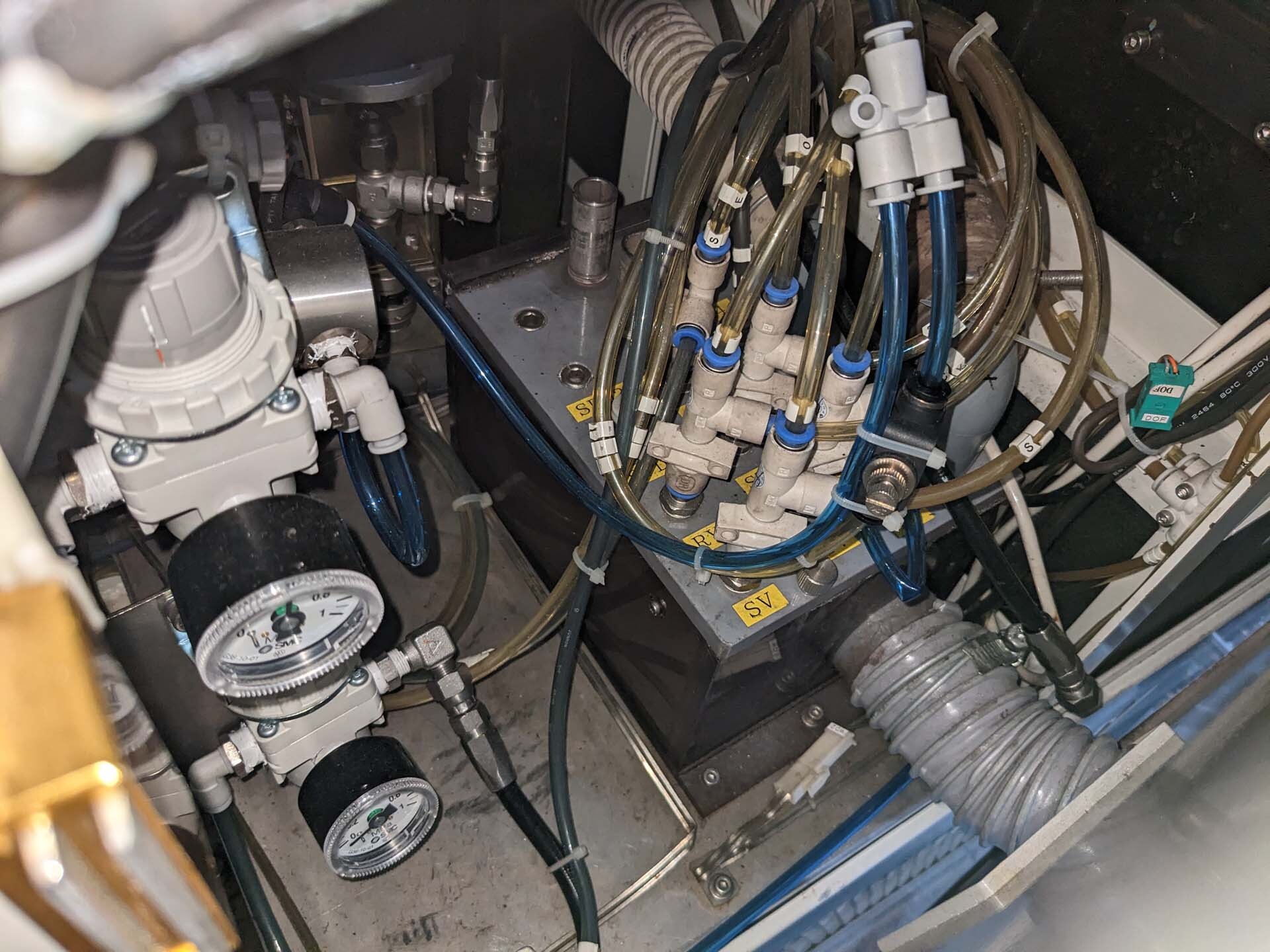

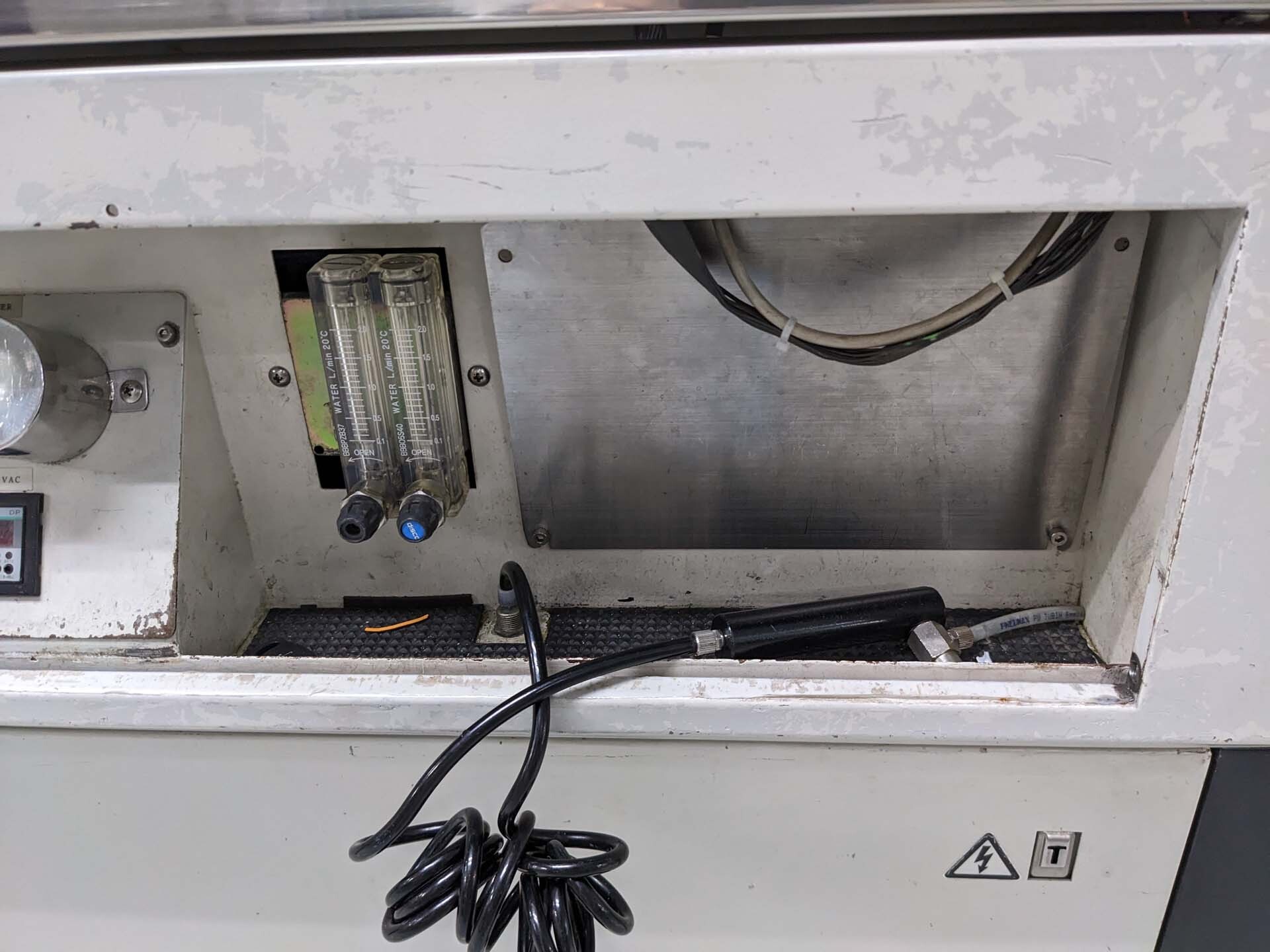

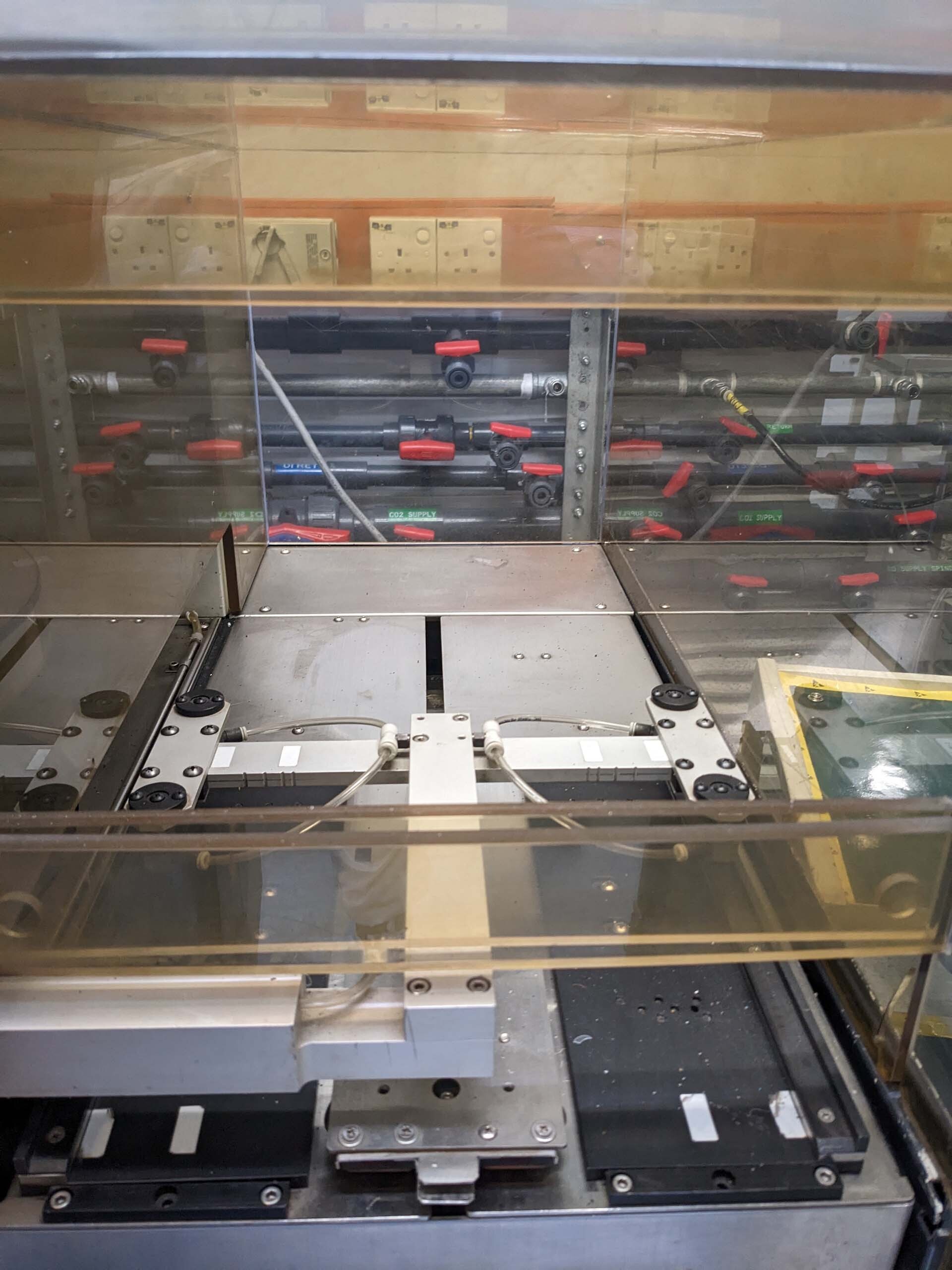

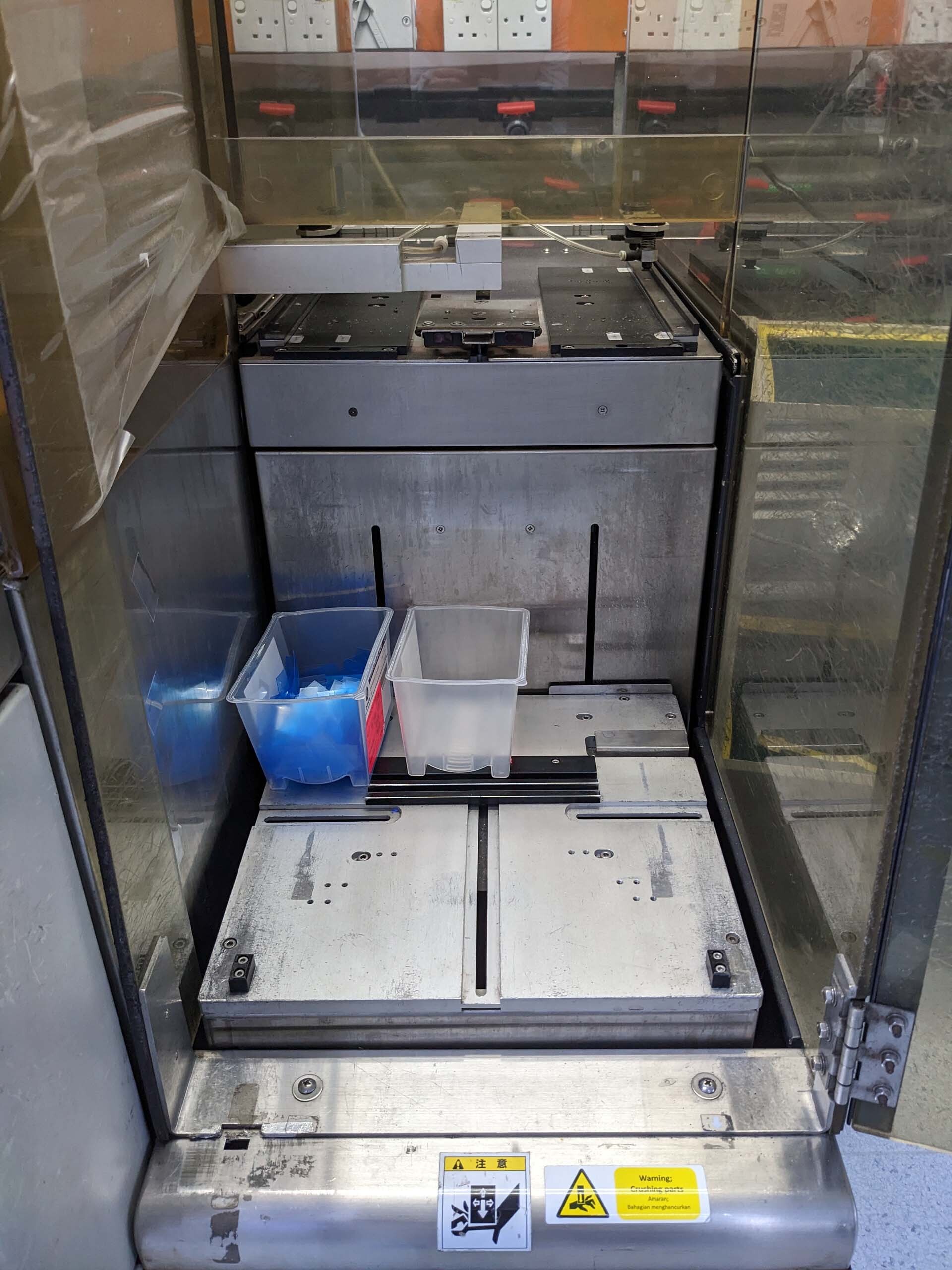

DISCO DFD 641 is a multi-functional scribing / dicing equipment that is tailored to meet the highly precise and accurate requirements of wafer processing procedures. It is able to automatically scribe thin lines on wafers for dicing purposes without any need for manual operation. DISCO DFD641 is equipped with a highly sensitive capacitance sensor that is able to detect the thickness of the thin lines that it scribes, enabling it to precisely measure and control the depth of the scribed lines. Furthermore, the system is able to minimize the heat induced to the substrate, allowing it to achieve precision scribing and dicing without damaging the material. The core of the unit is a two-step process that it performs: scribing and dicing. In the scribing stage, the machine is able to cut complex thin lines on the wafer with a minimum diameter of 10 microns at up to 400 mm/s, depending on the type of wafers being processed. This thin-line width is accurate to within ±5% of the target value. Additionally, it is capable of producing up to 15000 scribed lines per hour, depending on the material being processed. During the dicing stage, the tool uses air pressure to separate the diced pieces from the wafer frame itself. By precisely controlling the amount of pressure used, the asset is capable of accurately dividing the wafer into the desired shapes without causing any damage. The model contains multiple operation modes that can be selected depending on the requirements of the process. These include one-pass, half-etch, and etching protection modes. In one-pass mode, the equipment performs scribing and dicing in one continuous process. In the half-etch mode, the scribed lines are first etched by air pressure and only then is the dicing performed. Lastly, in etching protection mode, which is used when a high precision scribing process is required, the system can temporarily stop the etching process to avoid damage to the wafer. In addition, DFD 641 also contains multiple fail-safe mechanisms to ensure the highest performance and precision when processing. It uses a built-in failure prevention control unit in order to detect any anomalies or errors as they occur, allowing it to automatically detect and correct deviations from the programmed scribing or dicing process. It is also equipped with several features for managing the material process, such as a digital nozzle distance control, which ensures that the nozzle does not come into contact with the wafer at any time to reduce any kind of damage. Overall, DFD641 is a highly advanced and efficient machine, which is capable of providing stable, accurate, and high-precision scribing and dicing procedures. Its built-in safety mechanisms along with its various modes and wide range of capabilities make it an ideal choice for professionals in the wafer processing industry.

There are no reviews yet