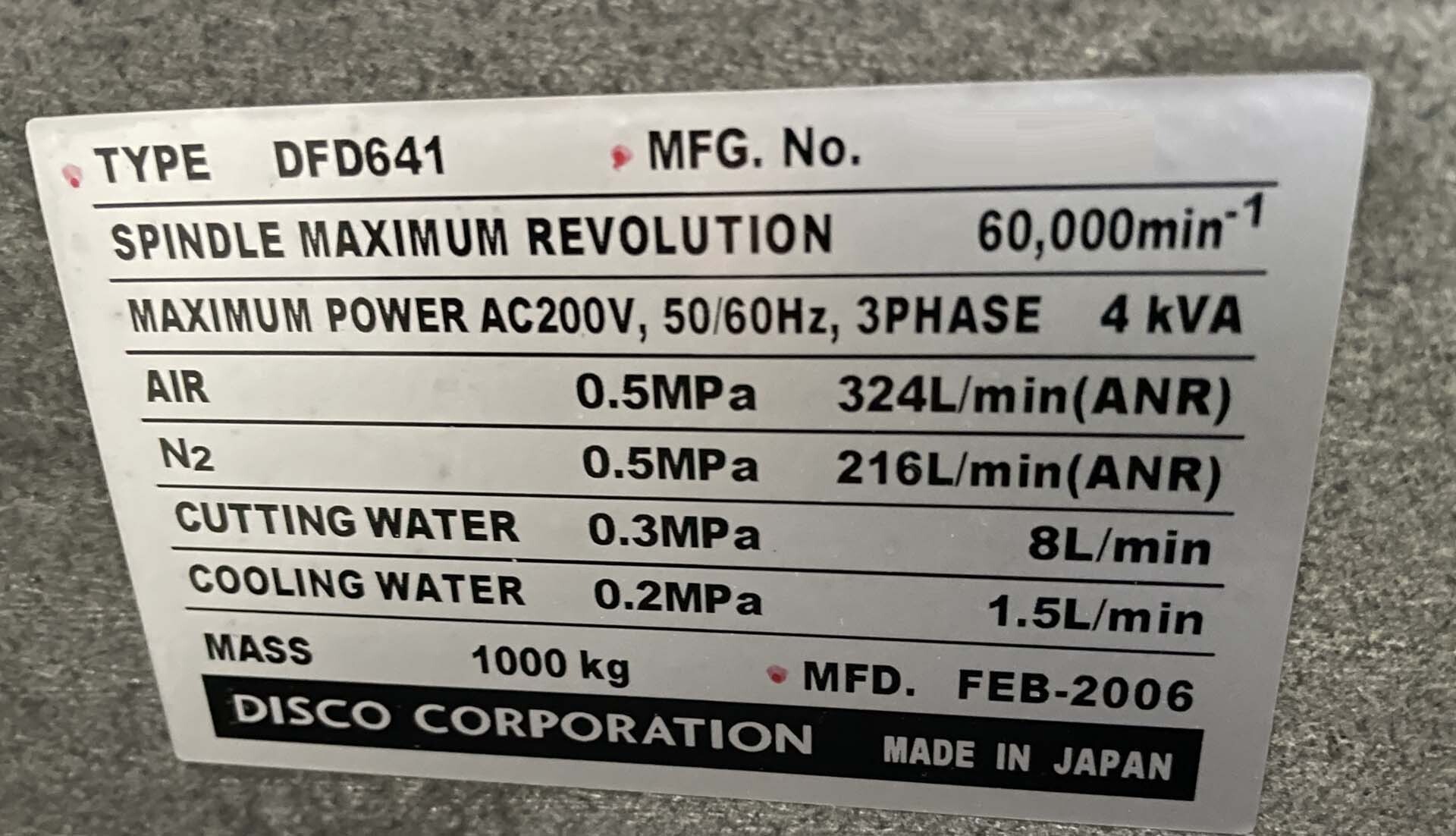

Used DISCO DFD 641 #293665955 for sale

URL successfully copied!

Tap to zoom

DISCO DFD 641 is a scribing and dicing equipment used in semiconductor manufacturing to perform precision cutting and splitting of semiconductor wafers. It utilizes a diamond-coated scribe wheel attached to a robotic arm to ±200 μm precision trim wafers into individual dies, eliminating the need for manual and costly slicing operations. This system has a maximum wafer size of 6 inch and a die size accuracy down to 10 μm. It is capable of processing up to 4200 wafers per hour and each wafer may contain thousands of dies. The unit has automatic failure monitoring with statistical process control features to limit dies that do not meet specification from entering the supply chain. Additionally, the machine has autofocus and edge detection capabilities to accurately position and cut wafers with 0.9 µm repeatability. The tool also features a wafer transport asset using real-time mathematical algorithms for engagement, allowing for wafer breakage, scribing, and dicing operations. The operating environment is a Class 1000 ISO Clean Room, with air plenums and custom filter systems to ensure particulate concentrations remain under 10 µg/m3. Fully enclosed cabinet with N2 purging and positive pressure controls prevent the introduction of dust and other contaminants during operation. Its user interface computer runs Windows and is configured with custom software programs for efficient job supervision. The model utilizes a standard laser safety curtain to ensure safety of operators. Additionally, all tools and fixtures that hold wafers, are designed to withstand up to 5G to prevent wafer breakage and ensure safety during operation. The breadboard program allows users to set parameters for optimal operation, allowing for easy task automation. The self-diagnostic parameters provide a visual indication of any faults or issues in the equipment, and real-time monitoring of the system parameters can be performed using the monitoring unit. This machine is an ideal tool for efficient and accurate die dicing and scribing, and can be used in many semiconductor manufacturing environments. It offers a fast and safe process of trimming and splitting wafers, with superior die size accuracy and repeatability, which not only increases process reliability, but reduces scrap and repair costs.

There are no reviews yet