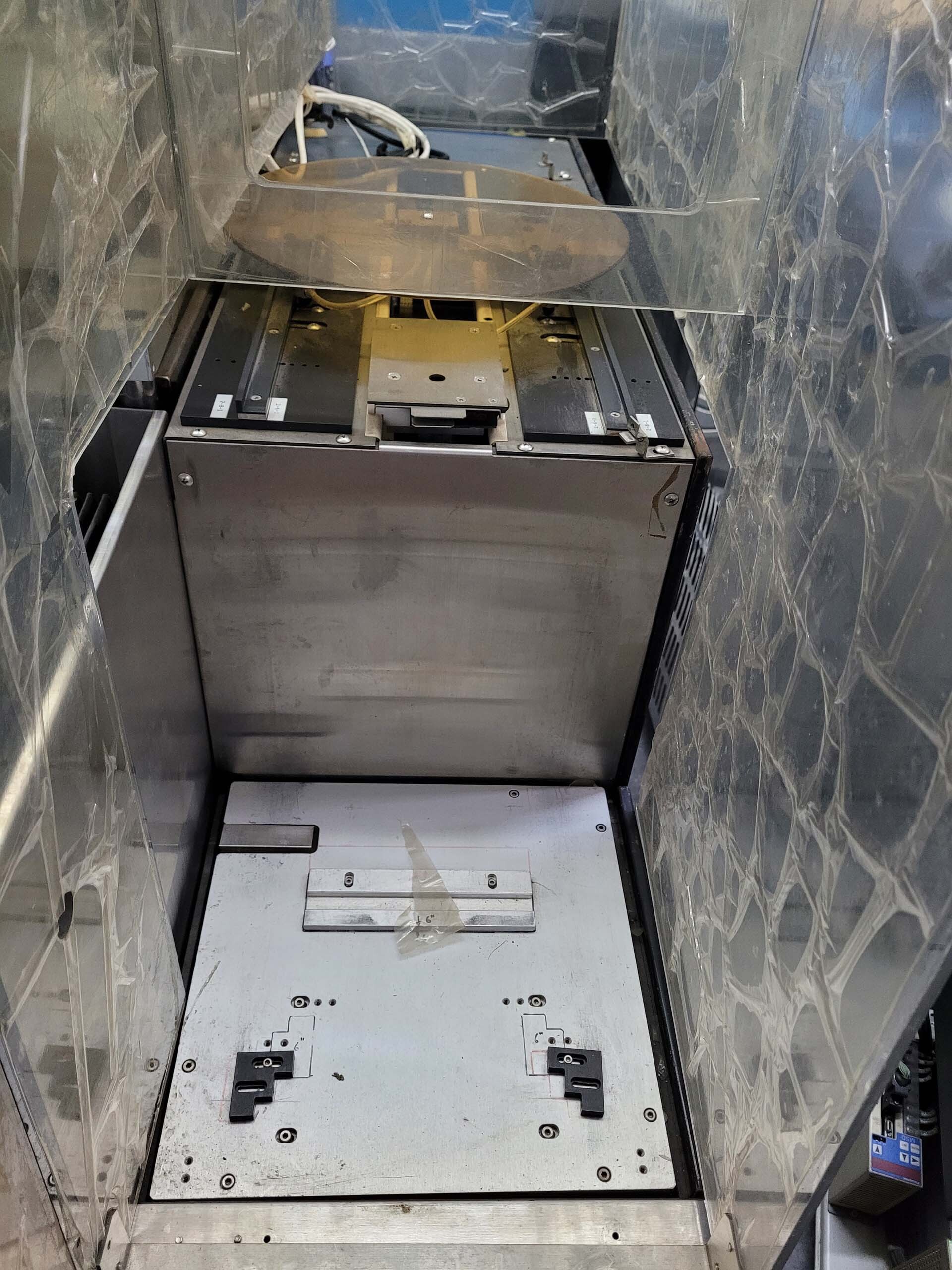

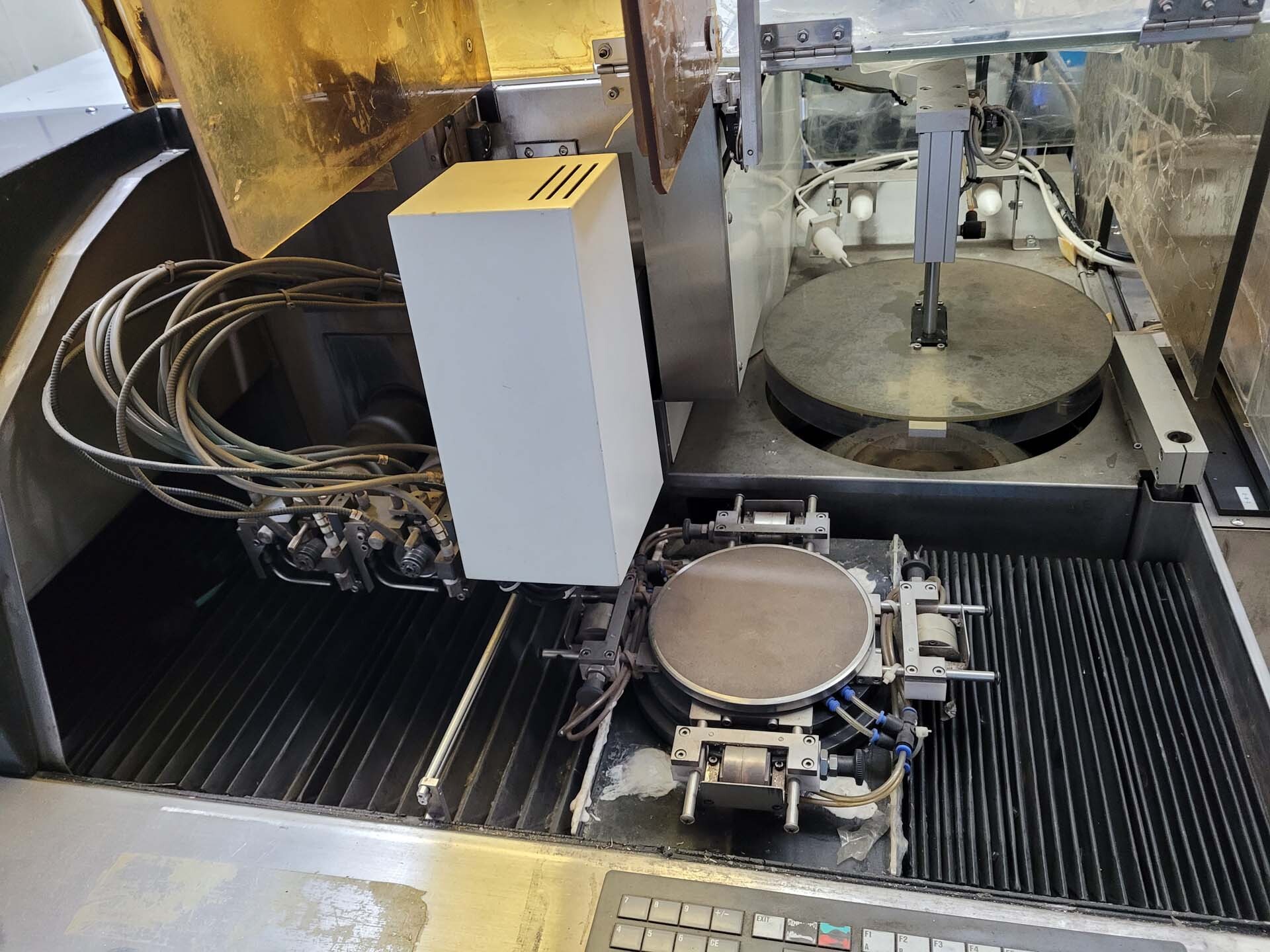

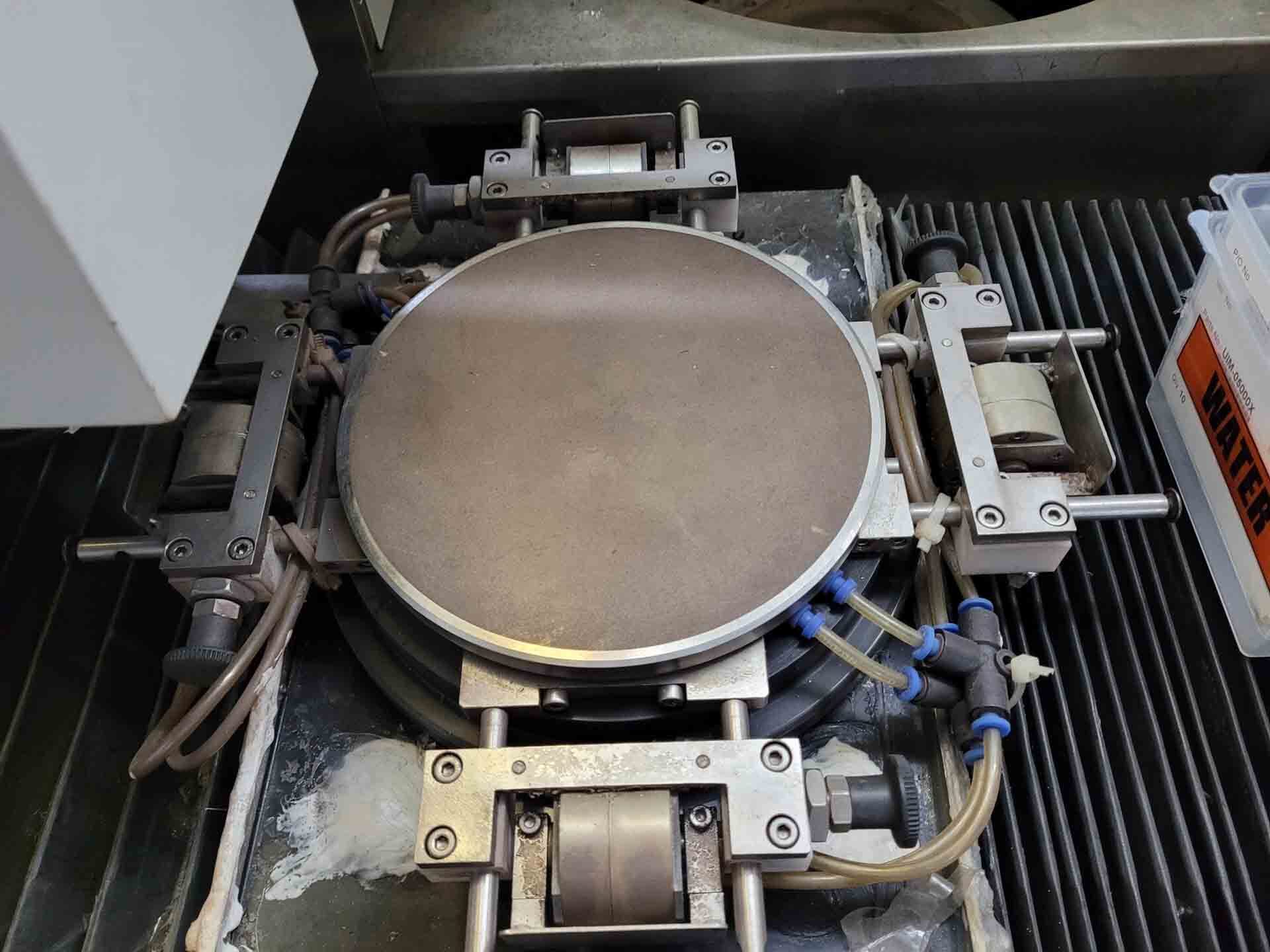

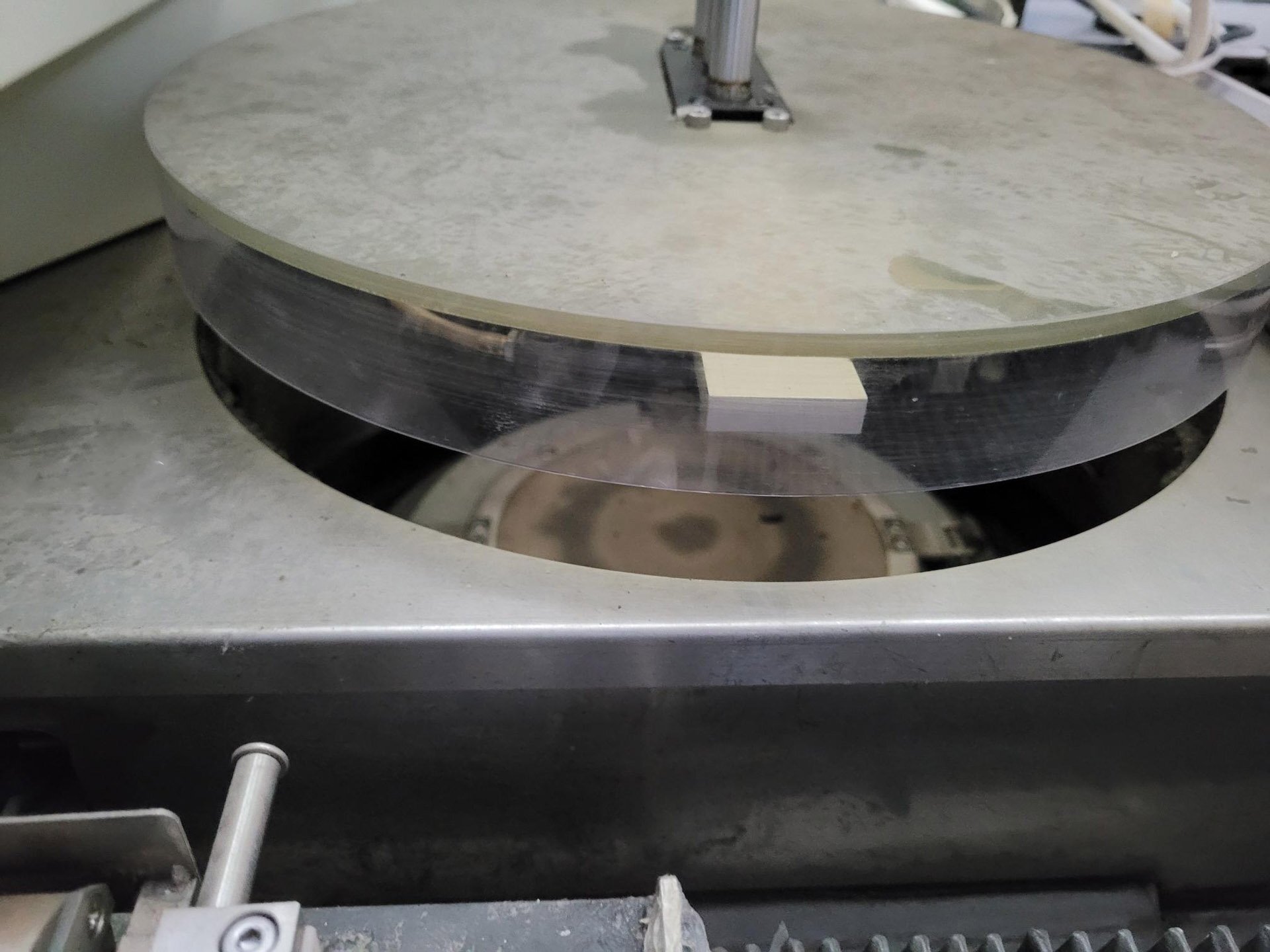

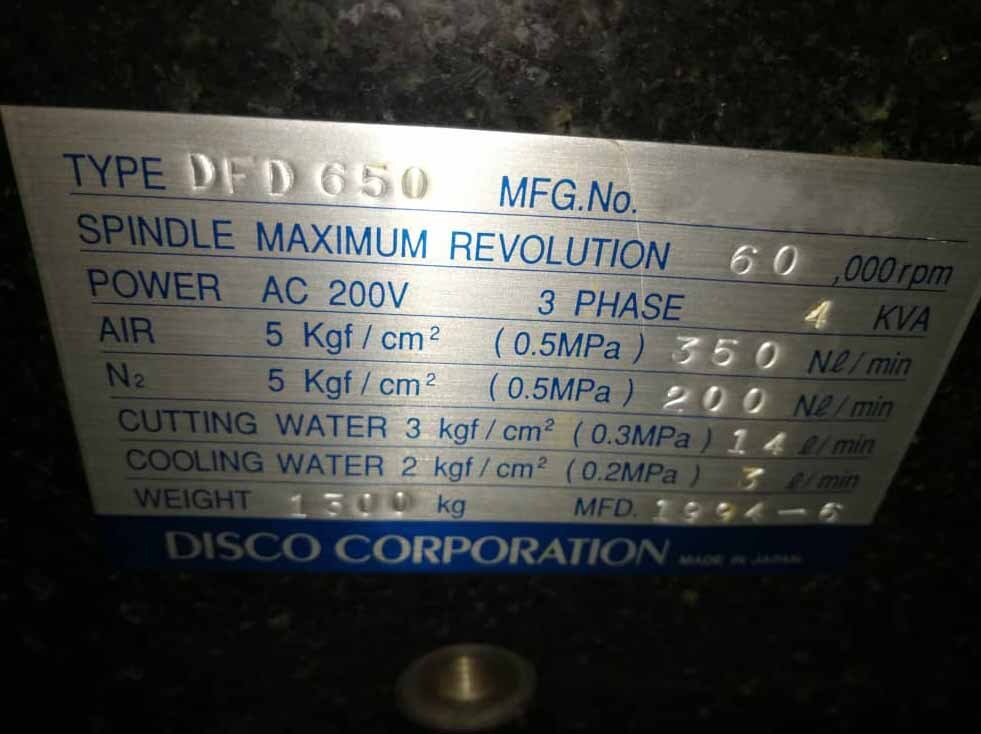

Used DISCO DFD 650 #9372468 for sale

URL successfully copied!

Tap to zoom

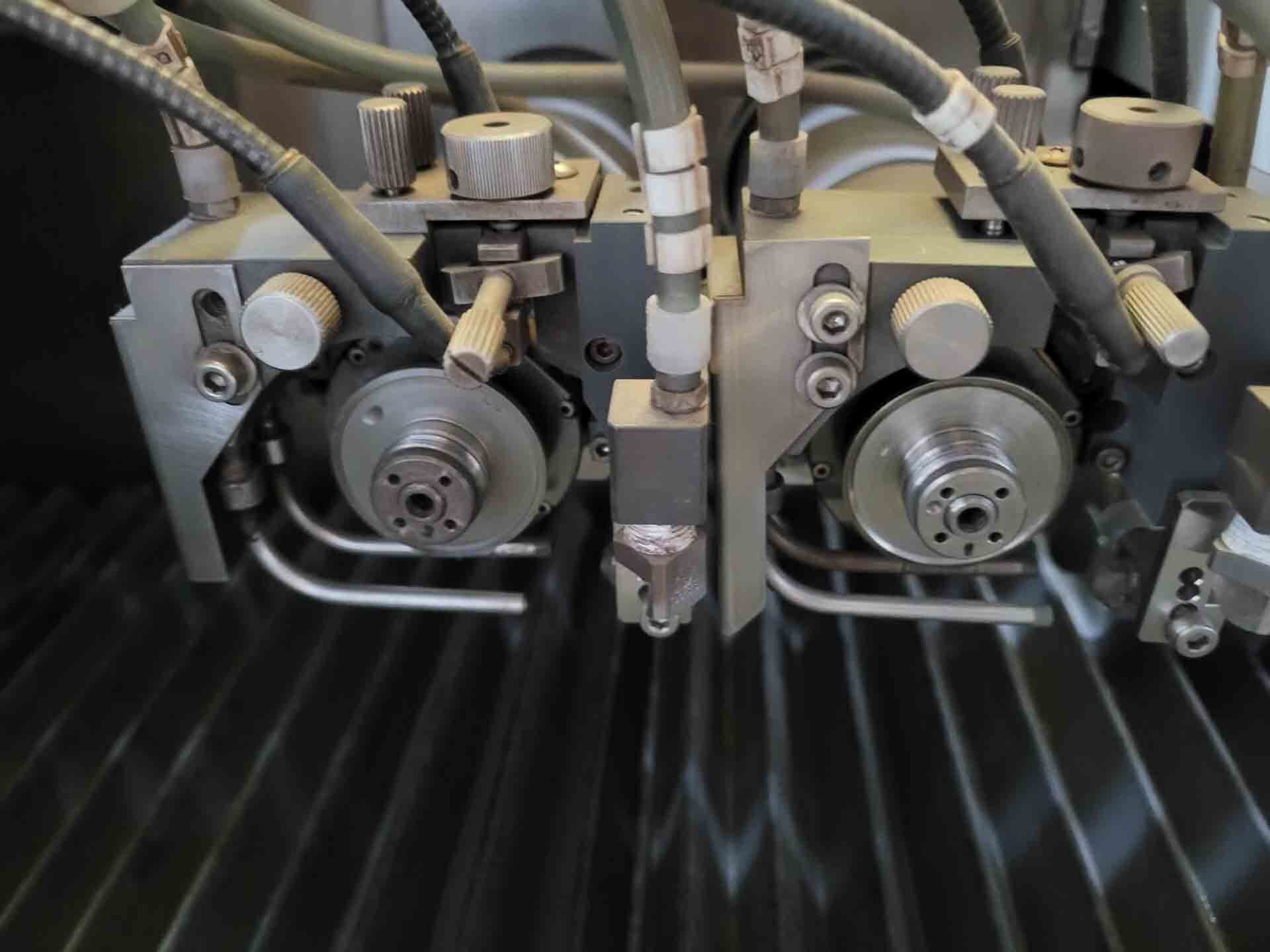

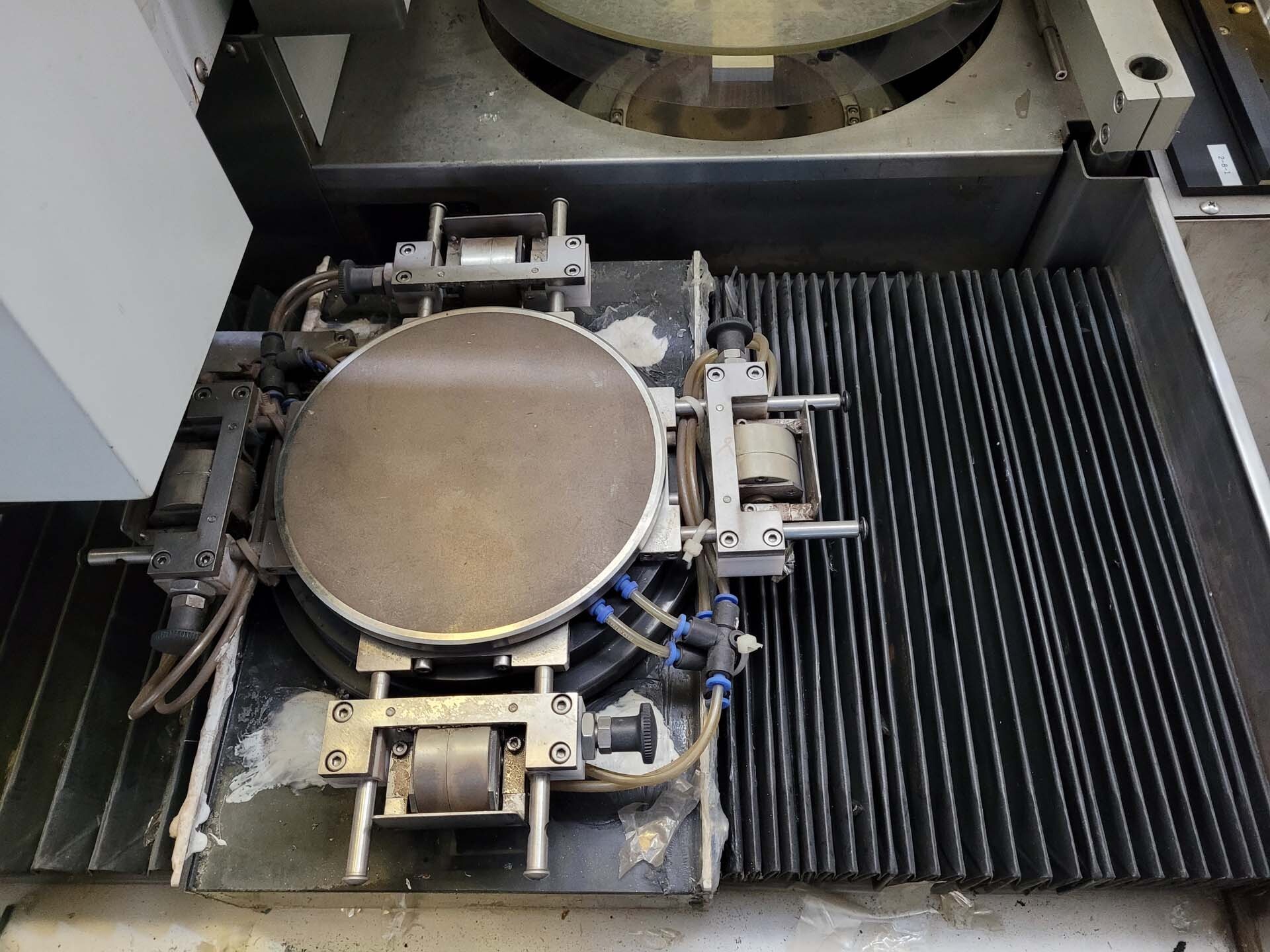

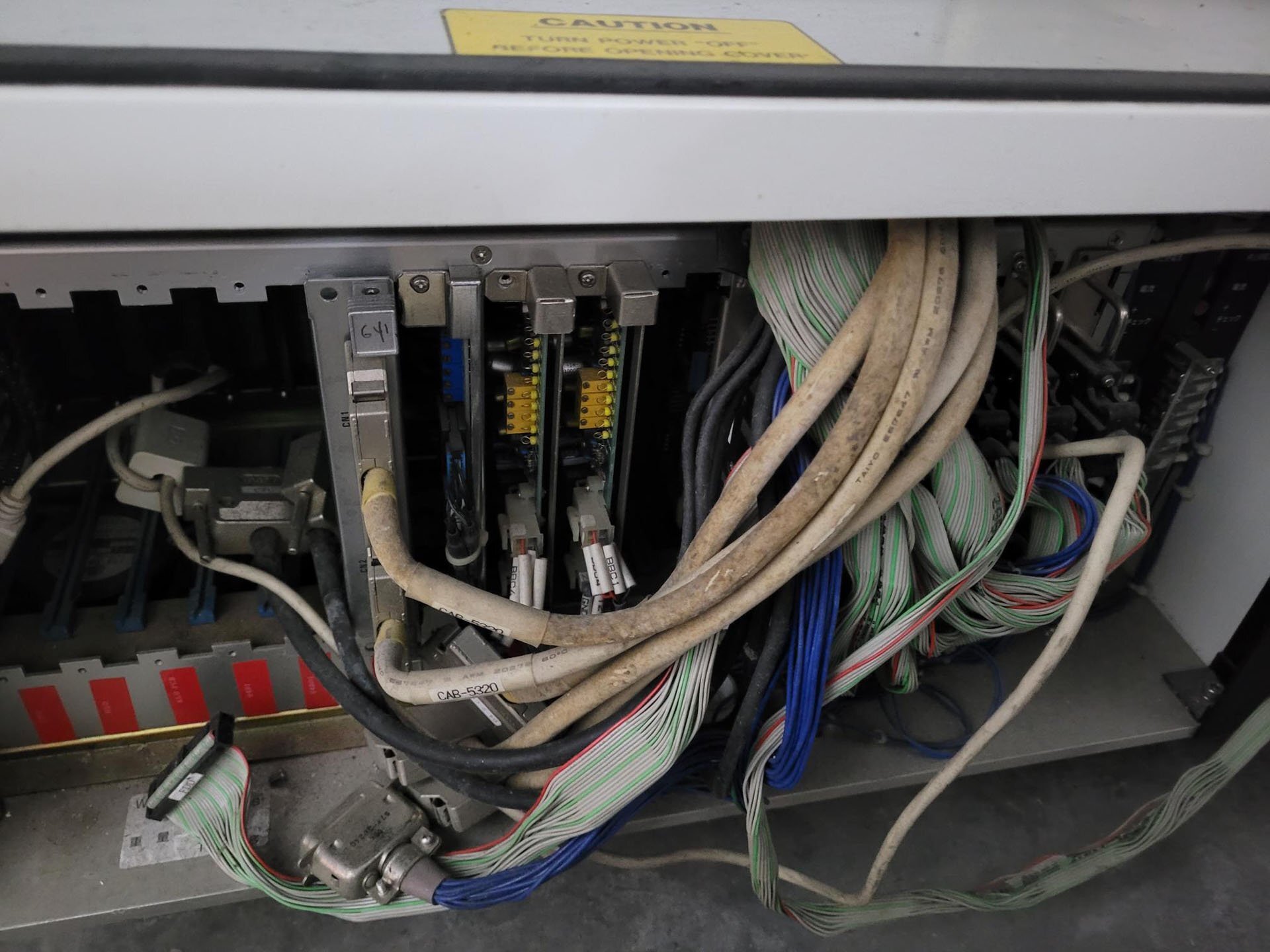

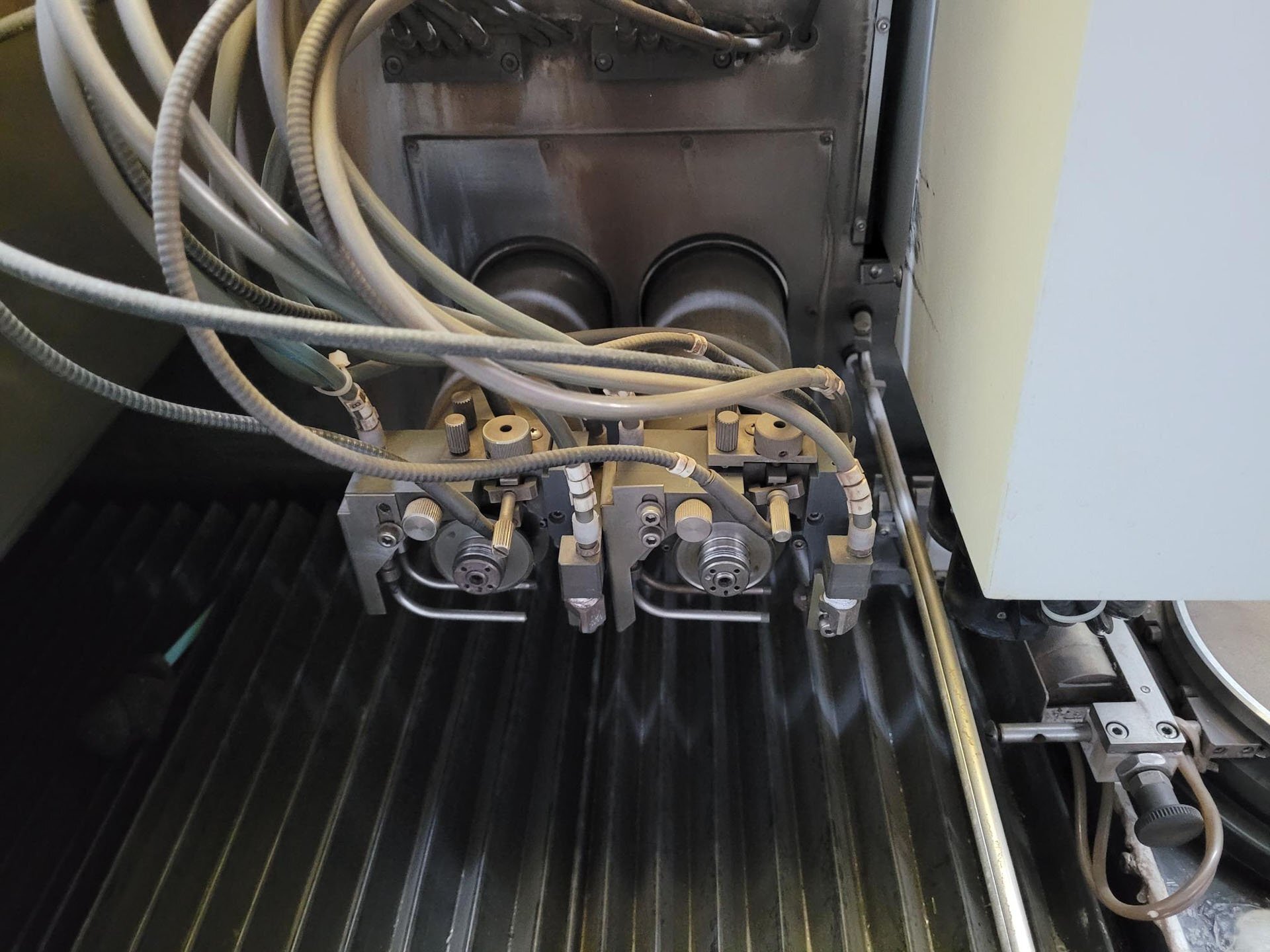

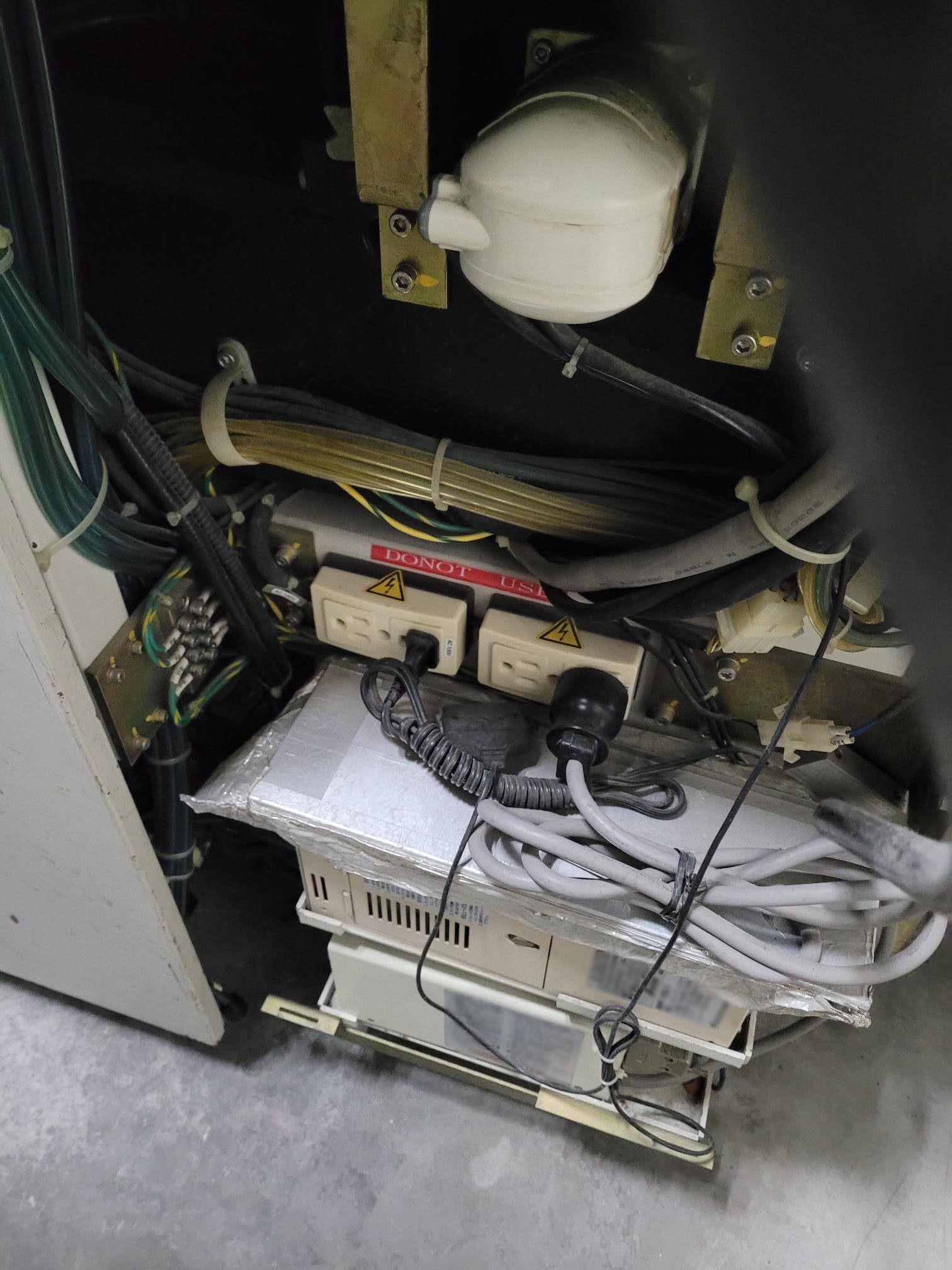

DISCO DFD 650 is a stateof-the-art scribing and dicing equipment designed to fulfil the demanding requirements of the semiconductor industry. The wide range of substrates that can be processed include both delicate silicon wafers and expensive metals. The system is designed to ensure the highest levels of safety and accuracy. The unit consists of several components, including a wafer stage, camera machine, beam positioning adjustment, and a motor driver unit. The wafer stage allows the substrate wafer to remain stationary while the motor driver unit moves the laser beam precisely over the wafer surface. The cameras provide a high-resolution image of the wafer surface, allowing the operator to easily identify potential defects such as surface cracking, thickness irregularities, and other blemishes. A built-in algorithm allows the operator to manually choose the best stitching pattern for the scribe and etch lines. The built-in beam positioning adjustment allows the operator to fine-tune the position of the laser beam with software programming. This feature greatly improves accuracy and minimizes damage to the wafer. The tool is also equipped with a range of safety mechanisms, including a safety switch and an emergency shutdown. Finally, the advanced laser technology allows operators to select a cutting diameter between 0.25mm and 1.2mm. This feature lets operators choose the optimal diameters for their particular applications. The asset lets operators carry out both scribing and dicing processes simultaneously, saving time and reducing costs. Overall, DISCO DFD650 is a highly advanced scribing and dicing model offering an excellent combination of accuracy, safety and performance. It is an ideal choice for semiconductor manufacturers who require reliable processing and control for a wide range of substrates.

There are no reviews yet