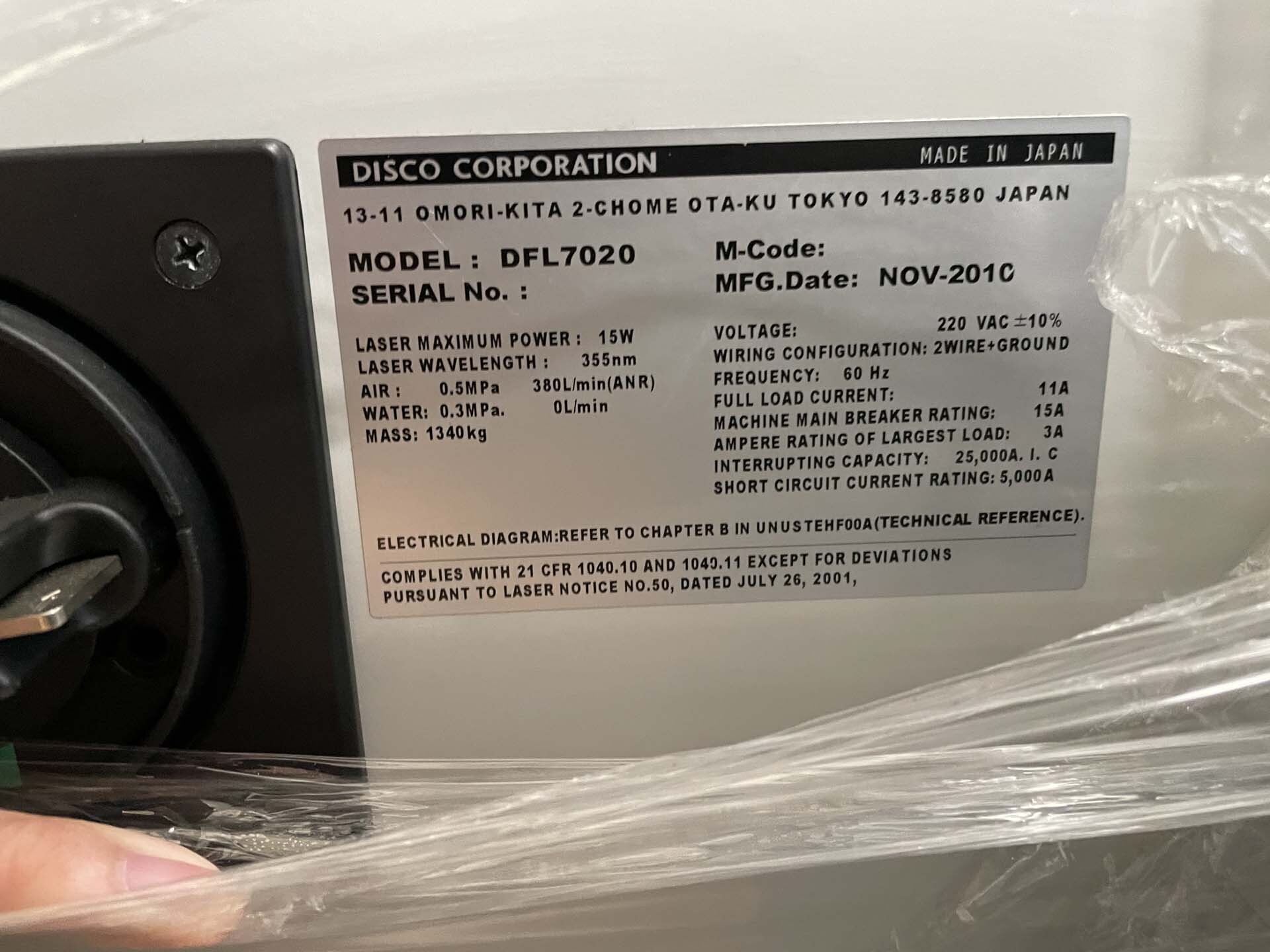

Used DISCO DFL 7020 #293635862 for sale

URL successfully copied!

Tap to zoom

DISCO DFL 7020 is a scribing / dicing equipment designed for precision engineering and precision manufacturing applications. It utilizes a pressure system with a range of 0.1-15 MPa, allowing for a wide range of cutting applications. The unit also incorporates a high-speed spindle machine and a patented coaxial laser position feedback tool that allows for precise control of axis motions, allowing users to achieve high levels of accuracy and reliability during the machining process. DISCO DFL7020 has a high-precision scribing stage which is operated through a combination of two stepper motors and an optical tracking mechanism. The stepper motors provide for a rapid positioning accuracy of ±1 μm and the optical tracking tracks the relative movements of the dicing media relative to the component to be machined, allowing for precise and repeatable machining sizes. The main components associated with the asset are the main frame enclosure, the robot stage (with the robot base), and the cutting tools. The main frame is made of an aluminium alloy and is designed to hold the motor, the power supply, and the control boards needed for precise control of the model. The robot stage, on the other hand, is made of welded steel and designed to provide stability and accurate control of the robot. It holds the robot arm and its electric motor, which is operated through a combination of a pulse train controller and the optical tracking mechanism. The cutting tools used with DFL-7020 are the scriber, dicer, and slicer blades. The scriber is used for the precise cutting of thin, thin-welded pieces of metal or other materials, while the dicer and slicer blades are used for the cutting of larger pieces of materials, for example for producing intricate shapes in metal or other materials. DFL7020 incorporates a high level of automation and control, as it is capable of running multiple programs at once and is able to read vector-designed G-code, engraving data, and drive a multitasking robot. It also has several programmable options that can be programmed to include specific filters, tie-points, and basic zero cuts. As a result, it offers a wide range of possibilities for precision cutting and machining applications.

There are no reviews yet