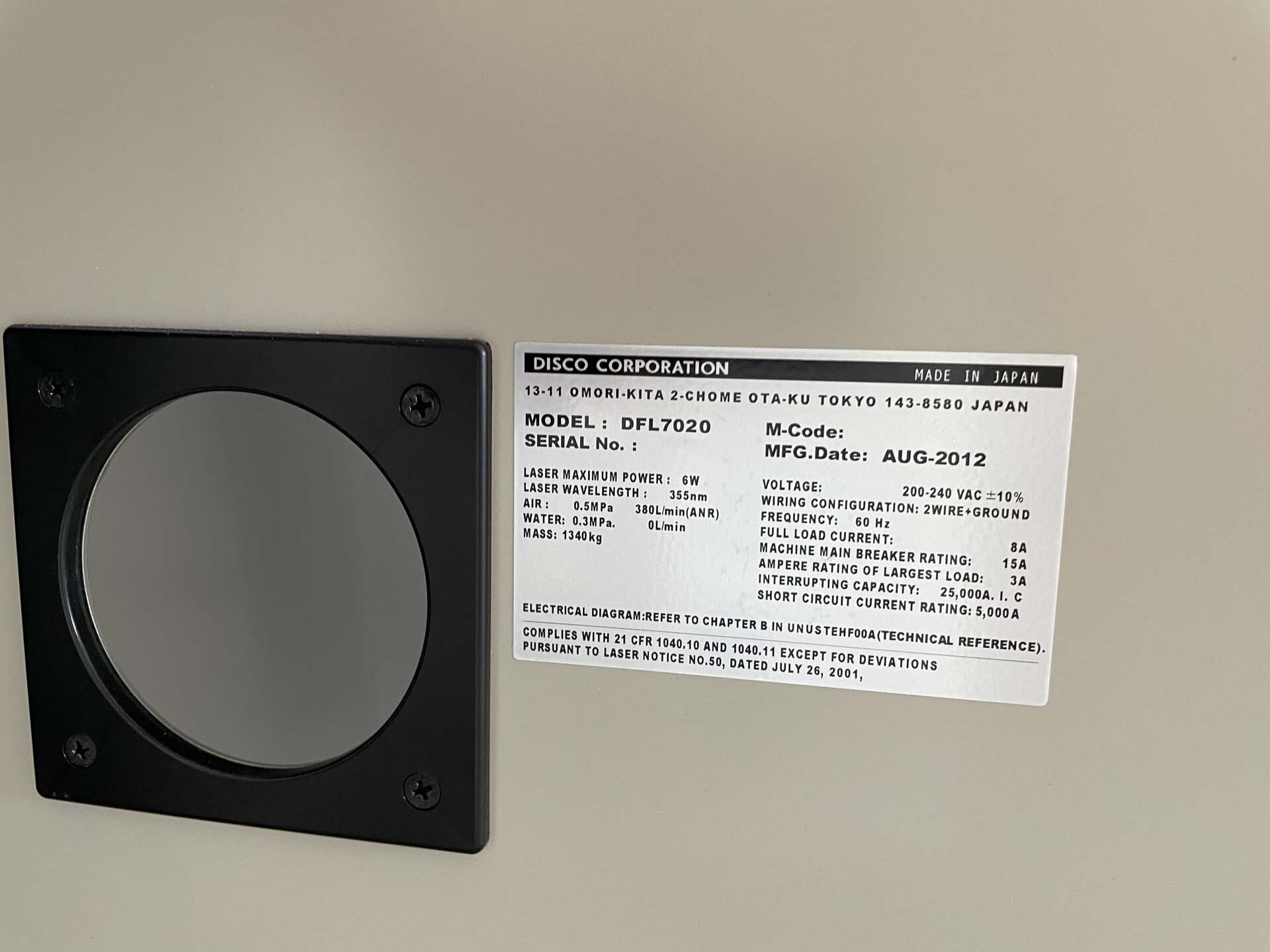

Used DISCO DFL 7020 #293635866 for sale

URL successfully copied!

Tap to zoom

DISCO DFL 7020 is a state-of-the-art scribing and dicing equipment used in semiconductor manufacturing. It allows for rapid scribing and dicing of wafers in a precise and efficient process. The machine is composed of several components, including a loading station, module, camera and laser system, scribe tool, and chip bin. The loading station collects the wafers and aligns them to the module, typically a 25 inch circular platform that holds the wafers in place. The camera and laser unit then captures detailed images of each wafer, providing precise measurements to ensure accurate scribing and dicing. The scribe tool utilizes a low-power laser beam to align the scribes directly onto the wafer. This alignment ensures that each scribe is accurately placed and of uniform width. The dicing process uses a vibrating blade to cut the wafer in a single pass, producing smooth, uniform designs. A chip bin is incorporated into the machine, allowing for precise sorting, storage, and retrieval of each processed wafer. DISCO DFL7020 is designed to be extremely fast and reliable, reducing cycle times and maintaining throughput at a maximum level. It features a compact design and requires minimal space, allowing for a wide array of applications. The tool can be connected to a wide variety of computer interfaces, allowing for user automation and easy integration with manufacturing systems. DFL-7020 also provides a high-resolution monitor that enables detailed observation of each scribing and dicing operation. The monitor also displays each wafer's processed images and can be used to review the accuracy of the dicing process. Additionally, the asset includes a wide range of safety features to protect operators from hazardous laser emissions. This ensures that the model's operation remains secure, safe, and reliable. Overall, DFL 7020 is a highly advanced and reliable scribing and dicing equipment which is used in many advanced semiconductor manufacturing processes. It is designed for speed, accuracy, and dependability, and is capable of handling a wide variety of applications. It provides a variety of features and options, making it an ideal system for any rigorous semiconductor manufacturing environment.

There are no reviews yet