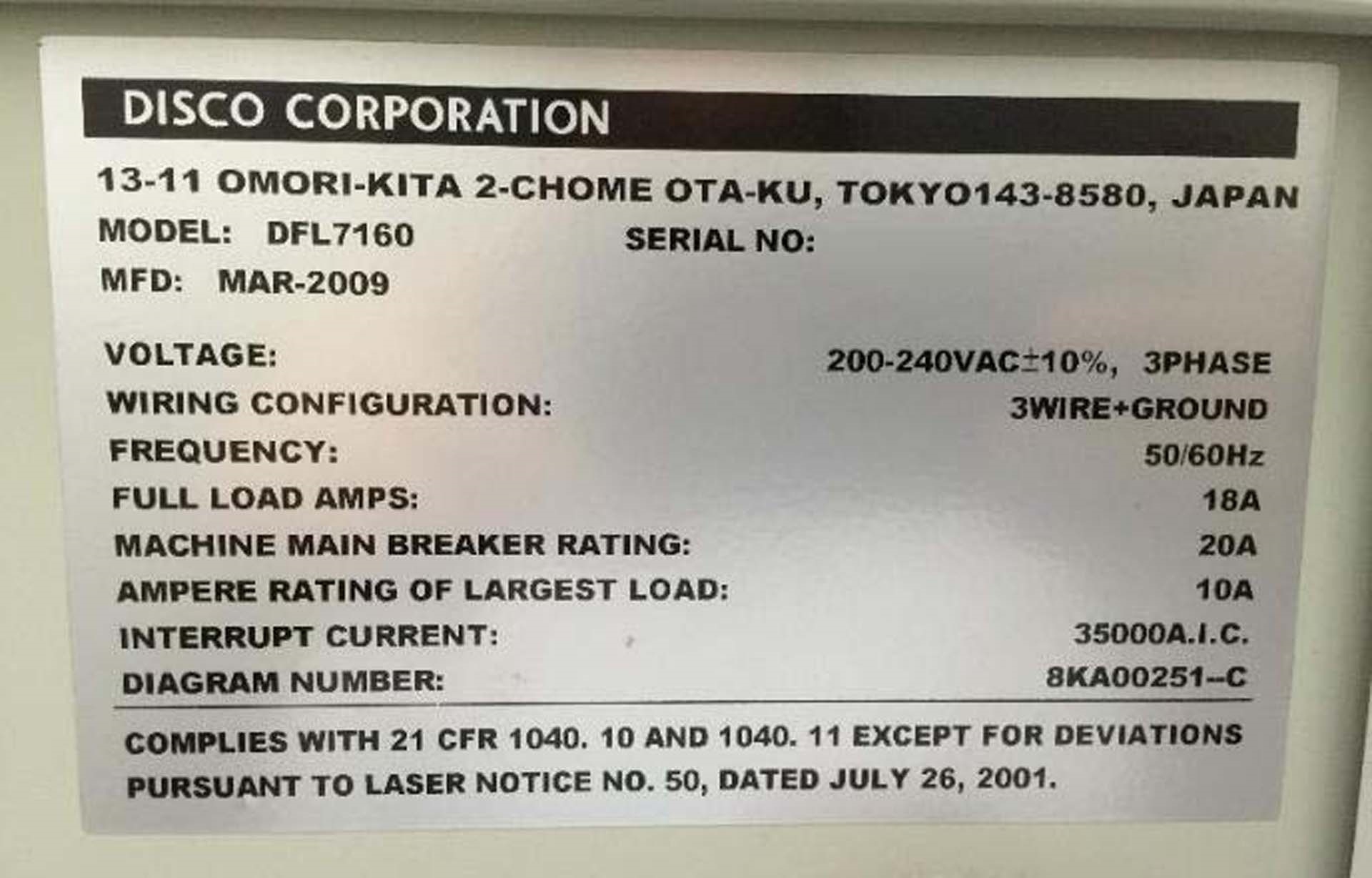

Used DISCO DFL 7160 #9263327 for sale

URL successfully copied!

Tap to zoom

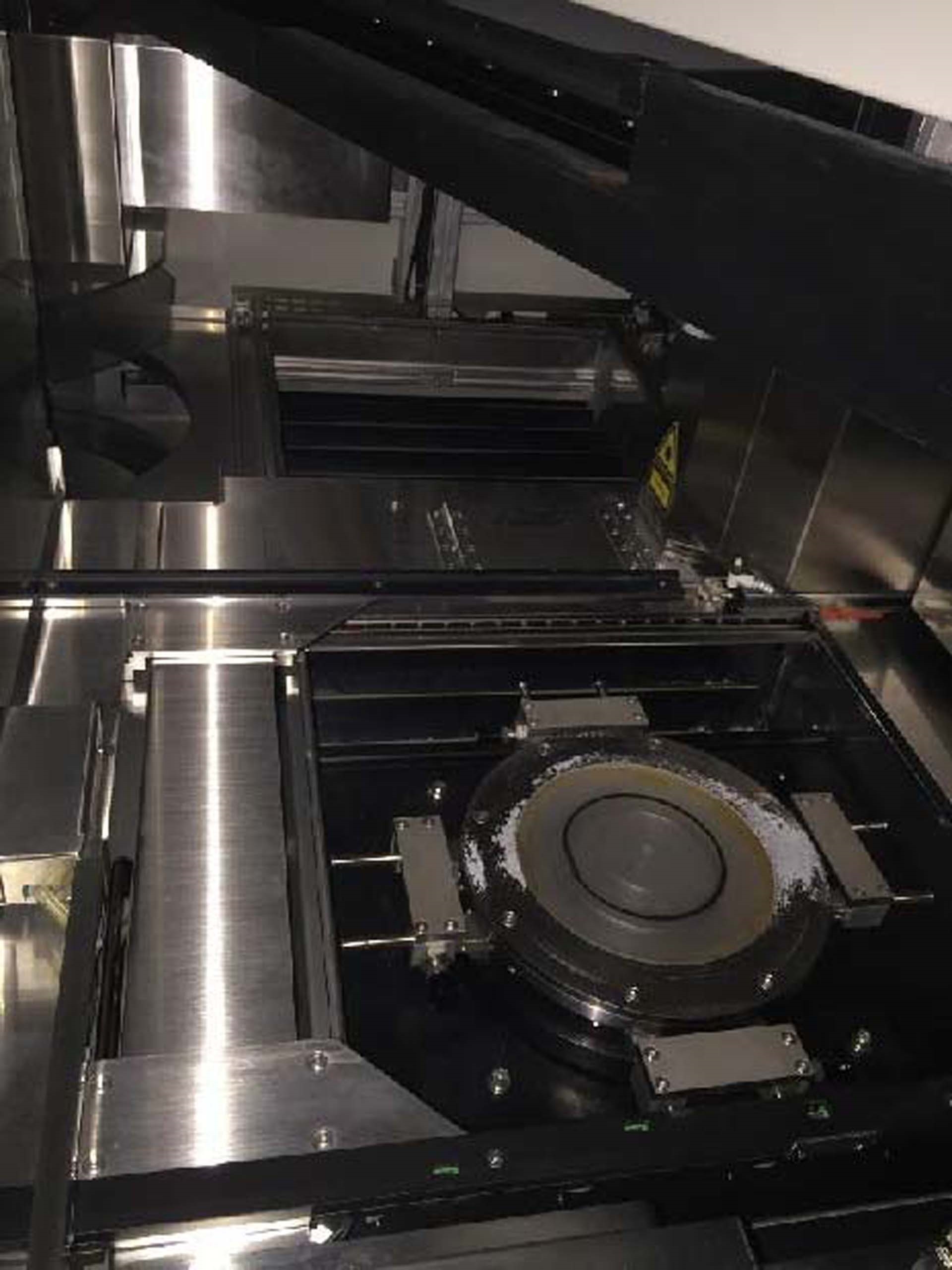

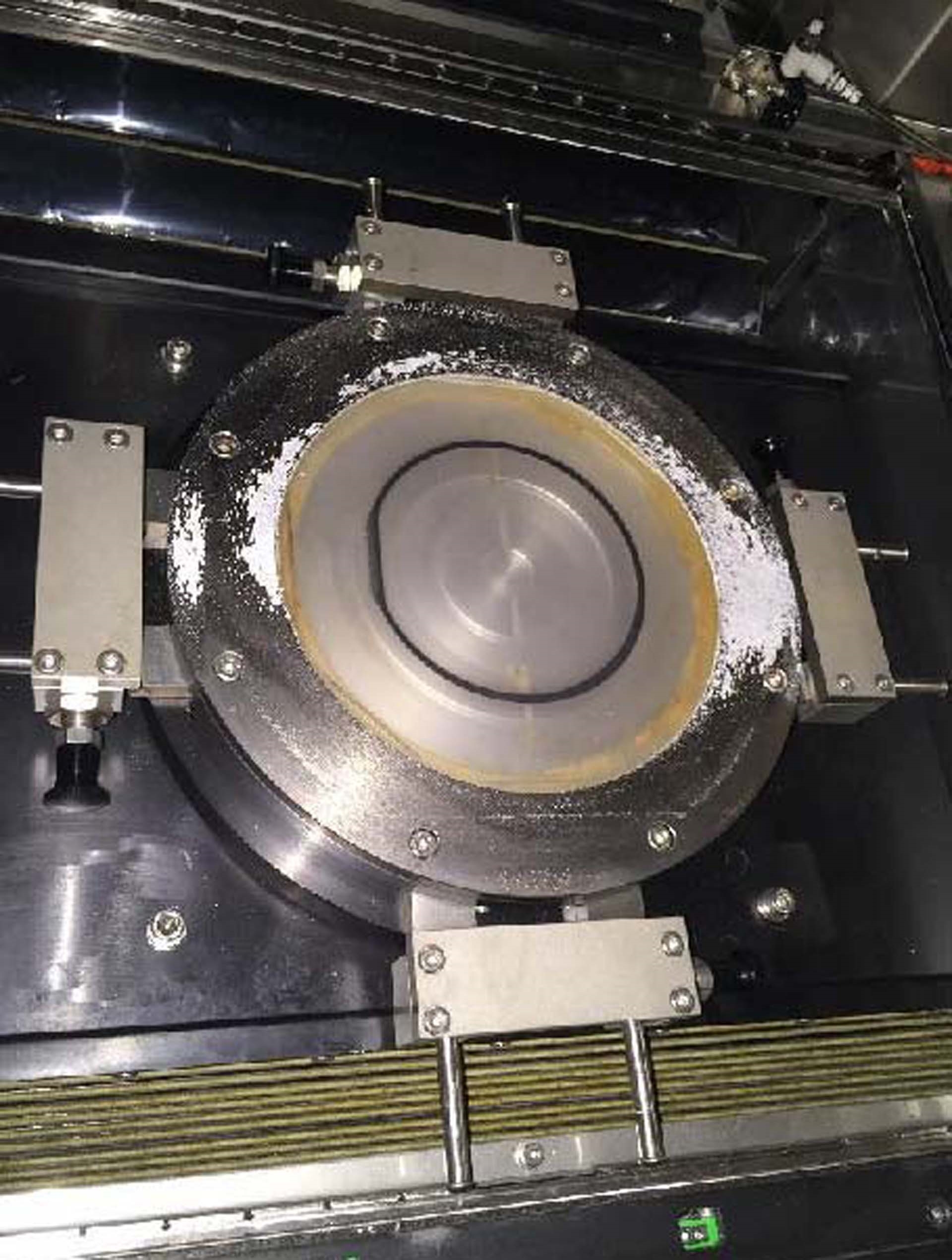

DISCO DFL 7160 is a highly advanced scribing/dicing equipment designed for use in mass production of microelectronic components. It offers a wide range of cutting and scribing processes for processing substrates such as silicon, quartz, silicon carbide, sapphire, and other optoelectronic materials. With DISCO DFL7160's high-speed galvo scanning, controlled by its SIIOS™ visualized scanning software, precision scribing and dicing are achieved with ease. Its laser scribing capabilities range from micrometer-level precision to up to 200um depth. Its spindle head is capable of reaching up to 30,000 revolutions per minute allowing for fast and accurate scribing. DFL-7160 is also equipped with a motorized XY stage that can be used to adjust the cutting length, width, and orientation. This allows for precise control of the cutting area. DFL7160 is also equipped with a CCD sensor to assist with automatic alignments and cycles, further enhancing the precision and accuracy of the system. The SIIOS™ visualized scanning software allows the operator to set up and adjust the scribing/dicing cycles quickly and easily with the help of 3D visualizations of each step. DISCO DFL-7160 is designed to be able to process substrates up to 127mm in size. It also features a modular feeding unit with multiple feeder lines and a collecting plate which can be used to achieve high volume production. It also features a touchscreen interface which allows the user to quickly enter parameters such as type of scribing lasers, speed, size of substrate, and other settings. Finally, DFL 7160 is also equipped with a waste management machine, designed to capture all waste generated during the scribing/dicing process. This ensures that all waste is properly stored and managed, while minimizing the environmental impact of the process. Overall, DISCO DFL 7160 is an advanced and powerful scribing/dicing tool designed to meet the demanding requirements of mass production microelectronic component production. Its high speed galvo scanning and precise control capabilities make it an ideal solution for high volume production. Its modular feeding asset and waste management model make it a great choice for environmentally conscious operations.

There are no reviews yet