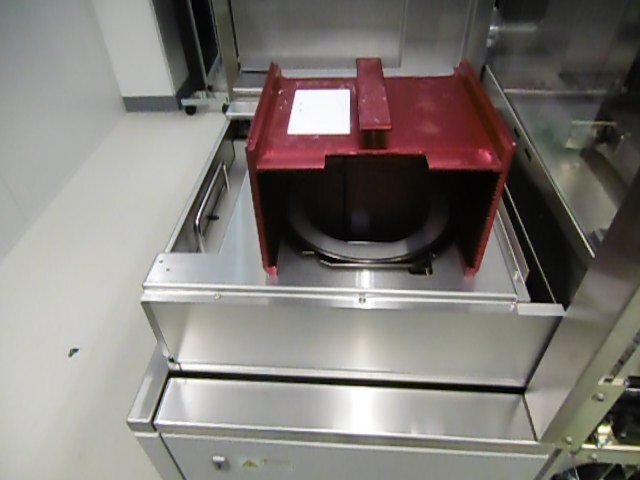

Used DISCO DFL 7161 #9220486 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9220486

Vintage: 2011

Fully automatic laser saw

(3) Chucks table, 6"

Field of application: Germanium wafer

Process chamber (Glass)

Coating and spinner (Porous)

Configured for cutting semiconductor substrates

Running hours: 383

Standby hours: 30,640

Laser head hours: 3743

Laser:

COHERENT AVIA 355-28 Power curve

Type-K with BSS4 Optical system

Head hours: 3,743

Nozzle: K-02

Pulse: ~30 ns

28 W of 355 nm at 110 kHz

E-Beam

Perm align solder-bonded optics technology

Aluminum-Free Active Area (AAA) (Diode material)

Field replaceable pump diode modules

Smart power supply with RS-232 interface

Pulse control system

HGX UV Generation technology

ThermEQ For uniform pulse energy across a burst of pulses

PulseEQ For locked pulse energy across a range of pulse repetition rates

PulseTrack For on-the-fly pulse energy control

Wavelength: 354.7 nm

Average output power:

26 W at 90 kHz

28 W at 110 kHz

23 W at 150 kHz

18 W at 180 kHz

Nominal repetition rate: 110 kHz

Beam optimization: 110 kHz

Motorized crystal shifter: 75 Spots/300 hours

Pulse repetition rate single-shot: 300 kHz

Pulse-to-pulse stability (Up to 140 kHz): <5% (1σ rms)

Average power stability (Over 8 hours): <2% (2σ rms)

Polarization ratio²: >100:1 Horizontal

Spatial mode²: TEM00 (M2 <1.3)

Beam divergence full angle²: (mrad): <0.3

Pulse width: <40 ns Up to 110 kHz

Beam pointing drift³: <25°C/μrad

Near-field pointing and rep. rate with posilock: 50 μm

1/e² Beam diameter²: 3.5 ±0.35 mm

Beam circularity: >85%

Warm-up time:

Standby mode: <15 Minutes

Cold: <40 Minutes

Bore-sight accuracy: ±0.5 mm and ±5 mrad

RoHS Compliant

Utility:

Single phase operating voltage: 100 to 240 VAC (Auto ranging)

Line frequency: 50/60 Hz (Auto ranging)

Laser power consumption: 900 W, 1.7 kW Maximum

Missing housing components:

LPAC-022222-1 Cover (R, F)

(2) LPAC-022223-3 Covers (R, B-R)

LPAC-022151-2 Cover (F, L)

2011 vintage.

DISCO DFL 7161 is a scribing and dicing equipment designed for precision wafer semiconductor processing. It features dual scan dual laser technology and an independent cross-axis for each laser beam. This allows it to create accurate gridded patterns within high-precision tolerances and is suitable for a variety of processes. DISCO DFL7161 has an elevated optical path design that allows for a wide range of wafer sizes and can be connected to equipment used for chemical mechanical polishing (CMP) as well as other wafer processes. It has an integrated design that eliminates the need for jigs, helping improve production efficiency, while its high-speed processing capability ensures it can keep up with the latest semiconductor production processes. DFL 7161 has a special feature that eliminates the need for an engineer to monitor the alignment process, allowing operators to minimize setup and calibration time. It can also be equipped with an enhanced laser control unit to reduce laser aberrations and control multiple lasers easily. This scribing and dicing system also supports auto compensation capabilities, which automatically detect wafer surface differences and compensate for them accordingly. The laser power adjustment unit is able to adjust the laser power according to different wafer types and its cutting accuracy can be fine-tuned for each wafer to ensure that the most consistent cut is produced. DFL7161 is a durable machine that can withstand long-term operation and meet ISO 14001 environmental specifications. It has excellent usability and support, making it easy to integrate with other tools. Plus, its discharge interval management is optimized for reducing waste and controlling costs. DISCO DFL 7161 is an essential scribing and dicing machine for precision semiconductor processing. Its dual laser technology, precision tolerances, and auto compensation capabilities make it ideal for creating accurate gridded patterns with high production efficiency. Furthermore, its reliability and ease of operation makes it a great investment for any semiconductor production line.

There are no reviews yet