Used INNOLAS / MERRIT PRECISION Impala Multibeam #9128357 for sale

URL successfully copied!

Tap to zoom

ID: 9128357

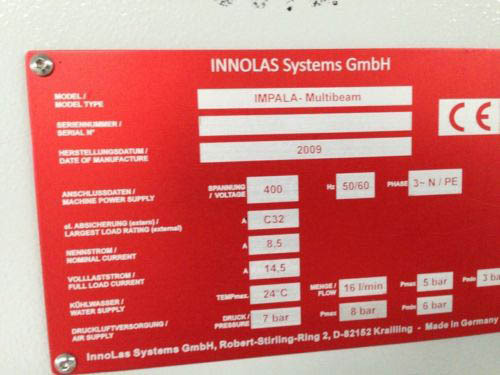

Vintage: 2009

Laser scriber

Format: 125 x 65 cm

(5) Process heads

Insulating track

X, Y, Z, A, and U - axis

CNC Controlled

Molybdenum metal layer / Glass sheets

Includes:

Documents

Drivers

Control cabinet

(2) Needle patterning

Calibration station

Laser patterning

Operation Storage Transport

Temperature 22 °C +/- 4°C +10 bis +40°C +10 bis +40°C

Moisture 30% bis 55% r F 5% bis 80% r. F 5% bis 80% r. F

Electrical requirements:

400 VAC, 3Ph+N+PE, 50/60 Hz, +5%-10%

Power consumption max./average: 3 kVA, 2 kVA

Protection: 32 A Pro phase

Cooling water:

Waste heat: Max.3.5 kW

Coverage: 3 -6 bar

Dure hulike: Min.12 l/min / max. 20 l/min

Differential pressure: Min. 3 bar

Water temperature: Min. 20°C, max. 22°C

Heat dissipation (Allowed): +/- 2°C

Ambient temperature: 20°C - 30°C

Compressed air:

Input pressure: Min.6 bar / max.8 bar

Consumption:

Type: 150 l/min

Peak: 250 l/min

Air quality: ISO 8573-1 class 3

Steckver binder NW 16 mm (OD)

Volume: Min.600 m³/h

Pressure: 60 mbar

DN 100 (110 x 5)

Filler: Cabin exhaust not filtered

Suction cup:

Volume: 100 m³/h

2009 vintage.

INNOLAS / MERRIT PRECISION Impala Multibeam is an advanced scribing and dicing equipment technology used for laser material processing. It features a number of precise and reliable capabilities such as ultra-fine scribing, high accuracy slicing, and intricate dicing. The system's dynamic optics provide dynamic beam characteristics, making it ideal for a large range of materials from high temperature to soft. The Impala utilizes a resonator-based laser source that has a power range of up to 3,000W and offers a wide range of laser materials, including silicon, glass, and metal. Additionally, its innovative cutting modes include single line, multi-line, and vector cutting to handle complex geometries with ease. In addition to high accuracy cutting, the Impala is designed to be extremely versatile for various applications. With intuitive software, it can produce a variety of structures in minimal time with minimal waste. Thanks to its short pulse length and high pulse repetition rate, clean cuts are easily achieved in both slow and fast speed. Additionally, its advanced unit control allows for precise control of the cutting parameters. The Impala's temperature-controlled laser head provides temperature stabilization to ensure consistent cutting and scribing quality. Additionally, the machine may be used in a nitrogen or air-controlled environment in order to minimize oxidation and carbon fragmentation during cutting and/or scribing. The Impala is designed with ergonomic features to ensure operator comfort and safety as users can access the operating centre without having to bend over or twist their body. With all these features, the Impala is an ideal tool for precise, efficient, and reliable material processing.

There are no reviews yet