Used K&S 775-4 #48115 for sale

URL successfully copied!

Tap to zoom

ID: 48115

Wafer Size: 6"

High powered dicing saw, 6"

Magnetic chuck (does not rotate)

Can be converted to vac chuck (this chuck would not rotate)

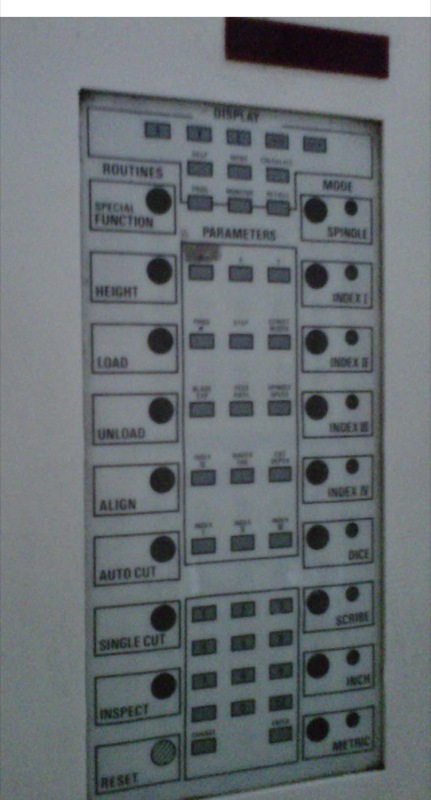

Computer controlled

TIC software

Includes: video camera and monitor.

K&S 775-4 Scribing and Dicing Equipment is a fully automated solution for microelectronic device processing. It efficiently processes and prepares substrates for the production of microelectronic components. It is the perfect solution for applications requiring high accuracy and precise scribing/dicing capabilities. The system utilizes a state-of-the-art dual field focusing optics for precise scribing/dicing. It processes substrates of various sizes, shapes and thicknesses, from 3" to 12". 775-4 operates in two separate chambers, a Load Chamber and a Process Chamber. The Load Chamber holds the substrate in a carrier, while the Process Chamber contains the optics, laser and mechanical cutting components. Once the substrate is loaded, K&S 775-4 is capable of scribing/dicing up to 4 lanes at a time. The maximum size of each scribe line is also adjustable, allowing for maximum flexibility and accuracy. The laser is tuned to provide a clean cut, with little to no debris or rough edges. 775-4 also features multiple safety features and failsafe systems, ensuring maximum safety of the user, operators, and the unit itself. The machine is also easy to maintain, with easy access to internal components should maintenance be needed. Additionally, it has an intuitive user interface for easy operation and set-up. Overall, K&S 775-4 is an excellent choice for a reliable, accurate and cost-effective scribing/dicing solution. It is the ideal solution for high-volume production of microelectronic components. With its robust design and easy to use controls, it is the perfect complement to any microelectronic production process.

There are no reviews yet