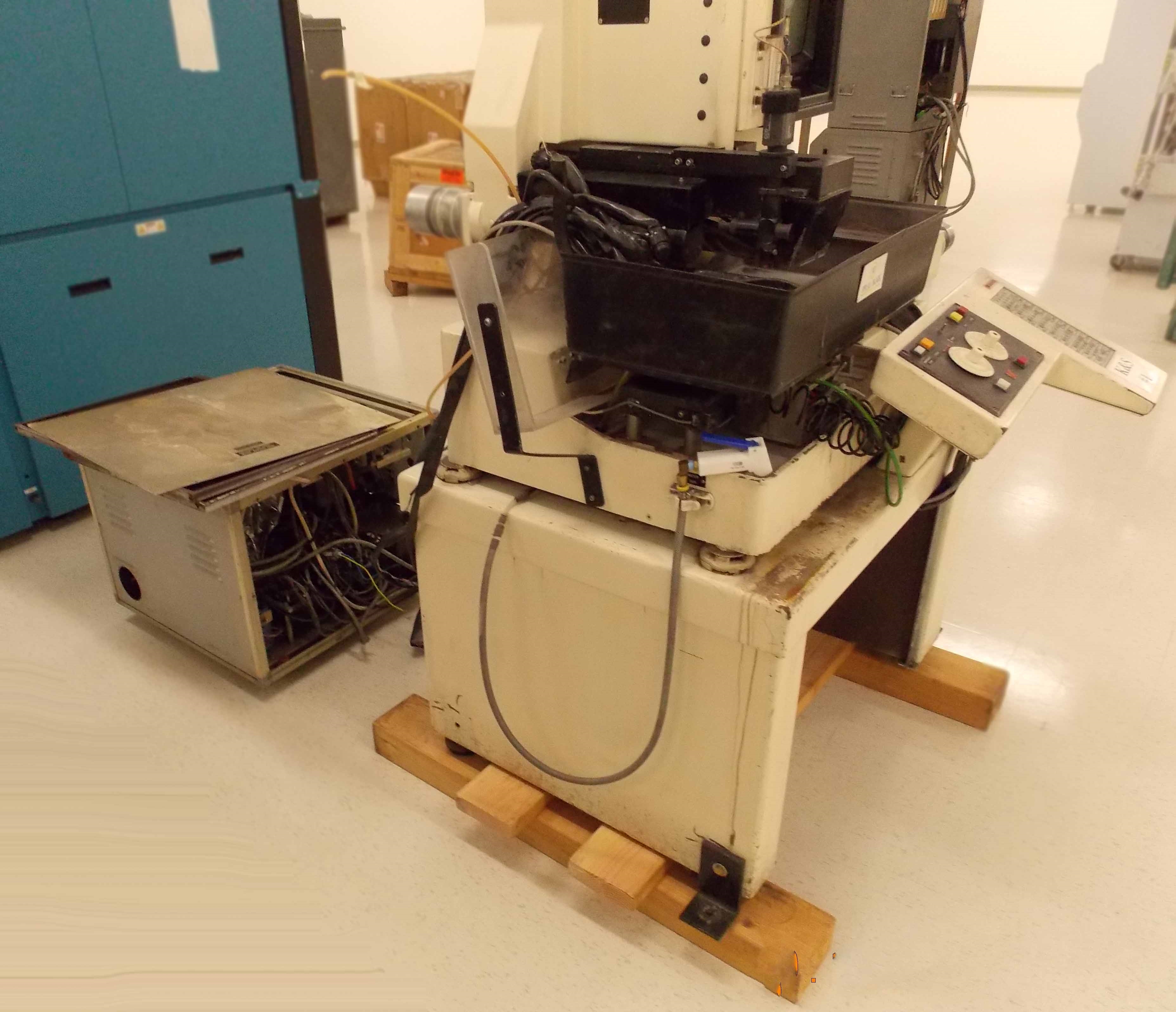

Used K&S 775 #9193292 for sale

URL successfully copied!

Tap to zoom

K&S 775 'Scribing / Dicing' Equipment is a next-generation processing technology for semiconductor manufacturing. It allows for precise cutting and structuring of semiconductor surfaces during fabrication. The system is designed to optimize the creation of defined elements with tighter accuracy and meeting more aggressive production tolerances compared to traditional scribing/dicing systems. 775 is operated by a compact UV laser generator, operating at 355nm, which provides higher precision and accuracy and is coupled with advanced motion control systems. The unit is also equipped with a superior optical focusing machine to tightly focus the laser beam to an extremely small spot size, enabling excellent dielectric scribing/dicing. K&S 775 also features a precision centering and alignment tool, providing a precise and continuous wafer scan with increased accuracy and repeatability. The built-in dual-axis scan stage is able to position and delineate with great precision with a single pass. This allows 775 to produce scribing/dicing lines with widths down to 20um and separation distances of several dozen microns. The asset also incorporates a blade-based dielectric cutter with improved durability and precision compared to traditional systems. Coupled with the laser generator, the blade-based dielectric cutter is able to scribe, dice and fine cut wafers in one action with accuracy and repeatability. K&S also offers the necessary tools for integration and commissioning of the model, allowing users to quickly and effectively calibrate and set up the equipment for optimal performance according to the desired application. In addition, the system allows for monitoring and instantaneous preview of the process. K&S 775 is supported by powerful integrated motion controls and sophisticated post-processing functions to provide exceptional cutting capability, accuracy and repeatability. The unit is easy to use, has a low learning curve and is capable of handling different production needs in both high and low yield processes. This makes it ideal for the creation of complex products and micro- scale structures demanded by semiconductor manufacturing and is a key component for the further development of integrated circuit production.

There are no reviews yet