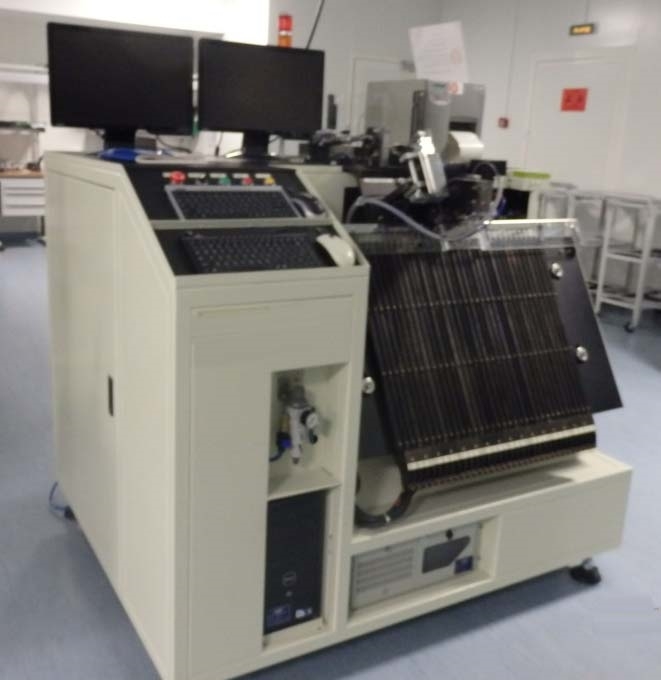

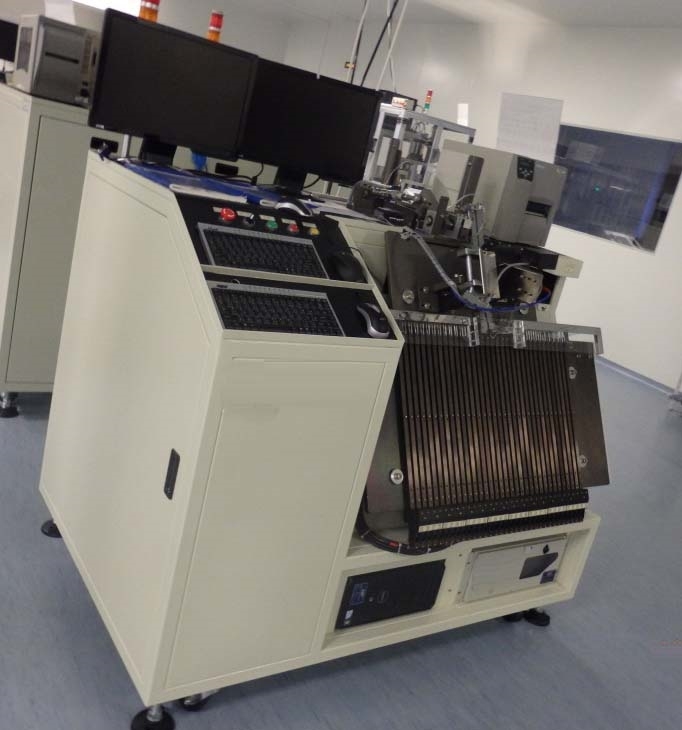

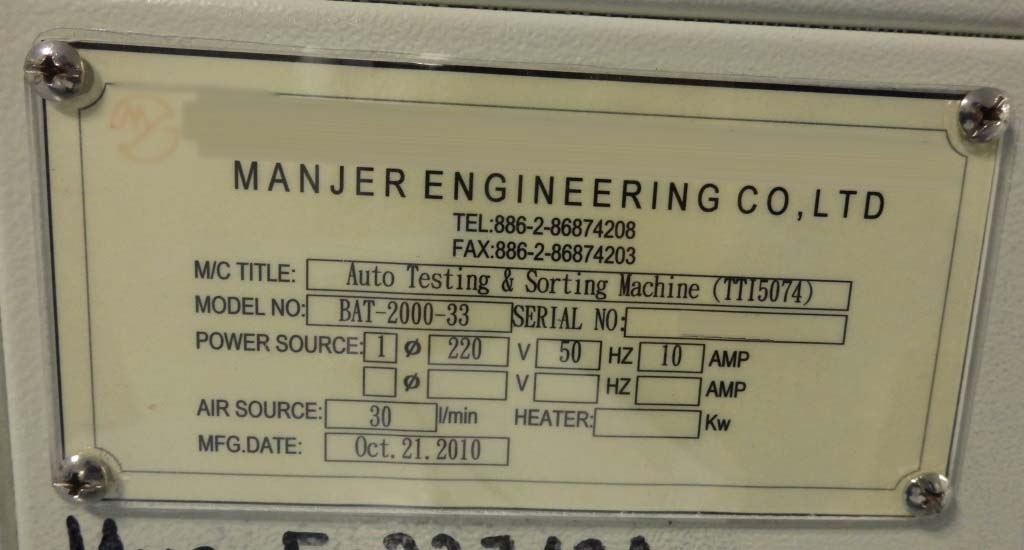

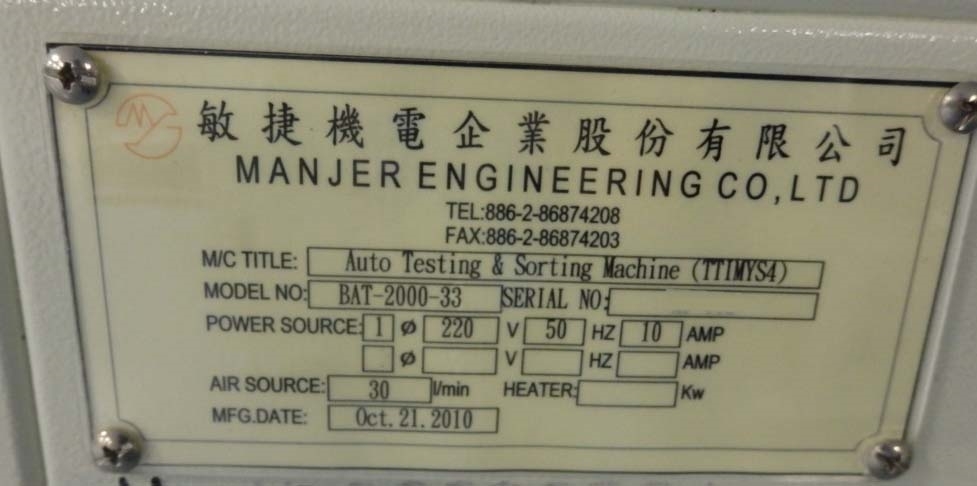

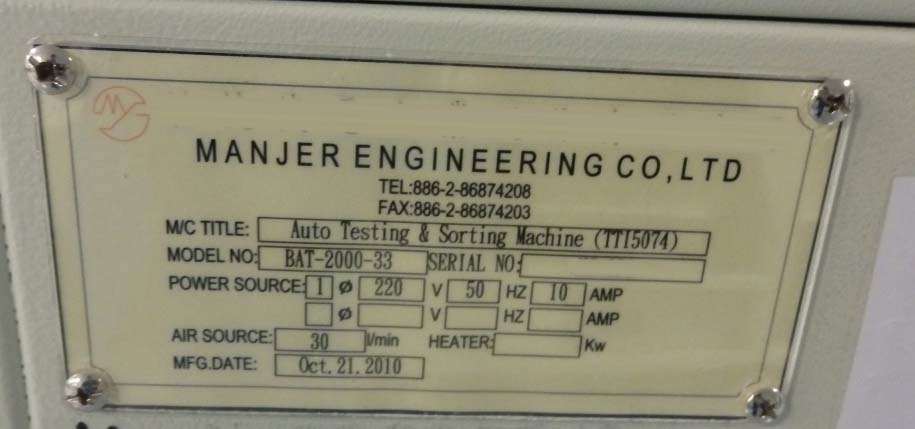

Used MANJER ENGINEERING BAT-2000-33 #9284246 for sale

URL successfully copied!

Tap to zoom

MANJER ENGINEERING BAT-2000-33 is a scribing/dicing equipment specially designed for precision applications. This system utilizes a high-speed air-bearing spindle which is driven by a direct drive motor with integrated encoder for precise speed control. The maximum spindle speed is up to 130,000 RPM. It also has a dielectric fluid supply which ensures precise cutting of fragile materials. The scribing/dicing unit is equipped with specialized indexing mechanisms including standard and coolant jets attachments for precise cutting of various materials such as silicon wafers, sapphire, quartz, ceramic and carbon fiber. Its patented vertical and horizontal spring-loaded machine ensures precise cutting depths while the automatic camera tool monitors the cutting process for improved accuracy. The asset contains a CNC precision stage for precise positioning and repeatable processing to achieve extremely accurate cut sizes. The CNC stage is connected to the spindle with a durable, low-friction air bearing that allows for stable operation and high-frequency moving. BAT-2000-33 is also capable of processing a variety of composite materials including polyimide, polyamide, and polyester using its high-power infrared laser cutting head. The laser is guided by the CNC precision stage to accurately cut complex shapes in these materials. The model is also capable of processing delicate glass, polycarbonate, polyurethane, and acrylic materials using its finely-tuned CO2 laser. The scribing/dicing equipment is equipped with an advanced monitoring system which includes several parameters such as temperature, pressure, force, temperature coefficient of thermal expansion (TCE), laser cutting speeds, and spindle speeds. The monitoring unit can be connected to an Enterprise Resource Planning (ERP) machine for better production and performance monitoring. MANJER ENGINEERING BAT-2000-33 is designed for processing high-precision components with extreme accuracy. Its specialized mechanism, CNC precision stage, and advanced monitoring systems make it ideal for applications in many industries such as high-tech electronics, computers, aerospace, automotive, semiconductors, solar energy, and many others.

There are no reviews yet