Used MITSUBOSHI DIAMOND INDUSTRIAL / MDI LC 800 #9246275 for sale

URL successfully copied!

Tap to zoom

ID: 9246275

Laser cutting machine

With UC-2000 laser controller

9010 LCD For gas detector

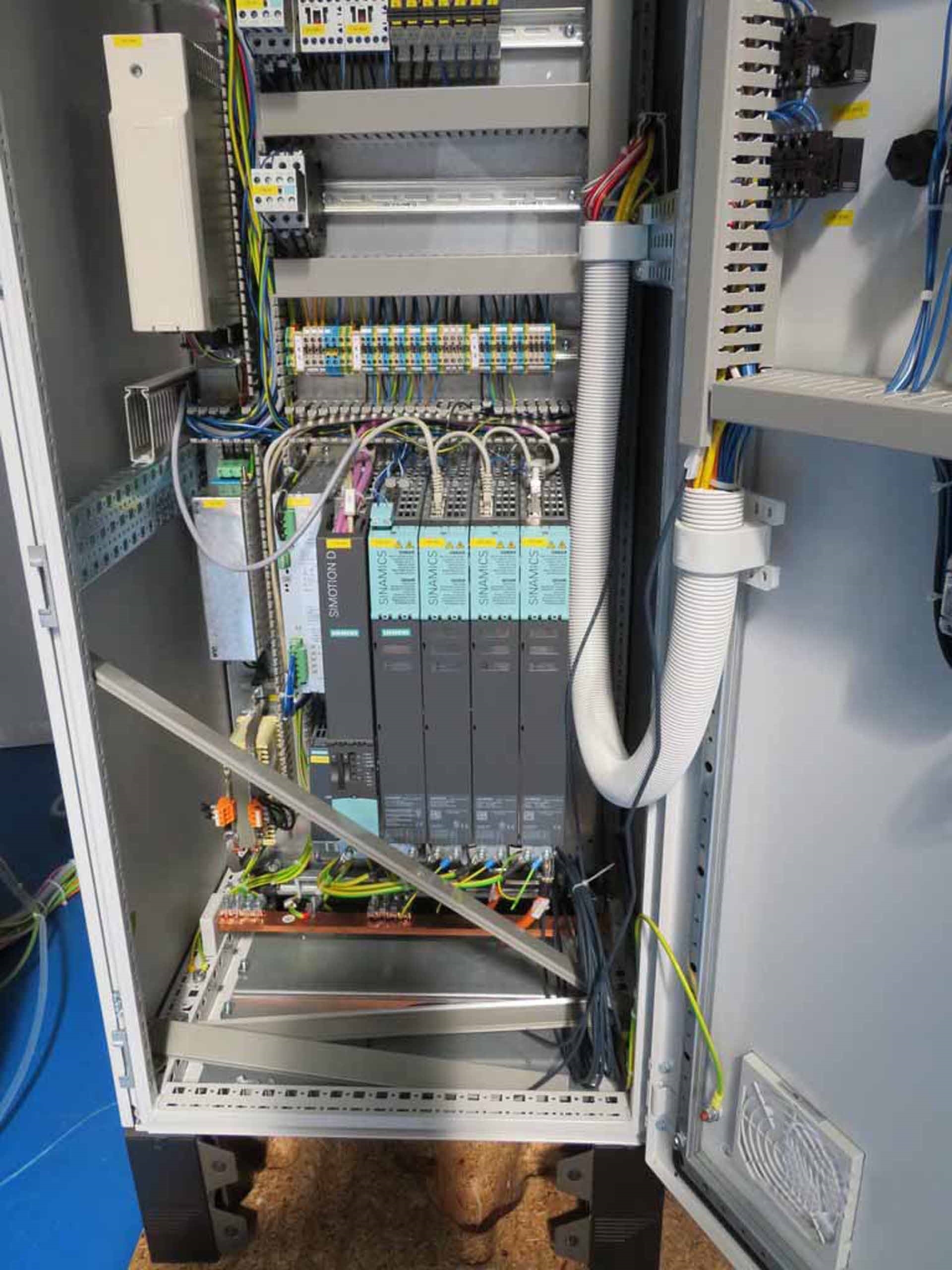

Control: SIEMENS S7-300 and SIEMENS Simotion spindle drives

Rotation axis: Harmonic drive

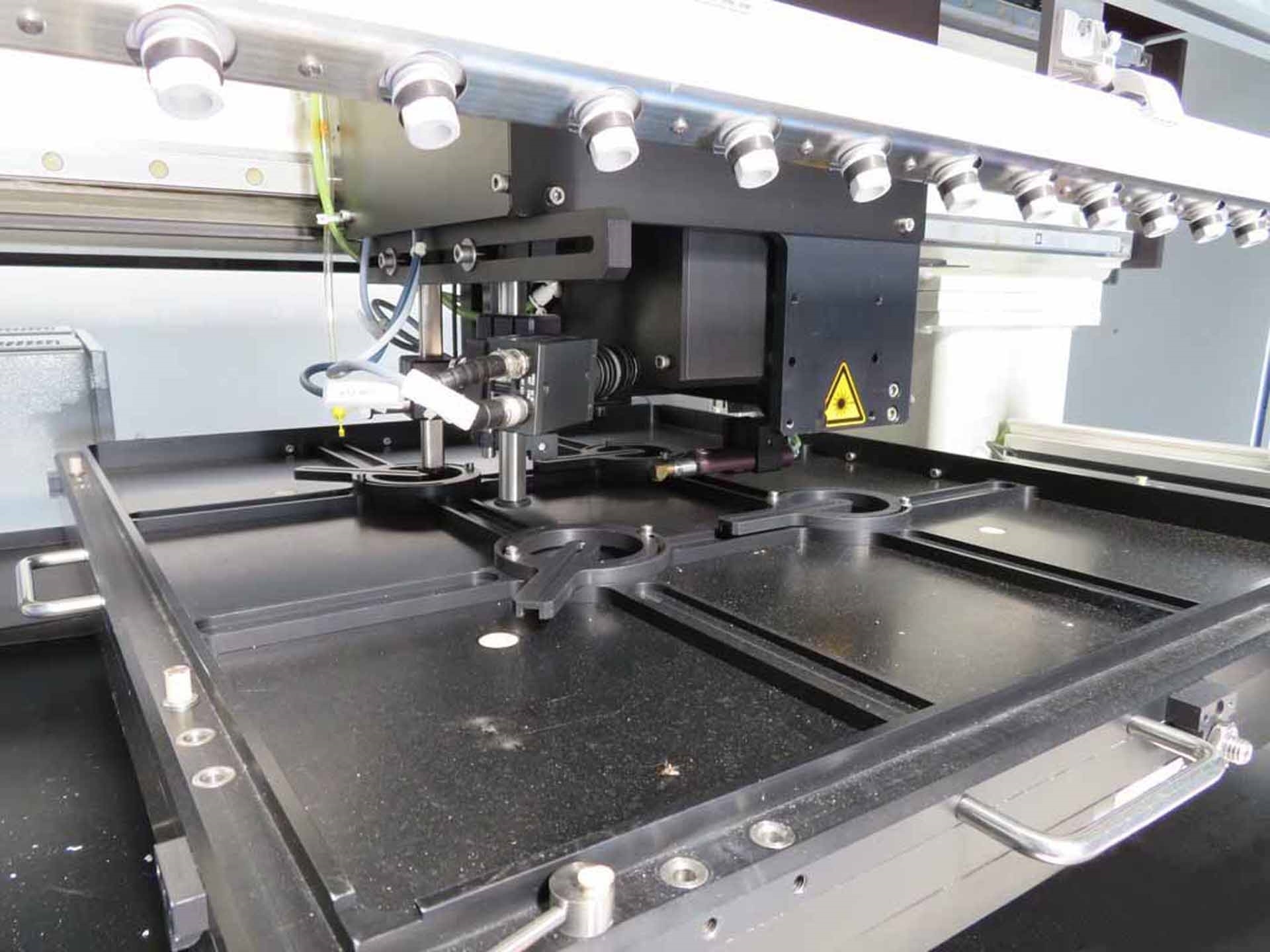

Table size: 810 mm x 680 mm

Maximum substrate size: 650 mm x 780 mm

(2) Cutting heads

Work-piece clamping: Laser cut frame for laser cutting

Vacuum plate for film cutting noise level: <75 dB (A)

Substrate data:

Substrate thickness: Glass thickness 1.1 mm

Film thickness approx: 1 mm

Maximum glass size 650 mm x 780 mm

Materials to be processed: EAGLE XG / OA-10

Laser data:

Laser type: CO2 Laser

Wavelength: 10.6 pm

Maximum laser power: 100 W

Laser protection class (laser): Laser class 4

Laser protection class (machine): Laser class 1

Power supply: 3 x 400 VAC NPE, 50 Hz

Connected load: 9 kVA

Control voltage: 24 V

Main fuse: NH 00 35 A

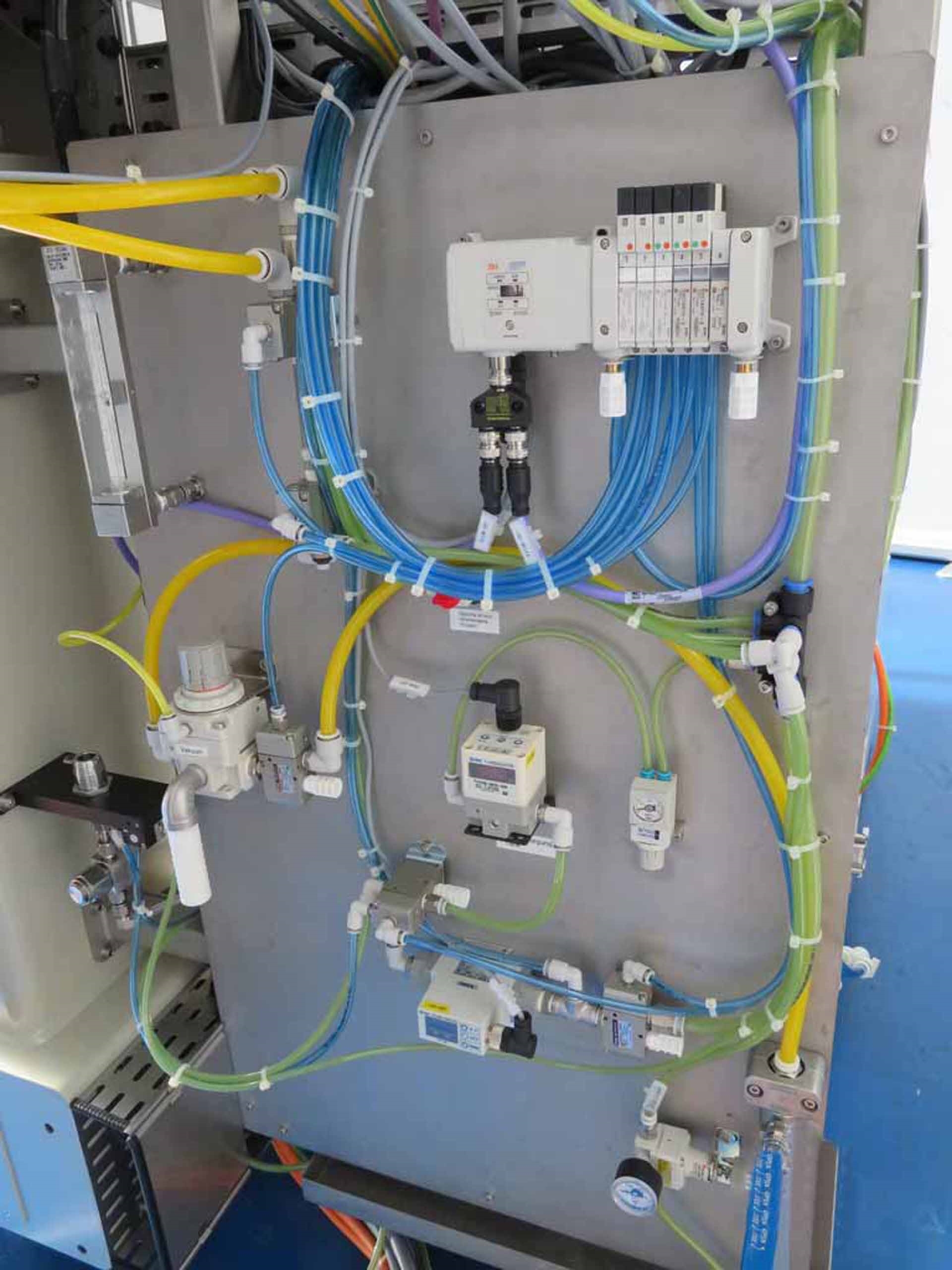

Compressed air: 6 bar (± 0.5 bar)

Vacuum flow: 3.6 mm³ / s

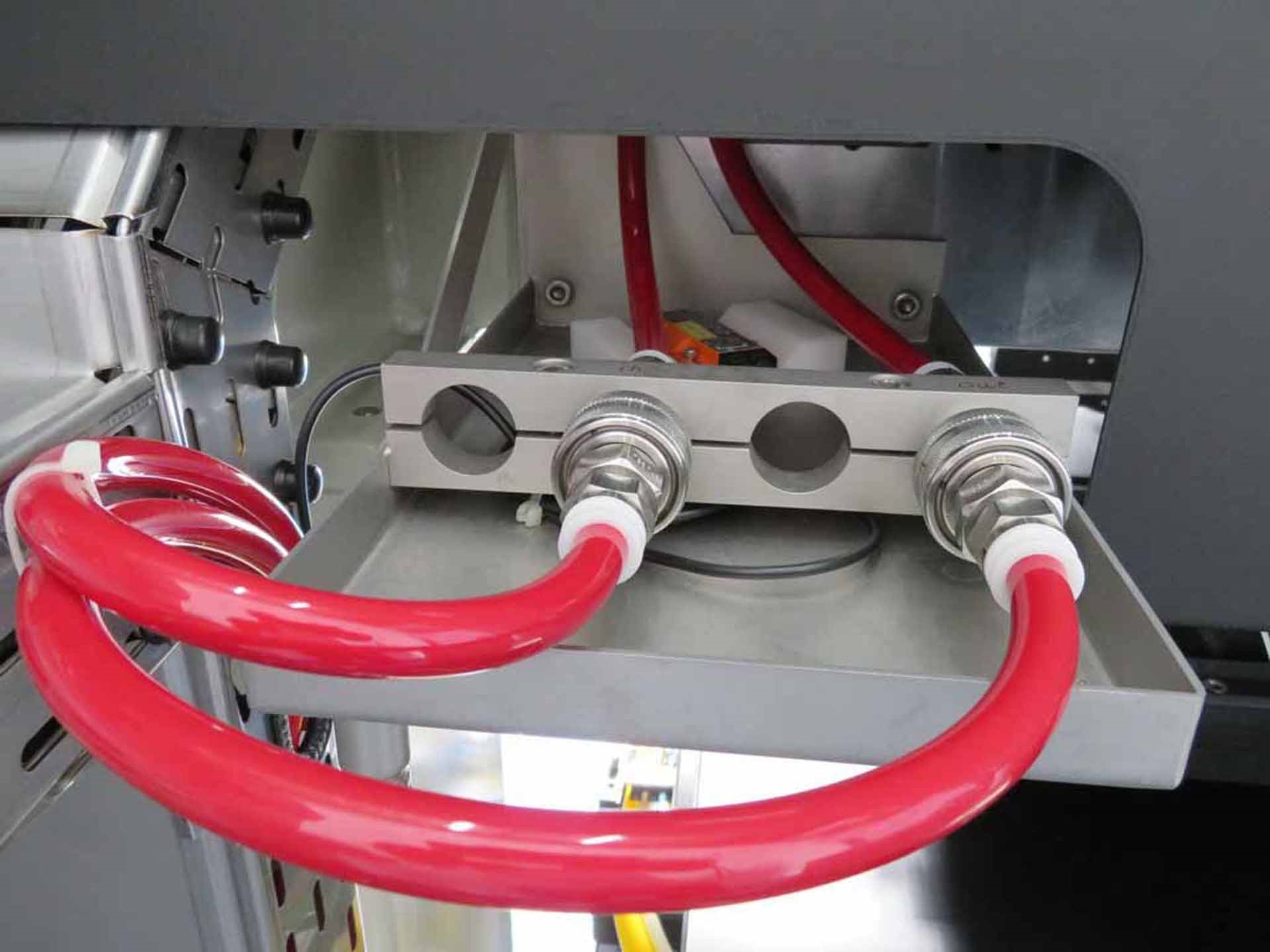

Cooling: Water ethanol air mixture process

Gas: Nitrogen (N2): 0.53 MPa (± 0.03 MPa).

MITSUBOSHI DIAMOND INDUSTRIAL / MDI LC 800 is a high-precision scribing and dicing equipment designed for use in the electronics, photovoltaic, and semiconductor industries. It is capable of performing two distinct processes: scribing and dicing. MDI LC 800 is designed to accurately and efficiently scribe and dice thin wafers. Its high-resolution linear motor and controlled beam supply a range of cutting options at variable depth. This provides the flexibility to accommodate wafers of various sizes and shapes. The system also features advanced data handling capabilities, which enables precise product programming and measurement output. The individual components of the unit can be freely reconfigured for optimal operation. A unique laser-marking machine permits the creation of intricate text or logos on different types of wafers. The LC 800is designed to scribe with a low beam power setting, creating even depth cuts with minimal heat generation. The tool's advanced deep-etch scribing depth ensures a more accurate cut than its counterparts. This enables fine control over the shape and size of the contours that a required for dicing and other applications. The machine also includes a quick-mix chiller with a set temperature and pressure output to ensure uniformity between hot and cold temperatures in the asset. The quick-mix chiller is also more eco-friendly than a traditional single-loop model, reducing energy consumption and providing easy cleaning for maintenance. MITSUBOSHI DIAMOND INDUSTRIAL LC 800 is also equipped with multi-axis robotic manipulators, allowing for freely controlled motion of the robotic arms. This allows the robotic arms to rotate in various directions and depths with precision. The precise and accurate positioning of the robotic arms allows for greater precision in operations such as scribing and dicing. The RC 800 is compliant with multiple safety regulations and features an ergonomic user experience for maximum efficiency. This equipment provides enhanced quality control and a long-term solution for automated scribing and dicing processes. It is a highly reliable and efficient system, making it an ideal choice for the quality-sensitive and safety-critical scribing and dicing applications.

There are no reviews yet