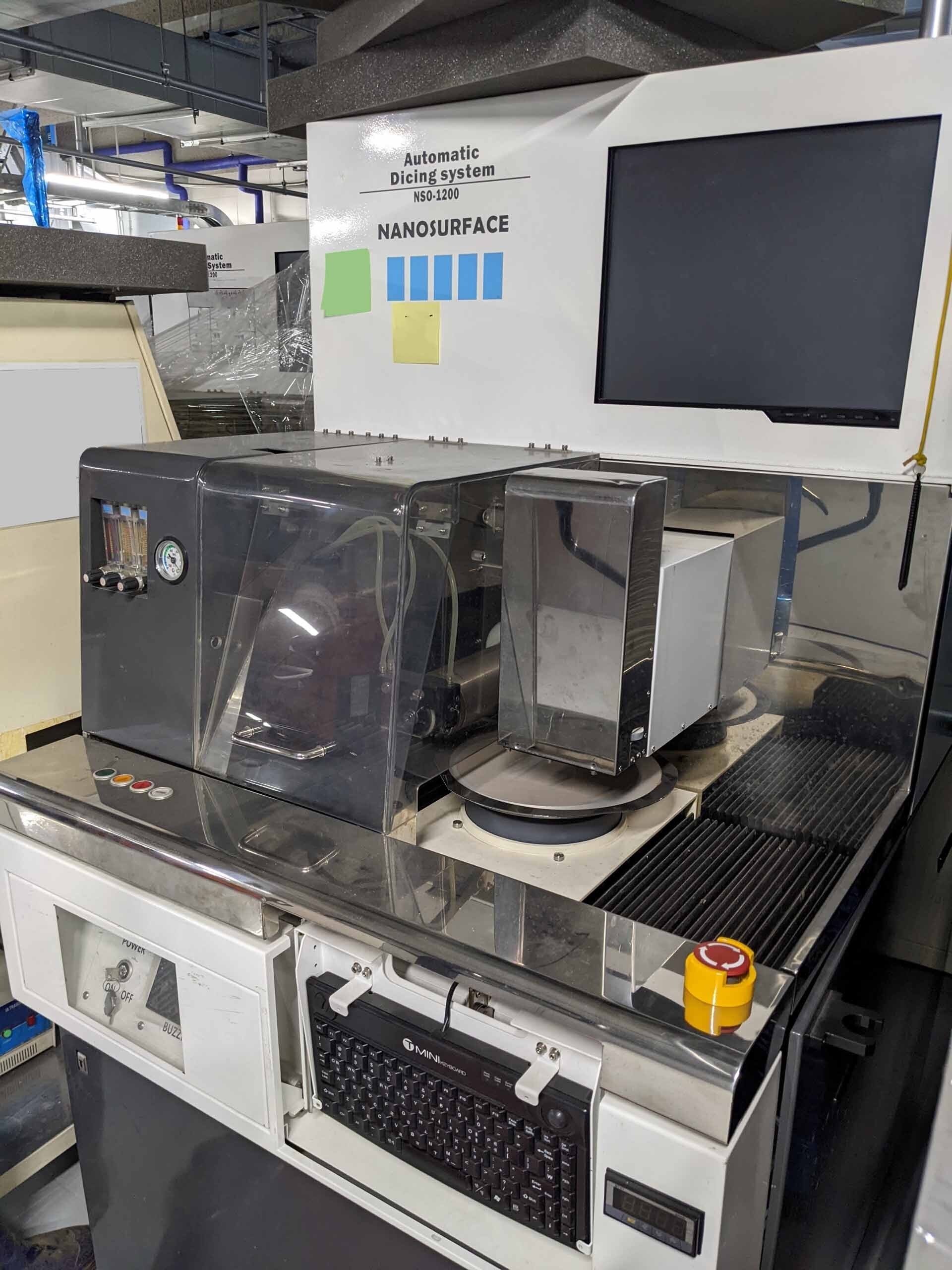

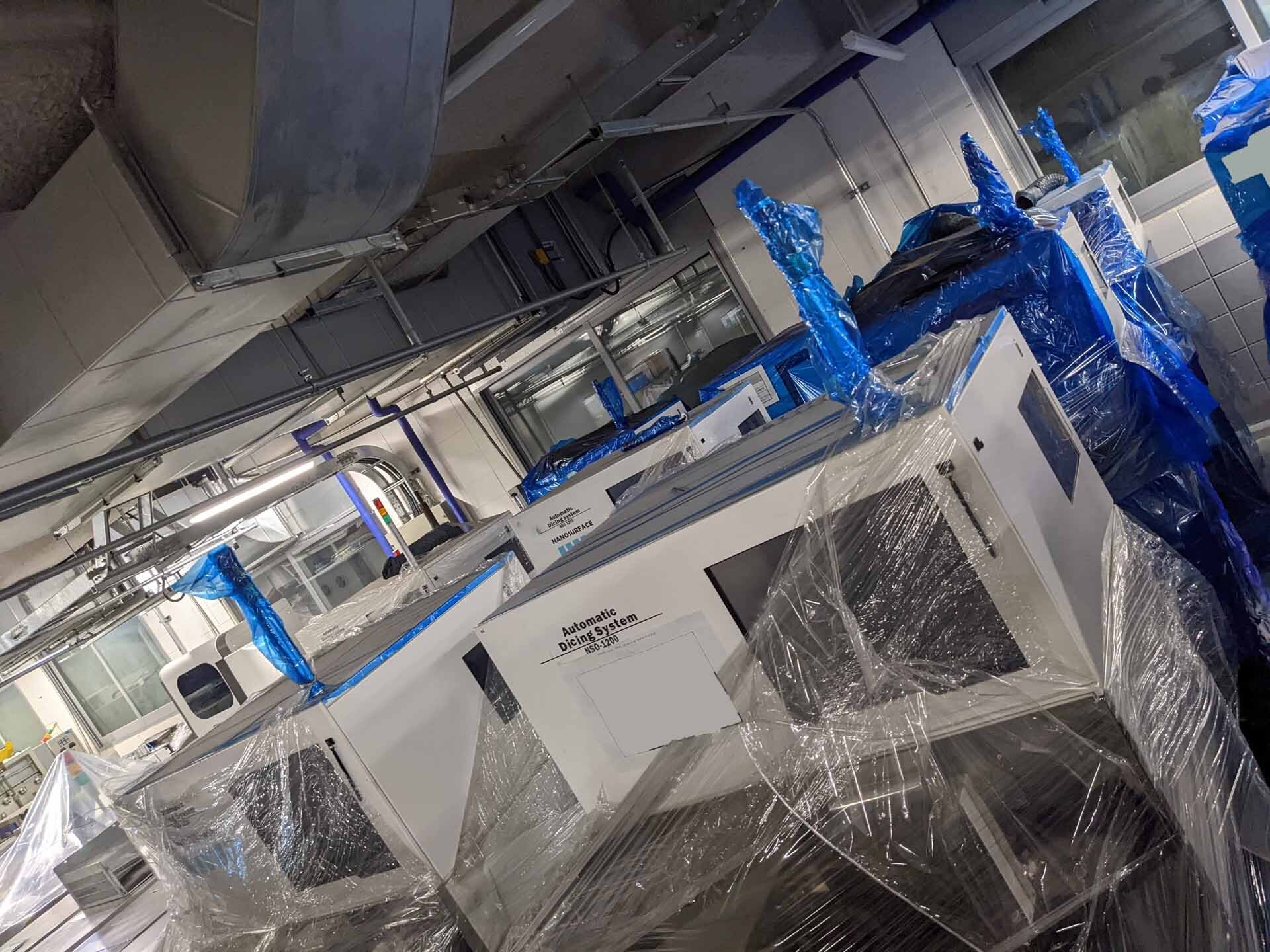

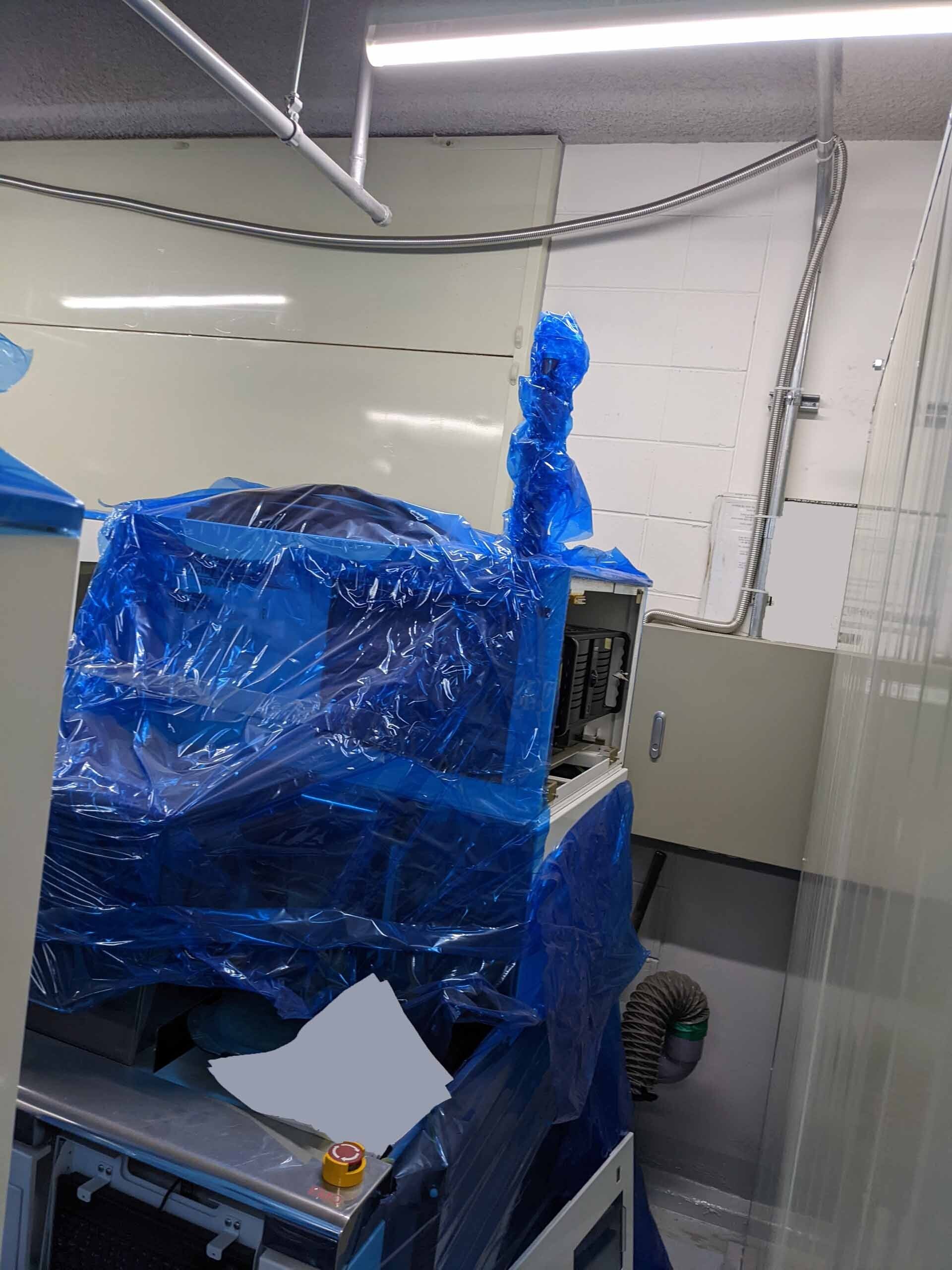

Used NTS / NANOSURFACE NSO-1200 #293643399 for sale

URL successfully copied!

Tap to zoom

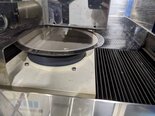

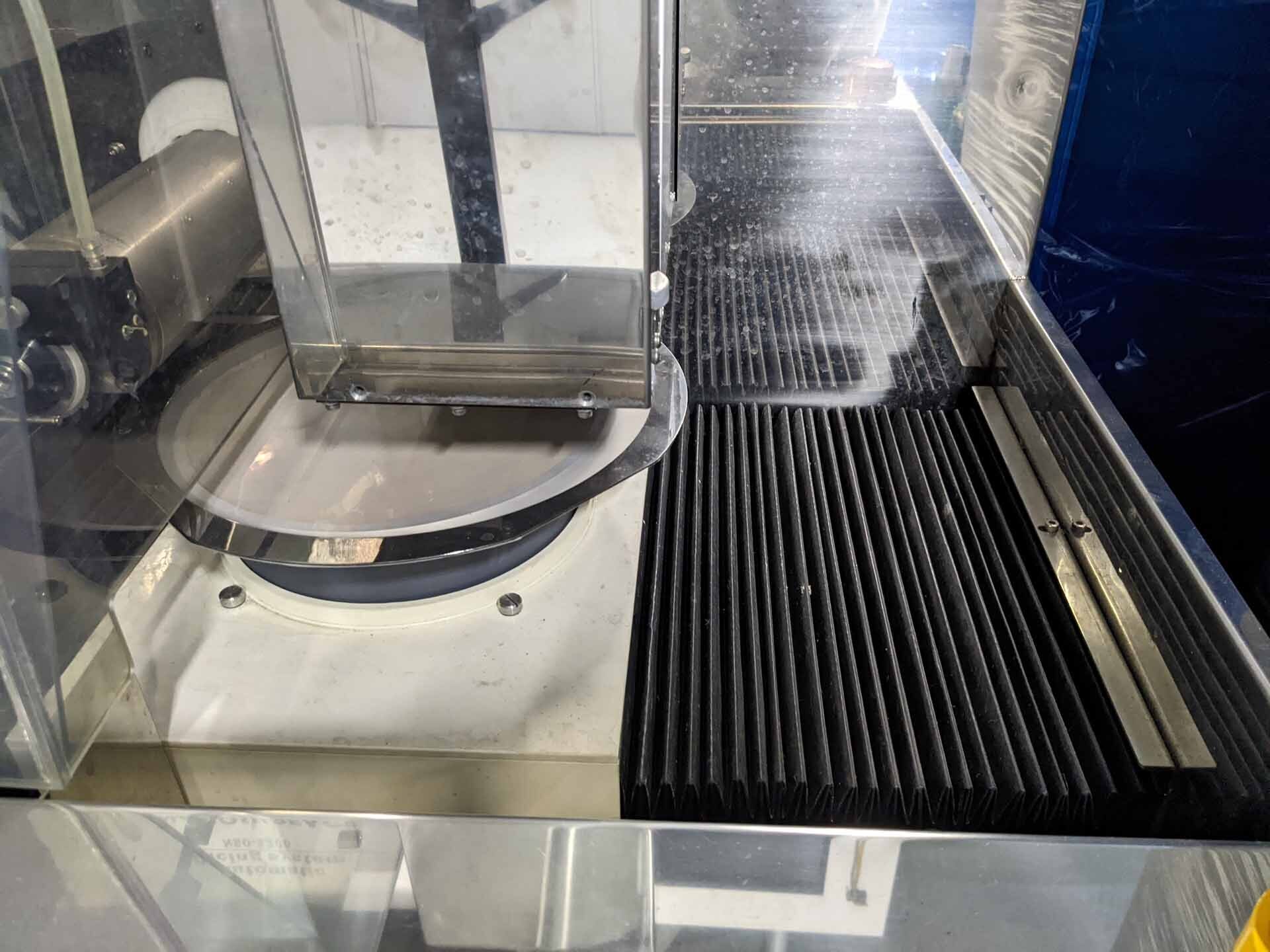

NTS / NANOSURFACE NSO-1200 scribing / dicing equipment is an ultra-precision system used for the precision ablation of hard and brittle substrates such as glass and silicon. The high speed, high precision NTS NSO-1200 unit is an advanced tool for scribing and dicing hard, fragile substrates with tight tolerances. The machine consists of a processing turret, a fixed scribe table, and a high speed air bearing dicing saw capable of slicing substrates as thin as 20 microns. Features such as automatic material detection, as well as user-friendly software, simplify processing. The turret of NANOSURFACE NSO-1200 advances each substrate individually into the scribing and dicing processes. Substrates are fed into the turret and gripped in place. They are then raised in order to reach the desired scribing and dicing height. The scribe table moves across the substrate and halves the material into strips. The strips are then diced into discrete units by the high-speed dicing saw. The saw is capable of making clean, fine cuts on brittle materials due to its air bearing tool, which brings the blade close to the substrate's surface and reduces chipping and debris. NSO-1200 is uniquely suited for machining silicon, sapphire, and other brittle materials. It can automatically detect the material type and adjust the machining parameters to achieve the desired cutting rate and accuracy. The asset can also facilitate multi-stage processes, such as etching and machining in one step. The user-friendly software provides a fully integrated model for easy operation and monitoring of the machining processes. NTS / NANOSURFACE NSO-1200's high speed, high precision cutting ability is suitable for a number of tasks, including cutting trimmable element pieces, splitting of die, trim shaping, and more. Its accuracy, repeatability and low costs make the equipment an attractive choice for a variety of ablation tasks. NTS NSO-1200 demonstrates optimal performance in abrasive machining applications and provides efficient and cost-effective processing solutions.

There are no reviews yet