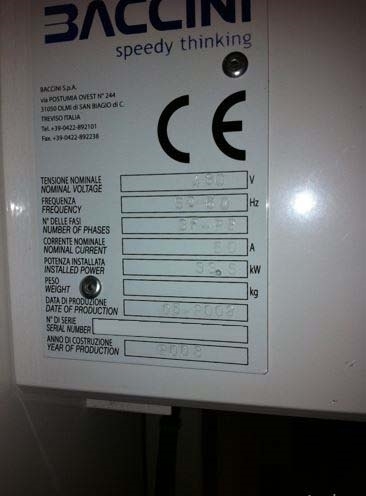

Used BACCINI / AMAT / APPLIED MATERIALS Softline 2.0 #9187077 for sale

URL successfully copied!

Tap to zoom

ID: 9187077

Vintage: 2008

Dual screen printer

Wafers semi square (Mono crystalline): 125 x 125 mm

Wafers poly Si square (Multi crystalline): 125 x 125 mm

Wafers semi square (Mono crystalline): 156 x 156 mm (95 mm Diameter)

Wafers poly Si square (Multi crystalline): 156 x 156 mm

BACCINI Line loader for stack magazines

(5) Empty magazines

(5) Full magazines

Cells each magazine: 200-300 (Depending on thickness)

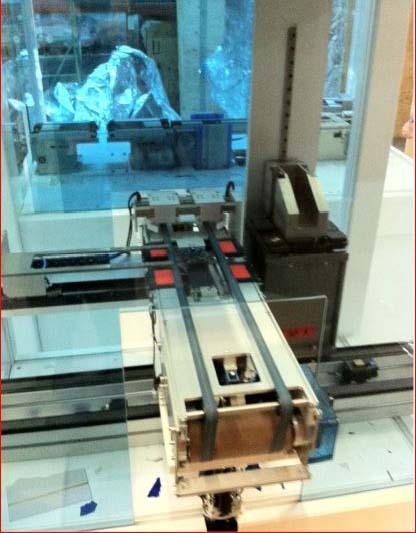

Transport belt:

Powered by servo motors are controlled by encoders

Soft rotary printer (Front print):

Fully automated high-speed solar cell printer

With rotary table and soft handling concept

Print head:

Screen frame: Type 10, 355 x 355 mm

Maximal printing area: 170 x 170 mm

Maximal squeegee stroke: 240 mm

Maximal squeegee speed: 333 mm/s

Maximal squeegee pressure: 150 N

Camera aligning system:

Alignment tolerance: < ± 20 µm

Flat belt dryer:

IR-Lamp heating system in combination

With blowing hot air

Technical data:

(3) IR Heating zones

Air heating zone

Exhaust

Maximum temperature: 250°C

Maximum temperature tolerance: +/- 5°C

Drying time (min./ max.): 20 s to 40 s

Lifting device with (2) fixed cassette magazine sidewalls

Equipped with motorized width

Adjustment to adapt to different wafer sizes

Working principle: FILO

Transport belt section

Cell presence control

Furnace loader:

Electro welded steel

Sick light barriers for easy access by operator

Firing furnace: With dryer section

Firing furnace unloader:

With double stack buffer

Stack magazines: 2 or 4 (2 + 2)

Wafers per magazine: 300 (Depends on wafer thickness)

Squeegees screen frame adapter

Industrial-PC with keyboard

TFT Screen

Graphical User Interface (GUI)

Wafer bow:

Room temperature:

Before firing: < 1 mm (Center to edge)

After firing: < 4 mm (Center to edge)

Up time: >95 %

Mechanical yield: 99.5 %

Minimum thickness of the wafers: 140 µm

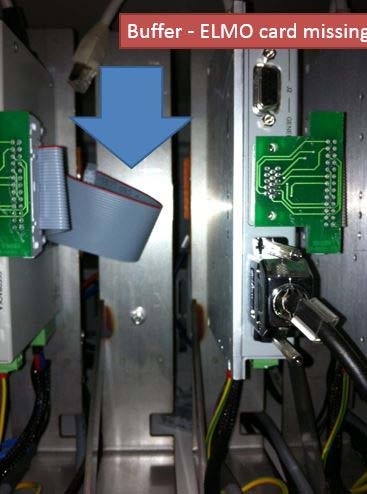

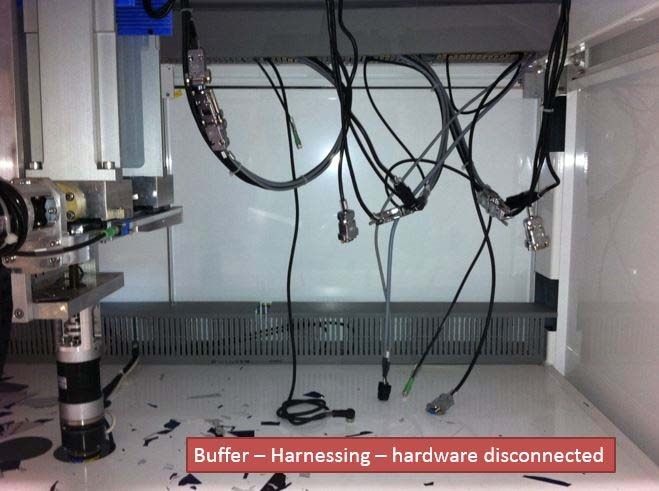

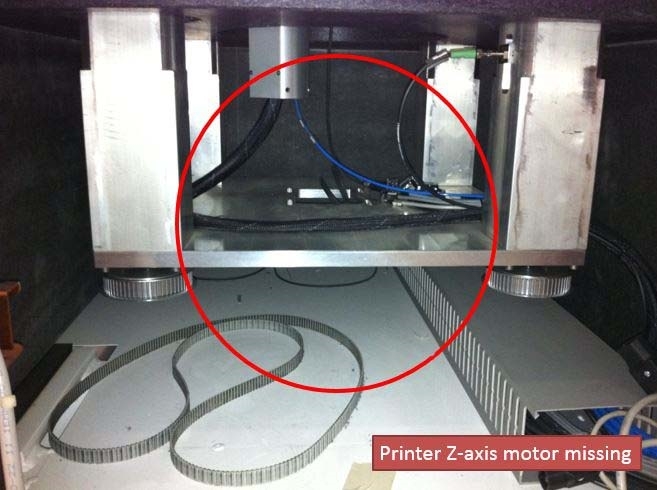

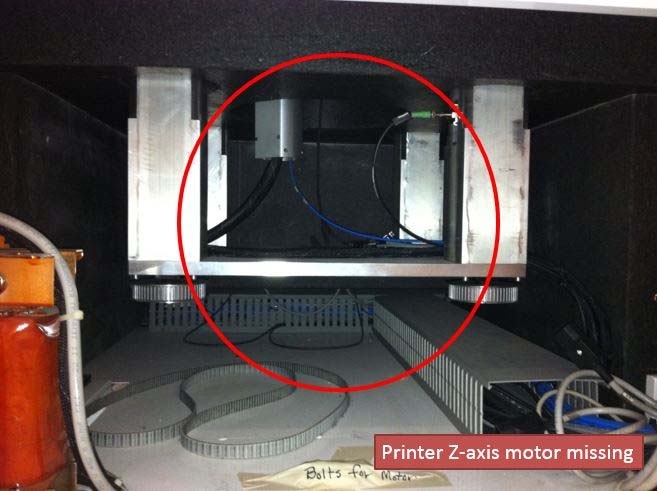

Missing parts:

ELMO Card

ELMO Card 115MG

Printer Z-axis motor

2008 vintage.

AMAT Softline 2.0 is a highly efficient solar production machine specially designed for the manufacture of solar cells. The machine uses advanced technology to produce high quality solar cells in a cost-effective manner. It has been developed in collaboration with BACCINI company and is a result of more than 25 years of intense research and development. The Softline 2.0 has integrated a powerful photovoltaic production line incorporating state-of-the-art equipment. The automatic cell production system is able to process high volumes of standard as well as custom programmed silicon-based materials in order to power a wide range of applications from residential to commercial installations. It is also possible to configure the production line to facilitate the production of high efficiency solar cells from innovative materials, including organic semiconductors. Part of the Softline 2.0 machinery is a texturing tool which has been designed to achieve textured surfaces for the production of more efficient solar cells. This tool features a multiple stage alkaline etching process in order to obtain the desired texture patterns. Additionally, it is equipped with high power infrared emitters and controlled temperature chambers for controlling the texture pattern depth and improving solar cell efficiency. The Softline 2.0 is also equipped with a wafer slicing module which is used to prepare the semiconductor material before it is processed. This module features an ultra-precise saw blade and is capable of slicing wafers with a cutting accuracy within 10 microns. This is used to ensure that wafer slices are of the correct size and thickness for high-quality solar cell production. Additionally, the machine is also equipped with a prober station which is used for metrology processes used to measure the performance of the solar cell. The prober station comes with specialized software that can detect and rectify any defective solar cells. This has become essential for quality assurance and compliance with international safety standards. Finally, the Softline 2.0 is highly energy efficient and produces virtually no emissions, making it an eco-friendly option for manufacturers. Its advanced technology significantly reduces energy consumption, while its user-friendly design ensures operability, faster throughput, and higher yields. Overall, APPLIED MATERIALS Softline 2.0 is a top-tier solar production machine offering a range of solar cell production features in a streamlined, cost-effective package.

There are no reviews yet