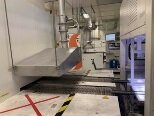

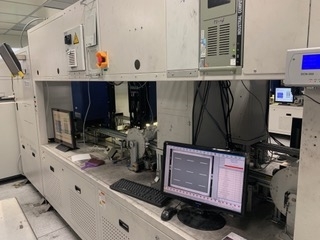

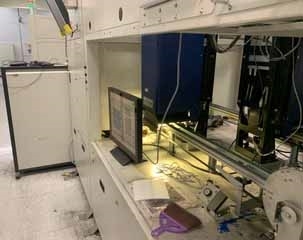

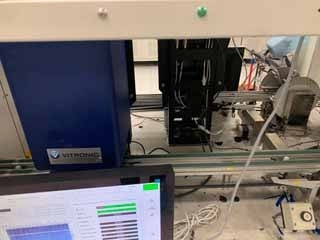

Used BACCINI / AMAT / APPLIED MATERIALS Tempo 2.0 #9272742 for sale

URL successfully copied!

Tap to zoom

ID: 9272742

Vintage: 2014

Systems

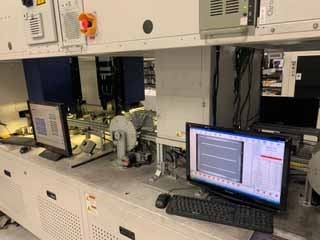

Throughput: 100000 / Day

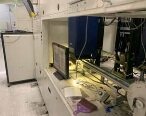

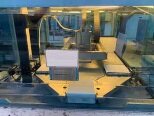

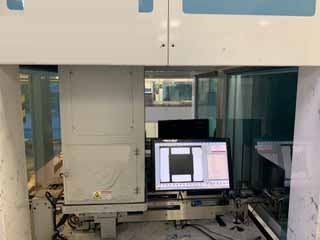

(3) Printer heads and (2) dryer ovens

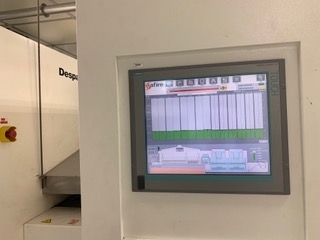

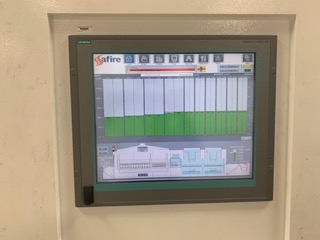

DESPATCH Safir

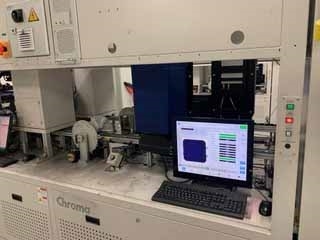

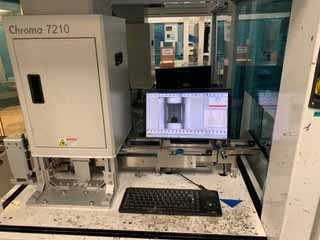

CHROMA Feeder and sorter 144 bins

With HALM IV light source

2014 vintage.

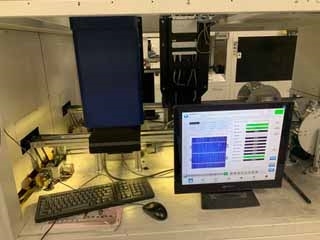

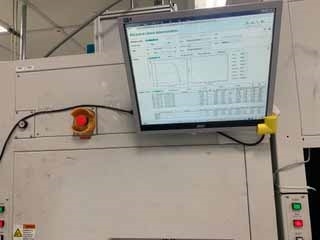

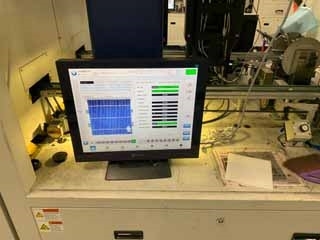

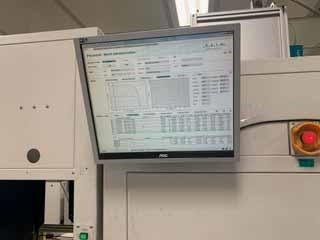

AMAT Tempo 2.0 is an advanced solar production equipment used to manufacture solar cells and other photovoltaic products. It is suitable for use in research and development as well as in production. This equipment provides a robust platform for automated processing of photovoltaics and cells with high precision and throughput. The base of the Tempo 2.0 consists of two stacked linear stages, offering a total of three axes of motion. The upper stage moves on the Y axis and the lower stage moves on the X and Z axes. All stages are driven by DC encoder motors that provide extremely accurate positioning and introduce minimal vibration during operation. The upper stage is also fitted with a multi-axis vibration controller, which eliminates any possible errors due to vibration. The stages are connected to the control cabinet, where all commands and feedbacks are exchanged, via a shielded electrical cable. The Tempo 2.0 has a multi-function port, called the System Bus Interface (SBI). It features an Ethernet network, an I/O interface, and a controller-to-controller communications bus. This allows for communication with other components of the production line and provides increased flexibility. The I/O interface can be used to control various systems such as an external vacuum unit or a plasma generator. The Tempo 2.0 includes a variety of tools and accessories that allow for accurate positioning and alignment of photovoltaic components. It also supports a broad range of process modules, including a cutting module and a dicing module. The cutting module is capable of precise cuts and depths, while the dicing module is designed to dice wafers into individual cells. A camera module is also available, which facilitates the inspection of the cutting process. The Tempo 2.0 offers several software features that allow users to customize their production line easily. It provides efficient process control, recipe and workflow management, and predictive maintenance. These features make it easy to integrate with other types of machines and with existing solar production processes. Finally, the Tempo 2.0 offers a reliable and safe environment for the production of photovoltaic cells and components. It includes several safety and environmental protection features, such as an emergency stop, a grounded retractable structure, and an isolated spraying zone. The machine also has built-in protection against dust and particle contamination. In conclusion, BACCINI Tempo 2.0 is an advanced and reliable solar production equipment. This tool enables highly precise and automated assembly and packaging of photovoltaic cells and components. It features a flexible multi-function port and a variety of tools and accessories for accurate positioning and alignment. It also provides efficient software features, allowing for easy integration with existing production processes. Furthermore, its safety and environmental protection features make it a safe and reliable solution for producing photovoltaic cells.

There are no reviews yet