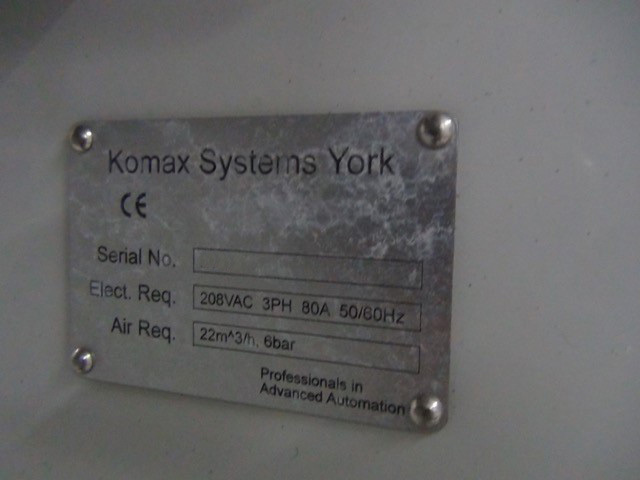

Used KOMAX Xcell 3400 2BB / 3BB #9122212 for sale

URL successfully copied!

Tap to zoom

ID: 9122212

System

Stringers: 125mm & 156mm Cells

String length: 2 & 3 BB

String flipper: 12 Cells

Cell spacing: 2 mm

Range: 1 mm to 3 mm

Throughput: 600 Cells per hour.

KOMAX Xcell 3400 2BB / 3BB is a fully automated, high-speed production equipment specifically designed for the solar photovoltaic cell manufacturing industry. It uses a combination of precise dicing, precise edge isolating, and precise metallization processes to produce precise and precise solar cells with a high degree of efficiency. The cutting technology used in Xcell 3400 2BB / 3BB eliminates cutting losses, making it a highly efficient tool for solar cell manufacturing. The high speed and accuracy of its cutting technology is achieved by combining a new-generation spindle, precise torque sensor, and modern high-torque motor with a cutting technology that allows it to perform multiple operations in a single pass. This system is programmed to optimize cutting accuracy, speed, and reliability. The unit combines a high-grade laser cutting head and laser vision guidance for the precise and accurate dicing process. The laser vision guidance controls movement in all axes, making KOMAX Xcell 3400 2BB / 3BB capable of cutting many different cells at once, with very precise and consistent results. The machine also includes an edge isolating process which gives a precise and clean edge to the cells, as well as an advanced metallization process. The metallization process applies an additional conductive layer to the edges of the cells, creating greater contact with the adjacent solar cell, while at the same time producing a low resistance path between the two cells. Xcell 3400 2BB / 3BB also allows for precise bottom-pin defect elimination and fast sorting processes, ensuring the cells are free from defects and optimized for production. KOMAX Xcell 3400 2BB / 3BB is a reliable and versatile solar cell manufacturing tool which performs precise and efficient cell production, ultimately improving the quality of solar cells. This asset also features a centralized control panel and monitoring model, which allow for multiple visualization capabilities, such as laser and spindle speed, position accuracy, and equipment feedback. With its built-in diagnostic tools, the system can quickly identify, diagnose, and address any errors that may arise during the production process. Xcell 3400 2BB / 3BB is equipped with highly efficient cutting, isolating, and metallization processes which allow it to produce precise and precise cells with a high degree of efficiency. Thus, KOMAX Xcell 3400 2BB / 3BB is an efficient, reliable, and precise solar cell manufacturing unit which is suitable for high-volume production, providing a cost-effective solution for photovoltaic cell manufacturers.

There are no reviews yet