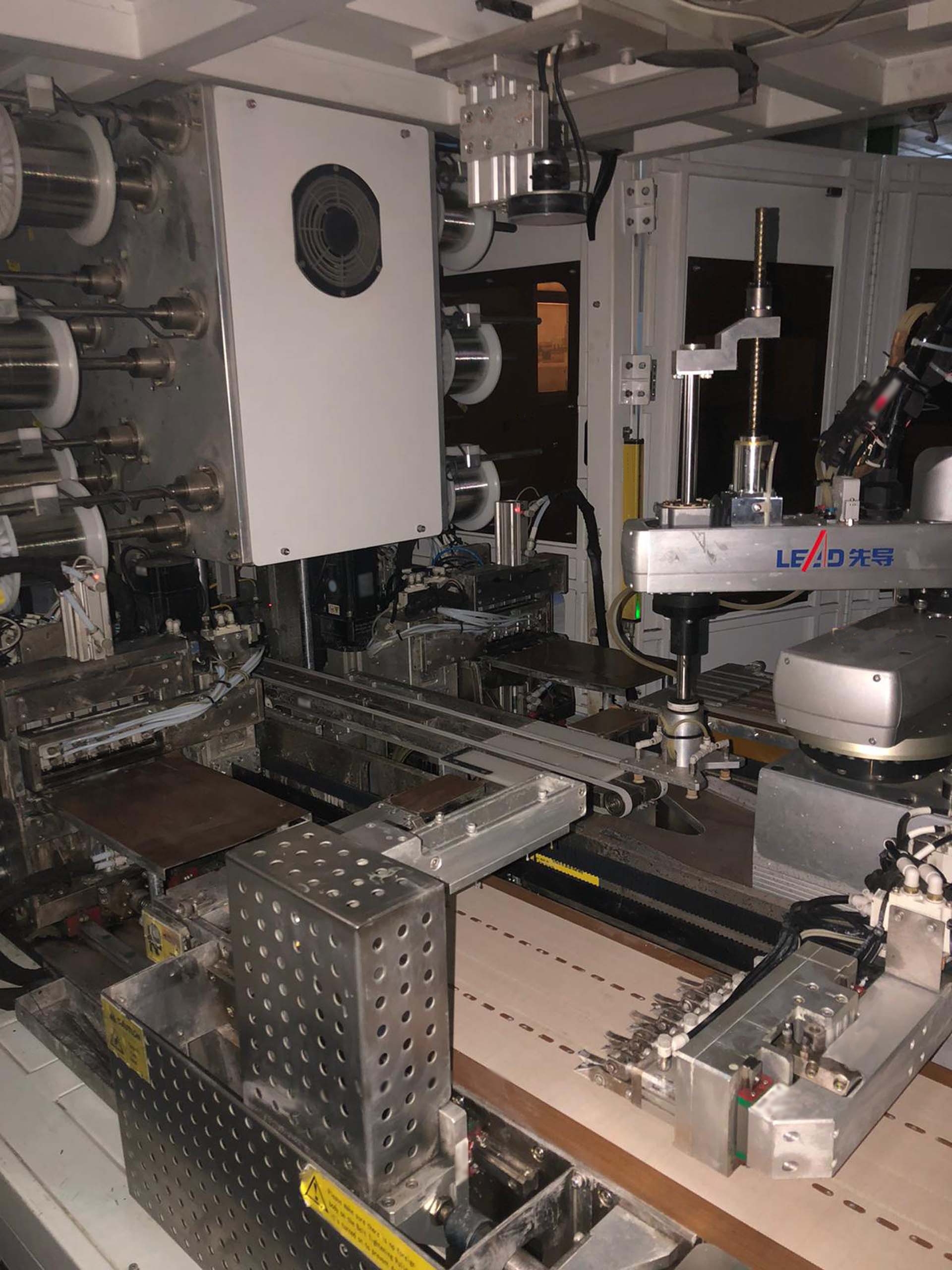

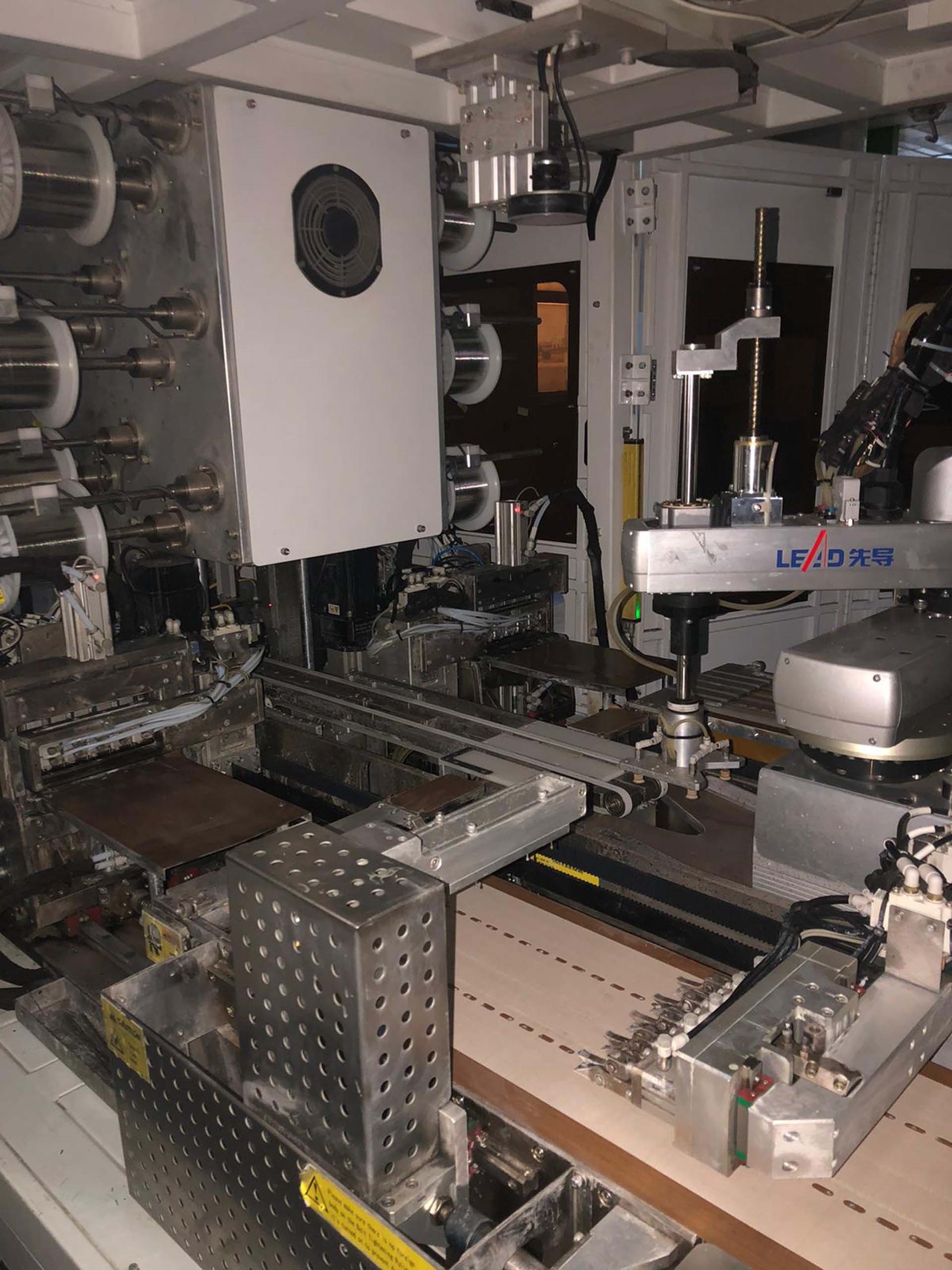

Used LEAD LDTS 2400 #9265709 for sale

URL successfully copied!

Tap to zoom

ID: 9265709

Vintage: 2017

Stringer systems

5BB

Exhaust:

(2) Pipes, 6"

Flow of pipe: 60 m³/hr

CDA Flow:

Maximum: 450 L/min

Average: 400 L/min

Pressure: 0.5-0.6 Mpa

Filtration precision: <40 um

CDA Dryer system

Busbar options: 3, 4 and 5

Cell inspection camera:

Resolution: 5MP

Rejection criteria:

Chips: 0.5 x 0.5 mm

Ribbon flex spray

Solar size: 156 x 156 mm

IR Soldering method

(13) Spring loaded SS pins

Cell breakages: ≤0.2%

Thickness: 0.2-0.25 mm (Also 1.6 mm)

Width: 1.6 3 bb, 1.3 4 bb, 0.9 5 bb

Throughput: 2100 pcs/h

Distance between two cells: 2-20 mm

Ribbon alignment: ≤ ±0.3 mm

Uptime: 98%

Loader: (4) Cell cases (120 pcs/case)

Power supply: 220 V, 14-20 kW, 60 Hz, Single phase

2017 vintage.

LEAD LDTS 2400 is a solar production equipment manufactured by LEAD and designed for the production of solar panels. The equipment offers a unique combination of proven technologies along with integrated optimization for improved operator efficiency and process reliability. The core of LDTS 2400 is its advanced and powerful processing power. The equipment is powered by an all-in-one high-efficiency engine that is capable of simultaneous operations of multiple processes, which eliminates extra load and unwanted energy loss. The continuous cutter spindle is capable of providing consistent power output and is also capable of feed forward optimization to help maintain accuracy. This spindle also helps to lower costs and save time, while simultaneously improving the overall efficiency and reliability of the process. The machine has advanced safety systems to prevent unnecessary injuries and to protect the operator. LEAD LDTS 2400 offers two specialized cameras that are designed for accurate scans of solar cells. These cameras utilize proprietary technologies to separate the light from the heat and accurately detect the defects while still preserving performance. Furthermore, the camera equipment ensures the solar cells move smoothly and accurately on the conveyor strip, improving the accuracy of the whole system. The machine is also uniquely designed with integrated thermal solutions that work together to improve the efficiency of the process. For example, the dual chiller unit works together to maintain a constant temperature during the process. The chiller machine also has an on-board temperature controller that enables the operator to adjust the temperature according to the requirements of the process. The overall design of LDTS 2400 is also optimized with the aim of reducing waste. It has been developed to be highly efficient and requires fewer resources to operate. The integrated systems also require fewer connections and provide reliability and accuracy. LEAD LDTS 2400 is an advanced piece of solar production equipment and provides operators with an effective and reliable tool that has been designed for efficiency and safety. Its optimized design reduces the need for manual intervention while maintaining accuracy and reliability. With such advanced technologies, the machine provides reliable performance and improved efficiency at a low cost.

There are no reviews yet