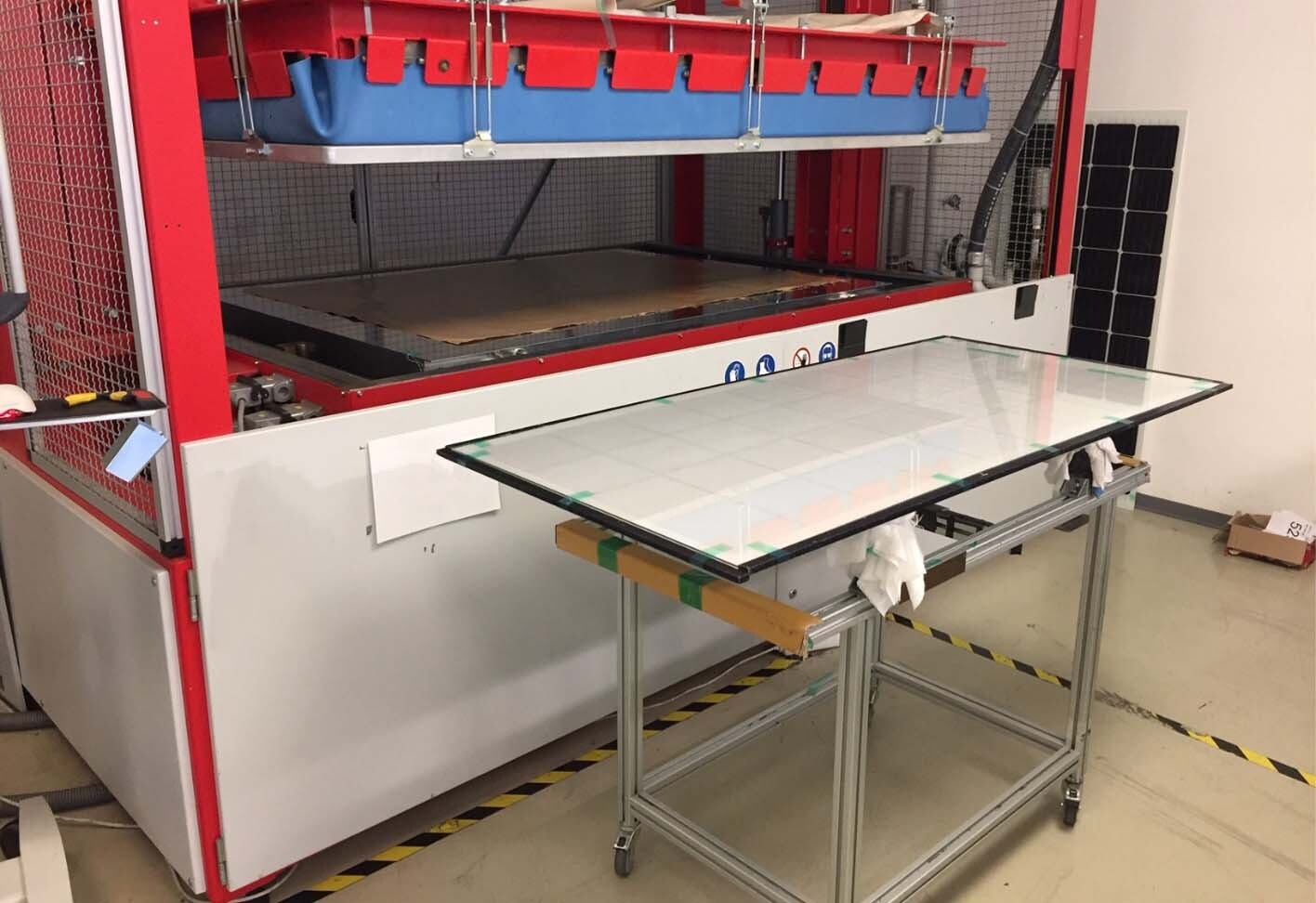

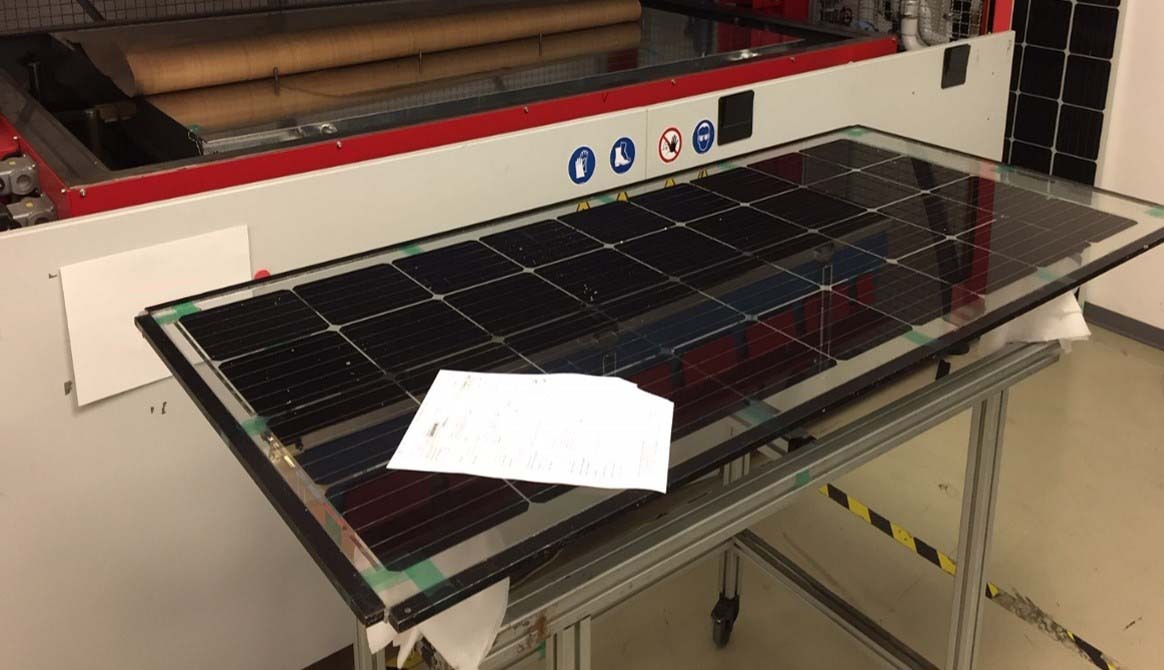

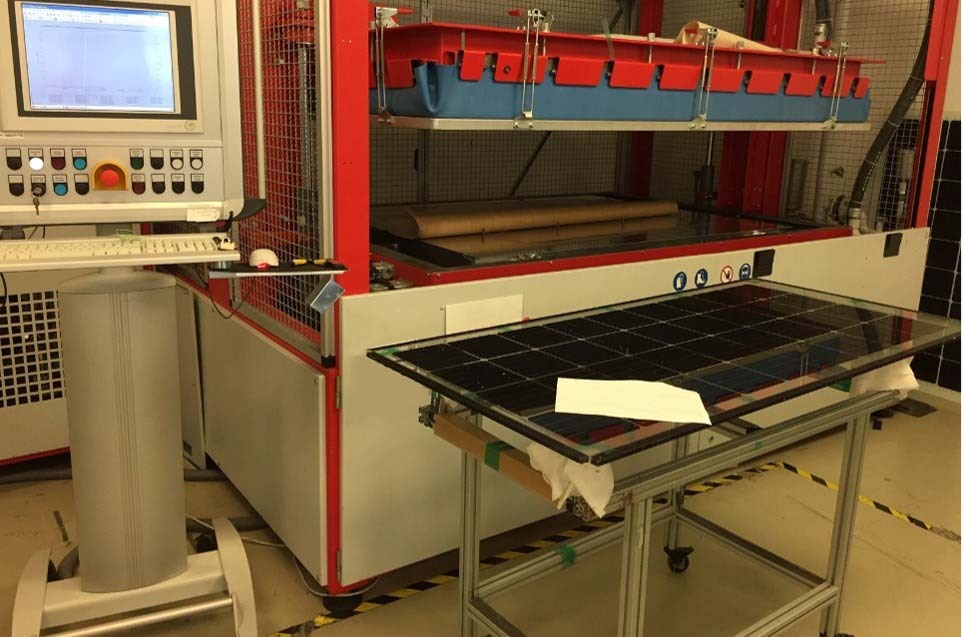

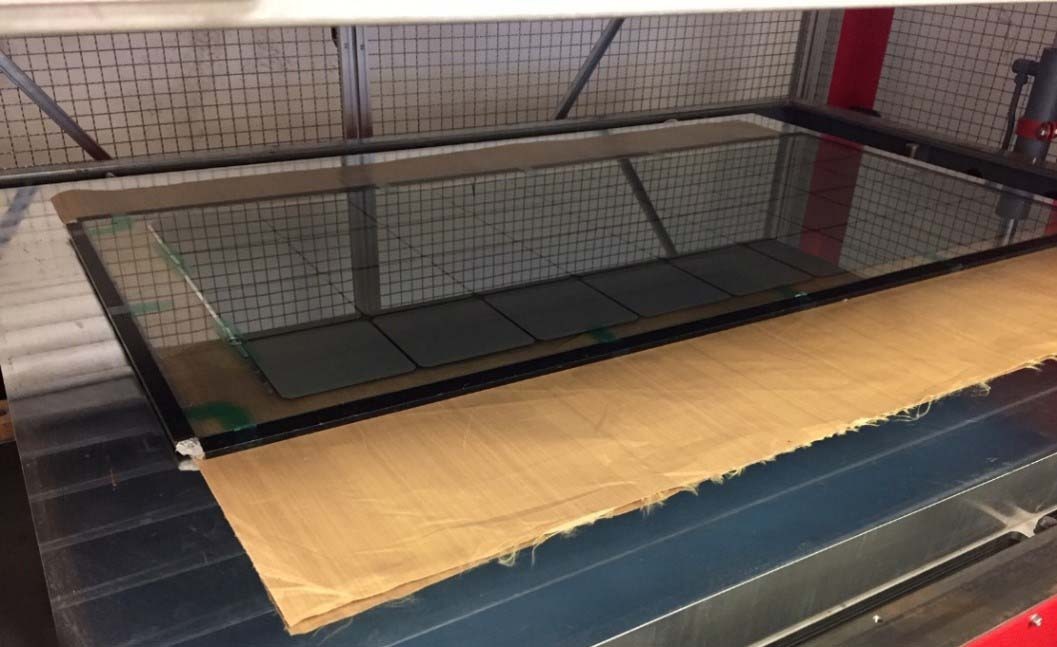

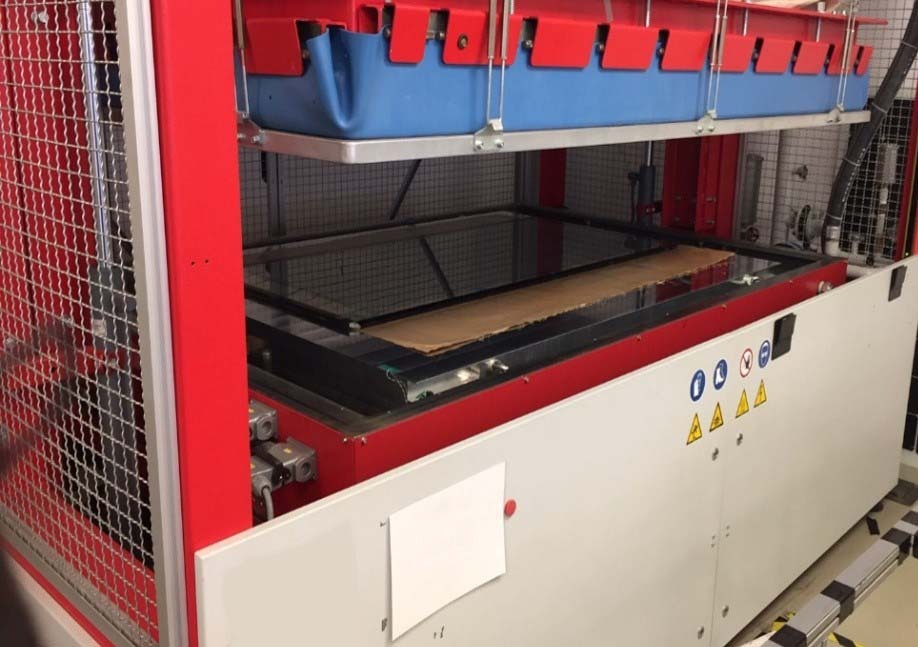

Used MEIER Icolam 18/14 #293608990 for sale

URL successfully copied!

Tap to zoom

ID: 293608990

Vintage: 2010

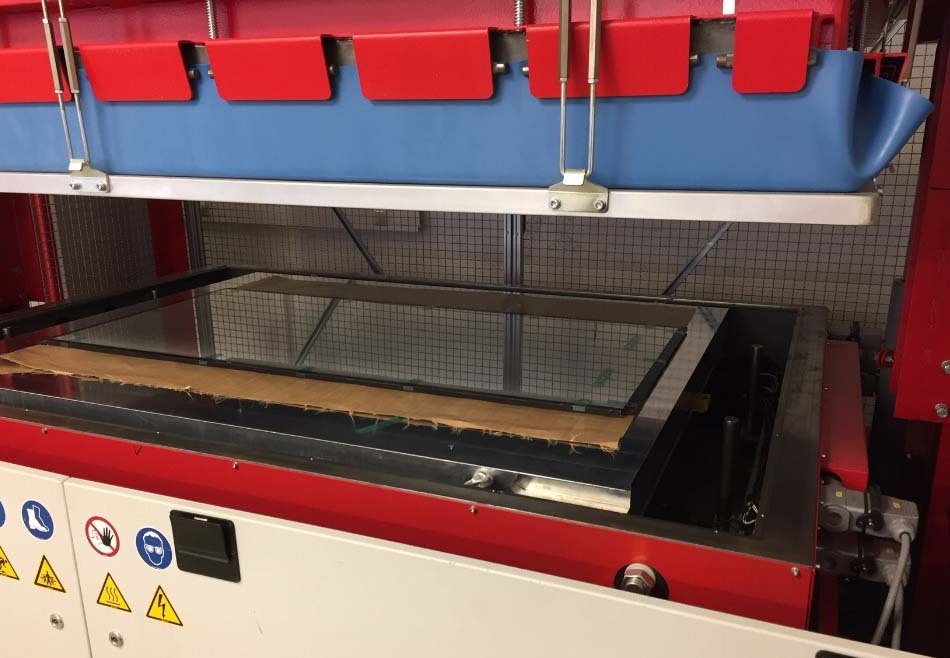

Laminator

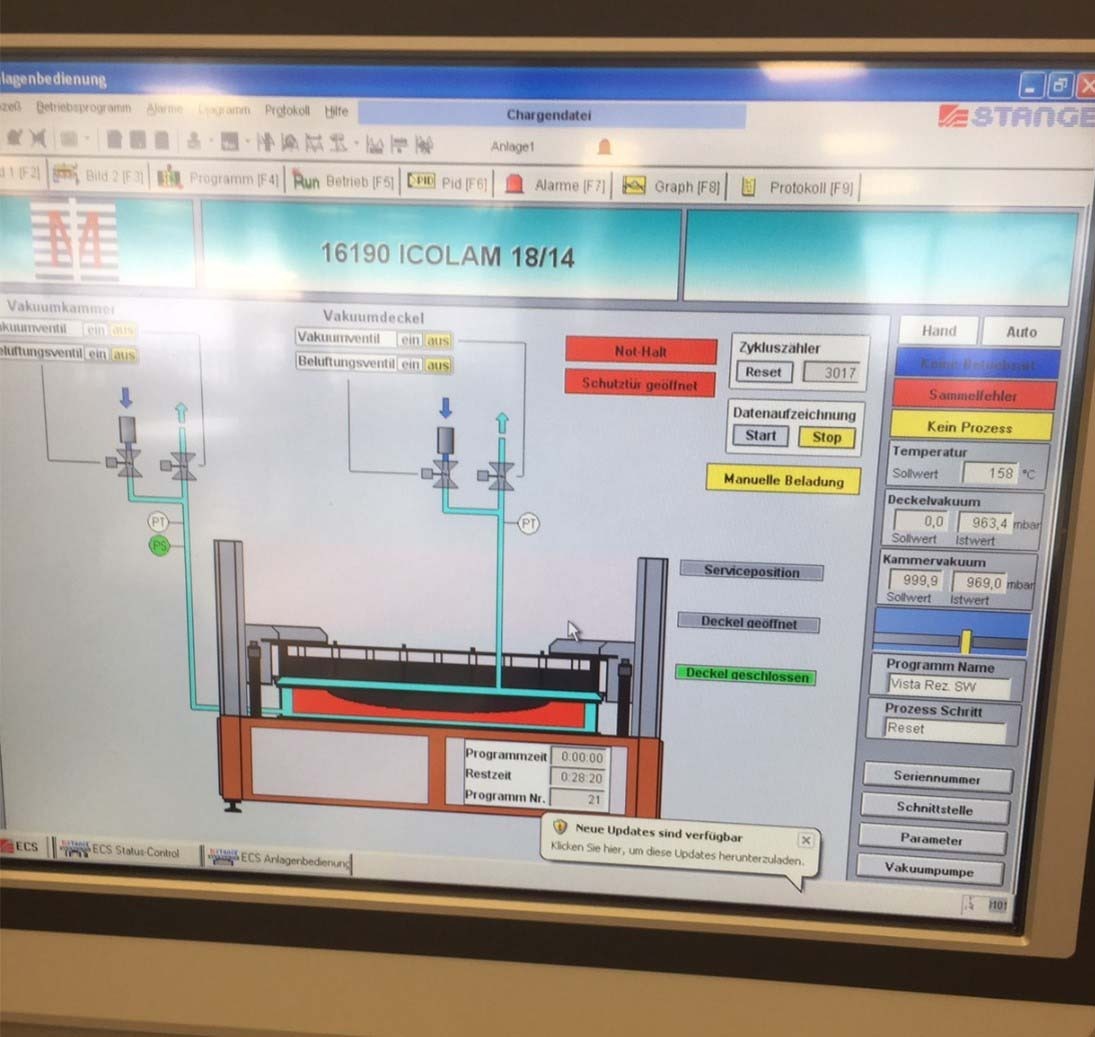

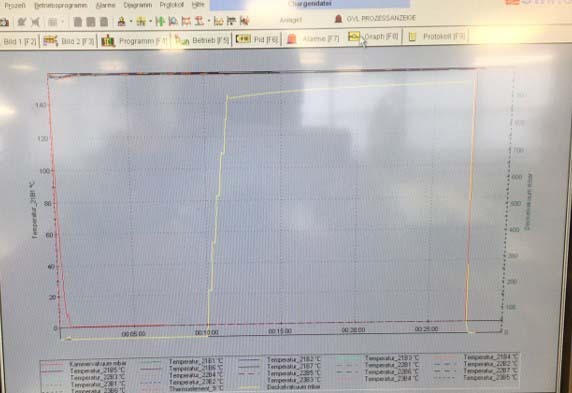

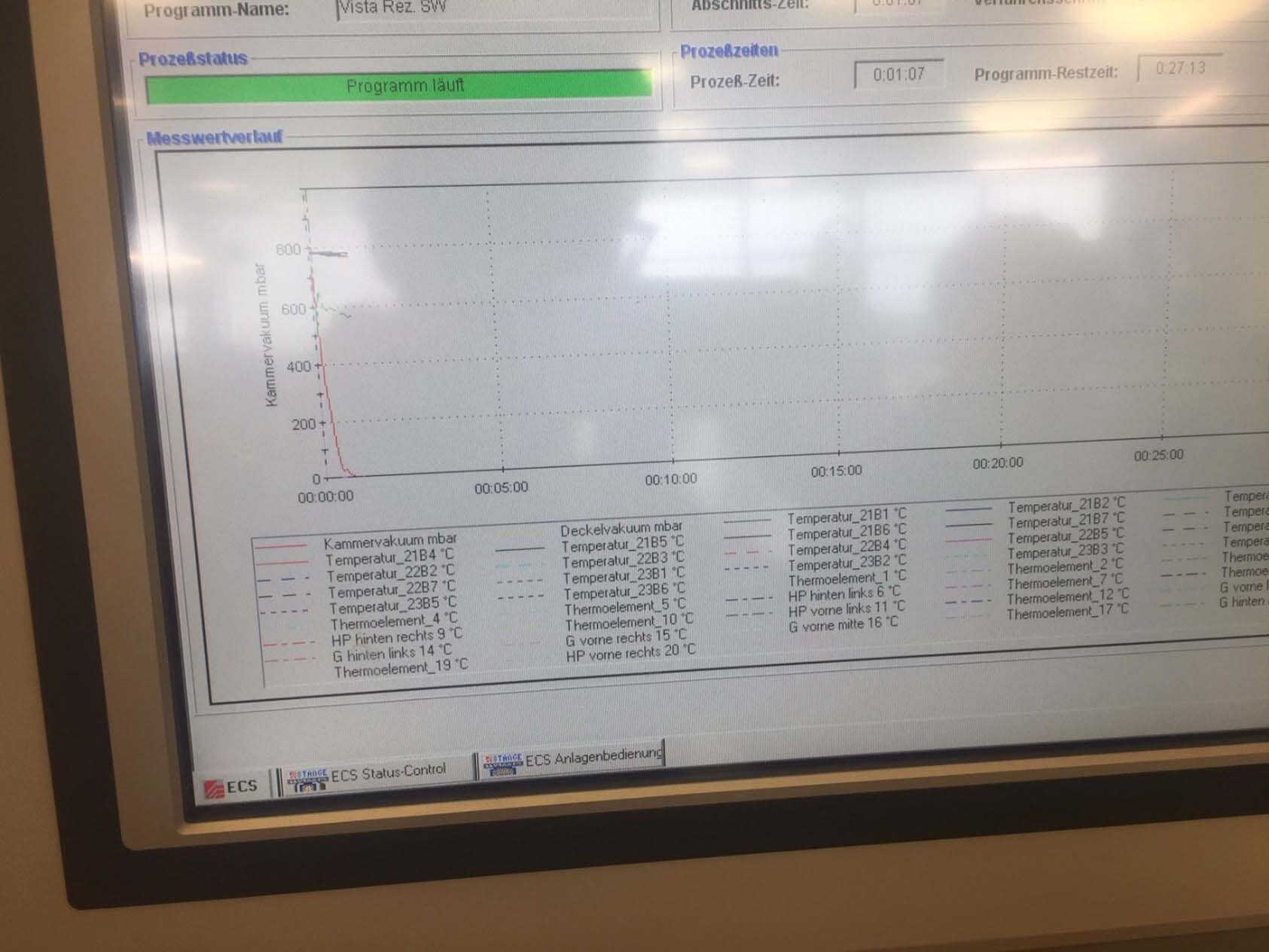

(4) Monitors

(2) Control cabinets

Vacuum pumping station:

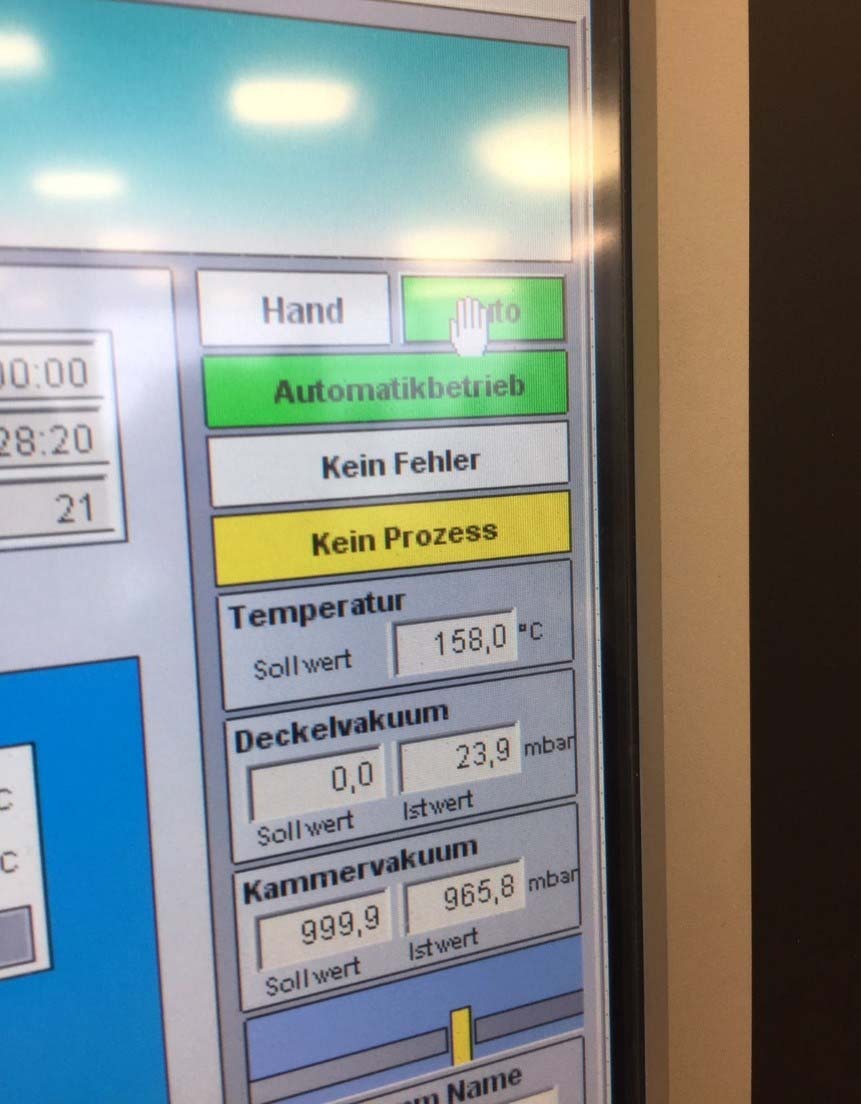

(5) Heating plates

(2) Pumps

Type: NC 0400 BLZ1, 7.5 kW

BUSCH Booster pump, 7AA112M-02 B14, 3 kW

Heat plate: 1800 mm x 1400 mm

Chamber height: 40 mm

Connection data:

Connected loaded: approx. 50 kW

Compressed air: 6-bar

Power supply: 3 x 400 V, 50 Hz, 26 A, 50 kW

2010 vintage.

MEIER Icolam 18/14 is a solar production equipment that uses silanes as key components to achieve a very high-efficiency solar cell production. This equipment utilizes the latest advancements in technology to increase production efficiency while minimizing costs. At the heart of the Icolam 18/14 solar production equipment is the platform, which is made up of a series of integrated equipment components. These components include a process chamber, an insulation chamber, a reactor, a photo lithography exposure unit, a cooling equipment, and a substrate handling system. The process chamber has been specifically designed to optimize the deposition of silanes, ensuring that the silane layer is even and homogenous for optimal performance. Additionally, the chamber has an efficient ventilation unit which provides an optimal working environment for the technicians. The insulation chamber is used to provide insulation between the process and exposure chambers, preventing heat from leaking out from the exposure chamber and affecting the quality of the luminescent material. It also helps prevent the formation of dust clouds which can cause unexpected particle effects. The reactor is where the silanes are first synthesized and prepared for further processing. It integrates in-situ refractory and catalytic materials which maximizes the efficiency of the conversion process. The reactor is an efficient and cost effective solution for solar cell manufacturing. The photo lithography exposure unit delivers ultra-fine definition and accuracy that is crucial for achieving the highest quality products. It also provides an integrated machine for controlling and monitoring optical parameters, enabling the equipment to be quickly recalibrated in order to achieve optimal results. The cooling tool is designed to quickly cool down the wafers after they have been exposed to the chemicals used in the process. This cooling asset ensures that the wafers can be handled immediately after the exposure process, reducing the potential of errors due to incorrect handling. The substrate handling model simplifies the process of moving the wafers between the different stations within the production equipment. This greatly reduces the potential human error caused by mistakenly transferring a wafer in the wrong order. It also ensures that the wafer can be moved in a safe and secure manner, protecting it from any potential contamination during the process. Overall, MEIER Icolam 18/14 solar production equipment is a highly efficient and cost effective tool for the production of high quality solar cells. By utilizing the latest advancements in technology, this equipment is capable of achieving an extremely high production rate with the utmost accuracy and precision.

There are no reviews yet