Used REIS / SOMONT / MONDRAGON Line #9120840 for sale

URL successfully copied!

Tap to zoom

ID: 9120840

Vintage: 2010-2012

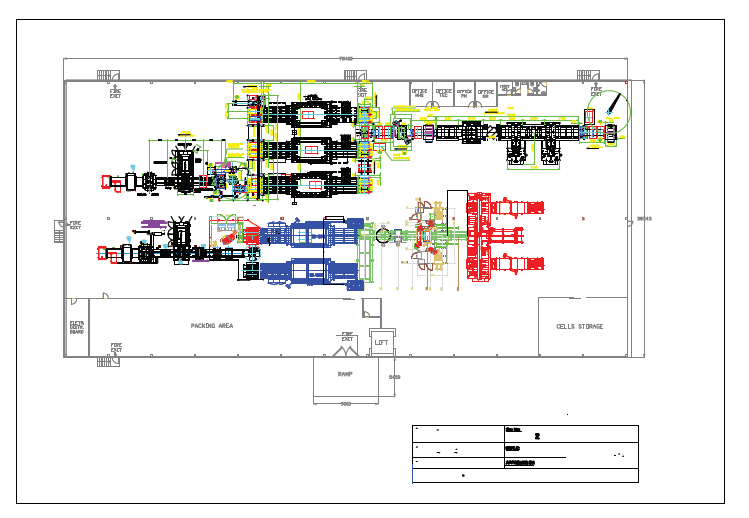

Line of PV Module Production Equipment

120 MW

Capacity: 60 and 70 cell modules

Currently configured for 60 cell

Busbar ribbon: 2, 3

Currently configured for 3 busbar

380 - 410 V, 3 phase, 50 Hz

2010-2012 vintage.

REIS / SOMONT / MONDRAGON Line is a world-leading solar production equipment that offers companies efficient and cost-effective options for manufacturing of solar panels. It is a fully automated equipment with multiple modules and a range of additional components, allowing for a complete production process with less manpower. This ensures a higher output rate and excellent cost savings. The system consists of four main stages, all with significantly increased efficiency compared to manual processes. The modules include the coating unit, the metrology machine, the laminator and the testing and sorting station. The coating module applies the aluminum oxide layers to the panel's front and back surfaces with amazing precision, ensuring a secure, well-protected and high-performance panel. This is followed by the metrology tool, which evaluates the panel's electrical characteristics and topography to make sure the panel meets the required specifications for top efficiency. The laminator then proceeds to seal the panel, providing moisture protection that will stand the test of time, even in extreme conditions. It is equipped with a dynamic force control asset that can easily be adjusted therefore offering great versatility and guaranteeing the end products are of the highest quality. Last, the testing and sorting station measures the panel's thermal and electric parameters and carries out multiple tests ensuring full functioning and the possibility of best performance. Qualifying modules can be added to the model as required, number of which can be adjusted as needed. This allows for flexibility and greater production speeds. These include the robotic end-ofREIS Line, which stacks and packages the panels to end-customer specifications. Furthermore, the front-end options can include automated crystalline cell handling and laser cell stringing on PERC or IBC cells and automated wafer dicing & pick modules to handle wafers of different sizes. The essence of SOMONT Line is that it is an incredibly resourceful solar manufacturing equipment that can fulfill nearly any product specifications, no matter the size or scope. With its high performance and unique features, it leads the market in cost efficiency, advanced technology, and production yields. Therefore, MONDRAGON Line is the ideal choice for anyone looking for efficient and cutting-edge solar panel production.

There are no reviews yet