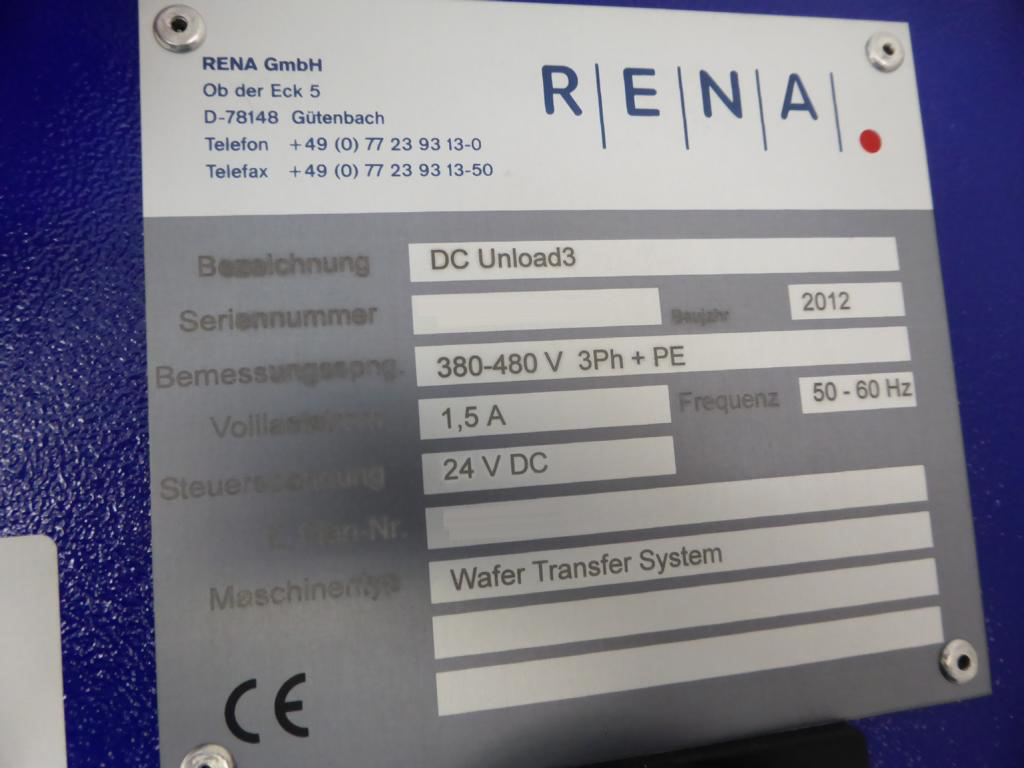

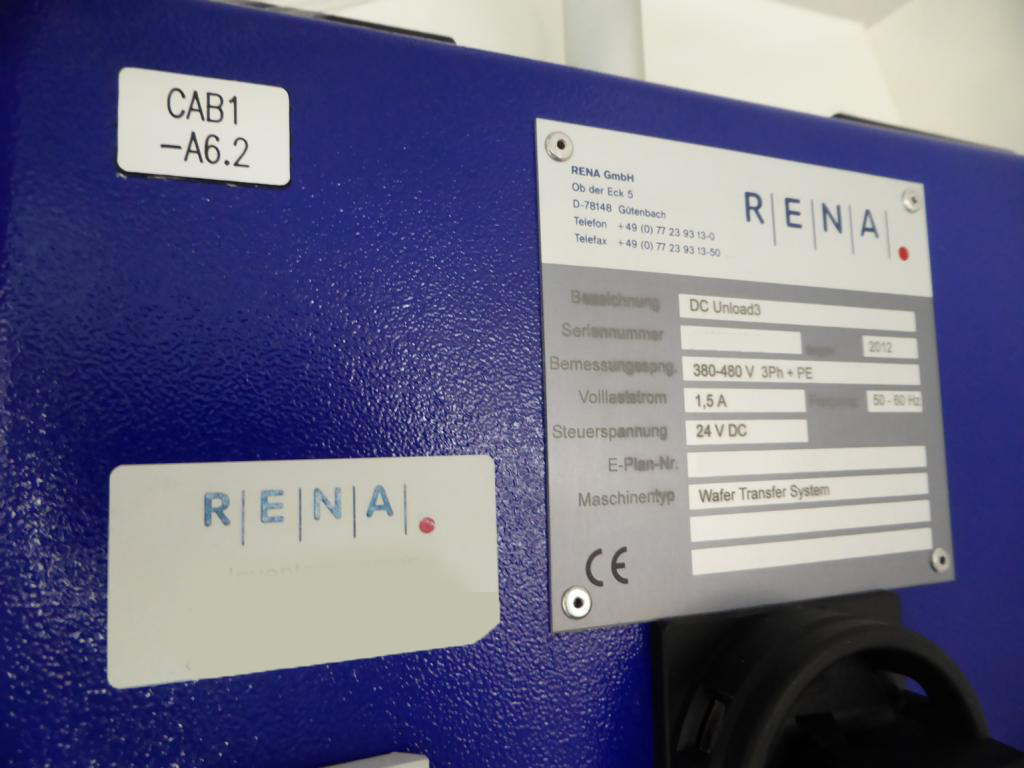

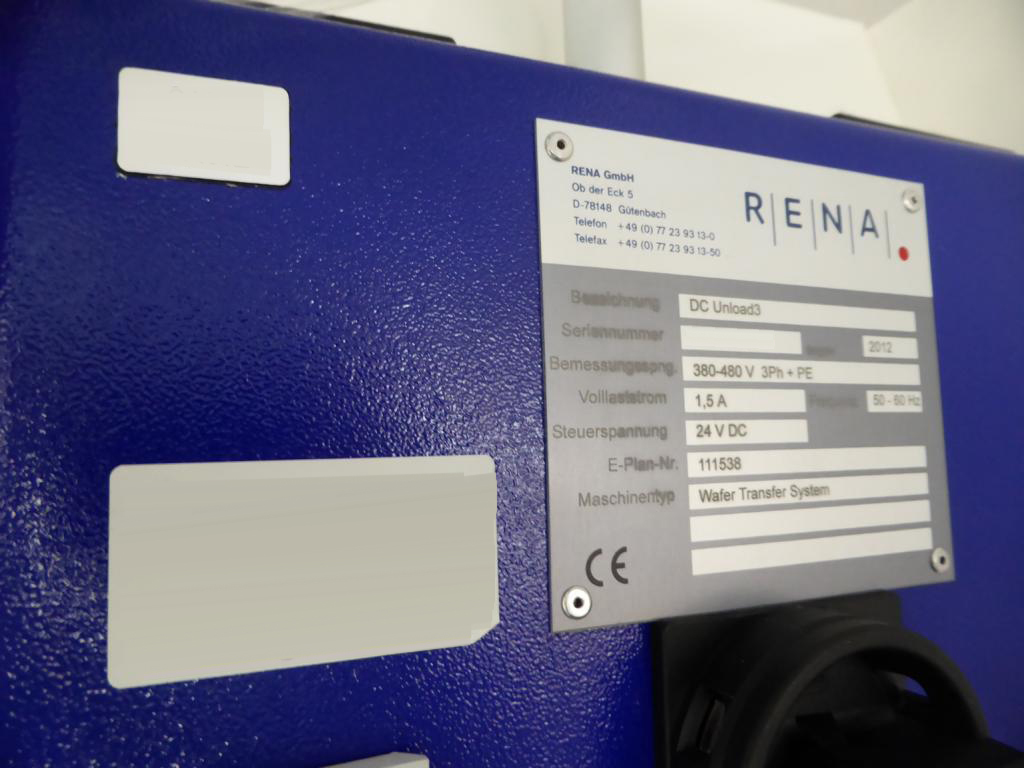

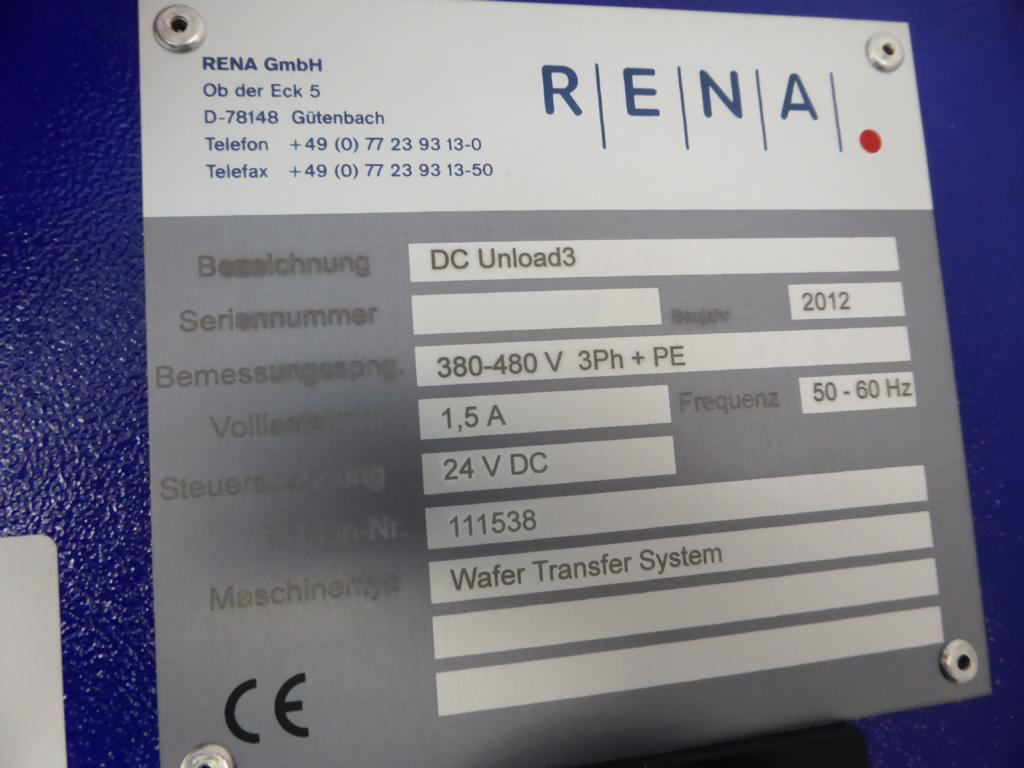

Used RENA DC Unload3 #9078517 for sale

URL successfully copied!

Tap to zoom

ID: 9078517

Vintage: 2012

Wafer transfer system

Unload inline system into carriers

Carrier type: RENA AAC 100X156 V01

Inline speed: >0.5 and <4m/min

Transport height: 950mm +/-50mm

Supply voltage: 380 - 480VAC +/-10%

Connected load: 1kVA

Full power current: 1.5A

Frequency: 50/60Hz

Connection cable: 3 phase + PE

Prefuse max: 16A

Cross section recommended: 2.5mm2

Cross section max.: 4mm2

Air consumption: 0 Nm3/h

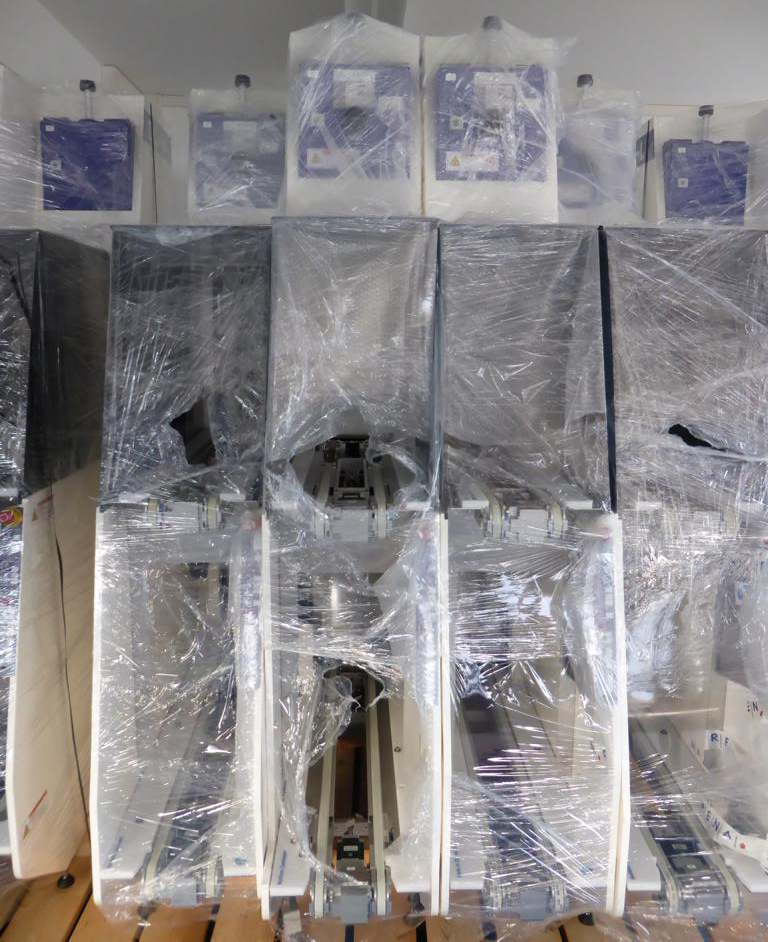

Lanes: 3

2012 vintage.

RENA DC Unload3 is a solar production equipment that is designed to ensure the highest levels of efficiency and safety when producing photovoltaic (PV) modules. The equipment utilizes a unique air flow design to cool and unload the PV cells while the process is being carried out. This helps to prevent any thermal damage to the cells, as well as prolonging the PV module's life. The system includes a patented safety mechanism to shut down the unit in the event of an overvoltage being detected. The machine includes an ultra-efficient intelligent control tool to monitor and adjust the speed of the conveyor asset to ensure optimum efficiency. It can detect any abnormalities in the model and shut down the facility automatically if necessary. A wide range of sensors are used to provide feedback to the control equipment, allowing for a detailed analysis of the total system output. The unit also features a high-power output of up to 2000 watts. The essential components of DC Unload3 machine include a conveyor belt, a heat exchanger, an inverter, and a radial airflow catalyst. The conveyor belt is designed to quickly move PV cells along to the unloading station by utilization of motorized rollers. The motorized rollers are powered by a high-efficiency DC motor that is capable of reaching speeds of up to 12 m/s. The heat exchanger is utilized to reduce the temperature of the cells before they are unloaded, minimizing the chances of thermal damage. The inverter is used to convert the DC current from the cells into AC current that is usable within the assembly facility. Finally, the radial airflow catalyst is designed to control the air flow within the facility and prevent it from becoming stagnant. RENA DC Unload3 tool also includes several advanced features to ensure the highest levels of safety and efficiency. These features include an automatic dust and debris removal asset, a programmable electrical lock-out model, and an energy monitoring equipment. The dust and debris removal system keeps the unit free of any debris or dust, prolonging the life of the PV cells and eliminating safety concerns. The programmable energy lock-out machine prevents any unforeseen power disruptions while the energy monitoring tool keeps track of the total energy usage of the asset. DC Unload3 model is a highly efficient and reliable solar production equipment that can help PV manufacturers increase their productivity levels with minimal risk. The equipment is suitable for use in a wide range of PV production facilities, and its advanced features ensure that production processes are kept safe and efficient.

There are no reviews yet