Used ROTH & RAU XXL #9117922 for sale

URL successfully copied!

Tap to zoom

ID: 9117922

Vintage: 2008

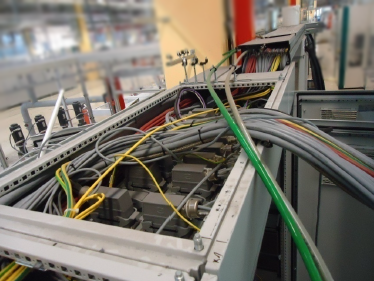

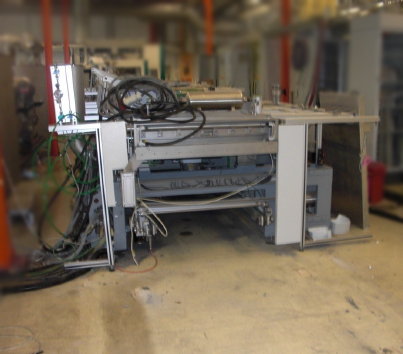

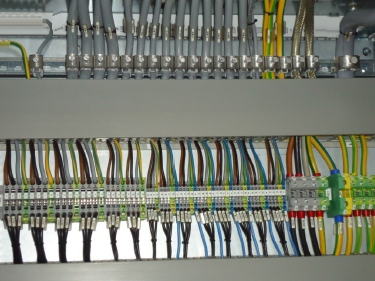

PECVD System

Environmental conditions:

Temperature: 22°C-25°C

Relative humidity: 30%-50% (Non condensing)

Process gas:

Silane SiH4 4.0 200 sccm per MFC 4 ¼"

Ammoniac NH3 3.8 1000 sccm per MFC 5 ¼”

Nitrogen N2 5.0 2000 sccm per MFC 2 ¼"

10000 sccm per MFC 1 auf N2 calibrated ¼"

Stirring gas and ventilation gas

Name: Nitrogen

Formula: N2

Pureness: 2.8 (Technical quality)

Inlet pressure device: 6-7 bar

Connection value (max. value): 1085 l/min

Average consumption: 735 l/min

Connection fitting with internal thread ½"

Inlet pressure purging function gas cabinet 2 bar

Inlet pressure valve control gas cabinet 5 bar

Inlet pressure for pressure storage

Lock chamber ventilation 4 bar

Compressed air

Quality: Oil content 0,01 mg/m³ (Oil and water-free)

Particle size: < 0.1 μm

Particle concentration: < 0.1 mg / m³

Working pressure: 6-7 bar

Connection fitting with internal thread 1/2"

Consumption (in average at cycle time): 111 l/min

Connection (max. value): 111 l/min

Cooling water:

Quality: Water hardness range “soft” less than 1.5

Millimol calcium carbonate per liter (Equals 8.4°dH)

PH Value: 7-9

Foreign particle size: < 0.2 mm

Dissolved chlorine Cl: < 20 mg/l

Dissolved carbon dioxide CO2: < 10 mg/l

Pressure flow: 4-6 Bar

Pressure spread p flow-outlet 3 bar

Temperature flow: 18°C < 22°C ( T 5K flow-outlet)

Consumption: 326 l/min

Connection feed and outlet: 2”- Fitting (External thread)

Power supply:

Connected voltage: 3 x 400 V ± 5 %+N+PE / 50 Hz

Electrical total load: 460 kVA

2008 vintage.

ROTH & RAU XXL is a solar production equipment that is designed to produce high-efficiency photovoltaic (PV) cells. It is specifically designed for solar cell manufacturing processes, including the introduction of wireless cell printing. The equipment is packed with a full suite of tools, components, and a special set up that enables efficient production of solar PV cells. The equipment includes an advanced photolithography equipment comprised of a high-resolution projector, an automated mask changer, an exposure chamber, and a pre-alignment camera. This system is capable of producing very precise and high-accuracy fabrication layouts. The optical unit is capable of producing cut-off frequencies with film thickness between 0.2 and 2.0 microns. XXL has a monitoring and process control machine that helps the cell manufacturer ensure that the fabrication process meets the required accuracy and production speed. This tool is composed of several integrated components, including process parameter logging, real-time process feedback, parameter-based equipment control, and statistical process control. This powerful monitoring asset also provides comprehensive data about current track settings, process parameters, cell temperature, PMU and substrate, along with an extensive array of other useful information. In addition, ROTH & RAU XXL is equipped with several advanced production tools, including an automated substrate handling model, a testing and inspection unit, a cell cleaving equipment, and an automatic liquid crystal display (LCD) module. This automated module supports sorting, framing, cleaning, mounting and lamination of cells. Finally, XXL also has a semi-automated process control system. This enables the creation and modification of various process steps, including masking, exposure, printing, drying, cleaning, sputter coating, and conductivity test. The unit is also built to control the cell yield and effect on process variations, as well as facilitate the management of process parameters throughout the implementation phase. Overall, ROTH & RAU XXL is a highly efficient solar production equipment with the capability of producing high-efficiency photovoltaic cells. It is compact, yet powerful enabling users to execute all the necessary fabrication processes quickly and accurately. It is also equipped with an extensive set of tools and components, making it a great choice for cell manufacturing processes.

There are no reviews yet