Used SPALECK STEVENS INNOTECH Incapcell 37-24 #9362023 for sale

URL successfully copied!

Tap to zoom

ID: 9362023

Vintage: 2010

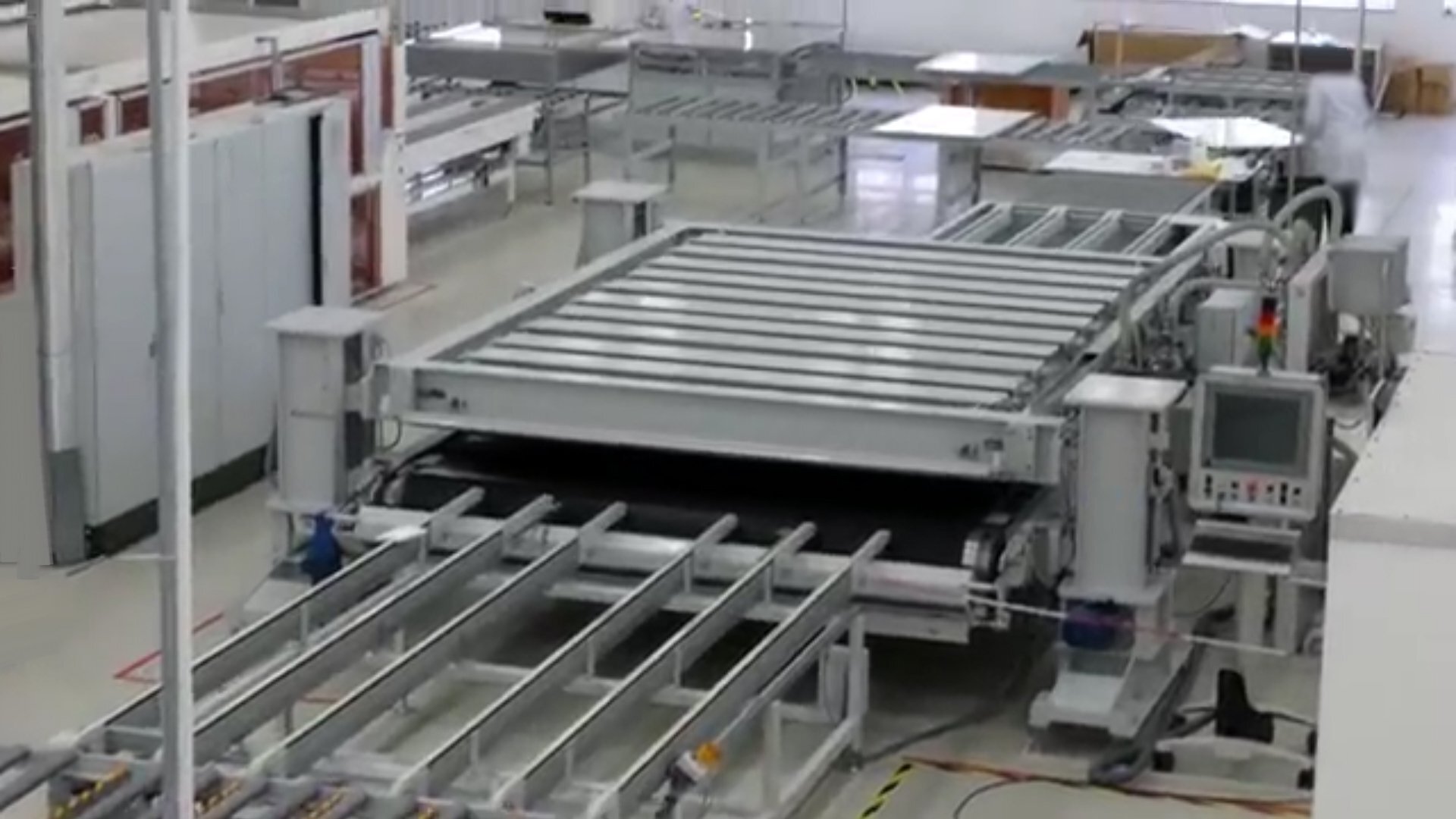

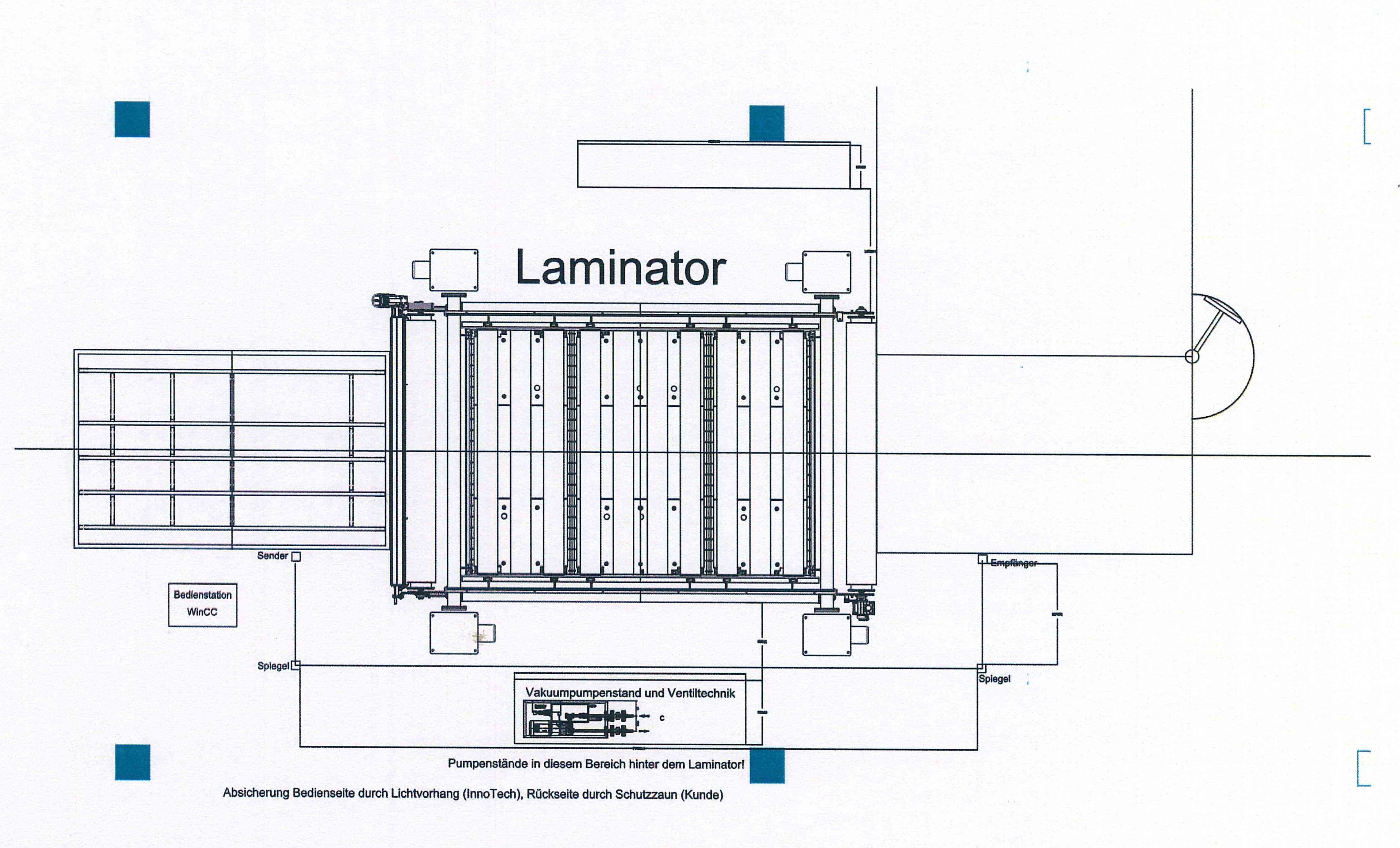

Photovoltaic laminator

Heat output: 172 kW

SV40 Vacuum pump BI Motor power at 50 Hz: 1.1 kW

SP 250 Vacuum pump, 7.3 kW

System volume: 20

Ambient temperature (Min to max): 10 to 50°C

Oil content of the compressed air: 0 to 5mg/m³

Sound pressure level: 70 dB

Heating zone: 3624 mm x 2430 mm

Heated up and down

Nominal suction:

Power: SV40 BI @ 50 Hz 42 m³/h

Power: SP 250 @ 50 Hz 270 m³/h

Oil circulation system:

Motor power pump at 50 Hz: 3 kW

Pump output: 80 m WS 25 l/min

Temperature limit: 200°C

Air supply:

Operating pressure (Min): 4 Bar

Operating pressure (Max): 10 Bar

Power supply:

Connection voltage: 3/N/PE, 400 V

Frequency: 50 Hz

Control voltage: 24 V (DC)

Connected load at 400 V: 200 kW

Amperage: 288 A

Main voltage vacuum pump: 400 V

2010 vintage.

SPALECK STEVENS INNOTECH Incapcell 37-24 is a precision solar production equipment that is designed to facilitate fast, efficient and cost-effective production of photovoltaic (PV) cells. This advanced equipment features the latest in solar cell processing technology to provide the ultimate in performance and productivity for solar manufacturers. Incapcell 37-24 utilizes a cutting-edge roll transfer module to move the solar cells from one process station to another. This non-stop system offers unprecedented accuracy and efficiency so that maximum speed is maintained without sacrificing quality. SPALECK STEVENS INNOTECH Incapcell 37-24 also features automatic loading and unloading of solar cells, providing a smooth transfer of product without the need for manual intervention. Incapcell 37-24 is designed to be incredibly user-friendly, featuring an intuitive interface and easy to understand controls. The unit includes multiple user functions that are designed to make operation and maintenance easy and straightforward. The user can easily regulate process parameters, monitor systems, and control all equipment from one central station. The machine also offers many safety features, including an emergency stop button and light curtain. To ensure the best possible performance, SPALECK STEVENS INNOTECH Incapcell 37-24 is equipped with the latest cutting-edge technologies. This includes an advanced high laser tool for cutting or drilling holes into cells, multiple high-speed pick-n-place systems for transferring cells from one process station to the next, and an integrated electroplating asset for processing devices. Incapcell 37-24 also offers advanced features for productivity optimization. This includes a fully automated panel splitting model for separating individual cells from the panel, a tracking equipment for improved tracking, and a partial load system for improved inventory and traceability. Furthermore, the unit can be integrated with other equipment to ensure maximum production capabilities. SPALECK STEVENS INNOTECH Incapcell 37-24 is robust and reliable, thanks to its state-of-the-art construction and robust design. The machine features a high degree of accuracy and repeatability, and a high level of efficiency that allows for greatly reduced downtime. Furthermore, its advanced production capability promises more output per shift and significantly improved yields. The team at SPALECK STEVENS INNOTECH have integrated all the latest technologies and features into Incapcell 37-24 to deliver optimal performance for solar cell production. The tool offers unprecedented flexibility and user-friendly controls that allow users to maximize their production capabilities. Its advanced features make SPALECK STEVENS INNOTECH Incapcell 37-24 ideal for any solar cell production process.

There are no reviews yet