Used SPIRE 6000 288 #9170537 for sale

URL successfully copied!

Tap to zoom

ID: 9170537

Assemblers

Solar cell geometry:

Square

Rectangular

Pseudo-square

Interconnect ribbon: 2-3 Ribbons

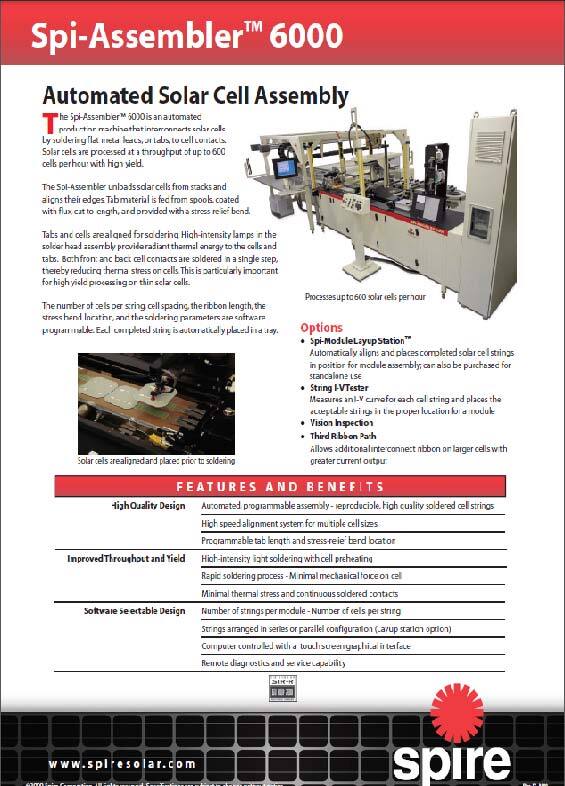

Maximum string length: 200 cm

Throughput: Up to 600 cell/hour

Options:

SPI-Module layup station

String I-V tester

Vision inspection

Third ribbon path

Solar cell dimensions:

125 mm x 125 mm (5 in. x 5 in.)

156 mm x 156 mm (6 in. x 6 in).

SPIRE 6000 288 is an automated, solar panel manufacturing machine and equipment used for high-volume production of photovoltaic (PV) modules and cells. It is currently being employed by many leading solar energy firms to efficiently mass-produce PV cells. The equipment consists of four main components: a robotic press, transfer stations, lamination stations and a product exit equipment. The press has a range of up to 288 panels per hour and is used for pressing photo-voltaic cells and cutting lamination material. Furthermore, the press is equipped with a force monitoring system, allowing for consistent and accurate press and cutoutputs. The transfer unit is a robust design that facilitates quick and efficient movement of PV cells and lamination material between the press and lamination systems. The unit is designed with an overhead gantry machine and offers high precision and repeatability. The lamination tool is highly automated, allowing for the fast, accurate and reliable manufacturing of photovoltaic cells. The unit consists of a heating and curing station as well as a testing station, all of which are designed to consistently produce quality cells. The equipment is also designed with safety features such as over temperature protection and pressure detection. 6000 288 solar production equiment also includes a products exit asset. This allows for quick and efficient sorting, packing and loading of manufactured cells. The design ensures that cells are separated, packaged and loaded safely and correctly. SPIRE 6000 288 is built for production efficiency, safety and accuracy. Its wide range of features and components make it the ideal choice for any solar production line. The cost-effectiveness of the equipment and its high degree of automation make it an attractive choice for any organisation looking to increase output of PV cells.

There are no reviews yet