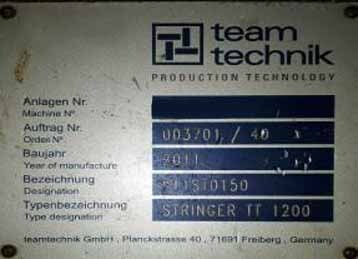

Used TEAM TECHNIK TT1200 #9176069 for sale

URL successfully copied!

Tap to zoom

ID: 9176069

Vintage: 2011

Single track stringer system

3BB

Hold-down device

Geometrical quality

Linearity

Length tolerance

Cell gap

Soldering technology: IR Light / laser

Cell technology / Types:

Mono / Poly-crystalline

Front and back side contacted

Cell alignment:

Optical alignment via camera

ROBOT For busbar / edge positioning

Cell inspection:

Vision system (camera)

Detection of accuracy for cracks

Broken edges and scratches: 0.5 x 0.5 mm

Grid-completeness check

Accurate cell and ribbon handling

IR Light soldering station

Suitable for lead-free (Pb) ribbons

Number of interconnection ribbons: 2-3 / 3-4

Range of solar cell sizes:

125 sq - 156 sq, 5"

Standard, 6"

Requires changeover parts, 5"

Busbar spacing:

30 - 78 mm

Standard 52 mm

Cell spacing: 2.0 - 35.0 mm

Cell positioning accuracy: ± 0.2 mm

Maximum length of strings: 2,000 mm

Accuracy in length: ± 1mm

1,400 cycles / hr

10 Cell-string with cell fluxing 1,272 Cells / hr

30 / 32 / 36 MWp pa

Technical availability: 95%

Noise level: 72 dB (A)

Electrical power requirement:

IR Light: 30 kVA / 17.5 kW / h

Compressed air: 600 kPa

Consumption (at 1 bar): 450 l / min

Cell thickness:

160 - 250 µm

Standard 180 µm

Flux application:

Fluxed with adjustable

Metered micro spray

Standard (Both sides)

Breakage rate:

Cell thicknesses down 180 μm

< 0.3 %

Ribbon sizes: Width > 1.0 mm

Ribbon positioning accuracy: ± 0.2 mm

Changeover time 2-3bb / 3-4bb: 2 Hours (Approx)

Operator interface (HMI):

Color touch screen with German / English / Chinese or Korean language

High throughput: < 2.5 Seconds cycle time

Low breakage rate: < 0.1 - 0.3%

Availability: > 95%

2011 vintage.

TEAM TECHNIK TT1200 is a state-of-the-art solar production equipment which offers reliable and efficient series string production for both residential and commercial applications. The machine features an integrated automatic cell positioning equipment which enables precise, high speed production. The motion control of the machine provides superior accuracy and repeatability. TEAM TECHNIK TT 1200 comes with a user-friendly color touch screen interface which allows the operator to manage a variety of machine settings. It also offers advanced trouble-shooting functions which enable faster and easier maintenance. The system provides data logging capability and has adjustable timeout parameters which ensure optimal production. TT1200 is equipped with an advanced vision unit which helps improve cell quality by utilizing pattern recognition, thickness inspection and color & contrast detection. The vision machine allows users to easily detect errors, increase reliable production and reduce downtime. The advanced packaging unit on the machine ensures efficient cell movement and packing. The packaging tool automatically feed cells into the pinching station, ensuring quality connection. The asset also includes anti-splicing safety sensors to prevent overcrowding and rejects faulty cells. TT 1200 has an integrated cooling model which helps keep temperatures stable throughout the production cycle. The cooling equipment is designed to dissipate heat, reduce degradation and extend the life of cells. Overall, TEAM TECHNIK TT1200 is one of the most advanced solar production equipment currently on the market. With its precise and repeatable motion control and advanced vision system, the machine ensures reliable and efficient solar production cycles. Its integrated cooling unit, packaging unit and anti-splicing safety sensors ensure high quality products, improved cell quality and minimized downtime.

There are no reviews yet