Used VARIOUS Lof of Production and Inspection line #9247863 for sale

URL successfully copied!

Tap to zoom

ID: 9247863

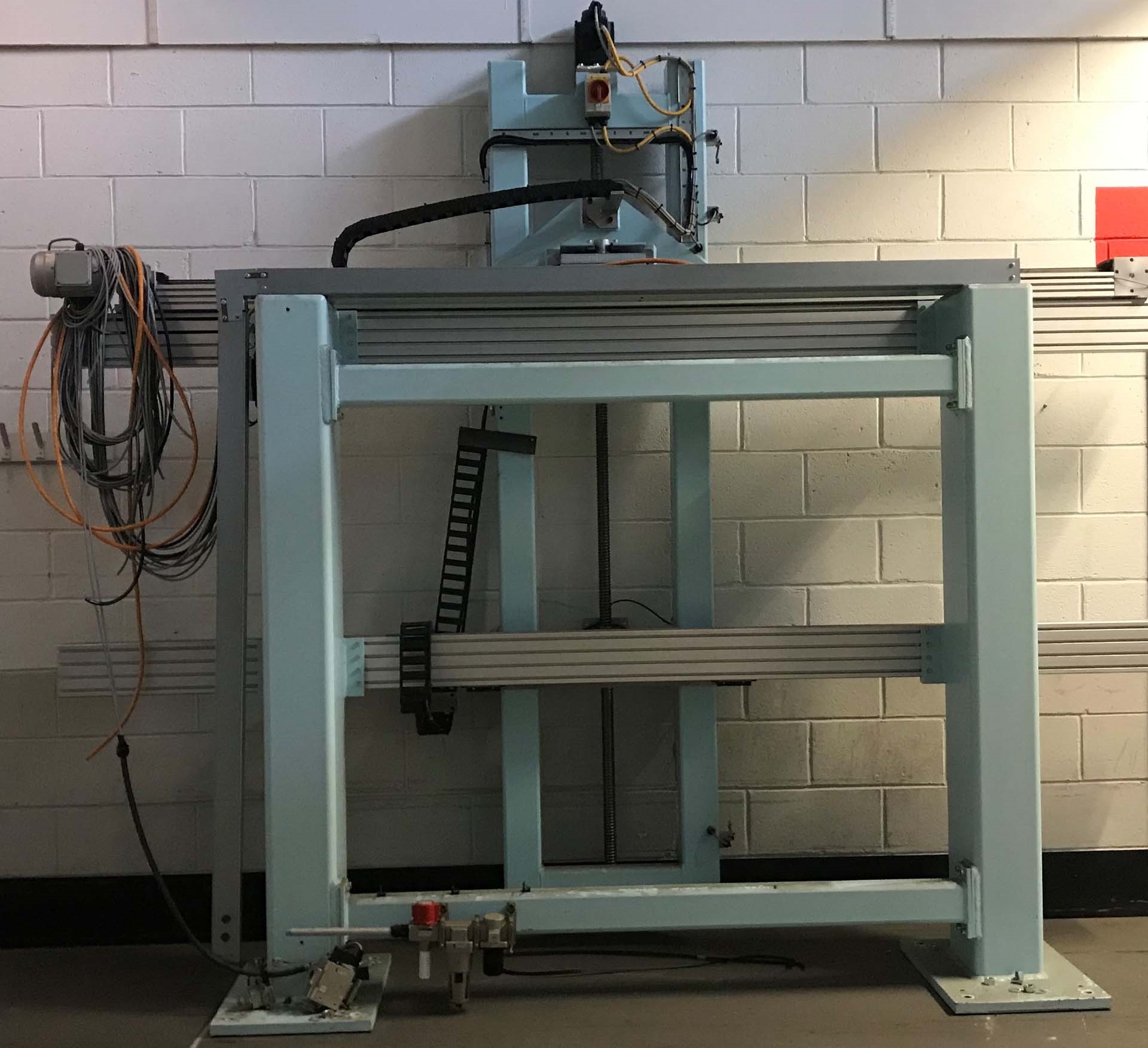

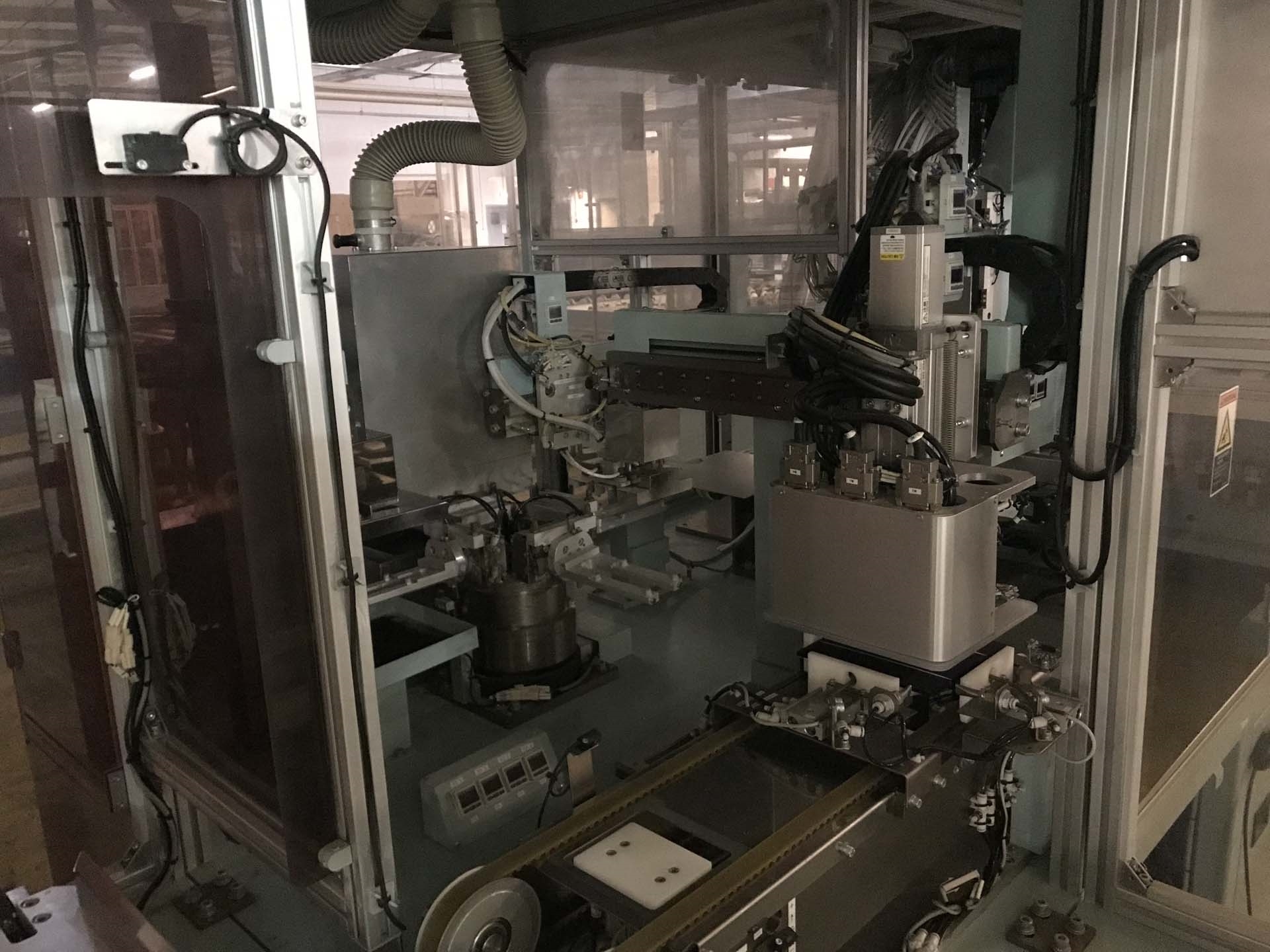

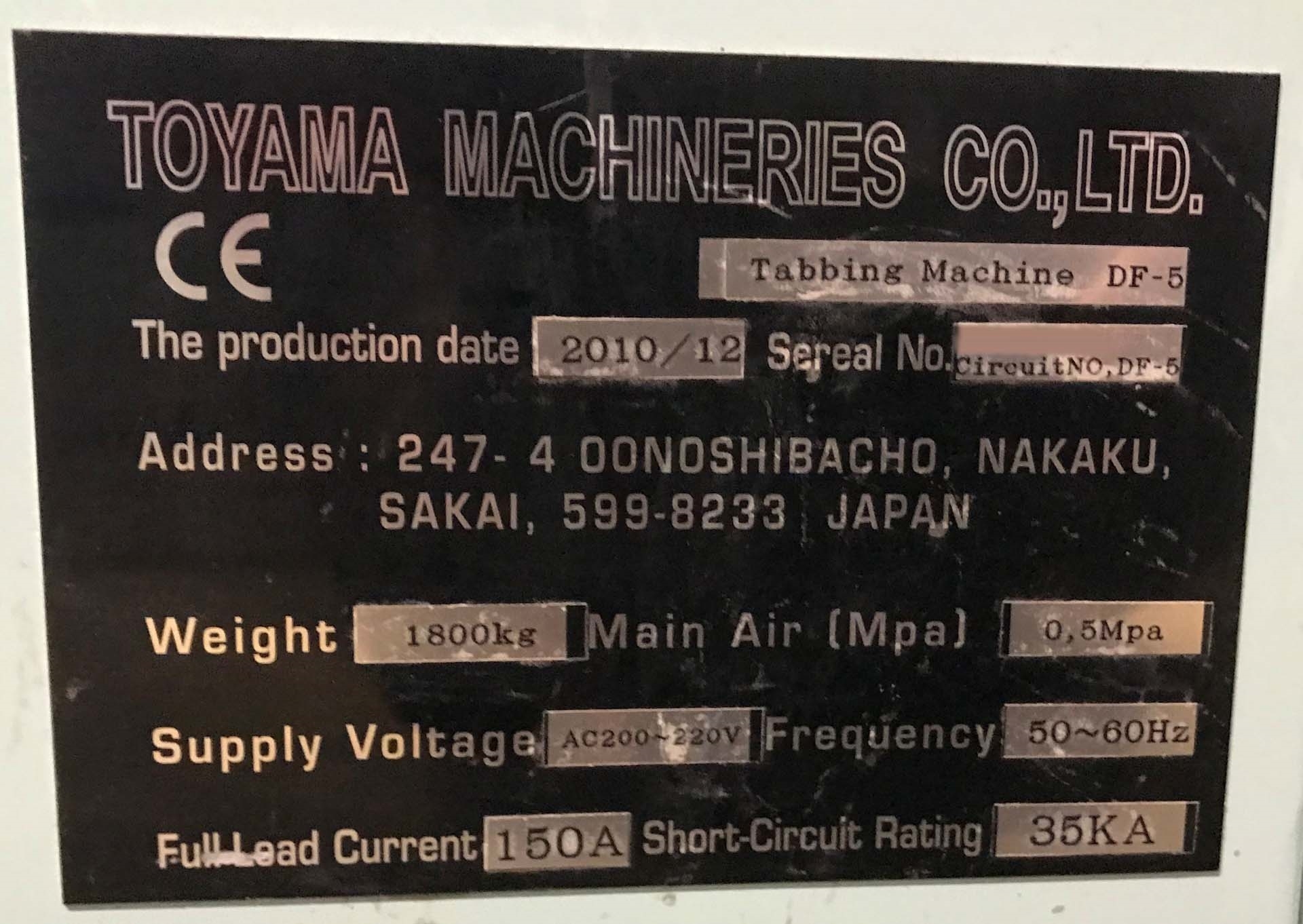

Tabbing machines

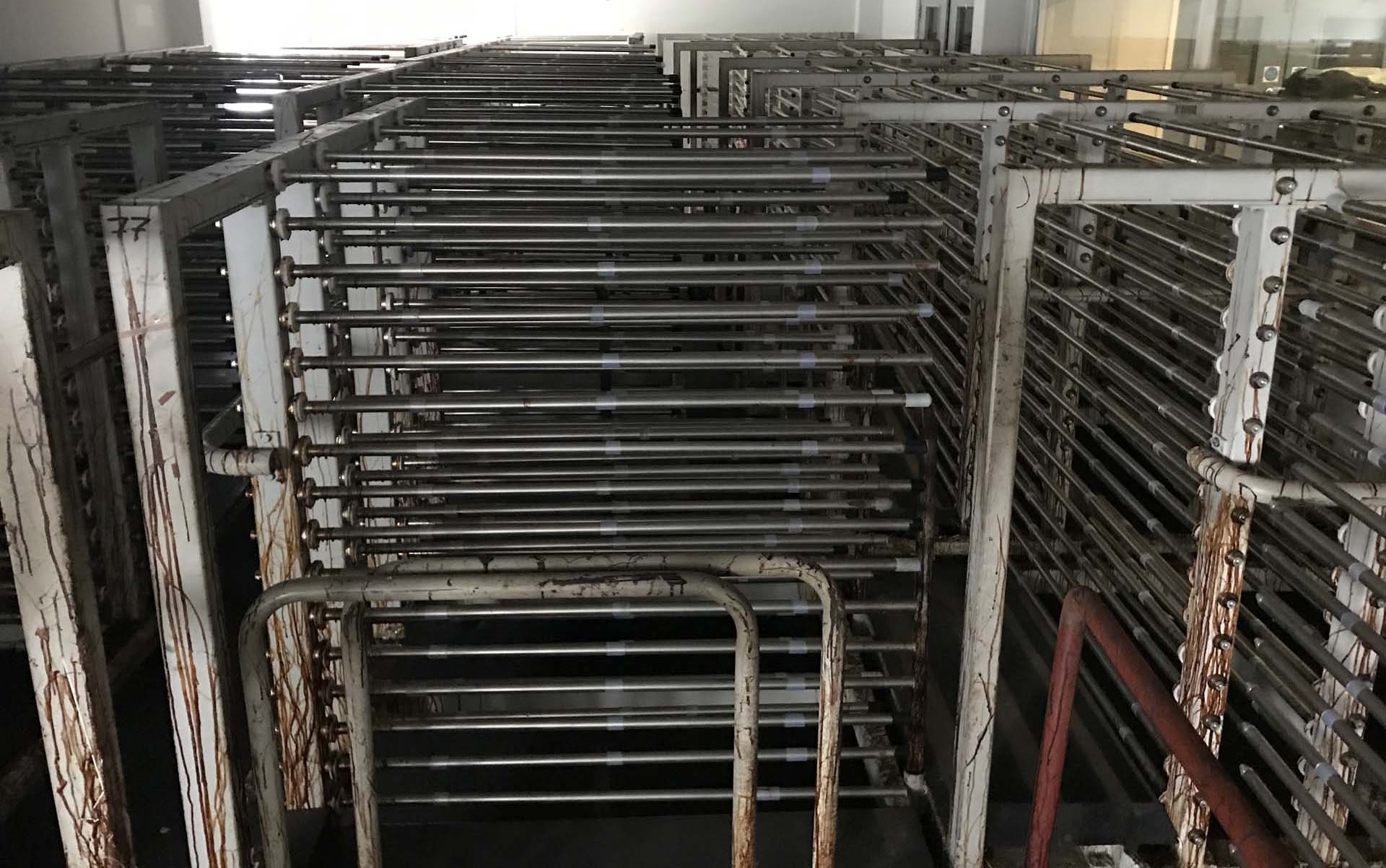

(3) Laminators

(3) Electric ovens

Vacuum pumps

Extractor units

(2) 546 CBM Ingersoll rand compressors

Extractor unit

Transformer, 200 V

Distribution board

Cables.

A typical Lot of Production and Inspection line for solar production equipment includes all the necessary machines, tools and components needed in order to manufacture the solar module. On the assembly line, solar cells are wired into the module frame and connected to each other. Next, the cells are tested to make sure they are working correctly, before the backsheet is attached to the module frame to complete the module. The first step in the production process involves preparing the solar cells for assembly by sorting, cleaning, cutting, and packaging them. Once prepared, they are fed to the assembly line for wiring. This process involves the placement of cells into the module frame and connecting them to each other. The connections are completed using an assembly jig which holds the cells in place and offers precise connections between each cell. Next, the cells are inspected for quality control purposes. VARIOUS tests such as visual, electrical and thermal are conducted to verify that the cells meet the desired specifications. Additionally, the modules may be tested for short circuit and open circuit conditions as well. This process ensures that the cells are able to function as expected. After the cells have been successfully inspected, they are placed in the module frame and the backsheet is attached. The backsheet is a protective layer that helps keep the cells from getting damaged or failing prematurely. After the backsheet has been attached, the module frames are filled with an anti-reflective epoxy and the banding material is placed in the junction box to protect the connections. Finally, the solar module frames are tested and inspected for quality assurance. It is during this process that the module is given its final rating. This rating is determined by the amount of current the module can produce as well as its efficiency rating. After the modules are successfully tested and rated, they are packaged up, tracked, and shipped to the customer. The Lot of Production and Inspection line process is a critical part of solar module manufacturing. With the implementation of a sophisticated and thorough inspection line, manufacturers can ensure that the final product meets all the desired specifications. In addition, having a rigorous inspection line helps manufacturers identify any defects or inconsistencies before shipping the module. Ultimately, this helps to guarantee high-quality, reliable, and safe solar modules.

There are no reviews yet