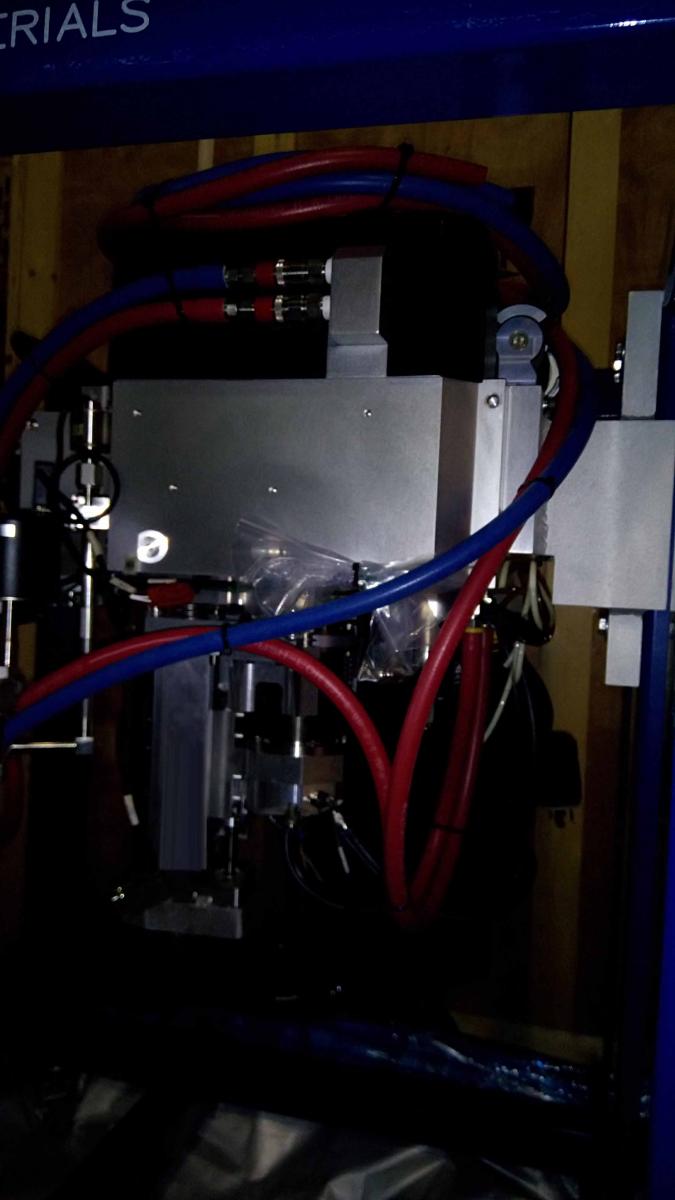

Used AMAT / APPLIED MATERIALS Centura DxZ #9176687 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9176687

Chamber, 8"

Wafer shape: SNNF

Chamber type:

PE TEOS DxZ (Delta MF oxide)

Chamber B:

Frequency type: Mixed

Heater: 0010-050254

Manometer type: Single 100 torr

Throttle valve: Dual spring

Chamber O-ring: Chemraz

Cover plate: Dimpled

Clean method: RF

Endpoint detector: Chamber

Gas delivery option:

Single line drop: No

Valve: FUJIKIN 5 Ramax

Filter: Millipore Ni 10 Ramax

MFC: STEC 4400 MC

Regulator: Verfilo

Transducer: MKS with display

Display gas pallet: Yes

Gas pallet:

Line 4: N2 Purge

Line 5: N2 Purge

Line 6: NF3 300 sccm

Line 7: C2F6 2 SLM

Line 8: O2 3 SLM

Line 9: N2 1 SLM

Liquid sources:

TEOS Delivery type: EPLIS

MFO Type: Unit 1661C

TEOS LFM: 1.5 QFM

LFM maker: STEC

Carrier 1: HE 3 SLM

Cable length:

Controller signal cable: 25ft

RF coaxial cable: 50ft

Pump signal cable: 50ft

RF generators:

HF RF generator: AE RFG 2000-2V

LF RF generator: AE PDX 900-2V.

AMAT / APPLIED MATERIALS Centura DxZ Reactor is an advanced, in-situ, high-temperature chemical vapor deposition (CVD) equipment designed to process silicon and compound semiconductor materials for advanced device fabrication. It is built for use in manufacturing process and for research and development laboratories. The system features a vacuum-tight, modular chamber and is equipped with temperature and gas controls, as well as sample handling and in-situ diagnostic capabilities. AMAT Centura DxZ Reactor is able to process both silicon and compound semiconductor materials, and can be configured as a single-wafer or batch process tool. The unit is also equipped with advanced, high-efficiency turbo-molecular pumps capable of delivering high-vacuum pressures, with a nominal performance of 2x10-4Torr. The machine is designed to process silicon and complex, compound semiconductor films at temperatures up to 1050°C, and can be configured with optional laser heating systems and sample chucks to reach higher temperatures. The environmentally-controlled chamber enables stable process temperature and gas control, resulting in improved process uniformity and reduced thermal drift, with temperature uniformity of ±3°C in a 675°C chamber. The tool is capable of precision gas flow control and pure gas delivery for up to 8 gases, with individual flow control for up to 8 zones, as well as batch process capabilities for improved process uniformity and reduced risk of film contamination. The asset is also equipped with in-situ diagnostics and a closed-loop feedback model designed to maintain process uniformity and repeatability. This feedback equipment can accurately monitor, record and control the entire process, while the in-situ diagnostics are able to measure, monitor and control film thickness and other parameters. The system is also capable of performing additional, different cuicuy processes, such as epitaxy deposition, in order to achieve desired material properties in complex layers of semiconductor films. APPLIED MATERIALS Centura DxZ Reactor is designed for both production and research, offering high-performance process capabilities, uniformity, and repeatability for a range of applications and research needs, including advanced device fabrication, thin-film solar cells, and many more. With its capabilities, the unit is expected to significantly improve film deposition results and accuracy, reducing cost and increasing device yields.

There are no reviews yet